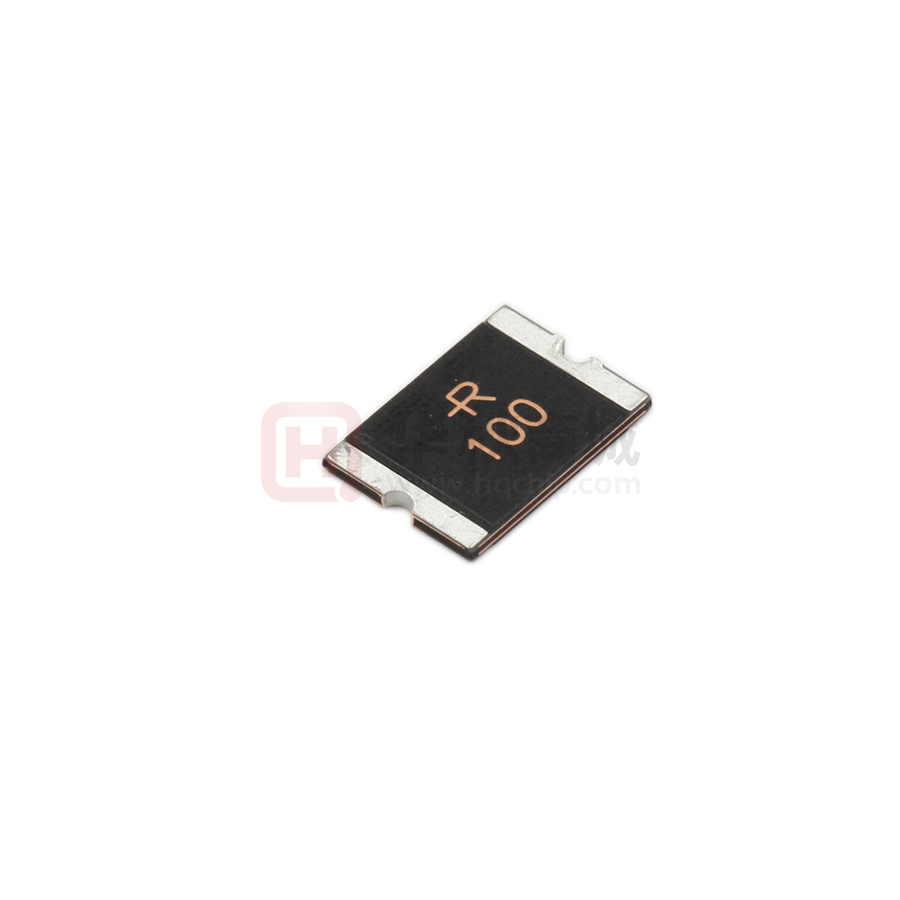

SMD2920 Series

Surface Mountable PTC Resettable Fuse

Features:

RoHS Compliant & Halogen Free

faster tripping, 2920 Dimension, Surface mountable, Solid state

Operation Current: 0.30A~3.00A

Maximum Voltage: 6V~60Vdc

Operating Temperature:-40℃ TO 85℃

Product Dimensions

Terminal pad materials :Tin-Plated Nickle-copper

Terminal pad solderability : Meets EIA specification

RS 186-9E and ANSI/J-STD-002 Category 3.

Pig.1

Unit :mm

Model

A

B

C

D

E

Min

Max

Min

Max

Min

Max

Min

Min

SMD2920P030TF

6.73

7.98

4.80

5.44

0.60

1.15

0.30

0.15

SMD2920P050TF

6.73

7.98

4.80

5.44

0.60

1.15

0.30

0.15

SMD2920P075TF/60

6.73

7.98

4.80

5.44

0.60

1.15

0.30

0.15

SMD2920P100TF

6.73

7.98

4.80

5.44

0.60

1.00

0.30

0.15

SMD2920P125TF

6.73

7.98

4.80

5.44

0.60

1.00

0.30

0.15

SMD2920P150TF

6.73

7.98

4.80

5.44

0.60

1.20

0.30

0.15

SMD2920P185TF

6.73

7.98

4.80

5.44

0.60

1.20

0.30

0.15

SMD2920P200TF

SMD2920P200TF/24

6.73

7.98

4.80

5.44

0.40

0.80

0.30

0.15

6.73

7.98

4.80

5.44

0.60

1.00

0.30

0.15

SMD2920P250TF

6.73

7.98

4.80

5.44

0.40

0.80

0.30

0.15

SMD2920P260TF/24

SMD2920P300TF

6.73

7.98

4.80

5.44

0.40

0.80

0.30

0.15

6.73

7.98

4.80

5.44

0.40

0.80

0.30

0.15

SMD2920P300TF/15

6.73

7.98

4.80

5.44

0.60

1.20

0.30

0.15

1/6

�SMD2920 Series

Surface Mountable PTC Resettable Fuse

Thermal Derating Chart-IH(A)

Maximum ambient operating temperatures(℃)

Model

-40

-20

0

25

40

50

60

70

85

SMD2920P030TF

0.44

0.37

0.35

0.30

0.28

0.23

0.20

0.18

0.14

SMD2920P050TF

0.73

0.62

0.59

0.50

0.47

0.38

0.34

0.30

0.24

SMD2920P075TF/60

1.09

0.92

0.88

0.75

0.70

0.56

0.50

0.45

0.36

SMD2920P100TF

1.45

1.23

1.17

1.10

0.93

0.75

0.67

0.60

0.48

SMD2920P125TF

1.81

1.54

1.46

1.25

1.16

0.94

0.84

0.75

0.60

SMD2920P150TF

2.18

1.85

1.76

1.50

1.40

1.13

1.01

0.90

0.72

SMD2920P185TF

2.68

2.28

2.16

1.85

1.72

1.39

1.24

1.11

0.89

SMD2920P200TF

SMD2920P200TF/24

2.90

2.46

2.34

2.00

1.86

1.50

1.34

1.20

0.96

2.90

2.46

2.34

2.00

1.86

1.50

1.34

1.20

0.96

SMD2920P250TF

3.63

3.08

2.93

2.50

2.33

1.88

1.68

1.50

1.20

SMD2920P260TF/24

SMD2920P300TF

3.77

3.20

3.04

2.60

2.42

1.95

1.74

1.56

1.25

4.35

3.69

3.51

3.00

2.79

2.25

2.01

1.80

1.44

SMD2920P300TF/15

4.35

3.69

3.51

3.00

2.79

2.25

2.01

1.80

1.44

Electrical Characteristic

Vmax

Imax

Ihold

Itrip

Pd

(Vdc)

(A)

(A)

(A)

Max.

(W)

Current

Time

Rimin

R1max

(A)

(Sec)

()

()

SMD2920P030TF

60

100

0.30

0.60

1.5

1.5

3.0

0.60

4.80

SMD2920P050TF

60

100

0.50

1.00

1.5

2.5

4.0

0.18

1.40

SMD2920P075TF/60

60

100

0.75

1.50

1.5

8.0

0.3

0.30

1.00

SMD2920P100TF

33

100

1.10

2.20

1.5

8.0

0.5

0.065

0.41

SMD2920P125TF

15

100

1.25

2.50

1.5

8.0

2.0

0.05

0.25

SMD2920P150TF

33

100

1.50

3.00

1.5

8.0

2.0

0.035

0.23

SMD2920P185TF

33

100

1.85

3.70

1.5

8.0

2.5

0.030

0.15

SMD2920P200TF

16

100

2.00

4.00

1.5

8.0

4.5

0.020

0.12

SMD2920P200TF/24

SMD2920P250TF

24

100

2.00

4.00

1.5

8.0

4.5

0.020

0.12

16

100

2.50

5.00

1.5

8.0

16.0

0.020

0.085

SMD2920P260TF/24

24

100

2.60

5.20

1.5

8.0

5.0

0.025

0.075

SMD2920P300TF

6

100

3.00

6.00

1.5

8.0

20.0

0.012

0.048

SMD2920P300TF/15

15

100

3.00

6.00

1.5

8.0

20.0

0.015

0.048

Model

2/6

Maximum time to trip

Resistence

�SMD2920 Series

Surface Mountable PTC Resettable Fuse

Test Procedures And Requirements

Accept/Reject Criteria

Resistance

Test Conditions

In still air @ 25℃

Rmin≤R≤R max

Time t o Trip

Sp ecified current,Vmax ,25℃

Tmaximum Time to Trip

Hold Current

30min,at IH

No trip

Trip Cyc le Life

V max,Imax,100cycles

No arcing or burning

Trip Endurance

Vmax,1 hours

No arcing or burning

Test

Physical Characteristics and Environmental Specifications

Physical Characteristics

Terminal materials :

Soldering

z on e

Tin-Plated Nickle-copper

Meets EIA specificatio n RS 1 86-9E and ANS I/J-STD-002 Catego ry 3.

Environmental Specifications

Conditions

Test

Resistance Change

Passive aging

Humidity aging

85℃,1000hours

±10%

85℃/85%RH.1000 hours

±5%

Thermal shock

Solvent Resistance

MIL-STD-202,Method 107G+85℃/-40℃,20times

-30% typical resistance change

MIL-STD-202,Method 215

no change

Vibration

ML-STD-883C,Test Condition A

No chage

3/6

�SMD2920 Series

Surface Mountable PTC Resettable Fuse

Electrical Specifications:

I hold = Hold Current. Maximum current device will not trip in 25°C still air.

I trip = Trip Current. Minimum current at which the device will always trip in 25°C still air.

Vmax = Maximum operating voltage device can withstand without damage at rated current (Imax).

I max = Maximum fault current device can withstand without damage at rated voltage (Vmax).

Pd=Maximum p ower di ssipatio n wh en device is in the tripp ed state in 25°C still air enviro nment at rated vol tage.

Rimin/max = Minimum/Maximum device resistance prior to tripping at 25°C.

R1max = Maximum device resistance is measured one hour post reflow.

Recommended pad layout (mm)

Solder reflow conditions

● Recommended reflow methods: IR, vapor phase oven, hot air oven, N2 environment for lead-free.

● Devices are not designed to be wave soldered to the bottom side of the board.

● Recommended maximum paste thickness is 0.25mm (0.010inch).

● Devices can be cleaned using standard industry methods and solvents.

4/6

�SMD2920 Series

Surface Mountable PTC Resettable Fuse

● Soldering temprature profile meets RoHs leadfree process.

Notes: If reflow temperatures exceed the recommended profile, devices may not meet the performance requirements

Tape Specification And

Reel Dimensions

Coverning Specifications

EIA 481-1(Unit:mm)

W

16± 0.3

P0

4.0 ± 0.10

P1

8.0 ± 0.10

P2

2.0 ± 0.10

A0

5.74 ± 0.10

B0

8.02 ± 0.10

D0

1.55 ± 0.05

F

7.5± 0.10

E1

1.75 ± 0.10

T

0.20± 0.10

Leader min.

390

Trailer min.

160

Reel Dimensions

A

178± 1

N

58± 1

W1

16.9± 0.80

W2

19.3± 0.1

5/6

�SMD2920 Series

Surface Mountable PTC Resettable Fuse

Storage

The maximum ambient temperature shall not exceed 38℃. Storage temperatures higher than 38℃ could result in the

defo rmatio n of p ackaging material s. The m aximum relative humidity recommended f o r sto rage is 60%. High humidity w ith

high temperature can accelerate the oxidation of the solder plating on the termination and reduce the solderability of the

components. Sealed plastic bags with desiccant shall be used to reduce the oxidation of the termination and shall only be

opened prior to use. The products shall not be stored in areas where harmful gases containing sulfur or chlorine are present

WARNING

• Use PPTC beyond the maximum ratings or improper use may result in device damage and possible electrical arcing and

flame.

• PPTC are intended for protection against occasional over current or over temperature fault conditions and should not be

used when repeated fault conditions or prolonged trip events are anticipated.

• Device performance can be impacted negatively if devices are handled in a manner inconsistent with recommended

electronic, thermal, and mechanical procedures for electronic components.

• Use PPTC with a large inductance in circuit will generate a circuit voltage (L di/dt) above the rated voltage of the PPTC.

• Avoid impact PPTC device its thermal expansion like placed under pressure or installed in limited space.

• Contamination of the PPTC material with certain silicon based oils or some aggressive solvents can adversely impact the

performance of the devices.PPTC SMD can be cleaned by standard methods.

• Requests that customers comply with our recommended solder pad layouts and recommended reflow profile. Improper

board layouts or reflow profilecould negatively impact solderability performance of our devices.

6/6

�

很抱歉,暂时无法提供与“SMD2920P100TF”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 10+0.51200

- 50+0.47360

- 200+0.44160

- 600+0.40960

- 1500+0.38400

- 3000+0.36800