Features

Applications

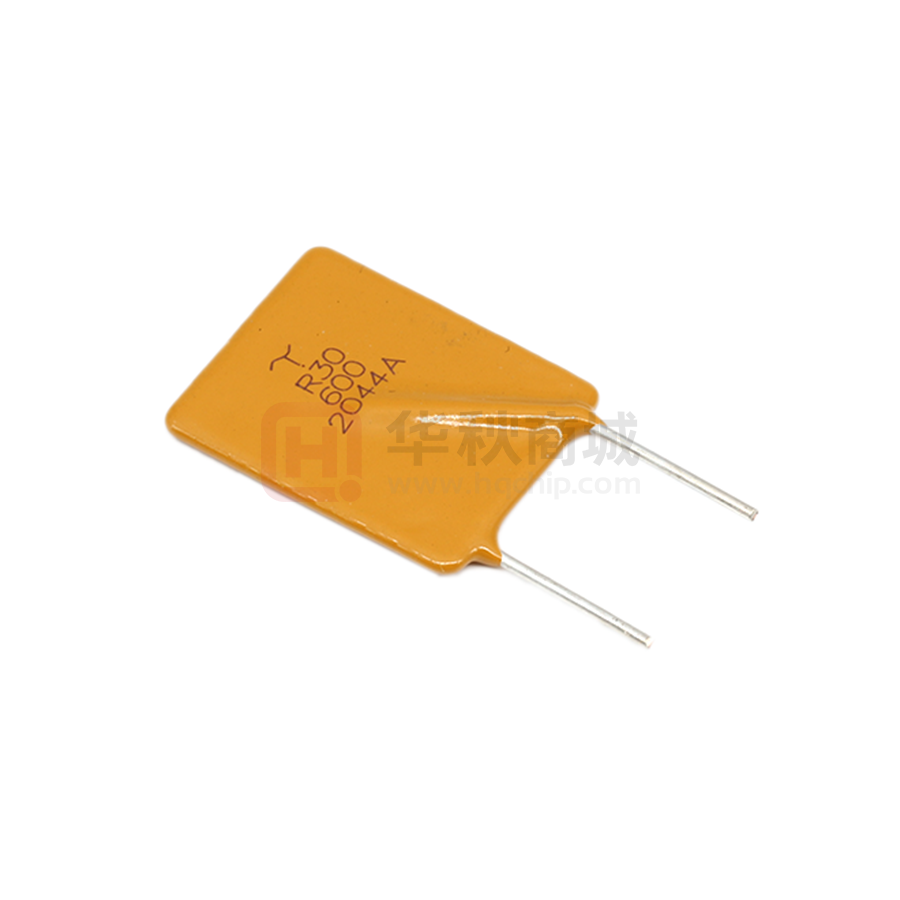

■ Radial Leaded Devices

Almost anywhere there is a low voltage

■ Cured, flame retardant epoxy polymer power supply, up to 30V and a load to be

insulating material meets

protected, including:

UL 94V-0 requirements

■ Personal computer

■ Bulk packaging,or tape and reel

■ Toys

■ Industrial controls

available on most models

R30 Series

Alpha-Top (Sea & Land Alliance)

Electrical Properties

Agency

Maximum

Resistance

Pd

Time To Trip

Approval

Model

Typ. Current Time

Rimin Rimax R1max

UL TUV

(A)

(Sec)

(Vdc)

(A)

(A)

(A)

(W)

(W)

(W)

(W)

R30-030

30

40

0.30

0.60

0.44

8.00

0.3

0.370 0.720 1.080

√

R30-040

30

40

0.40

0.80

0.45

8.00

0.3

0.250 0.430 0.645

√

R30-050

30

40

0.50

1.00

0.46

8.00

0.3

0.150 0.400 0.600

√

R30-065

30

40

0.65

1.30

0.47

8.00

0.4

0.120 0.300 0.450

√

R30-075

30

40

0.75

1.50

0.48

8.00

0.4

0.100 0.250 0.375

√

R30-090

30

40

0.90

1.80

0.6

4.50

5.9

0.070 0.145 0.220

√

√

R30-110

30

40

1.10

2.20

0.7

5.50

6.6

0.050 0.120 0.170

√

√

R30-135

30

40

1.35

2.70

0.8

6.75

7.3

0.040 0.085 0.130

√

√

R30-160

30

40

1.60

3.20

0.9

8.00

8.0

0.030 0.070 0.110

√

√

R30-185

30

40

1.85

3.70

1.0

9.25

8.7

0.030 0.060 0.090

√

√

R30-250

30

40

2.50

5.00

1.2

12.5

10.3

0.020 0.040 0.070

√

√

R30-300

30

40

3.00

6.00

2.0

15.0

10.8

0.020 0.050 0.080

√

√

R30-400

30

40

4.00

8.00

2.5

20.0

12.7

0.010 0.030 0.050

√

√

R30-500

30

40

5.00

10.00

3.0

25.0

14.5

0.010 0.030 0.050

√

√

R30-600

30

40

6.00

12.00

3.5

30.0

16.0

0.005 0.020 0.040

√

√

R30-700

30

40

7.00

14.00

3.8

35.0

17.5

0.005 0.020 0.030

√

√

R30-800

30

40

8.00

16.00

4.0

40.0

18.8

0.005 0.020 0.020

√

√

R30-900

30

40

9.00

18.00

4.2

40.0

20.0

0.005 0.010 0.020

√

√

Ihold = Hold Current : maximum current device will sustain for 4 hours without tripping in 25°C still air.

Itrip = Trip Current : minimum current at which the device will trip in 25°C still air.

Vmax = Maximum voltage device can withstand without damage at rated current (Imax).

Imax = Maximum fault current device can withstand without damage at rated voltage (Vmax).

Pd = Power dissipated from device when in the tripped state at 25°C still air.

Ri min/max = Minimum/Maximum resistance of device in initial (un-soldered) state.

R1 max = Maximum resistance of device at 25°C measured one hour after tripping.

CAUTION : Operation beyond the specified ratings may result in damage and possible arcing and flame.

Vmax

Imax

Ihold

Itrip

Environmental Specifications

Test

Conditions

Passive aging

+85°C, 1000 hrs.

Humidity aging

+85°C, 85% R.H.,1000 hrs

Thermal shock

+85°C to -40°C, 20 times

Resistance to solvent

MIL-STD-202,Method 215

Vibration

MIL-STD-202,Method 201

Ambient operating /storage conditions : - 40 °C to +85 °C

Maximum surface temperature of the device in the tripped state is 125 °C

In case of special use, please contact our engineer

Agency Approvals :

E201504(Alpha-Top)/E319079(Sea&Land)

R 50274672

Regulation/Standard:

2015/863/EU

EN14582

�R30 Series

Alpha-Top (Sea & Land Alliance)

Physical Dimensions (Unit: mm)

Model

R30-030

R30-040

R30-050

R30-065

R30-075

R30-090

R30-110

R30-135

R30-160

R30-185

R30-250

R30-300

R30-400

R30-500

R30-600

R30-700

R30-800

R30-900

A

Max.

7.4

7.4

7.4

7.4

7.4

7.4

7.4

8.9

8.9

10.2

11.4

11.4

14.0

14.0

16.5

19.1

21.6

24.1

B

Max.

10.2

11.4

11.4

11.4

11.4

12.2

14.2

13.5

15.2

15.7

18.3

18.3

20.1

24.9

24.9

26.7

29.2

29.7

C

Typ.

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

10.2

10.2

10.2

10.2

10.2

D

Min.

7.6

7.6

7.6

7.6

7.6

7.6

7.6

7.6

7.6

7.6

7.6

7.6

7.6

7.6

7.6

7.6

7.6

7.6

E

Max.

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

Dimensions

A

F

Max.

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

2.0

2.0

2.0

Lead

Style

Straight

Straight

Straight

Straight

Straight

Kink

Kink

Kink

Kink

Kink

Kink

Straight

Straight

Straight

Straight

Straight

Straight

Straight

Marking

A

E

A

E

C

B

B

D

R30

135

XXXXY

B

D

D

C

C

F

= Trademark

R30 = Radial type 30 Vrms

135 = 1.35A hold current

XXXX = Date code

Y = Factory code

Physical Characteristics

Lead Material :

R30-030 ~ 250: Tin-plated copper-clad steel, 0.205mm2 (24AWG), Φ0.51mm(0.020 in).

R30-300 ~ 900: Tin-plated copper, 0.52mm2 (20AWG), Φ0.81mm(0.032 in).

Lead Solderability : MIL-STD-202, Method 208

Order Information

R30

Radial type

30 V

Packing

135

Hold

Current

(A)

K or S

R or U

S=Straight

R=Tape&reel

U= Bulk

Model

R30-030 ~ R30-075

R30-090 ~ R30-250

R30-300 ~ R30-400

leads

packaged

R30-500 ~ R30-900

K= Kink leads

Devices taped with reference EIA468 standard.

Reel Q'ty

3000

1500

Bag Q'ty

500

500

500

-

500

�R30 Series

Alpha-Top (Sea & Land Alliance)

Typical Time-To-Trip Curve At 25°C

Thermal Derating Curve

Derating Curves for R30 Series

Average Time Current Curves

9.00A

0.30A

0.40A

0.50A

0.75A

TIME IN SECOND

100

0.65A

0.90A

1.10A

10

1.35A

1.60A

1.85A

2.50A

1

3.00A

4.00A

5.00A

0.1

6.00A

7.00A

8.00A

0.01

9.00A

0.1

1

10

CURRENT IN AMPERES

100

180

160

Percentage of Derated Current

0.30A

1000

140

120

100

80

60

40

20

0

-40

-20

0

20

40

60

80

Temperature (°C)

Ihold Versus Temperature

Model

R30-030

R30-040

R30-050

R30-065

R30-075

R30-090

R30-110

R30-135

R30-160

R30-185

R30-250

R30-300

R30-400

R30-500

R30-600

R30-700

R30-800

R30-900

Maximum ambient operating temperature (Tmao) vs. hold current (Ihold)

-40°C

-20°C

0°C

25°C

40°C

50°C

60°C

70°C

85°C

0.44

0.39

0.35

0.30

0.25

0.23

0.20

0.18

0.16

0.58

0.52

0.46

0.40

0.33

0.31

0.27

0.24

0.21

0.73

0.65

0.58

0.50

0.42

0.38

0.34

0.31

0.26

0.95

0.85

0.75

0.65

0.54

0.50

0.44

0.40

0.34

1.11

0.99

0.88

0.75

0.63

0.58

0.51

0.47

0.40

1.31

1.17

1.04

0.90

0.75

0.69

0.61

0.55

0.47

1.60

1.43

1.27

1.10

0.91

0.85

0.75

0.67

0.57

1.96

1.76

1.55

1.35

1.12

1.04

0.92

0.82

0.70

2.32

2.08

1.84

1.60

1.33

1.23

1.09

0.98

0.83

2.68

2.41

2.13

1.85

1.54

1.42

1.26

1.13

0.96

3.63

3.25

2.88

2.50

2.08

1.93

1.70

1.53

1.30

4.35

3.90

3.45

3.00

2.49

2.31

2.04

1.83

1.56

5.80

5.20

4.60

4.00

3.32

3.08

2.72

2.44

2.08

7.25

6.50

5.75

5.00

4.15

3.85

3.40

3.05

2.60

8.70

7.80

6.90

6.00

4.98

4.62

4.08

3.66

3.12

10.15

9.10

8.05

7.00

5.81

5.39

4.76

4.27

3.64

11.60

10.40

9.20

8.00

6.64

6.16

5.44

4.88

4.16

13.05

11.70

10.35

9.00

7.47

6.93

6.12

5.49

4.68

· Use PPTC beyond the maximum ratings or improper use may result in device damage and possible electrical arcing and

flame.

· PPTC are intended for protection against occasional over current or over temperature fault conditions and should not be

used when repeated fault conditions or prolonged trip events are anticipated.

· Device performance can be impacted negatively if devices are handled in a manner inconsistent with recommended

electronic, thermal, and mechanical procedures for electronic components.

· Use PPTC with a large inductance in circuit will generate a circuit voltage (L di/dt) above the rated voltage of the PPTC.

· Avoid impact PPTC device its thermal expansion like placed under pressure or installed in limited space.

�

很抱歉,暂时无法提供与“R30-600”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 1+1.09654

- 10+0.86911

- 30+0.77172