SPI(x1/x2/x4) NAND Flash

GD5F2GQ4xFxxG

DATASHEET

1

2G

�SPI(x1/x2/x4) NAND Flash

2G

Contents

1

FEATURE ........................................................................................................................................................... 4

2

GENERAL DESCRIPTION ............................................................................................................................... 5

2.1 PRODUCT LIST ............................................................................................................................................................... 6

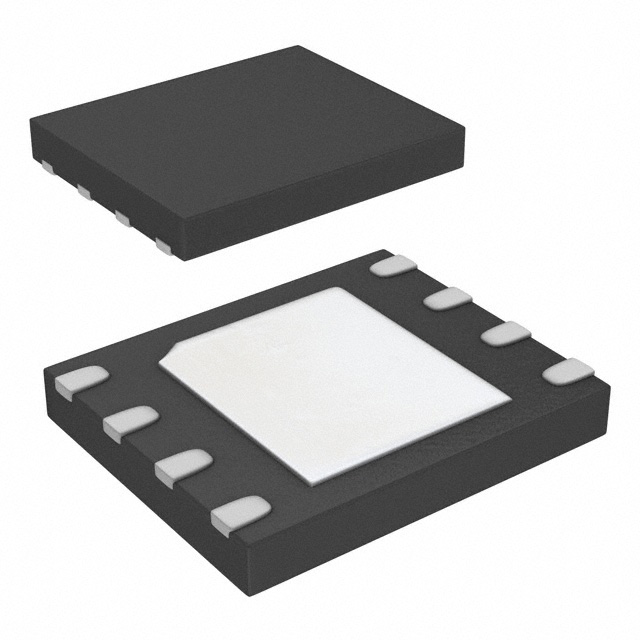

2.2 CONNECTION DIAGRAM .................................................................................................................................................. 7

2.3 PIN DESCRIPTION ........................................................................................................................................................... 7

2.4 BLOCK DIAGRAM ........................................................................................................................................................... 8

3

ARRAY ORGANIZATION ................................................................................................................................. 9

4

MEMORY MAPPING ....................................................................................................................................... 10

5

DEVICE OPERATION ..................................................................................................................................... 11

5.1 SPI MODES ................................................................................................................................................................ 11

5.2 HOLD MODE ............................................................................................................................................................. 12

5.3 WRITE PROTECTION ..................................................................................................................................................... 12

5.4 POWER OFF TIMING ..................................................................................................................................................... 12

6

COMMANDS DESCRIPTION ......................................................................................................................... 13

7

WRITE OPERATIONS .................................................................................................................................... 14

7.1 WRITE ENABLE (WREN) (06H) ..................................................................................................................................... 14

7.2 WRITE DISABLE (WRDI) (04H) ..................................................................................................................................... 14

FEATURE OPERATIONS ............................................................................................................................... 15

8

8.1 GET FEATURES (0FH) AND SET FEATURES (1FH) ............................................................................................................... 15

READ OPERATIONS ...................................................................................................................................... 17

9

9.1 PAGE READ................................................................................................................................................................. 17

9.2 PAGE READ TO CACHE (13H) ......................................................................................................................................... 17

9.3 READ FROM CACHE (03H) ............................................................................................................................................ 18

9.4 FAST READ FROM CACHE (0BH) ..................................................................................................................................... 18

9.5 READ FROM CACHE X2 (3BH) ........................................................................................................................................ 19

9.6 READ FROM CACHE X4 (6BH) ........................................................................................................................................ 19

9.7 READ FROM CACHE DUAL IO (BBH) ............................................................................................................................... 20

9.8 READ FROM CACHE QUAD IO (EBH)............................................................................................................................... 21

10

READ ID (9FH) ............................................................................................................................................ 22

11

PROGRAM OPERATIONS ......................................................................................................................... 23

11.1 PAGE PROGRAM ........................................................................................................................................................ 23

11.2 PROGRAM LOAD (PL) (02H) ....................................................................................................................................... 24

11.3 PROGRAM LOAD X4 (PL X4) (32H) ............................................................................................................................... 25

11.4 PROGRAM EXECUTE (PE) (10H) ................................................................................................................................... 26

11.5 INTERNAL DATA MOVE ............................................................................................................................................... 27

11.6 PROGRAM LOAD RANDOM DATA (84H) ........................................................................................................................ 27

2

�SPI(x1/x2/x4) NAND Flash

2G

11.7 PROGRAM LOAD RANDOM DATA X4 (C4H/34H) ............................................................................................................ 28

12

ERASE OPERATIONS ............................................................................................................................... 29

12.1 BLOCK ERASE (D8H) .................................................................................................................................................. 29

13

RESET OPERATIONS ................................................................................................................................ 30

13.1 SOFT RESET (FFH) ..................................................................................................................................................... 30

14

ADVANCED FEATURES ............................................................................................................................ 31

14.1 OTP REGION ............................................................................................................................................................ 31

14.2 BLOCK PROTECTION ................................................................................................................................................... 32

14.3 STATUS REGISTER AND DRIVER REGISTER ........................................................................................................................ 33

14.4 ASSISTANT BAD BLOCK MANAGEMENT .......................................................................................................................... 34

14.5 INTERNAL ECC .......................................................................................................................................................... 35

15

POWER ON TIMING ................................................................................................................................... 36

16

ABSOLUTE MAXIMUM RATINGS ............................................................................................................ 37

17

CAPACITANCE MEASUREMENT CONDITIONS .................................................................................... 38

18

DC CHARACTERISTIC .............................................................................................................................. 39

19

AC CHARACTERISTICS............................................................................................................................ 40

20

PERFORMANCE TIMING .......................................................................................................................... 41

21

ORDERING INFORMATION ...................................................................................................................... 43

22

PACKAGE INFORMATION ........................................................................................................................ 44

23

REVISION HISTORY................................................................................................................................... 46

3

�SPI(x1/x2/x4) NAND Flash

2G

1 FEATURE

◆

2Gb SLC NAND Flash

◆ Program/Erase/Read

Speed

- Page Program time: 400us typical

◆2048-Byte+128-Byte

Physical Page

Size(2)

- Block Erase time: 3ms typical

- Internal ECC Off (ECC_EN=0):

- Page read time: 80us maximum(w/I ECC)

2048-Byte+128-Byte Full Access

◆ Reliability

- Internal ECC On (ECC_EN=1, default):

◆

Program:

2048-Byte+64-Byte

- Endurance: 100K program/erase cycles

Read:

2048-Byte+128-Byte

- Data retention: 10 Years

Standard, Dual, Quad SPI

◆

Low Power Consumption

- Standard SPI: SCLK, CS#, SI, SO, WP#, HOLD#

- 40mA maximum active current

- Dual SPI: SCLK, CS#, SIO0, SIO1, WP#, HOLD#

- 110uA(1) maximum standby current

- Quad SPI: SCLK, CS#, SIO0, SIO1, SIO2, SIO3

◆

◆

Enhanced access performance

High Speed Clock Frequency

- 2kbyte cache for fast random read

- 120MHz for fast read with 30PF load

- Cache read and cache program

- Quad I/O Data transfer up to 480Mbits/s

◆

◆

Advanced Feature for NAND

Software/Hardware Write Protection

- Internal ECC option, per 528bytes

- Write protect all/portion of memory via software

- Internal data move by page with ECC

- Register protection with WP# Pin

- Top or Bottom, Block selection combination

◆

The first block(Block0) is guaranteed to be a valid block

at the time of shipment.

◆

Advanced security Features

- 8K-Byte OTP Region (4 page OTP)

◆

Single Power Supply Voltage

- Full voltage range for 1.8V: 1.7V ~ 2.0V

- Full voltage range for 3.3V: 2.7V ~ 3.6V

Note (1): When Temperature is 105℃, the maximum standby current is 200uA

(2). 2048Byte+128Byte Page Size can accommodate more advanced ECC algorithm by user’s choice, even though

the internal 4-bit ECC algorithm only requires 64-Byte spare area.

Internal 4-bit ECC is set to on (ECC_EN=1) as shipment default, it can be disabled by setting ECC_EN=0.

- When Internal ECC is enabled, user can only program the first 64-Byte portion of the entire 128-Byte spare

area, and the rest 64-Byte spare area cannot be programed. User can still read the entire 128-Byte spare area.

- When Internal ECC is disabled, user can read and program the entire 128-Byte spare area.

4

�SPI(x1/x2/x4) NAND Flash

2G

2 GENERAL DESCRIPTION

SPI (Serial Peripheral Interface) NAND Flash provides an ultra cost-effective while high density non-volatile memory

storage solution for embedded systems, based on an industry-standard NAND Flash memory core. It is an attractive

alternative to SPI-NOR and standard parallel NAND Flash, with advanced features:

• Total pin count is 8, including VCC and GND

• Density is 2Gbit

• Superior write performance and cost per bit over SPI-NOR

• Significant low cost than parallel NAND

This low-pin-count NAND Flash memory follows the industry-standard serial peripheral interface, and always remains the

same pin out from one density to another. The command sets resemble common SPI-NOR command sets, modified to

handle NAND specific functions and added new features. GigaDevice SPI NAND is an easy-to-integrate NAND Flash

memory, with specified designed features to ease host management:

• User-selectable internal ECC. ECC code is generated internally during a page program operation. When a page

is read to the cache register, the ECC code is detect and correct the errors when necessary. The 64-bytes spare area

is available even when internal ECC enabled. The device outputs corrected data and returns an ECC error status.

• Internal data move or copy back with internal ECC. The device can be easily refreshed and manage garbage

collection task, without need of shift in and out of data.

•Power on Read with internal ECC. It is programmed and read in page-based operations, and erased in blockbased operations. Data is transferred to or from the NAND Flash memory array, page by page, to a data register and

a cache register. The cache register is closest to I/O control circuits and acts as a data buffer for the I/O data; the data

register is closest to the memory array and acts as a data buffer for the NAND Flash memory array operation. The

cache register functions as the buffer memory to enable page and random data READ/WRITE and copy back

operations. These devices also use a SPI status register that reports the status of device operation.

5

�SPI(x1/x2/x4) NAND Flash

2G

2.1 Product List

Product Number

Density

Voltage

Package Type

GD5F2GQ4RFZIG

TFBGA24(6*4 Ball Array)

GD5F2GQ4RFZFG

1.7V to

2.0V

GD5F2GQ4RF9IG

GD5F2GQ4RF9JG

GD5F2GQ4UFZIG

GD5F2GQ4UF9IG

GD5F2GQ4UF9JG

-40℃ to 105℃

-40℃ to 85℃

-40℃ to 85℃

LGA8(6*8mm)

2Gbit

GD5F2GQ4UFZJG

GD5F2GQ4UFZFG

Page Size

-40℃ to 85℃

GD5F2GQ4RFZJG

GD5F2GQ4RF9FG

Temperature

TFBGA24(6*4 Ball Array)

2.7V to

3.6V

-40℃ to 105℃

-40℃ to 85℃

2Kbytes +

-40℃ to 85℃

128bytes

-40℃ to 105℃

-40℃ to 85℃

-40℃ to 85℃

LGA8(6*8mm)

GD5F2GQ4UF9FG

-40℃ to 105℃

-40℃ to 85℃

6

�SPI(x1/x2/x4) NAND Flash

2G

2.2 Connection Diagram

Top View

CS#

SO/

SIO1

1

8

2

Top View

WP#/

3

SIO2

VSS 4

VCC

A1

A2

A3

A4

NC

NC

NC

NC

B1

B2

B3

B4

NC

SCLK

VSS

VCC

C1

C2

C3

NC

CS#

NC

D2

D3

D1

C4

WP#(SIO2)

D4

SO(SIO1) SI(SIO0) HOLD#

(SIO3)

7 HOLD#

/SIO3

NC

E1

E2

E3

E4

6 SCLK

NC

NC

NC

NC

F1

F2

F3

F4

NC

NC

NC

NC

5

SI/

SIO0

8–LEAD LGA

24-BALL TFBGA (4x6 ball array)

Figure2-1 Connection Diagram

2.3 Pin Description

Pin Name

I/O

Description

CS#

I

Chip Select input, active low

SO/SIO1

I/O

Serial Data Output / Serial Data Input Output 1

WP#/SIO2

I/O

Write Protect, active low / Serial Data Input Output 2

VSS

Ground

Ground

SI/SIO0

I/O

Serial Data Input / Serial Data Input Output 0

SCLK

I

Serial Clock input

HOLD#/SIO3

I/O

Hold input, active low /Serial Data Input Output3

VCC

Supply

Power Supply

7

�SPI(x1/x2/x4) NAND Flash

2G

2.4 Block Diagram

SCLK

SI/SIO0

SO/SIO1

CS#

HOLD#/ WP#/

RESET#/ SIO2

SIO3

Serial NAND controler

Vcc

Vss

Cache

memory

ECC and status register

Figure2-2 Block Diagram

8

NAND

memory

core

�SPI(x1/x2/x4) NAND Flash

2G

3 ARRAY ORGANIZATION

Each device has

Each block has

Each page has

256M+16M

128K+8K

2K+128

bytes

2048 x 64

64

-

pages

2048

-

-

blocks

2G

Figure3-1. Array Organization

SO

Cache Register

2048

128

Data Register

2048

128

SI

1 page = (2K + 128 bytes)

1 block = (2K + 128 bytes) x 64 pages

= (128K + 8K) bytes

Per device:

2Gb: 2048blocks

1 device:

For 2Gb = (128K + 8K) bytes x 2048 blocks

= 1Gb

1 block

Internal ECC = OFF

SO

Cache Register

2048

64

Data Register

2048

64

SI

1 page

= (2K + 64 bytes)

1 block = (2K + 64 bytes) x 64 pages

= (128K + 4K) bytes

Per device:

2Gb: 2048blocks

1 device:

For 2Gb = (128K + 4K) bytes x 2048 blocks

= 2Gb

1 block

Internal ECC= ON

Note:

1.When Internal ECC is enabled,user can program the first 64 bytes of the entire 128 bytes spare area and the last 64

bytes of the whole spare area cannot be programed,user can read the entire 128 Byte spare area.

2.When Internal ECC is disabled,user can read and program the entire 128 bytes spare area.

9

�SPI(x1/x2/x4) NAND Flash

2G

4 MEMORY MAPPING

<

6

7

8

15

Blocks

RA

0

1

2

1023

Pages

RA

0

1

Bytes

CA

0

1

16 >

2047

63

2

2175

Note:

1.

CA: Column Address. The 12-bit address is capable of addressing from 0 to 4095 bytes; however, only bytes 0

through 2175 are valid. Bytes 2176 through 4095 of each page are “out of bounds,” do not exist in the device,

and cannot be addressed.

2.

RA: Row Address. RA selects a page inside a block, and RA selects a block:

10

�SPI(x1/x2/x4) NAND Flash

2G

5 DEVICE OPERATION

5.1 SPI Modes

SPI NAND supports two SPI modes:

• CPOL = 0, CPHA = 0 (Mode 0)

• CPOL = 1, CPHA = 1 (Mode 3)

Input data is latched on the rising edge of SCLK and data shifts out on the falling edge of SCLK for both modes. All timing

diagrams shown in this data sheet are mode 0. See Figure5-1 for more details.

Figure5-1. SPI Modes Sequence Diagram

CPOL CPHA

0

0 SCLK

1

1

SCLK

SI

MSB

LSB

SO

MSB

LSB

CS#

Note: While CS# is HIGH, keep SCLK at VCC or GND (determined by mode 0 or mode 3).

Standard SPI

SPI NAND Flash features a standard serial peripheral interface on 4 signals bus: Serial Clock (SCLK), Chip Select

(CS#), Serial Data Input (SI) and Serial Data Output (SO).

Dual SPI

SPI NAND Flash supports Dual SPI operation when using the x2 and dual IO commands. These commands allow

data to be transferred to or from the device at two times the rate of the standard SPI. When using the Dual SPI command

the SI and SO pins become bidirectional I/O pins: SIO0 and SIO1.

Quad SPI

SPI NAND Flash supports Quad SPI operation when using the x4 and Quad IO commands. These commands allow

data to be transferred to or from the device at four times the rate of the standard SPI. When using the Quad SPI command

the SI and SO pins become bidirectional I/O pins: SIO0 and SIO1, and WP# and HOLD# pins become SIO2 and SIO3.

11

�SPI(x1/x2/x4) NAND Flash

2G

5.2 HOLD Mode

The HOLD# function is only available when QE=0, If QE=1, The HOLD# functions is disabled, the pin acts as dedicated

data I/O pin.

The HOLD# signal goes low to stop any serial communications with the device, but doesn’t stop the operation of write

status register, programming, or erasing in progress.

The operation of HOLD, need CS# keep low, and starts on falling edge of the HOLD# signal, with SCLK signal being low

(if SCLK is not being low, HOLD operation will not start until SCLK being low). The HOLD condition ends on rising edge of

HOLD# signal with SCLK being low (If SCLK is not being low, HOLD operation will not end until SCLK being low).

The SO is high impedance, both SI and SCLK don’t care during the HOLD operation, if CS# drives high during HOLD

operation, it will reset the internal logic of the device. To re-start communication with chip, the HOLD# must be at high and

then CS# must be at low.

Figure5-2. Hold Condition

CS#

SCLK

HOLD#

HOLD

HOLD

5.3 Write Protection

SPI NAND provides Hardware Protection Mode besides the Software Mode. Write Protect (WP#) prevents the block lock

bits (BP0, BP1, BP2 and INV, CMP) from being over written. If the BRWD bit is set to 1 and WP# is LOW, the block protect

bits cannot be altered.

5.4 Power Off Timing

Please do not turn off the power before Write/Erase operation is complete. Avoid using the device when the battery is low.

Power shortage and/or power failure before Write/Erase operation is complete will cause loss of data and/or

damage to data.

12

�SPI(x1/x2/x4) NAND Flash

2G

6 COMMANDS DESCRIPTION

Table6-1. Commands Set

Command Name

Byte 1

Write Enable

Write Disable

Get Features

Set Feature

Page Read (to cache)

Read From Cache

Fast Read From Cache

Read From Cache x 2

Read From Cache x 4

Read From Cache Dual IO

Read From Cache Quad IO

Read ID(5)

Program Load

Program Load x4

Program Execute

Program Load Random Data

Program Load Random Data x4

Block Erase(128K)

Reset(6)

06H

04H

0FH

1FH

13H

03H

0BH

3BH

6BH

BBH

EBH

9FH

02H

32H

10H

84H(7)

C4H/34H(7)

D8H

FFH

Byte 2

Byte 3

A7-A0

A7-A0

A23-A16

dummy(2)

dummy(2)

dummy(2)

dummy(2)

A15-A0

A15-A0(4)

MID

A15-A8

A15-A8

A23-A16

A15-A8

A15-A8

A23-A16

(D7-D0)

(D7-D0)

A15-A8

A15-A8

A15-A8

A15-A8

A15-A8

dummy(3)

(D7-D0)x4

DID

A7-A0

A7-A0

A15-A8

A7-A0

A7-A0

A15-A8

Byte 4

Byte 5

Wrap(9)

dummy(1)

A7-A0

A7-A 0(8)

A7-A0

A7-A0

A7-A0

(D7-D0)x2

DID

(D7-D0)

(D7-D0)x4

A7-A0

(D7-D0)

(D7-D0)x4

A7-A0

(D7-D0)

dummy(2)

dummy(2)

dummy(2)

(D7-D0)

(D7-D0)x2

(D7-D0)x4

Next byte

Next byte

Byte N

Byte N

Next byte

Next byte

Byte N

Byte N

Notes:

1.

The dummy byte can be inputted or not.

2.

The x8 clock = dummy.

3.

The x8 clock = dummy, D7-D0.

4.

The x8 clock = A15-A0, dummy, D7-D0.

5.

MID is Manufacture ID (C8h for GigaDevice), DID is Device ID.

6.

Reset command:

• During busy, Reset will reset PAGE READ/PROGRAM/ERASE operation.

• During idle, Reset will reset status register bits P_FAIL/E_FAIL/WEL/OIP/ECCS bits.

7.

Those commands are only available in Internal Data Move operation.

8.

A0 need be 0 for the 03H command.

9.

The output would be updated by real-time, until CS# is driven high.

13

Byte N

�SPI(x1/x2/x4) NAND Flash

2G

7 WRITE OPERATIONS

7.1 Write Enable (WREN) (06H)

The Write Enable (WREN) command is for setting the Write Enable Latch (WEL) bit. The Write Enable Latch (WEL) bit

must be set prior to following operations that change the contents of the memory array:

• Page program

• OTP program/OTP protection

• Block erase

The WEL bit can be cleared after a reset command.

Figure7-1. Write Enable Sequence Diagram

CS#

SCLK

0

1

2

3

4

5

6

7

Command

SI

06H

High-Z

SO

7.2 Write Disable (WRDI) (04H)

The Write Disable command is for resetting the Write Enable Latch (WEL) bit. The WEL bit is also reset by following

condition:

• Page program

• OTP program/OTP protection

• Block erase

Figure7-2. Write Disable Sequence Diagram

CS#

SCLK

SI

SO

0

1

2

3

4

5

Command

04H

High-Z

14

6

7

�SPI(x1/x2/x4) NAND Flash

2G

8 FEATURE OPERATIONS

8.1 Get Features (0FH) and Set Features (1FH)

The GET FEATURES (0FH) and SET FEATURES (1FH) commands are used to monitor the device status and alter the

device behavior. These commands use a 1-byte feature address to determine which feature is to be read or modified.

Features such as OTP and block locking can be enabled or disabled by setting specific feature bits (shown in the following

table). The status register is mostly read, except WEL, which is a writable bit with the WRITE ENABLE (06H) command.

When a feature is set, it remains active until the device is power cycled or the feature is written to. Unless otherwise

specified in the following table, once the device is set, it remains set, even if a RESET (FFH) command is issued.

Table8-1. Features Settings

Register Addr.

7

6

5

4

3

2

1

0

Protection A0H

BRWD

Reserved

BP2

BP1

BP0

INV

CMP

Reserved

Feature

B0H

OTP_PRT

OTP_EN

Reserved

ECC_EN

Reserved

Reserved

Reserved

QE

Status

C0H

Reserved

ECCS2

ECCS1

ECCS0

P_FAIL

E_FAIL

WEL

OIP

Feature

D0H

Reserved

DS_IO[1]

DS_IO[0]

Reserved

Reserved

Reserved

Reserved

Reserved

Note: If BRWD is enabled and WP# is LOW, then the block lock register cannot be changed.

If QE is enabled, the quad IO operations can be executed.

All the reserved bits must be held low when the feature is set.

00h is the default data byte value for Output Driver Register after power-up.

These registers are write/read type, except for Register of Status (C0H) is read only.

Figure8-2. Get Features Sequence Diagram

CS#

SCLK

SI

0

1

2

3

4

6

7

8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

1 byte address

Command

0FH

SO

5

High-Z

7

6

5

4

3

2

1

0

Data byte

MSB

7

MSB

Note: The output would be updated by real-time, until CS# is driven high.

15

6

5

4

3

2

1

0

�SPI(x1/x2/x4) NAND Flash

2G

The set features command supports a dummy byte mode after the data byte as well. The features in the feature byte B0H

are all volatile except OTP_PRT bit.

Figure8-3. Set Features Sequence Diagram

CS#

SCLK

SI

0

1

2

3 4

6

7

8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Command

1FH

SO

5

Data byte

1 byte address

7 6

MSB

5

4

3

High-Z

16

2 1

0

7

MSB

6

5

4

3

2

1

0

�SPI(x1/x2/x4) NAND Flash

2G

9 READ OPERATIONS

9.1 Page Read

The PAGE READ (13H) command transfers the data from the NAND Flash array to the cache register. The command

sequence is as follows:

• 13H (PAGE READ to cache)

• 0FH (GET FEATURES command to read the status)

• 03H or 0BH (Read from cache)/3BH (Read from cache x2)/6BH (Read from cache x4)/BBH (Read from cache

dual IO)/EBH (Read from cache quad IO)

The PAGE READ command requires a 24-bit address. After the block/page addresses are registered, the device starts

the transfer from the main array to the cache register, and is busy for tRD time. During this time, the GET FEATURE (0FH)

command can be issued to monitor the status. Followed the page read operation, the RANDOM DATAREAD

(03H/0BH/3BH/6BH/BBH/EBH) command must be issued in order to read out the data from cache. The output data starts

at the initial address specified in the command, and will continue until CS# is pulled high to terminate this operation.

Refer waveforms to view the entire READ operation.

9.2 Page Read to Cache (13H)

Figure9-1.Page Read to cache Sequence Diagram

CS#

0

1

2

3

4

5

6

7

8

9 10

28 29 30 31

SCLK

Command

SI

24-bit address

13H

23 22 21

3

2

1

0

High-Z

SO

CS#

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15

SLK

tCS

0FH

7

MSB

High-Z

SO

CS#

16 17 18 19 20 21 22 23 24

SCLK

SI

Data byte

SO

7

6

5

1 byte address

Get Feature

SI

4

3

2

1

0

7

MSB

17

6

5

4

3

2

1

0

�SPI(x1/x2/x4) NAND Flash

2G

9.3 Read From Cache (03H)

Figure9-2. Read From Cache Sequence Diagram

CS#

0

1

2

3

4

5

6

8

7

9 10 11 12 13 14 15 16 17 18 19 20 21

30 31

SCLK

Command

SI

Dummy Byte

7

03H

6

5

4

3

2

1

A15-0

0 15 14 13 12 11

3

2

1

0

High-Z

SO

CS#

32 33 34 35 36 37 38 39

SCLK

SI

SO

7 6

MSB

Byte 0

4 3

5

2

1

0

7 6

MSB

Byte 1

5

9.4 Fast Read From Cache (0BH)

Figure9-3. Read From Cache Sequence Diagram

CS#

0

1

2

3

4 5

6

7

8

9 10 11 12 13 14 15 16 17 18 19 20 21

30 31

SCLK

Command

SI

Dummy Byte

7

0BH

6

5

4

3

2

1

A15-0

0 15 14 13 12 11

High-Z

SO

CS#

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

SCLK

Dummy Byte

SI

SO

7

6

5

4

3

2

1

0

7 6

MSB

5

Byte 0

4 3

18

2

1

0

7 6

MSB

Byte 1

5

3

2

1

0

�SPI(x1/x2/x4) NAND Flash

2G

9.5 Read From Cache x2 (3BH)

Figure9-4. Read From Cache x2 Sequence Diagram

CS#

0

1

2

3

4

5

6

8

7

9 10 11 12 13 14 15 16 17 18 19 20 21

30 31

SCLK

Command

SI

Dummy Byte

7

3BH

6

5

4

3

2

A15-0

0 15 14 13 12 11

1

3

2

1

0

High-Z

SO

CS#

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

SCLK

Dummy Byte

SI

7

6

5

4

3

2

1

0

SO

6

4

0

6

4

0

6

7

Byte 0

5 3 1

7

Byte 1

5 3 1

7

2

MSB

2

4

2

Byte 2

5 3

MSB

9.6 Read From Cache x4 (6BH)

The Quad Enable bit (QE) of feature (B0[0]) must be set to enable the read from cache x4 command.

Figure9-5. Read From Cache x4 Sequence Diagram

CS#

0

1

2

3

4

5

6

8

7

9 10 11 12 13 14 15 16 17 18 19 20 21

30 31

SCLK

Command

SI

Dummy Byte

7

6BH

6

5

4

3

2

A15-0

0 15 14 13 12 11

1

High-Z

SO

CS#

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

SCLK

Dummy Byte

7

6

5

4

3

2

1

0

4

0

4

0

4

0

4

0

4

SO(SIO1)

5

1

5

1

5

1

5

1

5

WP#(SIO2)

6

2

6

2

6

2

6

2

6

HOLD#(SIO3)

7 3 7 3 7 3 7 3 7

Byte0 Byte1 Byte2 Byte3

SI(SIO0)

19

3

2

1

0

�SPI(x1/x2/x4) NAND Flash

2G

9.7 Read From Cache Dual IO (BBH)

The Read from Cache Dual I/O command (BBH) is similar to the Read form Cache x2 command (3BH), followed by a 12bit

column address for the starting byte address and a dummy byte by SIO0 and SIO1, each bit being latched in during the

rising edge of SCLK, then the cache contents are shifted out 2-bit per clock cycle from SIO0 and SIO1. The first address

byte can be at any location. The address increments automatically to the next higher address after each byte of data shifted

out until the end of whole page.

Figure9-6. Read From Cache Dual IO Sequence Diagram

CS#

0

SCLK

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

6

4

2

0

6

4

2

0

6

4

2

0

6

4

2

0

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

Command

SI(SIO0)

BBH

SO(SIO1)

A7-0

Dummy, A11-8

Dummy

CS#

23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39

SCLK

SI(SIO0)

6

4

2

0

6

4

2

0

6

4

2

0

6

4

2

0

6

SO(SIO1)

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

Byte1

Byte2

Byte3

Byte4

20

Byte0

�SPI(x1/x2/x4) NAND Flash

2G

9.8 Read From Cache Quad IO (EBH)

The Read from Cache Quad IO command is similar to the Read from Cache x4 command, followed a 12-bit column address

for the starting byte address and a dummy byte by SIO0, SIO1, SIO3, SIO4, each bit being latched in during the rising

edge of SCLK, then the cache contents are shifted out 4-bit per clock cycle from SIO0, SIO1, SIO2, SIO3. The first byte

addressed can be at any location. The address is automatically incremented to the next higher address after each byte of

data is shifted out until the end of whole page. The Quad Enable bit (QE) of feature (B0[0]) must be set to enable the read

from cache quad IO command.

Figure9-7. Read From Cache Quad IO Sequence Diagram

CS#

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

4

0

4

0

4

0

4

0

4

0

4

SO(SIO1)

5

1

5

1

5

1

5

1

5

1

5

WP#(SIO2)

6

2

6

2

6

2

6

2

6

2

6

HOLD#(SIO3)

7

3

7

3

7

3

7

3

7

3

7

SCLK

Command

SI(SIO0)

EBH

A7-0

Dummy, A11-A8

21

Dummy

Byte0 Byte1

�SPI(x1/x2/x4) NAND Flash

2G

10 Read ID (9FH)

The READ ID command is used to identify the NAND Flash device.

• The READ ID command outputs the Manufacturer ID and the device ID. See Table10-1 for details.

Figure10-1. Read ID Sequence Diagram

CS#

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15

7

Manufacturer ID

6 5 4 3 2 1

SCLK

Command

SI

9FH

High-Z

SO

CS#

0

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

SCLK

SI

Device ID(Byte 1)

SO

7

6

5

4

3

2

1

MSB

Device ID(Byte 2)

0

7

6

5

4

3

2

1

0

MSB

Table10-1. READ ID Table

ID

Description

Part No

Value

Manufacture ID (GigaDevice)

SPI NAND 3.3V

GD5F2GQ4UFxxG

C8h

SPI NAND 1.8V

GD5F2GQ4RFxxG

Device ID

SPI NAND 3.3V

GD5F2GQ4UFxxG

B2h

2Kbyte +

(Byte 1)

SPI NAND 1.8V

GD5F2GQ4RFxxG

A2h

128Byte

Device ID

SPI NAND 2Gbit 3.3V

GD5F2GQ4UFxxG

48h

(Byte 2)

SPI NAND 2Gbit 1.8V

GD5F2GQ4RFxxG

22

Page Size

�SPI(x1/x2/x4) NAND Flash

2G

11 PROGRAM OPERATIONS

11.1 Page Program

The PAGE PROGRAM operation sequence programs 1 byte to 2176 bytes of data with in a page. The page program

sequence is as follows:

• 02H (PROGRAM LOAD)/32H (PROGRAM LOAD x4)

• 06H (WRITE ENABLE)

• 10H (PROGRAM EXECUTE)

• 0FH (GET FEATURE command to read the status)

Firstly, a PROGRAM LOAD (02H/32H) command is issued. PROGRAM LOAD consists of an 8-bit Op code, followed by 4

dummy bits and a 12-bit column address, then the data bytes to be programmed. The data bytes are loaded into a cache

register that is 2176 bytes long. If more than 2176bytes are loaded, then those additional bytes are ignored by the cache

register. The command sequence ends when CS# goes from LOW to HIGH. Figure11-1 shows the PROGRAMLOAD

operation. Secondly, prior to performing the PROGRAM EXECUTE operation, a WRITE ENABLE (06H) command must

be issued. As with any command that changes the memory contents, the WRITEENABLE must be executed in order to set

the WEL bit. If this command is not issued, then the rest of the program sequence is ignored.

Note:

1.

The contents of Cache Register doesn’t reset when Program Load (02h) command, Program Random Load (84h)

command and RESET (FFh) command.

2.

When Program Execute (10h) command was issued just after Program Load (02h) command, SPI-NAND controller

outputs 0xFF data to the NAND for the address that data was not loaded by Program Load (02h) command.

3.

When Program Execute (10h) command was issued just after Program Load Random Data (84h) command, SPINAND controller outputs contents of Cache Register to the NAND.

4.

The addressing should be done in sequential order in a block.

23

�SPI(x1/x2/x4) NAND Flash

2G

11.2 Program Load (PL) (02H)

Figure11-1. Program Load Sequence Diagram

CS#

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14

0

0

22 23

SCLK

Command

SI

Dummy, A11-A0

02H

0 0 11 10

3

2

1

0

CS#

24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39

17424

17431

SCLK

Data Byte0

SI

7 6

MSB

5

4

3

Data Byte1

2

1

0 7

6

5

4

3

2

1

0

7

6

Data Byte

2175/2111

5 4 3 2 1

0

Note: when internal ECC disabled the Data Byte is 2175, when internal ECC enabled the Data Byte is 2111.

24

�SPI(x1/x2/x4) NAND Flash

2G

11.3 Program Load x4 (PL x4) (32H)

The Program Load x4 command (32H) is similar to the Program Load command (02H) but with the capability to input the

data bytes by four pins: SIO0, SIO1, SIO2, and SIO3. The command sequence is shown below. The Quad Enable bit (QE)

of feature (B0[0]) must be set to enable the program load x4 command.

Figure11-2. Program Load x4 Sequence Diagram

CS#

0

1

2

3

4

5

6

7

8

9 10

20 21 22 23 24 25 26 27 28 29 30 31

SCLK

Command

SI(SIO0)

Dummy, A11-A0

32H

15 14 13

3

2

1

Byte0 Byte1 Byte2 Byte3

0 4

0

4

0

4

0

4

0

SO(SIO1)

5

1

5

1

5

1

5

1

WP#(SIO2)

6

2

6

2

6

2

6

2

HOLD#(SIO3)

7

3

7

3

7

3

7

3

CS#

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

SCLK

Byte

2175/2111

Byte4 Byte5 Byte6 Byte7 Byte8 Byte9 Byte10Byte11

SI(SIO0)

4

SO(SIO1)

5 1

5 1

5 1

5 1

5 1

5 1

5 1

5 1

5 1

5 1

5 1

5 1

WP#(SIO2)

6 2

6 2

6 2

6 2

6 2

6 2

6 2

6 2

6 2

6 2

6 2

6 2

HOLD#(SIO3) 7 3

7 3

7 3

7 3

7 3

7 3

7 3

7 3

7 3

7 3

7 3

7 3

0

4

0

4

0

4

0

4

0

4

0

4

0

4

0

4

0

4

0

4

Note: when internal ECC disabled the Byte is 2175, when internal ECC enabled the Byte is 2111

25

0

4

0

�SPI(x1/x2/x4) NAND Flash

2G

11.4 Program Execute (PE) (10H)

After the data is loaded, a PROGRAM EXECUTE (10H) command must be issued to initiate the transfer of data from the

cache register to the main array. PROGRAM EXECUTE consists of an 8-bit Op code, followed by a 24-bit address. After

the page/block address is registered, the memory device starts the transfer from the cache register to the main array, and

is busy for tPROG time. This operation is shown in Figure11-3. During this busy time, the status register can be polled to

monitor the status of the operation (refer to Status Register). When the operation completes successfully, the next series

of data can be loaded with the PROGRAMLOAD command.

Figure11-3. Program Execute Sequence Diagram

CS#

0

1

2

3

4

5

6

7

8

9 10

28 29 30 31

SCLK

Command

SI

24-bit address

10H

23 22 21

3

2

1

0

High-Z

SO

CS#

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15

SCLK

tCS

0FH

7

6

5

4

3

2

1

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34

SCLK

SI

Status register data out

SO

0

MSB

High-Z

SO

CS#

Status register address

get feature

SI

7

MSB

6

5

4

3

2

1

0

Status register data out

7

MSB

26

6

5

4

3

2

1

0

7

6

�SPI(x1/x2/x4) NAND Flash

2G

11.5 Internal Data Move

The INTERNAL DATA MOVE command sequence programs or replaces data in a page with existing data. The

INTERNAL DATA MOVE command sequence is as follows:

• 13H (PAGE READ to cache)

• Optional 84H/C4H/34H (PROGRAM LOAD RANDOM DATA)

• 06H (WRITE ENABLE)

• 10H (PROGRAM EXECUTE)

• 0FH (GET FEATURE command to read the status)

Prior to performing an internal data move operation, the target page content must be read out into the cache register by

issuing a PAGE READ (13H) command. The PROGRAM LOAD RANDOM DATA (84H/C4H/34H) command can be

issued, if user wants to update bytes of data in the page. New data is loaded in the 12-bit column address. If the random

data is not sequential, another PROGRAM LOAD RANDOM DATA (84H/C4H/34H) command must be issued with the

new column address. After the data is loaded, the WRITE ENABLE command must be issued, and the na

PROGRAMEXECUTE (10H) command can be issued to start the programming operation.

11.6 Program Load Random Data (84H)

This command consists of an 8-bit Op code, followed by 4 dummy bits, and a 12-bit column address. New data is loaded

in the column address provided with the 12 bits. If the random data is not sequential, then another PROGRAM LOAD

RANDOM DATA (84H) command must be issued with a new column address, see Figure11-4 for details. This command is

only available during internal data move sequence.

Figure11-4. Program Load Random Data Sequence Diagram

CS#

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14

22 23

SCLK

Dummy, A11-A0

Command

SI

84H

0

0

0 0 11 10

3

2

1

0

CS#

24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39

17424

17431

SCLK

Data Byte0

SI

7 6

MSB

5

4

3

Data Byte1

2

1

0

7

6

5

4

3

2

1

0

7

6

Data Byte

2175/2111

5 4 3 2 1

0

Note: when internal ECC disabled the Data Byte is 2175, when internal ECC enabled the Data Byte is 2111.

27

�SPI(x1/x2/x4) NAND Flash

2G

11.7 Program Load Random Data x4 (C4H/34H)

The Program Load Random Data x4 command (C4H/34H) is similar to the Program Load Random Data command (84H)

but with the capability to input the data bytes by four pins: SIO0, SIO1, SIO2, and SIO3. The command sequence is shown

below. The Quad Enable bit (QE) of feature (B0[0]) must be set to enable for the program load random data x4 command.

See Figure11-5 for details. Those two commands are only available during internal data move sequence.

Figure11-5. Program Load Random Data x4 Sequence Diagram

CS#

0

1

2

3

4

5

6

7

8

9 10

20 21 22 23 24 25 26 27 28 29 30 31

SCLK

Command

SI(SIO0)

Dummy, A11-A0

C4H/34H

15 14 13

3

2

1

Byte0 Byte1

0 4

0

4

0

4

0

4

0

SO(SIO1)

5

1

5

1

5

1

5

1

WP#(SIO2)

6

2

6

2

6

2

6

2

HOLD#(SIO3)

7

3

7

3

7

3

7

3

CS#

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

SCLK

Byte

2175/2111

Byte10Byte11

SI(SIO0)

4

SO(SIO1)

5 1

5 1

5 1

5 1

5 1

5 1

5 1

5 1

5 1

5 1

5 1

5 1

WP#(SIO2)

6 2

6 2

6 2

6 2

6 2

6 2

6 2

6 2

6 2

6 2

6 2

6 2

HOLD#(SIO3) 7 3

7 3

7 3

7 3

7 3

7 3

7 3

7 3

7 3

7 3

7 3

7 3

0

4

0

4

0

4

0

4

0

4

0

4

0

4

0

4

0

4

0

4

Note: when internal ECC disabled the Data is 2175, when internal ECC enabled the Data is 2111.

28

0

4

0

�SPI(x1/x2/x4) NAND Flash

2G

12 ERASE OPERATIONS

12.1 Block Erase (D8H)

Figure12-1. Block Erase Sequence Diagram

CS#

0

1

2

3

4

5

6

7

8

9 10

28 29 30 31

SCLK

Command

SI

24-bit address

D8H

23 22 21

3

2

1

0

High-Z

SO

CS#

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15

SLK

tCS

Status register address

get feature

SI

0FH

7

High-Z

SO

CS#

6

5

4

3

2

1

0

MSB

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34

SCLK

SI

Status register data out

SO

7

6

5

4

3

2

1

MSB

0

Status register data out

7

6

5

4

3

2

1

0

7

6

MSB

The BLOCK ERASE (D8H) command is used to erase at the block level. The blocks are organized as 64 pages per

block, 2176 bytes per page (2048 + 128 bytes). Each block is136 Kbytes. The BLOCK ERASE command (D8H) operates

on one block at a time. The command sequence for the BLOCK ERASE operation is as follows:

• 06H (WRITE ENBALE command)

• D8H (BLOCK ERASE command)

• 0FH (GET FEATURES command to read the status register)

Prior to performing the BLOCK ERASE operation, a WRITE ENABLE (06H) command must be issued. As with any

command that changes the memory contents, the WRITEENABLE command must be executed in order to set the WEL

bit. If the WRITE ENABLE command is not issued, then the rest of the erase sequence is ignored. A WRITE ENABLE

command must be followed by a BLOCK ERASE (D8H) command. This command requires a 24-bit address. After the

row address is registered, the control logic automatically controls timing and erase-verify operations. The device is busy

for tERS time during the BLOCK ERASE operation. The GET FEATURES (0FH) command can be used to monitor the

status of the operation.

When

a

block

erase

operation

is

in

progress,

user

(03H/0BH/3BH/6BH/BBH/EBH) to read the data in the cache.

29

can

issue

normal

read

from

cache

commands

�SPI(x1/x2/x4) NAND Flash

2G

13 RESET OPERATIONS

13.1 Soft Reset (FFH)

Figure13-1. Reset Sequence Diagram

CS#

tCS

0

1

2

3

4

5

6

7

SCLK

Command

SI

FFH

High-Z

SO

CS#

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15

SLK

Status register address

get feature

SI

0FH

High-Z

SO

CS#

7

6

5

4

3

2

1

0

MSB

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34

SCLK

SI

Status register data out

SO

7

6

5

4

3

2

1

0

MSB

Status register data out

7

6

5

4

3

2

1

0

7

6

MSB

The RESET (FFH) command stops all operations. For example, in case of a program or erase or read operation, the

reset command can make the device enter the wait state.

During a cache program or cache read, a reset can also stops the previous operation and the pending operation. The

OIP status can be read from 300ns after the reset command is sent.

30

�SPI(x1/x2/x4) NAND Flash

2G

14 ADVANCED FEATURES

14.1 OTP Region

The serial device offers a protected, One-Time Programmable NAND Flash memory area. 4 full pages (2176 bytes per

page) are available on the device. Customers can use the OTP area any way they want, like programming serial

numbers, or other data, for permanent storage. When delivered from factory, feature bit OTP_PRT is 0.

To access the OTP feature, the user must set feature bits OTP_EN/OTP_PRT by SET FEATURES command. When the

OTP is ready for access, pages 00h–03H can be programmed in sequential order by PROGRAM LOAD (02H) and

PROGRAM EXECUTE(10H) commands ( when not yet protected), and read out by PAGE READ (13H) command and

output data by READ from CACHE(03H/0BH/3BH/6BH/BBH/EBH).

Whether ECC is enabled or disabled, data written in the OTP area is ECC protected.

Table14-1. OTP States

OTP_PRT

OTP_EN

State

x

0

Normal operation

0

1

Access OTP region, read and program data.

1

1

1.

When the device power on state OTP_PRT is 0, user can set feature bit

OTP_PRT and OTP_EN to 1, then issue PROGRAM EXECUTE (10H) to

lock OTP, and after that OTP_PRT will permanently remain 1.

2.

When the device power on state OTP_PRT is 1, user can only read the

OTP region data.

Note: The OTP space cannot be erased and after it has been protected, it cannot be programmed again, please use this

function carefully.

Access to OTP data

• Issue the SET FEATURES command (1FH)

• Set feature bit OTP_EN

• Issue the PAGE PROGRAM (only when OTP_PRT is 0) or PAGE READ command

Protect OTP region

Only when the following steps are completed, the OTP_PRT will be set and users can get this feature out with 0FH

command.

• Issue the SET FEATURES command (1FH)

• Set feature bit OTP_EN and OTP_PRT

• 06H (WRITE ENABLE)

• Issue the PROGRAM EXECUTE (10H) command.

31

�SPI(x1/x2/x4) NAND Flash

2G

14.2 Block Protection

The block lock feature provides the ability to protect the entire device, or ranges of blocks, from the PROGRAM and ERASE

operations. After power-up, the device is in the “locked” state, i.e., feature bits BP0, BP1and BP2are set to 1, INV, CMP

and BRWD are set to 0. To unlock all the blocks, or a range of blocks, the SET FEATURES command must be issued to

alter the state of protection feature bits. When BRWD is set and WP# is LOW, none of the writable protection feature bits

can be set. Also, when a PROGRAM/ERASE command is issued to a locked block, status bit OIP remains 0.When an

ERASE command is issued to a locked block, the erase failure, 04H, is returned. When a PROGRAM command is issued

to a locked block, program failure,08h is returned.

Table14-1. Block Lock Register Block Protect Bits

CMP

INV

BP2

BP1

BP0

Protect Row Address

Protect Rows

2G

x

x

0

0

0

NONE

None—all unlocked

0

0

0

0

1

1F800h ~ 1FFFFh

Upper 1/64 locked

0

0

0

1

0

1F000h ~ 1FFFFh

Upper 1/32 locked

0

0

0

1

1

1E000h ~ 1FFFFh

Upper 1/16 locked

0

0

1

0

0

1C000h ~ 1FFFFh

Upper 1/8 locked

0

0

1

0

1

18000h ~ 1FFFFh

Upper 1/4 locked

0

0

1

1

0

10000h ~ 1FFFFh

Upper 1/2 locked

x

x

1

1

1

0000h ~ 1FFFFh

All locked (default)

0

1

0

0

1

0000h ~7FFh

Lower 1/64 locked

0

1

0

1

0

0000h ~FFFh

Lower 1/32 locked

0

1

0

1

1

0000h ~ 1FFFh

Lower 1/16 locked

0

1

1

0

0

0000h ~ 3FFFh

Lower 1/8 locked

0

1

1

0

1

0000h ~ 7FFFh

Lower 1/4 locked

0

1

1

1

0

0000h ~ FFFFh

Lower 1/2 locked

1

0

0

0

1

0000h ~ 1F7FFh

Lower 63/64 locked

1

0

0

1

0

0000h ~ 1EFFFh

Lower31/32 locked

1

0

0

1

1

0000h ~ 1DFFFh

Lower 15/16 locked

1

0

1

0

0

0000h ~ 1BFFFh

Lower7/8 locked

1

0

1

0

1

0000h ~ 17FFFh

Lower3/4 locked

1

0

1

1

0

0000h ~ 003Fh

1

1

0

0

1

0800h ~ 1FFFFh

Upper 63/64 locked

1

1

0

1

0

1000h ~ 1FFFFh

Upper31/32 locked

1

1

0

1

1

2000h ~ 1FFFFh

Upper 15/16 locked

1

1

1

0

0

4000h ~ 1FFFFh

Upper7/8 locked

1

1

1

0

1

8000h ~ 1FFFFh

Upper3/4 locked

1

1

1

1

0

0000h ~ 003Fh

Block0

Block0

When WP# is not LOW, user can issue bellows commands to alter the protection states as want.

• Issue SET FEATURES register write (1FH)

• Issue the feature bit address (A0h) and the feature bits combination as the table

32

�SPI(x1/x2/x4) NAND Flash

2G

14.3 Status Register and Driver Register

The NAND Flash device has a 16-bit status register that software can read during the device operation for operation state

query. The status register can be read by issuing the GET FEATURES (0FH)command, followed by the feature address

C0h (see FEATURE OPERATION). The Output Driver Register can be set and read by issuing the SET FEATURE (0FH)

and GET FEATURE command followed by the feature address D0h (see FEATURE OPERATION)..

Table14-2. Status Register Bit Descriptions

Bit

Bit Name

Description

P_FAIL

Program

This bit indicates that a program failure has occurred (P_FAIL set to 1). It will also be

Fail

set if the user attempts to program an invalid address or a protected region, including

the OTP area. This bit is cleared during the PROGRAM EXECUTE command

sequence or a RESET command (P_FAIL = 0).

E_FAIL

Erase Fail

This bit indicates that an erase failure has occurred (E_FAIL set to 1). It will also be

set if the user attempts to erase a locked region. This bit is cleared (E_FAIL = 0) at

the start of the BLOCK ERASE command sequence or the RESET command.

WEL

Write

This bit indicates the current status of the write enable latch (WEL) and must be set

Enable

(WEL = 1), prior to issuing a PROGRAM EXECUTE or BLOCK ERASE command. It

Latch

is set by issuing the WRITE ENABLE command. WEL can also be disabled (WEL =

0), by issuing the WRITE DISABLE command.

OIP

Operation

This bit is set (OIP = 1 ) when a PROGRAM EXECUTE, PAGE READ, BLOCK

In Progress

ERASE, or RESET command is executing, indicating the device is busy. When the bit

is 0, the interface is in the ready state.

ECCS2~ECCS0

ECC Status

ECCS2~ECCS0 provides ECC status as the following table.

Table14-3. ECC Status

ECCS2

ECCS1

ECCS0

Description

0

0

0

No bit errors were detected during the previous read algorithm.

0

0

1

Bit errors(8, error exceeded. And cannot be corrected.

Table14-4. Driver Register Bits Descriptions

DS_S1

DS_S0

Driver Strength

0

0

50%

0

1

25%

1

0

75%

1

1

100%

33

�SPI(x1/x2/x4) NAND Flash

2G

14.4 Assistant Bad Block Management

As a NAND Flash, the device may have blocks that are invalid when shipped from the factory, and a minimum number of

valid blocks (NVB) of the total available blocks are specified. An invalid block is one that contains at least one page that has

more bad bits than can be corrected by the minimum required ECC. Additional bad blocks may develop with use. However,

the total number of available blocks will not fall below NVB during the endurance life of the product.

Although NAND Flash memory devices may contain bad blocks, they can be used reliably in systems that provide badblock management and error-correction algorithms, which ensure data integrity. Internal circuitry isolates each block from

other blocks, so the presence of a bad block does not affect the operation of the rest of the NAND Flash array.

NAND Flash devices are shipped from the factory erased. The factory identifies invalid blocks before shipping by

programming the Bad Block Mark (00h) to the first spare area location in each bad block. This method is compliant with

ONFI Factory Defect Mapping requirements. See the following table I bad-block mark.

System software should initially check the first spare area location for non-FFH data I first page of each block prior to

performing any program or erase operations on the NAND Flash device. A bad-block table can then be created, enabling

system software to map around these areas. Factory testing is performed under worst-case conditions. Because invalid

blocks may be marginal, it may not be possible to recover the bad-block marking if the block is erased.

To simplify the system requirement and guard the data integration, GigaDevice SPI NAND provides assistant Management

options as below.

Table14-5. Bad Block Mark information

Description

Density

Requirement

Minimum number of valid blocks (NVB)

2G

2008

Total available blocks per die

2G

2048

First spare area location

Byte 2048

Bad-block mark

00h(use non FFH to check)

34

�SPI(x1/x2/x4) NAND Flash

2G

14.5 Internal ECC

The serial device offers data corruption protection by offering optional internal ECC.READs and PROGRAMs with internal

ECC can be enabled or disabled by setting feature bit ECC_EN. ECC is enabled after device power up, so the default

READ and PROGRAM commands operate with internal ECC in the “active” state. To enable/disable ECC, perform the

following command sequence:

• Issue the SET FEATURES command (1FH).

• Set the feature bit ECC_EN as you want:

1.

To enable ECC, Set ECC_EN to 1.

2.

To disable ECC, Clear ECC_EN to 0.

During a PROGRAM operation, the device calculates an ECC code on the 2k page in the cache register, before the page

is written to the NAND Flash array.

During a READ operation, the page data is read from the array to the cache register, where the ECC code is calculated

and compared with the ECC code value read from the array. If error bits are detected, the error is corrected in the cache

register. Only corrected data is output on the I/O bus. The ECC status bit indicates whether or not the error correction was

successful. The ECC Protection table below shows the ECC protection scheme used throughout a page.

With internal ECC, the user must accommodate the following:

• Spare area definitions provided in the ECC Protection table below.

• ECC can protect according main and spare areas. WRITEs to the ECC area are ignored.

Table14-6. ECC Protection and Spare Area

Min Byte Address

Max Byte Address

ECC Protected

Area

Description

000h

1FFh

Yes

Main 0

User data 0

200h

3FFh

Yes

Main 1

User data 1

400h

5FFh

Yes

Main 2

User data 2

600h

7FFh

Yes

Main 3

User data 3

800h

80Fh

Yes

Spare 0

User meta data 0(1)

810h

81Fh

Yes

Spare 1

User meta data 1

820h

82Fh

Yes

Spare 2

User meta data 2

830h

83Fh

Yes

Spare 3

User meta data 3

840h

87Fh

Yes

Spare Area

Internal ECC parity data

Note

1.800H is reserved for initial bad block mark, and please check the initial bad block mark with internal ECC off.

2.When Internal ECC is enabled,user cannot program the Address 840H~87FH but user can read the Address 840H~87FH.

3. When Internal ECC is disabled, the whole page area is open for user.

35

�SPI(x1/x2/x4) NAND Flash

2G

15 POWER ON TIMING

Figure15-1. Power on Timing Sequence

Vcc(max)

Chip Selection is not allowed

Vcc(min)

tVSL

Device is fully

accessible

VWI

Time

Table15-1. Power-On Timing and Write Inhibit Threshold for 1.8V/3.3V

Symbol

tVSL

VWI

Parameter

Min

VCC(min) To CS# Low

Write Inhibit Voltage

Max

5

ms

1.8V

1.7

3.3V

2.5

36

Unit

V

�SPI(x1/x2/x4) NAND Flash

2G

16 ABSOLUTE MAXIMUM RATINGS

Table16-1. Absolute Maximum Ratings

Parameter

Value

Unit

Ambient Operating Temperature

-40 to 105

℃

Storage Temperature

-65 to 150

℃

Applied Input/Output Voltage

-0.6 to VCC+0.4

V

VCC(3.3V)

-0.6 to 4.0

V

VCC(1.8V)

-0.6 to 2.5

V

Figure16-1. Input Test Waveform and Measurement Level

Maximum Negative Overshoot Waveform

20ns

Maximum Positive Overshoot Waveform

20ns

20ns

Vss

Vcc + 2.0V

Vss-2.0V

Vcc

20ns

20ns

37

20ns

�SPI(x1/x2/x4) NAND Flash

2G

17 CAPACITANCE MEASUREMENT CONDITIONS

Symbol

Parameter

Min

Typ

Max

Unit

Conditions

CIN

Input Capacitance

6

pF

VIN=0V

COUT

Output Capacitance

8

pF

VOUT=0V

CL

Load Capacitance

30

pF

Input Rise And Fall time

5

ns

Input Pulse Voltage

0.1VCC to 0.8VCC

V

Input Timing Reference Voltage

0.2VCC to 0.7VCC

V

Output Timing Reference Voltage

0.5VCC

V

Figure17-1. Input Test Waveform and Measurement Level

Input timing reference level

0.8VCC

0.7VCC

0.1VCC

0.2VCC

Output timing reference level

AC Measurement Level

Note: Input pulse rise and fall time are