TC58CVG2S0HRAIG

KIOXIA

4Gb 3.3V

Serial Interface NAND

Technical Data Sheet

Rev. 2.0

2019 – 10 – 01

KIOXIA Coporation

© 2016-2019 KIOXIA Corporation

1

2019-10-01

�TC58CVG2S0HRAIG

CONTENTS

1.

Introduction ............................................................................................................................................................ 5

1.1. General Description ......................................................................................................................................... 5

1.2. Definitions and Abbreviations .......................................................................................................................... 5

1.3. Features .......................................................................................................................................................... 6

2.

Memory Organization ............................................................................................................................................ 7

2.1. Pin Descriptions .............................................................................................................................................. 7

2.2. Pin Assignment (Top View) .............................................................................................................................. 7

2.3. Block Diagram ................................................................................................................................................. 8

2.4. Cell Layout ...................................................................................................................................................... 8

2.5. Addressing ...................................................................................................................................................... 9

2.6. Valid Blocks ..................................................................................................................................................... 9

3.

Physical Interface ................................................................................................................................................ 10

3.1. Absolute Maximum Rating ............................................................................................................................. 10

3.2. Capacitance .................................................................................................................................................. 10

3.3. DC Operating Conditions............................................................................................................................... 10

3.4. Signal Timing .................................................................................................................................................. 11

3.5. AC Characteristics ......................................................................................................................................... 13

3.6. DC Operating Characteristics ........................................................................................................................ 13

3.7. Programming, Reading and Erasing Characteristics ..................................................................................... 14

3.8. Power ON/OFF Sequence............................................................................................................................. 14

3.9. AC Test Condition .......................................................................................................................................... 14

4.

Command Description and Device Operation ................................................................................................... 15

4.1. Command Set ............................................................................................................................................... 15

4.2. Page Read Operation .................................................................................................................................... 16

4.2.1. Read Cell Array (13h) .......................................................................................................................... 16

4.2.2. Read Buffer (03h or 0Bh)..................................................................................................................... 17

4.2.3. Read Buffer x2 (3Bh) ........................................................................................................................... 18

4.2.4. Read Buffer x4 (6Bh) ........................................................................................................................... 19

4.3. Page Read Operation - High Speed Mode .................................................................................................... 19

4.4. Page Program Operation............................................................................................................................... 20

4.4.1. Program Load (02h) ............................................................................................................................ 20

4.4.2. Program Execute (10h) ....................................................................................................................... 21

4.4.3. Program Load Random Data (84h) ..................................................................................................... 22

4.5.

4.6.

4.7.

4.8.

4.9.

Internal Data Move Operation ....................................................................................................................... 22

Block Erase (D8h) ......................................................................................................................................... 23

Reset (FFh or FEh)........................................................................................................................................ 24

Write Enable (06h) / Write Disable (04h) ....................................................................................................... 25

Set Feature (1Fh) / Get Feature (0Fh)........................................................................................................... 26

4.9.1. Set Feature (1Fh) ................................................................................................................................ 29

4.9.2. Get Feature (0Fh)................................................................................................................................ 29

4.10. Block Lock Operation .................................................................................................................................... 30

4.11. Block Protection Operation (One Time Program) .......................................................................................... 30

4.11.1. Protect Execute (2Ah)........................................................................................................................ 31

4.12. Parameter Page Read Operation .................................................................................................................. 32

4.13. Read ID (9Fh) ................................................................................................................................................ 33

4.14. Unique ID Read Operation ............................................................................................................................ 33

4.15. Bad Block Inhibit ............................................................................................................................................ 33

4.16. Internal ECC .................................................................................................................................................. 34

4.16.1.

4.16.2.

4.16.3.

4.16.4.

4.16.5.

ECC Switch ....................................................................................................................................... 34

ECC Status........................................................................................................................................ 34

ECC Bit Flip Count Detection ............................................................................................................ 34

ECC Bit Flip Count Report................................................................................................................. 35

ECC Maximum Bit Flip Count Report ................................................................................................ 36

© 2016-2019 KIOXIA Corporation

2

2019-10-01

�TC58CVG2S0HRAIG

5.

Package Information............................................................................................................................................ 37

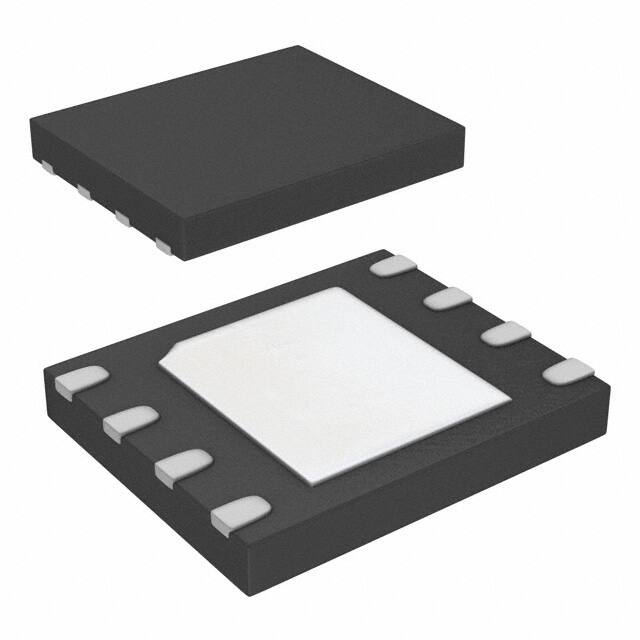

5.1. WSON8 (P-WSON8-0608-1.27-003) ............................................................................................................. 37

6.

Application Notes ................................................................................................................................................ 38

6.1. Prohibition of Unspecified Commands........................................................................................................... 38

6.2. Restriction of Commands while in the Busy State ......................................................................................... 38

6.3. Addressing for Page Program Operation....................................................................................................... 38

6.4. Several Programming Cycles on the Same Page (Partial Page Program) .................................................... 38

6.5. Power Off Timing ........................................................................................................................................... 39

6.6. Invalid Blocks (Bad Blocks) ........................................................................................................................... 39

6.7. Failure Phenomena ....................................................................................................................................... 40

6.8. Reliability Guidance ....................................................................................................................................... 41

6.9 NAND Management ...................................................................................................................................... 42

7.

Revision History................................................................................................................................................... 43

RESTRICTIONS ON PRODUCT USE ........................................................................................................................... 44

© 2016-2019 KIOXIA Corporation

3

2019-10-01

�TC58CVG2S0HRAIG

LIST of FIGURES

Figure 1. WSON8 Pin Assignment .............................................................................................................................. 7

Figure 2. Block Diagram .............................................................................................................................................. 8

Figure 3. Cell Layout ................................................................................................................................................... 8

Figure 4. Addressing.................................................................................................................................................... 9

Figure 5. SPI Timing .................................................................................................................................................. 11

Figure 6. Serial Input Timing...................................................................................................................................... 11

Figure 7. Serial Output Timing ................................................................................................................................... 11

Figure 8. Hold Timing ................................................................................................................................................ 12

Figure 9. WP Timing (Example) ................................................................................................................................. 12

Figure 10. Power ON/OFF Timing ............................................................................................................................. 14

Figure 11. Page Read from Cell Array to Buffer......................................................................................................... 16

Figure 12. Page Read from Buffer Timing ................................................................................................................. 17

Figure 13. Page Read from Buffer x2 Timing ............................................................................................................ 18

Figure 14. Page Read from Buffer x4 Timing ............................................................................................................ 19

Figure 15. Program Load........................................................................................................................................... 20

Figure 16. Program Execute Timing .......................................................................................................................... 21

Figure 17. Program Load Random Data Timing ........................................................................................................ 22

Figure 18. Block Erase Timing ................................................................................................................................... 23

Figure 19. Reset Timing ............................................................................................................................................ 24

Figure 20. Write Enable Timing ................................................................................................................................. 25

Figure 21. Write Disable Timing................................................................................................................................. 25

Figure 22. Set Feature Timing ................................................................................................................................... 29

Figure 23. Get Feature Timing ................................................................................................................................... 29

Figure 24. Protect Execute Timing ............................................................................................................................ 31

Figure 25. Read ID Timing ......................................................................................................................................... 33

LIST of TABLES

Table 1

Table 2

Table 3

Table 4

Table 5

Table 6

Table 7

Table 8

Table 9

Table 10

Table 11

Table 12

Table 13

Table 14

Table 15

Table 16

Table 17

Table 18

Table 19

Table 20

Table 21

Table 22

Table 23

Table 24

Table 25

Table 26

Table 27

Table 28

Pin Descriptions.......................................................................................................................................... 7

Valid Blocks ................................................................................................................................................ 9

Absolute Maximum Rating ........................................................................................................................ 10

Capacitance (TOPR = 25°C, f = 1MHz) ...................................................................................................... 10

DC Operating Condition ........................................................................................................................... 10

AC Characteristics (TOPR = −40 to 85°C, VCC = 2.7 to 3.6V) ................................................................... 13

DC & Operating Characteristics (TOPR = −40 to 85°C, VCC = 2.7 to 3.6V) ............................................... 13

Programming, Reading and Erasing Characteristics (TOPR = −40 to 85°C, VCC = 2.7 to 3.6V)................ 14

Power on Timing ....................................................................................................................................... 14

AC Test Condition ..................................................................................................................................... 14

Command Set ........................................................................................................................................... 15

Feature Table ........................................................................................................................................... 26

Feature Table - A0h Address Description ................................................................................................. 27

Feature Table - B0h Address Description ................................................................................................. 27

Feature Table - C0h Address Description ................................................................................................. 28

Block Lock Setting .................................................................................................................................... 30

Block Protection Setting ........................................................................................................................... 30

Block Number for Block Protection ........................................................................................................... 30

Parameter Page ....................................................................................................................................... 32

ID Table .................................................................................................................................................... 33

Page Assignment ..................................................................................................................................... 34

Definition of 528 bytes Data Pair .............................................................................................................. 34

Bit Flip Count Detection Setting (BFD) ..................................................................................................... 34

Bit Flip Count Detection Status (BFS) (Feature Table - 20h Address Description) ................................... 35

Bit Flip Count Report for Sector 0 (BFR) .................................................................................................. 35

Sector Definition (BFR) ............................................................................................................................ 36

Maximum Bit Flip Count (MBF) ................................................................................................................ 36

Maximum Bit Flip Count Sector (MFS) ..................................................................................................... 36

© 2016-2019 KIOXIA Corporation

4

2019-10-01

�TC58CVG2S0HRAIG

1. Introduction

1.1. General Description

The TC58CVG2S0HRAIG is a Serial Interface NAND Flash memory for embedded applications which supports the

SPI interface. The TC58CVG2S0HRAIG is organized as (4096 + 128) bytes × 64 pages × 2048 blocks. The device

has a 4224 byte data buffer which allows program and read data to be transferred between the buffer and the memory

cell array in 4224-byte increments. The Erase operation is implemented in a single block unit (256 Kbytes + 8 Kbytes:

4224 bytes × 64 pages). The device has the high speed mode for sequential Page Read operation. When high speed

mode is enabled, the average of tR is shortened.

The TC58CVG2S0HRAIG has ECC logic on the chip and 8bit read errors for each (512 bytes + 16 bytes) can be

corrected. The internal ECC logic has detailed Bit Flip Count Report.

1.2. Definitions and Abbreviations

SPI

Serial Peripheral Interface

Address

The address is comprised of a column address (CA) with 13 bits and a row address (RA) with 17 bits. The row

address identifies the page and block to be accessed. The column address identifies the byte within a page to

access.

Column

The byte location within the page

Row

Refer to the block and page to be accessed

Sector

The (512 bytes+16 bytes) unit in a page

Page

The smallest addressable unit for the Read and the Program operations

Block

Consists of multiple pages and is the smallest addressable unit for the Erase operation.

Data Buffer

Buffer used to transfer data to and from the cell array

Cell Array

Memory cells of NAND Flash

Device

The packaged NAND unit

ECC

Error Correction Code

© 2016-2019 KIOXIA Corporation

5

2019-10-01

�TC58CVG2S0HRAIG

1.3. Features

Organization

Organization (Internal ECC is enabled, default)

Memory Cell Array

4224 × 64 × 2048 × 8 bits

Data Buffer

4224 × 8 bits

Page Size

4224 bytes

Block Size

(256K + 8K) bytes

Organization (Internal ECC is disabled)

Memory Cell Array

4352 × 64 × 2048 × 8 bits

Data Buffer

4352 × 8 bits

Page Size

4352 bytes

Block Size

(256K + 16K) bytes

ECC

The device has ECC logic internally. When internal ECC is disabled, 8 bit ECC for each 512 bytes is

required.

Mode

Page Read, Page Program, Block Erase, Internal Data Move, Reset, Write Enable, Write Disable,

Block Lock, Get Feature, Set Feature, Block Protection, Parameter Page Read, Read ID,

Unique ID Read

Power Supply

VCC = 2.7 V to 3.6 V

Access Time

Cell Array to Data Buffer

Data Transfer rate

280

115

104

s max

s typ.

MHz max

Program/Erase Time

Programming Time

Block Erasing Time

450

2.0

s/page typ.

ms/block typ.

Operating Current

Read Operation Current with HSE ON (Average)

21

Read Operation Current with HSE OFF (Average) 15

Program Operation Current (Average)

18

Erase Operation Current (Average)

22

Standby Current

180

35

Reliability

Refer to reliability note

Package

WSON8 (P-WSON8-0608-1.27-003)

mA max

mA max

mA max

mA max

A max

A typ.

Weight: 0.12 g typ.

Part Numbering Information

TC58CVG2S0HRAIG 4Gb, 3.3V, WSON8 Serial Interface NAND

© 2016-2019 KIOXIA Corporation

6

2019-10-01

�TC58CVG2S0HRAIG

2. Memory Organization

2.1. Pin Descriptions

Table 1 Pin Descriptions

Pin Name

----------

CS

SO/SO1

------------

WP/SO2

SI/SO0

------------------

HOLD/SO3

SCK

VCC

VSS

Pin Function

Chip Select

Serial Data Output / Serial Data Output 1

Write Protect / Serial Data Output 2

Serial Data Input / Serial Data Output 0

Hold Input / Serial Data Output 3

Serial Clock Input

Power Supply

Ground

----------

Note: If the WP pin is low and BRWD bit is set to 1, the overwriting for the BRWD (bit [7]) and the BL bits (bits [5:3]) in address

A0h of the feature table shown in Table

12 is prohibited.----------------The users

should

keep

the

status

of

WP

signal while CS pin is low.

--------------------------The HOLD pin and the WP pin are pull up to VCC internally.

2.2. Pin Assignment (Top View)

1

8

SO/SO1

2

7

WP /SO2

3

6

SCK

VSS

4

5

SI/SO0

CS

VCC

HOLD/SO3

Figure 1. WSON8 Pin Assignment

© 2016-2019 KIOXIA Corporation

7

2019-10-01

�TC58CVG2S0HRAIG

2.3. Block Diagram

VCC VSS

ECC Logic

Control Logic

----------

CS

Data Buffer

SO/SO1

------------

W P /SO2

Command Register

Memory cell array

SI/SO0

-------------------

Address Register

HOL D /SO3

SCK

Status Register

Figure 2. Block Diagram

2.4. Cell Layout

The Program operation works on page units while the Erase operation works on block units.

When internal ECC is turned ON, a page consists of 4224 bytes in which 4096 bytes are used for main memory

storage and 128 bytes are used for redundancy or for other uses. In the case that internal ECC is turned OFF,

the redundancy area will be expanded to 256 bytes automatically.

Data Cache 1

4096

128

Data Cache 1

4096

256

Data Cache 0

4096

128

Data Cache 0

4096

256

64 Pages=1 block

64 Pages=1 block

131072

pages

2048 blocks

131072

Pages

2048 blocks

8 bits

8 bits

4352

4224

Internal ECC = ON

Internal ECC = OFF

Figure 3. Cell Layout

© 2016-2019 KIOXIA Corporation

8

2019-10-01

�TC58CVG2S0HRAIG

2.5. Addressing

There are two address types used; the column address and the row address. The column address is used to

access bytes within a page. The row address is used to address pages and blocks. There are some operations

that may require only row addresses, such as Block Erase.

Row Address (RA): 17 bits

Block Address (2048 blocks/device)

Page Address (64 pages/block)

: 11 bits

: 6 bits

Column Address (CA): 13 bits

Column Address (4224 or 4352 bytes/page)

: 13 bits

MSB

LSB

Block Address

Page Address

Column Address

Row Address

Figure 4. Addressing

2.6. Valid Blocks

Table 2 Valid Blocks

SYMBOL

PARAMETER

MIN

TYP.

MAX

UNIT

NVB

Number of Valid (Good) Blocks

2008

-

2048

Block

Note: The device occasionally contains unusable blocks.

The first block (Block 0) is guaranteed to be a valid block at the time of shipment.

The specification for the minimum number of valid blocks is applicable over the lifetime.

© 2016-2019 KIOXIA Corporation

9

2019-10-01

�TC58CVG2S0HRAIG

3. Physical Interface

3.1. Absolute Maximum Rating

Stresses greater than those listed in Table 3 may cause permanent damage to the device. This is a stress rating

only.

Table 3 Absolute Maximum Rating

Symbol

Parameter

Value

Unit

−0.3 to 3.9

V

VCC

Power Supply Voltage

VIN

Input Voltage

−0.3 to VCC +0.3 (≤ 3.9 V)

V

VI/O

Input /Output Voltage

−0.3 to VCC +0.3 (≤ 3.9 V)

V

PD1

Power Dissipation 1

0.42

W

PD2

Power Dissipation 2

(WSON8 ePAD without solder)

0.27

W

TSOLDER

Soldering Temperature (10 s)

260

°C

TSTG

Storage Temperature

−55 to 150

°C

TOPR

Operating Temperature

−40 to 85

°C

Note: Avoid locations where the device may be exposed to water (wet, rain, dew condensation, etc.)

3.2. Capacitance

Table 4

Symbol

Capacitance (TOPR = 25 °C, f = 1 MHz)

Parameter

Condition

Min

Max

Unit

CIN

Input

VIN = 0 V

-

2.5

pF

COUT

Output

VOUT = 0 V

-

4

pF

Note: This parameter is periodically sampled and is not tested for every device.

3.3. DC Operating Conditions

Table 5 DC Operating Condition

Symbol

Parameter

Min

Typ.

Max

Unit

2.7

-

3.6

V

VCC

Power Supply Voltage

VIH

High Level Input Voltage

VCC × 0.8

-

VCC + 0.3

V

VIL

Low Level Input Voltage

−0.3

-

VCC × 0.2

V

© 2016-2019 KIOXIA Corporation

10

2019-10-01

�TC58CVG2S0HRAIG

3.4. Signal Timing

The device supports SPI mode 0 and mode 3. Input-----------------data is latched at the rising edge of SCK and data is output

at the falling edge of SCK for mode 0 and 3. When HOLD goes Low, the communication is held. The hold state

begins at the falling edge of SCK.

Mode 0

Mode 3

CPOL CPHA

0

0

SCK

1

1

SCK

CS

SI

MSB

LSB

SO

MSB

LSB

Figure 5. SPI Timing

tSLCH

tCHSL

tCHSH

tCHCL tCLCH

tSHCH

SCK

tSHSL

CS

tCHDX

tDVCH

SI

SO

MSB

LSB

High-Z

: Don’t care

Figure 6. Serial Input Timing

tCLL tCLH

SCK

CS

SI

High-Z

tCLQV

SO

tCLQX

High-Z

tSHQZ

LSB OUT

: Don’t care

Figure 7. Serial Output Timing

© 2016-2019 KIOXIA Corporation

11

2019-10-01

�TC58CVG2S0HRAIG

tCHHL

tHHCH

tHLCH

SCK

tCHHH

CS

SI

tHLQZ

tHHQX

SO

High-Z

HOLD

Figure 8. Hold Timing

0

1

2

3

4

5

6

7

8

9

10 11 12

13 14 15 16

17 18 19 20 21

SCK

CS

Command (1Fh)

Address (A0h)

SI

7 6

MSB

SO

5

4

3

2

Data byte

1

0

7

6

MSB

5

4

3

2

High-Z

tWHSL

WP

1

17

18

19

20

21 22 23

SCK

CS

Data byte

SI

6

5

SO

4

3

2

1

0

High-Z

tSHWL

WP

1

Figure 9. WP Timing (Example)

© 2016-2019 KIOXIA Corporation

12

2019-10-01

�TC58CVG2S0HRAIG

3.5. AC Characteristics

Table 6 AC Characteristics (TOPR = −40 to 85 °C, VCC = 2.7 to 3.6 V)

Symbol

Parameter

Min

Typ.

Max

Unit

FC

Serial Clock Frequency for All Operations

-

-

104

MHz

tCLH

Serial Clock High Time

4.5

-

-

ns

tCLL

Serial Clock Low Time

4.5

-

-

ns

tCLCH

Serial Clock Rise Time (Slew Rate)

0.1

-

-

V/ns

tCHCL

Serial Clock Fall Time (Slew Rate)

0.1

-

-

V/ns

4.6

-

-

ns

5

-

-

ns

5

-

-

ns

5

-

-

ns

100

-

-

ns

-

-

20

ns

tSLCH

---------

CS Active Setup Time

---------

tCHSH

tSHCH

tCHSL

tSHSL

CS Active Hold Time

---------

CS Not Active Setup Time

---------

CS Not Active Hold Time

---------

tSHQZ

CS High Time

Output Disable Time

tCLQX

Output Hold Time

1

-

-

ns

tDVCH

Data In Setup Time

2

-

-

ns

tCHDX

Data In Hold Time

5

-

-

ns

5

-

-

ns

5

-

-

ns

5

-

-

ns

5

-

-

ns

-

-

7

ns

-

-

7

ns

tHLCH

tHHCH

tCHHL

tCHHH

tHLQZ

tHHQX

tCLQV

tWHSL

----------------

HOLD Low Setup Time (relative to Clock)

----------------

HOLD High Setup Time (relative to Clock)

----------------

HOLD High Hold Time (relative to Clock)

----------------

HOLD Low Hold Time (relative to Clock)

----------------

HOLD Low to High-Z Output

----------------

HOLD High to Output

-

20

-

100

-

-

Clock Low to Output Valid

----------

---------

WP Setup Time Before CS Low

----------

tSHWL

-

7.0(CL=10 pF)

7.5(CL=20 pF)

8.0(CL=30 pF)

-

---------

WP Hold Time After CS High

ns

ns

ns

3.6. DC Operating Characteristics

Table 7 DC & Operating Characteristics (TOPR = −40 to 85 °C, VCC = 2.7 to 3.6 V)

Symbol

Parameter

Condition

Min

Typ.

Max

Unit

IIL

Input Leakage Current

VIN = 0 V to VCC

-

-

±10

A

ILO

Output Leakage Current

VOUT = 0 V to VCC

-

-

±10

A

ICCOA1

Read Operation Current

(Average)

FC = 104 MHz

High Speed Mode = Enable

Read Buffer Command: 03h or 0Bh (x1)

-

-

21

mA

ICCOA2

Read Operation Current

(Average)

FC = 104 MHz

High Speed Mode = Disable

Read Buffer Command: 03h or 0Bh (x1)

-

-

15

mA

ICCOA3

Program Operation Current

(Average)

FC = 104 MHz

-

-

18

mA

ICCOA4

Erase Operation Current

(Average)

FC 104 MHz

-

-

22

mA

ICCS

Standby Current

C S = VCC 0.2 V, WP = VCC, HOLD = VCC

-

35

180

A

VOH

High Level Output Voltage

IOH = −0.1 mA

VCC 0.2

-

-

V

VOL

Low Level Output Voltage

IOL = 0.1 mA

-

-

0.2

V

----------

----------------

Note: Refer to the High Speed Mode in 4.3. Page Read Operation - High Speed Mode.

ICCOA1 to ICCOA4 are the average current during the full operation sequence.

Typ. values reflect values obtained in specific test environments under typical test parameters. Actual results will vary

based on the conditions and environment in which the part is used.

© 2016-2019 KIOXIA Corporation

13

2019-10-01

�TC58CVG2S0HRAIG

3.7. Programming, Reading and Erasing Characteristics

Table 8 Programming, Reading and Erasing Characteristics (TOPR = −40 to 85 °C, VCC = 2.7 to 3.6 V)

Symbol

Parameter

Min

Typ.

Max

Unit

450

600

s

tPROG

Programming Time (with ECC)

-

N

Number of Partial Program Cycles in the Same Page

-

-

4

times

tBERASE

Block Erasing Time

Cell Array to the Buffer (with ECC)

(High Speed Mode = Disable)

Average Read Time for Sequential Read (with ECC)

(High Speed Mode = Enable, Read Buffer x4)

Device Reset Time (Read)

-

2

7

ms

-

115

280

s

-

35

-

s

-

-

280

s

Device Reset Time (Program)

-

-

600

s

Device Reset Time (Erase)

-

-

7

ms

tR

tRHSA4

tRST

Note: Refer to the data pair of ECC calculation in 4.16. Internal ECC.

Refer to the High Speed Mode in 4.3. Page Read Operation - High Speed Mode.

tR is the average busy time for Page Read operation of 64 pages continuously in a block.

tRHSA4 is the average busy time for sequential Page Read operation with all data output in each page of 64 pages

continuously in a block.

The busy time after Protect Execute command is shorter than t PROG (max).

Typ. values reflect values obtained in specific test environments under typical test parameters. Actual results will vary

based on the conditions and environment in which the part is used.

3.8. Power ON/OFF Sequence

The timing sequence shown in the figure below is necessary for the power ON/OFF sequence.

The device internal initialization starts after the power supply reaches an appropriate level in the power on

sequence. The users cannot issue any commands while tVSL. From the end of tVSL to the end of tVOP, Get

Feature and Reset operation can be issued. OIP bit in the Feature Table indicates the busy state in this time

period. All operations are available after tVOP.

VCC

2.7 V

2.7 V

tPUW

tVSL

0.5 V

tVOP

0 V

2.7 V

0.5 V

Available operations:

All Operations

Available operations:

Reset, Get Feature

Figure 10. Power ON/OFF Timing

Table 9 Power on Timing

Symbol

Parameter

---------

Min

Max

Unit

tVSL

VCC(min) to CS Low

-

100

s

tVOP

VCC(min) to all operation

-

1.1

ms

tPUW

Waiting time for power on

1

-

ms

VCCSR

VCC Slew Rate

-

216

mV/s

3.9. AC Test Condition

Table 10 AC Test Condition

Parameter

Condition

VCC: 2.7 to 3.6 V

Input level

Input pulse rise and fall time

VCC × 0.2 to VCC × 0.8

2 ns

Input comparison level

VCC / 2

Output data comparison level

VCC / 2

Output load

© 2016-2019 KIOXIA Corporation

CL (30 pF) + 1 TTL

14

2019-10-01

�TC58CVG2S0HRAIG

4. Command Description and Device Operation

4.1. Command Set

Table 11 Command Set

Operation

Read Cell Array

Read Buffer

Read Buffer x2

Read Buffer x4

Program Load

Byte 1

(CMD)

13h

03h / 0Bh

3Bh

6Bh

02h

Byte 2

Byte 3

Byte 4

Dummy +

RA16

(Input)

Dummy +

CA12-CA8

(Input)

Dummy +

CA12-CA8

(Input)

Dummy +

CA12-CA8

(Input)

Dummy +

CA12-CA8

RA15-RA8

RA7-RA0

(Input)

(Input)

CA7-CA0

Dummy

(Input)

CA7-CA0

Dummy

(Input)

CA7-CA0

Dummy

(Input)

CA7-CA0

Byte 5

Byte N

-

-

D*-D*

D*-D*

(Output)

(Output)

D*-D*

D*-D*

(Output)

(Output)

D*-D*

D*-D*

(Output)

(Output)

D*-D*

D*-D*

D*-D*

(Input)

(Input)

-

-

-

-

(Input)

(Input)

(Input)

RA15-RA8

RA7-RA0

(Input)

(Input)

RA15-RA8

RA7-RA0

(Input)

(Input)

CA7-CA0

D*-D*

D*-D*

D*-D*

(Input)

(Input)

-

-

FFh / FEh

Dummy +

RA16

(Input)

Dummy +

RA16

(Input)

Dummy +

CA12-CA8

(Input)

Dummy +

RA16

(Input)

-

Write Enable

06h

Write Disable

04h

Program Execute

Protect Execute

Program Load Random Data

Block Erase

Reset

10h

2Ah

84h

D8h

Get Feature

0Fh

Set Feature

1Fh

Read ID

9Fh

(Input)

(Input)

RA15-RA8

RA7-RA0

(Input)

(Input)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

A7-A0

(Input)

A7-A0

D7-D0

(Output)

D7-D0

D7-D0

(Output)

D7-D0

(Output)

D7-D0

(Output)

(Input)

(Input)

ID

Byte 0

(Output)

-

-

-

Reserved

Reserved

(Output)

(Output)

Dummy

ID

Byte 1

(Output)

Note: 1) Input of a command other than those specified in Table 11 is prohibited. Stored data may be corrupted if an unknown

command is entered during the command cycle.

2) During the operation in progress, do not input any command except 0Fh, FFh and FEh.

3) The users can issue the Protect Execute (2Ah) only one time for each block.

4) Once the Get Feature command is issued, the status and setting information are outputted continuously.

© 2016-2019 KIOXIA Corporation

15

2019-10-01

�TC58CVG2S0HRAIG

4.2. Page Read Operation

The Read Cell Array and Read Buffer commands are required to read the data in a page. The Read Cell Array

command reads the page data from the NAND cell array to the data buffer. The Read Buffer command reads

the data from the data buffer. The operation sequence is as follows.

1. Read Cell Array (13h)

2. Get Feature (0Fh)

3. Read Buffer (03h or 0Bh)

or Read Buffer x2 (3Bh)

or Read Buffer x4 (6Bh)

: To read the data from the cell array to the internal data buffer

: To read the status (OIP, ECCS0 and ECCS1 bits) of the device

: To output the data from the internal data buffer

The Read Buffer, Read Buffer x2, Read Buffer x4 and Get Feature commands are repeatable commands.

For the Read Buffer x2 and Read Buffer x4 read modes are available as shown in Figure 13 and Figure 14.

The users are able to check the detailed bit flip count using ECC Bit Flip Count Detection and other functions

using Get Feature command.

4.2.1. Read Cell Array (13h)

0

1

2

3

4

5

6

7

8

9

10

11

12 13 14

15 16 17 18 19 20 21 22 23 24 25

SCK

CS

Command (13h)

SI

6

SO

17-bit row address

7 dummy bits

5

4

3

2

1

0

16 15

14 13

12 11 10

9

8

7

6

High-Z

1

23

24 25 26 27 28 29 30 31

0

1

2

3

4

5

6

7

8

9

10

11 12 13

14 15

SCK

CS

17-bit row address

SI

8

7

6

5

4

3

Get Feature (0Fh)

2

1

Feature Table address (C0h)

0

7

6

MSB

5

4

3

2

1

0

High-Z

SO

1

2

13

14

15

2

1

0

16 17 18

19

20 21

22 23

SCK

CS

SI

Feature Table data out

SO

7

6

MSB

5

4

3

2

Feature Table data out

1

0

7

6

MSB

5

4

3

2

1

0

2

: Don’t care

Figure 11. Page Read from Cell Array to Buffer

© 2016-2019 KIOXIA Corporation

16

2019-10-01

�TC58CVG2S0HRAIG

4.2.2. Read Buffer (03h or 0Bh)

0

1

2

3

4

5

6

7

8

9

10 11 12 13 14 15 16 17 18 19 20 21 22 23

24 25

SCK

CS

Command (03h or 0Bh)

SI

3 dummy bits

2

SO

1

0

13-bit column address

12 11 10

MSB

9

8

7

6

5

1 dummy byte

4

3

2

1

0

High-Z

1

23

24 25 26 27 28 29 30 31 32

33 34 35 36 37 38 39

33815

33823

SCK

CS

1 dummy byte

SI

High-Z

0

Data byte 1

SO

High-Z

7 6

MSB

5

4

3

Data byte 4224

2

1

0

7 6

MSB

1

5

4

3

2

1

0

: Don’t care

Note: When internal ECC is turned OFF, the maximum output data size is 4352 Bytes.

Figure 12. Page Read from Buffer Timing

© 2016-2019 KIOXIA Corporation

17

2019-10-01

�TC58CVG2S0HRAIG

4.2.3. Read Buffer x2 (3Bh)

0

1

2

3

4

5

6

7

8

9

10

11 12

13

14 15 16

17 18

19

20

4

3

21

22 23

24 25

SCK

CS

Command (3Bh)

2

SO/

SO1

13-bit column address

3 dummy bits

SI

SO0

1

0

12 11 10

MSB

9

8

7

6

5

1 dummy byte

2

1

0

High-Z

1

23

24 25 26 27 28 29 30 31

32

33 34 35 36 37 38 39

16919

16927

SCK

CS

1 dummy byte

SI switches from input to output

SI/

SO0

High-Z

6

4

2

0

6

4

2

0

6

4

2

0

6

4

2

0

SO/

SO1

High-Z

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

Data byte 1

Data byte 2

Data byte 4223

Data byte 4224

1

: Don’t care

Note: When internal ECC is turned OFF, the maximum output data size is 4352 Bytes.

Figure 13. Page Read from Buffer x2 Timing

© 2016-2019 KIOXIA Corporation

18

2019-10-01

�TC58CVG2S0HRAIG

4.2.4. Read Buffer x4 (6Bh)

0

1

2

3

4

5

6

7

8

9 10

11

12

13

14

15 16 17 18 19 20 21 22 23

24

25

SCK

CS

3 dummy bits

Command (6Bh)

SI/

SO0

2

SO/

SO1

High-Z

WP /

SO2

High-Z

HOLD /

SO3

High-Z

1

0

13-bit column address

12 11 10

MSB

9

8

7

6

5

4

1 dummy byte

3

2

1

0

1

23

24

25

26

27 28

29

30 31

32 33

34 35 36 37

38 39

SCK

CS

1 dummy byte

SI switches from input to output

SI/

SO0

High-Z

4

0

4

0

4

0

4

0

4

SO/

SO1

High-Z

5

1

5

1

5

1

5

1

5

WP /

SO2

High-Z

6

2

6

2

6

2

6

2

6

HOLD /

SO3

High-Z

7

3

7

3

7

3

7

3

7

Byte 1

Byte 2

Byte 3

Byte 4

1

: Don’t care

Figure 14. Page Read from Buffer x4 Timing

4.3. Page Read Operation - High Speed Mode

The device has a high speed mode for sequential read operation. When high speed mode is enabled, the

average tR is shortened. The command sequence is the same as the Page Read operation. The users set or

clear the HSE bit which enables or disables the high speed mode in the feature table as shown in Table 12.

High speed mode is enabled (HSE bit is set to 1) in the default condition. When the users switching the HSE

bit, the users have to issue the Set Feature command just before the Read Cell Array (13h) command.

When the users use the random page read, the recommended setting of the HSE bit is 0 (disable) since tR

becomes longer.

© 2016-2019 KIOXIA Corporation

19

2019-10-01

�TC58CVG2S0HRAIG

4.4. Page Program Operation

The Program Load and Program Execute commands are required to program data to a page. The Program

Load command transfers data to the buffer. The unit of data transfer is a byte. The Program Execute command

programs data from the buffer to the cell array. The operation sequence is as follows.

1. Write Enable (06h)

2. Program Load (02h)

3. Program Execute (10h)

4. Get Feature (0Fh)

: To enable the Program Operation

: To transfer data to the internal data buffer

: To program data from the buffer to the cell array

: To read the status (OIP and PRG_F bits) of the device

The internal data buffer is cleared by the Program Load command.

The Program Load Random Data (84h) command is also available to transfer data to the internal buffer. The

users issue Program Load Random Data and the column address before the Program Execute (10h). The

operation sequence is as follows.

1. Write Enable (06h)

2. Program Load (02h)

3. Program Load Random Data (84h)

4. Program Execute (10h)

5. Get Feature (0Fh)

: To enable the Program operation

: To transfer data to the internal data buffer

: To transfer data to the internal data buffer

: To program data from the buffer to the cell array

: To read the status (OIP and PRG_F bits) of the device

Program Load Random Data and Get Feature commands are repeatable command.

The internal data buffer is not cleared by the Program Load Random Data command.

4.4.1. Program Load (02h)

0

1

2

3

4

5

6

7

8

9

10 11

12

13 14 15 16 17 18 19 20 21 22

23

24

0

7

25

SCK

CS

Command (02h)

13-bit column address

3 dummy bits

SI

2

1

0

12 11 10

MSB

9

8

7

6

5

Data byte 1

4

3

2

1

6

1

23

24

25

26

27 28

29 30

31

32 33

34

35 36

37 38

39

33808

33815

SCK

CS

Data byte 1

SI

7

6

5

4

3

Data byte 2

2

1

0

7

6

5

4

3

Data byte 4224

2

1

0

7

6

5

4

3

2

1

0

1

: Don’t care

Note: When internal ECC is turned OFF, the maximum input data size is 4352 Bytes.

Figure 15. Program Load

© 2016-2019 KIOXIA Corporation

20

2019-10-01

�TC58CVG2S0HRAIG

4.4.2. Program Execute (10h)

0

1

2

3

4

5

6

7

8

9

10

11

12 13

14 15 16 17 18 19 20

21

22 23

24

25

SCK

CS

7 dummy bits

Command (10h)

SI

6

5

4

3

2

17-bit row address

1

0

16 15

14 13 12 11 10

9

8

7

6

High-Z

SO

1

23 24

25 26 27 28 29 30 31

0

1

2

3

4

5

6

7

8

9

10

11

12 13

14 15

SCK

CS

17-bit row address

SI

7

6

5

4

3

2

1

Get Feature (0Fh)

Feature Table address (C0h)

0

7 6

MSB

5

4

3

2

1

0

High-Z

SO

1

12

2

13 14 15 16 17 18 19 20

21 22 23

24

25

26 27 28

29

30

31

1

0

SCK

CS

SI

2

1

0

Feature Table data out

SO

High-Z

7 6

MSB

5

4

3

2

Feature Table data out

1

0

7

6

MSB

5

4

3

2

2

: Don’t care

Figure 16. Program Execute Timing

© 2016-2019 KIOXIA Corporation

21

2019-10-01

�TC58CVG2S0HRAIG

4.4.3. Program Load Random Data (84h)

0

1

2

3

4

5

6

7

8

9

10 11 12 13 14 15 16 17

18

19

20

21 22 23

24

25

SCK

CS

Command (84h)

13-bit column address

3 dummy bits

SI

2

1

0

12 11

MSB

10

9

8

7

6

5

4

Data byte 1

3

2

1

0

7

6

1

23

24

25

26

27 28

29

30 31

32 33

34

35 36

37

38 39

33808

33815

SCK

CS

Data byte 1

SI

7

6

5

4

3

Data byte 2

2

1

0

7

6

5

4

3

Data byte 4224

2

1

0

7

6

5

4

3

2

1

0

1

Note: When internal ECC is turned OFF, the maximum input data size is 4352 Bytes.

Figure 17. Program Load Random Data Timing

4.5. Internal Data Move Operation

The Internal Data Move Operation is used to change the data in a page without data output. Before using this

operation, the users must disable the Page Read High Speed Mode. The operation sequence is as follows.

1. Set Feature (1Fh)

2. Read Cell Array (13h)

3. Get Feature (0Fh)

4. Write Enable (06h)

5. Program Load Random Data (84h)

6. Program Execute (10h)

7. Get Feature (0Fh)

: To disable Page Read High Speed Mode

: To read data from the cell array to internal buffer

: To read the status (OIP, ECCS0 and ECCS1 bits) of the device

: To enable the write

: To change the data in the internal buffer

: To program data from the buffer to the cell array

: To read the status (OIP, PRG_F bits) of the device

Program Load Random Data and Get Feature commands are repeatable command.

The status of the internal ECC depends on ECC_E bit in the feature table. When internal ECC is disabled, bit

flips are not managed by the device.

© 2016-2019 KIOXIA Corporation

22

2019-10-01

�TC58CVG2S0HRAIG

4.6. Block Erase (D8h)

The Block Erase Operation erases the selected block. The page address is ignored automatically.

The operation sequence is as follows.

1. Write Enable (06h)

2. Block Erase (D8h)

3. Get Feature (0Fh)

: To enable the Erase operation

: To erase data in the block

: To read the status (OIP and ERS_F bits) of the device

Get Feature command is repeatable command.

0

1

2

3

4

5

6

7

8

9

10

11

12 13

14 15 16 17 18 19 20

21

22 23 24

25

SCK

CS

Command (D8h)

SI

6

SO

17-bit row address

7 dummy bits

5

4

3

2

1

0

16 15 14 13

12 11 10

9

8

7

6

High-Z

1

23 24 25 26 27 28 29 30 31

0

1

2

3

4

5

6

7

8

9

10 11 12 13 14 15

SCK

CS

17-bit row address

SI

7

6

5

4

3

2

Get Feature (0Fh)

1

Feature Table address (C0h)

0

7 6

MSB

5

4

3

2

1

0

High-Z

SO

1

12

2

13 14

15

2

0

16 17

18 19

20

21 22 23

SCK

CS

SI

1

Feature Table data out

SO

High-Z

7

6

MSB

5

4

3

2

1

Feature Table data out

0

7

6

MSB

5

4

3

2

1

0

2

: Don’t care

Figure 18. Block Erase Timing

© 2016-2019 KIOXIA Corporation

23

2019-10-01

�TC58CVG2S0HRAIG

4.7. Reset (FFh or FEh)

The device offers Reset operation by command FFh or FEh. For example, in case of a Program or Erase

operation, the internally generated voltage is discharged and the device enters the busy state. The operation

sequence is as follows.

1. Reset (FFh or FEh)

2. Get Feature (0Fh)

: To reset the device

: To read the status of the device

Get Feature command is repeatable command.

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

8

9

10 11

12 13

14 15

SCK

CS

Command (FFh or FEh)

Get Feature (0Fh)

Feature Table address (C0h)

SI

7

6

MSB

SO

5

4

3

2

1

0

High-Z

1

13

14 15 16

17 18

19

20 21 22 23

SCK

CS

SI

2

1

0

Feature Table data out

SO

7

6

MSB

5

4

3

2

1

Feature Table data out

0

7

6

MSB

5

4

3

2

1

0

1

: Don’t care

Figure 19. Reset Timing

© 2016-2019 KIOXIA Corporation

24

2019-10-01

�TC58CVG2S0HRAIG

4.8. Write Enable (06h) / Write Disable (04h)

The Write Enable/Disable commands set or reset the WEL (Write Enable Latch) bit in the feature table shown

in Table 12. The Write Enable command sets the WEL bit to 1. The Write Enable command must be issued

before the Page Program, Block Protection and Block Erase operations. The Write Disable command clears

the WEL bit to 0. If the WEL bit is cleared, Page Program, Block Protection and Block Erase commands are

ignored by the device.

0

1

2

3

4

5

6

7

SCK

CS

Command (06h)

SI

Figure 20. Write Enable Timing

0

1

2

3

4

5

6

7

SCK

CS

Command (04h)

SI

Figure 21. Write Disable Timing

© 2016-2019 KIOXIA Corporation

25

2019-10-01

�TC58CVG2S0HRAIG

4.9. Set Feature (1Fh) / Get Feature (0Fh)

The users set individual features using the Set Feature operation and get feature settings or status of the device

using the Get Feature operation. Feature settings and status are shown in Table 12. Refer to other sections for

the details of each setting and status. When a feature is set once by the Set Feature command, the device

keeps the bit until power OFF even if a Reset (FFh or FEh) command is issued.

Table 12 Feature Table

Address

Bit

6

5

4

3

2

1

0

A0h

BRWD

(R/W)

7

Reserved

BL2

(R/W)

BL1

(R/W)

BL0

(R/W)

Reserved

Reserved

Reserved

B0h

PRT_E

(R/W)

IDR_E

(R/W)

Reserved

ECC_E

(R/W)

Reserved

BBI

(R)

HSE

(R/W)

Reserved

C0h

Reserved

Reserved

ECCS1

(R)

ECCS0

(R)

PRG_F

(R)

ERS_F

(R)

WEL

(R/W)

OIP

(R)

10h

BFD3

(R/W)

BFD2

(R/W)

BFD1

(R/W)

BFD0

(R/W)

Reserved

Reserved

Reserved

Reserved

20h

BFS7

(R)

BFS6

(R)

BFS5

(R)

BFS4

(R)

BFS3

(R)

BFS2

(R)

BFS1

(R)

BFS0

(R)

30h

MBF3

(R)

MBF2

(R)

MBF1

(R)

MBF0

(R)

Reserved

MFS2

(R)

MFS1

(R)

MFS0

(R)

40h

BFR7

(R)

BFR6

(R)

BFR5

(R)

BFR4

(R)

BFR3

(R)

BFR2

(R)

BFR1

(R)

BFR0

(R)

50h

BFR15

(R)

BFR14

(R)

BFR13

(R)

BFR12

(R)

BFR11

(R)

BFR10

(R)

BFR9

(R)

BFR8

(R)

60h

BFR23

(R)

BFR22

(R)

BFR21

(R)

BFR20

(R)

BFR19

(R)

BFR18

(R)

BFR17

(R)

BFR16

(R)

70h

BFR31

(R)

BFR30

(R)

BFR29

(R)

BFR28

(R)

BFR27

(R)

BFR26

(R)

BFR25

(R)

BFR24

(R)

Note: (R/W): Read / Write, (R): Read only

The users must use the Write Enable (06h) or the Write Disable (04h) command to switch the WEL bit since Set Feature

command cannot change it.

The value of Reserved bits in Feature Table is 0.

The access to any unknown address which is not defined in this Feature Table is not allowed.

The bits in Feature Table which are related to ECC functions become valid when the Internal ECC is turned on by the

setting of ECC_E bit (bit [4]) in address B0h.

All the bits in Feature Table will be back to the default value after the power on sequence.

© 2016-2019 KIOXIA Corporation

26

2019-10-01

�TC58CVG2S0HRAIG

Table 13 Feature Table - A0h Address Description

Bit

Symbol

Parameter

Read

/ Write

Description

R/W

When W P pin is Low and BRWD is set to 1, over write for BRWD and BL bits are prohibit.

1b: Disable

0b: Enable (Default)

------------

Block Register

Write Disable

7

BRWD

6

Reserved

5

BL2

Block Lock 2

R/W

4

BL1

Block Lock 1

R/W

3

BL0

Block Lock 0

R/W

2

Reserved

-

-

The users set the locked blocks as entire of device or portion of device using the BL bits.

000b: All Unlocked

001b: Upper 1/64 Locked

010b: Upper 1/32 Locked

011b: Upper 1/16 Locked

100b: Upper 1/8 Locked

101b: Upper 1/4 Locked

110b: Upper 1/2 Locked

111b: All Locked (Default)

Reserved

1

Reserved

-

-

Reserved

0

Reserved

-

-

Reserved

-

-

Reserved

Note: (R/W): Read / Write, (R): Read only

Refer to the description of BRWD and BL2-0 in 4.10 Block Lock Operation.

Table 14 Feature Table - B0h Address Description

Bit

Symbol

Parameter

Read

/ Write

Description

7

PRT_E

Block Protect Enable

R/W

The setting for Block Protection.

0b: Normal Operation (Default)

1b: Block Protection Enable – The Protect Execute command (2Ah) is acceptable

for Block Protection.

6

IDR _E

ID Read Enable

R/W

The setting for Parameter Page Read and Unique ID Read.

0b: Normal Operation (Default)

1b: Parameter Page Read and Unique ID read mode

5

Reserved

4

ECC _E

3

Reserved

2

BBI

Bad Block Inhibit

1

HSE

High Speed Mode Enable

R/W

0

Reserved

-

-

ECC Enable

R/W

-

Reserved

The setting for internal ECC Function.

0b: Internal ECC Disable

1b: Internal ECC Enable (Default)

-

Reserved

R

The setting for Bad Block Inhibit Function.

0b: Not Available

1b: Bad Block Inhibit Enable (Default)

The setting for Page Read High Speed Mode.

0b: High Speed Mode Disable

1b: High Speed Mode Enable (Default)

Reserved

Note: (R/W): Read / Write, (R): Read only

Refer to the description of PRT_E in 4.11. Block Protection Operation (One Time Program).

Refer to the description of ECC_E in 4.16.1. ECC Switch.

Refer to the description of BBI in 4.15. Bad Block Inhibit.

Refer to the description of HSE in 4.3. Page Read Operation - High Speed Mode.

© 2016-2019 KIOXIA Corporation

27

2019-10-01

�TC58CVG2S0HRAIG

Table 15 Feature Table - C0h Address Description

Bit

Symbol

Parameter

Read

/ Write

7

Reserved

-

-

Reserved

6

Reserved

-

-

5

ECCS1

ECC Status 1

R

4

ECCS0

ECC Status 0

R

Reserved

ECC status bits indicate the status of internal ECC operation.

00b: No bit flips were detected in previous page read.

01b: Bit flips were detected and corrected.

Bit flip count was less than the threshold bit count.

The threshold bit count is set by bits [7:4] in address 10h in the feature table.

10b: Multiple bit flips were detected and not corrected.

11b: Bit flips were detected and corrected.

Bit flip count was equal to or more than the threshold bit count.

The threshold bit count is set by bits [7:4] in address 10h in the feature table.

Description

3

PRG_F

Program Fail

R

Program fail bit indicates that a program failure has occurred in the previous

Program or Block Protection operation.

0b: Program Pass

1b: Program Fail

2

ERS_F

Erase Fail

R

Erase fail bit indicates that an erase failure has occurred in the previous Erase

operation.

0b: Erase Pass

1b: Erase Fail

1

WEL

Write Enable Latch

0

OIP

Operation In Progress

R/W

R

This bit indicates the status of write enable/disable.

0b: Write Disable (Default)

1b: Write Enable

This bit indicates the status of the device. This bit will be set while busy state.

0b: Operation is not in progress. Ready state.

1b: Operation is in progress. Busy state.

Note: (R/W): Read / Write, (R): Read only

The users must use the Write Enable (06h) or the Write Disable (04h) command to switch the WEL bit since Set Feature

command cannot change it.

Once the Get Feature command is issued, the status and setting information are outputted continuously.

OIP, PRG_F, ERS_F bits are updated automatically during the status information are outputted continuously.

© 2016-2019 KIOXIA Corporation

28

2019-10-01

�TC58CVG2S0HRAIG

4.9.1. Set Feature (1Fh)

0

1

2

3

4

5

6

7

8

9

10

11

12 13

14 15

16 17 18 19 20 21 22 23

SCK

CS

Command (1Fh)

Feature Table address

SI

7

6

MSB

5

4

3

2

Data byte

1

0

6

7

MSB

5

4

3

2

1

0

Figure 22. Set Feature Timing

4.9.2. Get Feature (0Fh)

After the Get Feature command and the address are input, the 8bit status and setting information will be output

continuously until CS goes High.

----------

0

1

2

3

4

5

6

7

8

9

10 11 12 13 14 15 16 17 18

SCK

CS

Command (0Fh)

Feature Table address

SI

7 6

MSB

5

4

3

2

1

0

7

6

MSB

High-Z

SO

5

1

14

15

1

0

16 17

18

19 20

21 22 23

SCK

CS

SI

Feature Table data out

SO

7

6

MSB

5

4

3

2

1

Feature Table data out

0

7

6

MSB

5

4

3

2

1

1

0

: Don’t care

Figure 23. Get Feature Timing

© 2016-2019 KIOXIA Corporation

29

2019-10-01

�TC58CVG2S0HRAIG

4.10. Block Lock Operation

The Block Lock Operation prevents Page Program, Block Protection and Block Erase operations. The users

set the range of locked blocks as the entire device or a portion of the device using the BL bits (bits [5:3]) in

address A0h of the feature table shown in Table 12. The users set the BL bits by the Set Feature operation.

After the power on sequence, all blocks are locked (bits [5:3] are all set to 1). If the Program Execute (10h),

Protect Execute (2Ah) or Block Erase (D8h) command is issued to locked blocks, Program Fail or Erase Fail

will be indicated in the feature table shown in Table 12.

The users must clear / change the BL bits using Set Feature command to unlock the entire of the device or

portion of the device. When BRWD bit is set and WP pin is Low, the users cannot switch the BRWD and the

BL bits.

The Block Lock Operation is different from the Block Protection Operation.

-------------

Table 16 Block Lock Setting

BL2

BL1

BL0

0

0

0

All Unlocked

Protected Area

None

Protected Blocks

0

0

1

Upper 1/64 Locked

Block 2016 to 2047

0

1

0

Upper 1/32 Locked

Block 1984 to 2047

0

1

1

Upper 1/16 Locked

Block 1920 to 2047

1

0

0

Upper 1/8 Locked

Block 1792 to 2047

1

0

1

Upper 1/4 Locked

Block 1536 to 2047

1

1

0

Upper 1/2 Locked

Block 1024 to 2047

1

1

1

All Locked

Block0 to 2047

4.11. Block Protection Operation (One Time Program)

The Block Protection Operation provides the function to prohibit the Program and Erase operations to user

selected blocks. The users protect individual blocks using the Set Feature, Write Enable and Protect Execute

commands. The last 128 blocks of the device are able to be set to protected blocks. The block protection setting

is permanent. Once a block is protected, the users cannot unprotect the block.

When PRT_E (bit [7]) in address B0h of the feature table is set to 1, and the users issue the Protect Execute

command (2Ah), the user block will become a protected block. The users must set the PRT_E bit (bit [7]) just

before the Write Enable command for the Protect Execute. After the protection to the block, the users must

clear bit [7] in address B0h using the Set Feature command. The users can issue the Protect Execute (2Ah)

only one time for each block.

The Block Protection Operation is different from the Block Lock Operation.

The operation sequence to set block “N” as a protected block is as follows.

1. Set Feature (1Fh)

2. Write Enable (06h)

3. Protect Execute (2Ah) for block “N”

4. Get Feature (0Fh)

5. Set Feature (1Fh)

: To set PRT_E bit [7] in address B0h to block protection mode

: To enable the Protect Execute command

: To protect the block “N”

: To read the status (OIP and PRG_F bits) of the device

: To clear PRT_E bit [7] in address B0h

Get Feature command is repeatable command.

Table 17 Block Protection Setting

PRT_E

State

0

Normal Operation (Default)

1

Block Protection Enable – The Protect Execute command (2Ah) is acceptable for Block Protection.

Table 18 Block Number for Block Protection

Block Number

Block Protection

Block 0 – Block 1919

The users cannot protect these blocks by Block Protection operation.

Block 1920 – Block 2047

The users can protect these blocks by Block Protection operation.

© 2016-2019 KIOXIA Corporation

30

2019-10-01

�TC58CVG2S0HRAIG

4.11.1. Protect Execute (2Ah)

0

1

2

3

4

5

6

7

8

9

10 11

12 13 14

15

16

17 18 19

20

21

22

23 24

25

SCK

CS

7 dummy bits

Command (2Ah)

SI

6

5

4

3

17-bit row address

2

1

0

16 15

14 13 12 11 10

9

8

7

6

High-Z

SO

1

23

24 25

26 27

28

29 30

31

0

1

2

3

4

5

6

7

8

9

10 11 12 13 14 15

SCK

CS

17-bit row address

SI

7

6

5

4

3

2

Get Feature (0Fh)

1

Feature Table address (C0h)

0

7

6

MSB

5

4

3

2

1

0

High-Z

SO

1

12

2

13 14 15 16 17

18 19

20

21 22 23

24

25

26

27 28 29

30 31

SCK

CS

SI

2

1

0

Feature Table data out

SO

High-Z

7 6

MSB

5

4

3

2

Feature Table data out

1

0

7

6

MSB

5

4

3

2

1

0

2

: Don’t care

Figure 24. Protect Execute Timing

© 2016-2019 KIOXIA Corporation

31

2019-10-01

�TC58CVG2S0HRAIG

4.12. Parameter Page Read Operation

The device has a parameter page. The operation sequence is as follows.

1. Set Feature (1Fh) with address B0h and set bit [6] : To set the IDR_E bit in the feature table

2. Read Cell Array (13h) with address 01h

: To read the parameter page

3. Get Feature (0Fh)

: To read the status (OIP bit) of the device

4. Read Buffer (03h or 0Bh) with address 00h

: To output the parameter page

or Read Buffer x2 (3Bh)

or Read Buffer x4 (6Bh)

5. Set Feature (1Fh) with address B0h and clear bit [6] : To clear the IDR_E bit in the feature table

Read Buffer, Read Buffer x2, Read Buffer x4 and Get Feature commands are repeatable commands.

Table 19 Parameter Page

Byte

Parameter

Value

0-3

4 - 31

Signature

Reserved

32 - 43

Device manufacturer

44 - 63

Device model; TC58CVG2S0HRAIG

64

65 - 79

80 - 83

84 - 85

86 - 89

90 - 91

92 - 95

96 - 99

100

101

102

103 - 104

105 - 106

107

108 - 109

110

111

112

113 - 127

128

129 - 132

Manufacturer ID

Reserved

Number of data bytes per page

Number of spare bytes per page

Number of data bytes per partial page

Number of spare bytes per partial page

Number of pages per block

Number of blocks per unit

Number of logical units

Reserved

Number of bits per cell

Bad blocks maximum per unit

Block endurance

Guaranteed valid blocks at beginning of target

Reserved

Number of programs per page

Reserved

Number of ECC bits

Reserved

I/O pin capacitance

Reserved

4Eh, 41h, 4Eh, 44h

All 00h

54h, 4Fh, 53h, 48h, 49h, 42h, 41h, 20h, 20h, 20h,

20h, 20h

54h, 43h, 35h, 38h, 43h, 56h, 47h, 32h, 53h, 30h,

48h, 52h, 41h, 49h, 47h, 20h, 20h, 20h, 20h, 20h

98h

All 00h

00h, 10h, 00h, 00h

80h, 00h

00h, 02h, 00h, 00h

10h, 00h

40h, 00h, 00h, 00h

00h, 08h, 00h, 00h

01h

00h

01h

28h, 00h

01h, 05h

01h

All 00h

04h

00h

00h

All 00h

04h

All 00h

133 - 134

tPROG maximum page program time

58h, 02h

135 - 136

tBERASE maximum block erase time

58h, 1Bh

137 - 138

tR maximum page read time

Reserved

Integrity CRC

Value of bytes 0–255

Value of bytes 0–255

18h, 01h

139 - 253

254 - 255

256 - 511

512 - 767

All 00h

F5h, E1h

-

Note: The value of all parameters are default setting of the device.

When the users change the setting of the device such as internal ECC enable/disable, parameter page is not updated.

The Integrity CRC (Cyclic Redundancy Check) field is used to verify that the contents of the Parameter Page were

transferred correctly to the host. The CRC of the Parameter Page is a word (16-bit) field. The CRC calculation covers all

of data between byte 0 and byte 253 of the Parameter Page inclusive.

The CRC shall be calculated on byte (8-bit) quantities starting with byte 0 in the Parameter Page. The bits in the 8-bit

quantity are processed from the most significant bit (bit 7) to the least significant bit (bit 0).

The CRC shall be calculated using the following 16-bit generator polynomial:

G(X) = X16 + X15 + X2 + 1