IS31FL3218

18 CHANNELS LED DRIVER

October 2020

GENERAL DESCRIPTION

FEATURES

IS31FL3218 is comprised of 18 constant current

channels each with independent PWM control,

designed for driving LEDs. The output current of each

channel can be set at up to 38mA (Max.) by an external

resistor. The average LED current of each channel can

be changed in 256 steps by changing the PWM duty

cycle through an I2C interface.

The chip can be turned off by pulling the SDB pin low or

by using the software shutdown feature to reduce

power consumption. The slave address is fixed “1010

1000”.

2.7V to 5.5V supply

I2C interface, automatic address increment

function

Internal reset register

Modulate LED brightness with 256 steps PWM

Each channel can be controlled independently

-40°C to +85°C temperature range

QFN-24 (4mm×4mm), SOP-24 packages

APPLICATIONS

IS31FL3218 is available in QFN-24 (4mm × 4mm) and

SOP-24 packages. It operates from 2.7V to 5.5V over

the temperature range of -40°C to +85°C.

Mobile phones and other hand-held devices for

LED display

LED in home appliances

TYPICAL APPLICATION CIRCUIT

VBattery

VBattery

3

OUT1

VCC

1 F

OUT2

0.1 F

OUT3

OUT4

OUT5

VDD

4.7k

OUT6

5

6

Micro

Controller

OUT7

4.7k

24

IS31FL3218

OUT8

SDA

OUT9

SCL

OUT10

SDB

OUT11

OUT12

100k

OUT13

OUT14

2

OUT15

R_EXT

OUT16

3.3k

4

OUT17

GND

OUT18

Figure 1

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

Typical Application Circuit

Note 1: The maximum output current is set up to 23mA when REXT= 3.3kΩ. The maximum output current can be set by external resistor, REXT.

Please refer to the detail information in Page 9.

Note 2: The IC should be placed far away from the mobile antenna in order to prevent the EMI.

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

1

�IS31FL3218

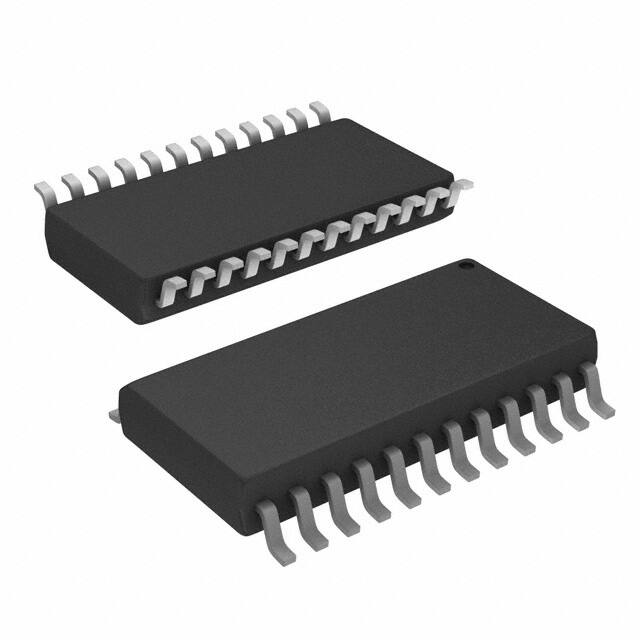

PIN CONFIGURATION

Package

Pin Configuration (Top View)

QFN-24

SOP-24

PIN DESCRIPTION

No.

Pin

Description

1

OUT18

Output channel for LEDs.

2

R_EXT

Input terminal used to connect an external resistor.

This regulates the output current.

3

VCC

Power supply.

4

GND

Ground.

5

SDA

I2C serial data.

6

SCL

I2C serial clock.

7~23

OUT1 ~ OUT17

Output channel for LEDs.

24

SDB

Shutdown the chip when pulled low.

Thermal Pad

Connect to GND.

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

2

�IS31FL3218

ORDERING INFORMATION

Industrial Range: -40°C to +85°C

Order Part No.

Package

QTY

IS31FL3218-QFLS2-TR

IS31FL3218-GRLS2-TR

IS31FL3218-GRLS2

QFN-24, Lead-free

SOP-24, Lead-free

SOP-24, Lead-free

2500/Reel

1000/Reel

30/Tube

Copyright © 2020 Lumissil Microsystems. All rights reserved. Lumissil Microsystems reserves the right to make changes to this specification and its

products at any time without notice. Lumissil Microsystems assumes no liability arising out of the application or use of any information, products or

services described herein. Customers are advised to obtain the latest version of this device specification before relying on any published information and

before placing orders for products.

Lumissil Microsystems does not recommend the use of any of its products in life support applications where the failure or malfunction of the product can

reasonably be expected to cause failure of the life support system or to significantly affect its safety or effectiveness. Products are not authorized for use in

such applications unless Lumissil Microsystems receives written assurance to its satisfaction, that:

a.) the risk of injury or damage has been minimized;

b.) the user assume all such risks; and

c.) potential liability of Lumissil Microsystems is adequately protected under the circumstances

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

3

�IS31FL3218

ABSOLUTE MAXIMUM RATINGS

Supply voltage, VCC

Voltage at SCL, SDA, SDB, OUT1 ~ OUT18

Maximum junction temperature, TJMAX

Storage temperature range, TSTG

Operating temperature range, TA

Package thermal resistance, junction to ambient (4 layer standard test

PCB based on JESD 51-2A), θJA

ESD (HBM)

ESD (CDM)

-0.3V ~ +6.0V

-0.3V ~ VCC+0.3V

+150°C

-65°C ~ +150°C

-40°C ~ +85°C

29°C /W (QFN)

40.8°C /W (SOP)

±4kV

±1kV

Note: Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings

only and functional operation of the device at these or any other condition beyond those indicated in the operational sections of the specifications

is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

ELECTRICAL CHARACTERISTICS

TA= -40°C ~ +85°C, VCC= 2.7V ~ 5.5V, unless otherwise noted. Typical values are TA= 25°C, VCC= 3.6V.

Symbol

Parameter

Condition

VCC

Supply voltage

IMAX

Maximum output current of each VCC= 4.2V, VOUT= 0.8V

channel

REXT= 2kΩ (Note 1)

ICC

Min.

Typ.

2.7

Max.

Unit

5.5

V

38

mA

Quiescent power supply current REXT= 3.3kΩ

5.25

mA

ISD

Shutdown current

VSDB= 0V or software shutdown

3.1

μA

IOZ

Output leakage current

VSDB= 0V or software shutdown,

VOUT= 5V

VEXT

1

Output voltage of R-EXT pin

1.3

μA

V

Logic Electrical Characteristics (SDA, SCL, SDB)

VIL

Logic “0” input voltage

VCC= 2.7V

VIH

Logic “1” input voltage

VCC= 5.5V

IIL

Logic “0” input current

(Note 2)

5

nA

IIH

Logic “1” input current

(Note 2)

5

nA

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

0.4

1.4

V

V

4

�IS31FL3218

DIGITAL INPUT SWITCHING CHARACTERISTICS (Note 2)

Symbol

Parameter

Condition

Min.

Typ.

Max.

Unit

400

kHz

fSCL

Serial-Clock frequency

tBUF

Bus free time between a STOP and a START

condition

1.3

μs

tHD, STA

Hold time (repeated) START condition

0.6

μs

tSU, STA

Repeated START condition setup time

0.6

μs

tSU, STO

STOP condition setup time

0.6

μs

tHD, DAT

Data hold time

tSU, DAT

Data setup time

100

ns

tLOW

SCL clock low period

1.3

μs

tHIGH

SCL clock high period

0.7

μs

0.9

μs

tR

Rise time of both SDA and SCL signals,

receiving

(Note 3)

20+0.1Cb

300

ns

tF

Fall time of both SDA and SCL signals,

receiving

(Note 3)

20+0.1Cb

300

ns

Note 1: The recommended minimum value of REXT is 2kΩ, or it may cause a large current.

Note 2: Guaranteed by design.

Note 3: Cb= total capacitance of one bus line in pF. ISINK ≤ 6mA. tR and tF measured between 0.3 × VCC and 0.7 × VCC.

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

5

�IS31FL3218

FUNCTIONAL BLOCK DIAGRAM

VCC

IS = 7.8/REXT

R_EXT

OUT1~OUT18

R_EXT

Block

SDA

SCL

I2C

PWM

Register

Comparator

SDB

POR

OSC

Counter

BG

GND

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

6

�IS31FL3218

DETAILED DESCRIPTION

Then the master sends an SCL pulse. If the

IS31FL3218 has received the address correctly, then it

holds the SDA line low during the SCL pulse. If the SDA

line is not low, then the master should send a “STOP”

signal (discussed later) and abort the transfer.

I2C INTERFACE

The IS31FL3218 uses a serial bus, which conforms to

the I2C protocol, to control the chip’s functions with two

wires: SCL and SDA. The IS31FL3218’s slave address

is “1010 1000”. It only supports write operations.

Following acknowledge of IS31FL3218, the register

address byte is sent, most significant bit first.

IS31FL3218 must generate another acknowledge

indicating that the register address has been received.

The SCL line is uni-directional. The SDA line is

bi-directional (open-collector) with a pull-up resistor

(typically 4.7kΩ). The maximum clock frequency

specified by the I2C standard is 400kHz. In this

discussion, the master is the microcontroller and the

slave is the IS31FL3218.

Then 8-bit of data byte are sent next, most significant

bit first. Each data bit should be valid while the SCL

level is stable high. After the data byte is sent, the

IS31FL3218 must generate another acknowledge to

indicate that the data was received.

The timing diagram for the I2C is shown in Figure 2.

The SDA is latched in on the stable high level of the

SCL. When there is no interface activity, the SDA line

should be held high.

The “STOP” signal ends the transfer. To signal “STOP”,

the SDA signal goes high while the SCL signal is high.

The “START” signal is generated by lowering the SDA

signal while the SCL signal is high. The start signal will

alert all devices attached to the I2C bus to check the

incoming address against their own chip address.

ADDRESS AUTO INCREMENT

To write multiple bytes of data into IS31FL3218, load

the address of the data register that the first data byte

is intended for. During the IS31FL3218 acknowledge of

receiving the data byte, the internal address pointer will

increment by one. The next data byte sent to

IS31FL3218 will be placed in the new address, and so

on. The auto increment of the address will continue as

long as data continues to be written to IS31FL3218

(Figure 5).

The 8-bit chip address is sent next, most significant bit

first. Each address bit must be stable while the SCL

level is high.

After the last bit of the chip address is sent, the master

checks for the IS31FL3218’s acknowledge. The master

releases the SDA line high (through a pull-up resistor).

Figure 2

Interface timing

Figure 3

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

Bit transfer

7

�IS31FL3218

Figure 4

Figure 5

Writing to IS31FL3218 (Typical)

Writing to IS31FL3218 (Automatic Address Increment)

REGISTERS DEFINITIONS

Table 1 Register Function

Address

00h

Name

Function

R/W

Table

Shutdown Register

Set software shutdown mode

2

PWM Register

18 channels PWM duty cycle data register

3

13h

LED Control Register 1

Channel 1 to 6 enable bit

4

14h

LED Control Register 2

Channel 7 to 12 enable bit

15h

LED Control Register 3

Channel 13 to 18 enable bit

16h

Update Register

Load PWM Register and LED Control

Register’s data

-

17h

Reset Register

Reset all registers into default

-

01h~12h

W

0000

0000

6

xxxx

xxxx

Table 3 01h~12h PWM Register (OUT1~OUT18)

Table 2 00h Shutdown Register

Bit

D7:D1

D0

Bit

D7:D0

Name

Reserved

SSD

Name

PWM

Default

000000

0

Default

0000 0000

The Shutdown Register sets software shutdown mode

of IS31FL3218.

SSD

0

1

5

Default

Software Shutdown Enable

Software shutdown mode

Normal operation

The PWM Registers adjusts LED luminous intensity in

256 steps.

The value of a channel’s PWM Register decides the

average output current for each output, OUT1~OUT18.

The average output current may be computed using

the Formula (1):

I OUT

I MAX 7

D[n] 2 n

256 n0

(1)

Where “n” indicates the bit location in the respective

PWM register.

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

8

�IS31FL3218

For example: D7:D0 = 10110101,

IOUT = IMAX (20+22+24+25+27)/256

See Formula (2) in Page 10 to calculate the IMAX.

Table 4 13h LED Control Register 1

(OUT1~OUT6)

Bit

D7:D6

D5:D0

Name

Reserved

OUT6:OUT1

Default

00

000000

Table 5 14h LED Control Register 2

(OUT7~OUT12)

Bit

D7:D6

D5:D0

Name

Reserved

OUT12:OUT7

Default

00

000000

16h PWM Update Register

The data sent to the PWM Registers and the LED

Control Registers will be stored in temporary registers.

A write operation of “0000 0000” value to the Update

Register is required to update the registers (01h~15h).

17h Reset Register

Once user writes “0000 0000” data to the Reset

Register, IS31FL3218 will reset all registers to default

value. On initial power-up, the IS31FL3218 registers

are reset to their default values for a blank display.

Table 6 15h LED Control Register 3

(OUT13~OUT18)

Bit

D7:D6

D5:D0

Name

Reserved

OUT18:OUT13

Default

00

000000

The LED Control Registers store the on or off state of

each column LED.

OUTx

0

1

LED State

LED off

LED on

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

9

�IS31FL3218

APPLICATION INFORMATION

PWM CONTROL

256

The PWM Registers (01h~12h) can modulate LED

brightness of 18 channels with 256 steps. For example,

if the data in PWM Register is “0000 0100”, then the

PWM is the fourth step.

224

PWM Data

192

Writing new data continuously to the registers can

modulate the brightness of the LEDs to achieve a

breathing effect.

160

128

96

64

REXT

32

The maximum output current of OUT1~OUT18 can be

adjusted by the external resistor, REXT, as described in

Formula (2).

I MAX

V

x EXT

REXT

0

0

4

8

Figure 6

The recommended minimum value of REXT is 2kΩ.

GAMMA CORRECTION

In order to perform a better visual LED breathing effect

we recommend using a gamma corrected PWM value

to set the LED intensity. This results in a reduced

number of steps for the LED intensity setting, but

causes the change in intensity to appear more linear to

the human eye.

Gamma correction, also known as gamma

compression or encoding, is used to encode linear

luminance to match the non-linear characteristics of

display. Since the IS31FL3218 can modulate the

brightness of the LEDs with 256 steps, a gamma

correction function can be applied when computing

each subsequent LED intensity setting such that the

changes in brightness matches the human eye's

brightness curve.

Table 7 32 Gamma Steps With 256 PWM Steps

16

20

24

28

32

Intensity Steps

(2)

x = 58.5, VOUT = 0.8V, VEXT = 1.3V.

12

Gamma Correction (32 Steps)

Choosing more gamma steps provides for a more

continuous looking breathing effect. This is useful for

very long breathing cycles. The recommended

configuration is defined by the breath cycle T. When

T=1s, choose 32 gamma steps, when T=2s, choose

64 gamma steps. The user must decide the final

number of gamma steps not only by the LED itself, but

also based on the visual performance of the finished

product.

Table 8

64 Gamma Steps With 256 PWM Steps

C(0)

C(1)

C(2)

C(3)

C(4)

C(5)

C(6)

C(7)

0

1

2

3

4

5

6

7

C(8)

C(9)

C(10)

C(11)

C(12)

C(13)

C(14)

C(15)

8

10

12

14

16

18

20

22

C(16)

C(17)

C(18)

C(19)

C(20)

C(21)

C(22)

C(23)

24

26

29

32

35

38

41

44

C(24)

C(25)

C(26)

C(27)

C(28)

C(29)

C(30)

C(31)

47

50

53

57

61

65

69

73

C(32)

C(33)

C(34)

C(35)

C(36)

C(37)

C(38)

C(39)

77

81

85

89

94

99

104

109

C(40)

C(41)

C(42)

C(43)

C(44)

C(45)

C(46)

C(47)

114

119

124

129

134

140

146

152

C(48)

C(49)

C(50)

C(51)

C(52)

C(53)

C(54)

C(55)

C(0)

C(1)

C(2)

C(3)

C(4)

C(5)

C(6)

C(7)

0

1

2

4

6

10

13

18

C(8)

C(9)

C(10)

C(11)

C(12)

C(13)

C(14)

C(15)

22

28

33

39

46

53

61

69

158

164

170

176

182

188

195

202

C(16)

C(17)

C(18)

C(19)

C(20)

C(21)

C(22)

C(23)

C(56)

C(57)

C(58)

C(59)

C(60)

C(61)

C(62)

C(63)

78

86

96

106

116

126

138

149

209

216

223

230

237

244

251

255

C(24)

C(25)

C(26)

C(27)

C(28)

C(29)

C(30)

C(31)

161

173

186

199

212

226

240

255

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

10

�IS31FL3218

256

SHUTDOWN MODE

224

Shutdown mode can either be used as a means of

reducing power consumption or generating a flashing

display (repeatedly entering and leaving shutdown

mode). During shutdown mode all registers retain their

data.

PWM Data

192

160

128

Software Shutdown

96

64

32

0

0

8

16

24

32

40

48

56

64

Intensity Steps

Figure 7

Gamma Correction (64 Steps)

Note, the data of 32 gamma steps is the standard value and the data

of 64 gamma steps is the recommended value.

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

By setting SSD bit of the Configuration Register (00h)

to “0”, the IS31FL3218 will operate in software

shutdown mode, wherein they consume only 3.1μA

(Typ.) current. When the IS31FL3218 is in software

shutdown mode, all current sources are switched off.

Hardware Shutdown

The chip enters hardware shutdown mode when the

SDB pin is pulled low.

11

�IS31FL3218

CLASSIFICATION REFLOW PROFILES

Profile Feature

Pb-Free Assembly

Preheat & Soak

Temperature min (Tsmin)

Temperature max (Tsmax)

Time (Tsmin to Tsmax) (ts)

150°C

200°C

60-120 seconds

Average ramp-up rate (Tsmax to Tp)

3°C/second max.

Liquidous temperature (TL)

Time at liquidous (tL)

217°C

60-150 seconds

Peak package body temperature (Tp)*

Max 260°C

Time (tp)** within 5°C of the specified

classification temperature (Tc)

Max 30 seconds

Average ramp-down rate (Tp to Tsmax)

6°C/second max.

Time 25°C to peak temperature

8 minutes max.

Figure 8

Classification profile

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

12

�IS31FL3218

PACKAGE INFORMATION

QFN-24

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

13

�IS31FL3218

SOP-24

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

14

�IS31FL3218

RECOMMENDED LAND PATTERN

QFN-24

SOP-24

Note:

1. Land pattern complies to IPC-7351.

2. All dimensions in MM.

3. This document (including dimensions, notes & specs) is a recommendation based on typical circuit board manufacturing parameters. Since

land pattern design depends on many factors unknown (eg. user’s board manufacturing specs), user must determine suitability for use.

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

15

�IS31FL3218

REVISION HISTORY

Revision

Detail Information

Data

A

Initial release

2012.01.09

B

1. Page 3 ORDERING INFORMATION, SOP-24 QTY changes to 30/Tube

2. Remove TAPE AND REEL INFORMATION

2012.04.08

C

Absolute Maximum Ratings: voltage at OUTX change from 5V to -0.3V~VCC+0.3V

2014.09.04

D

1. Update POD

2. Update ESD (HBM)

3. Add land pattern

4. Add θJA

5. Add ESD(CDM)

2016.09.02

E

Update θJA for QFN package

2017.06.06

F

1. Add 1000/Reel packing for SOP-24

2. Update RJA and land pattern

2020.10.10

Lumissil Microsystems – www.lumissil.com

Rev. F, 10/10/2020

16

�