产品承认书

SPECIFICATION FOR APPROVAL

CUSTOMER:

CUSTOMER P/N:

CND-TEK P/N. :

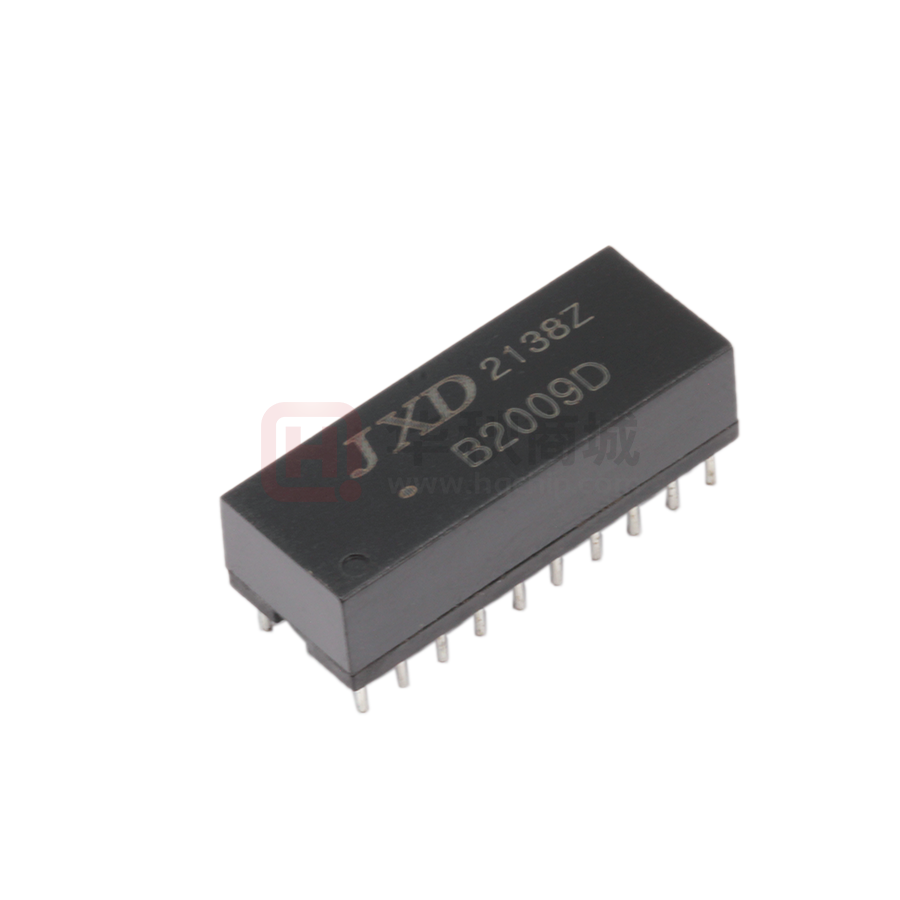

B2009D

DESCRIPTION:

10/100 BASE-T MAGNETICS MODULES

REF NO:

QTC-001

REV/NO:

V1.02

DATE:

2015/03/02

ATTACHMENT:

■ SPECIFICATION

■ SAMPLE

Q’TY OF SAMPLES

PCS

√

FULL APPROVED

CONDITIONAL APPROVED

REJECTED

CUSTOMER'S SIGNATURE

REMARK

�B2009D

10/100 BASE-T MAGNETICS MODULES

V1.0.2

Feb 2, 2015

␡ൣ⻱㚄䗮⭥ᆀᴹ䲀ޜਨ

6KHQ]KHQ�&1'�7(.�Electronics�&R��/WG

ޜਨൠ൰��␡ൣᐲইኡ४㾯ѭ䭷街道百旺社区牛城村牛城路221号505

7(/�� ����������������������)$;�86-��������������

(PDLO��sales2#FG�WHN�FRP

+WWS����ZZZ�FG�WHN�FRP

�1. FEATURES:

1.1 Quad Port transformer Modules (10/100 Base-TX) for Auto MDI/MDIX applications.

1.2

Compatible with IEEE 802.3 and ANSI X3.236 standard.including baseline wander compensation

specification OF 350μH OCL when Biased at 8mA from 0℃ to 70℃.

1.3 Availiable in Through Hole package.

1.4 Operating Temperature range: 0℃ TO +70℃

1.5 Storage temperature range: -25℃ TO +125℃

2. DIMENSIONS & MARKING

CND-TEK

xxxx

B2009D

Note:1、Dimension:mm

2、Unless otherwise specified,all tolerances are:±0.05mm

�3. SCHEMATICS:

4.ELECTRICAL SPECIFICATIONS @25℃

4.1 OCL :

350 μH Min. @ 100 KHz, 100mV with 8mA DC Bias

4.2 Leakage Inductance:

0.5 μH Max. @ 100KHz, 0.2V

4.3 Cw/w:

56 pF Max. @ 100KHz, 0.2V

4.4 DCR:

1.20 ΩMax.

4.5 Turns Ratio(±5%):

1CT:1CT(TX), 1CT:1CT(RX)

4.6 Polarity:

1-20, 4-17, 6-15, 9-12 In-Phase

4.7 Insertion Loss:

-1.1 dB Max. @ 1-100MHz

4.8 Return Loss:

-18 dB Min. @ 0.5-30MHz

-15 dB Min. @ 40 MHz

-13 dB Min.@ 60 MHz

-11 dB Min @ 80 MHz

-10 dB Min.@ 100 MHz

4.9 Cross Talk:

-45 dB Min.@ 30 MHz

-40 dB Min.@ 60 MHz

-35 dB Min.@ 100 MHz

4.10 Common Mode Rejection : -43 dB Min.@ 1-30 MHz

-37dB Min.@ 60 MHz

-33dB Min.@ 80-100 MHz

4.11 Isolation HI-POT:

1500Vrms 1mA 1Second

�5. Recommended Lead Free IR Reflow Soldering Curve:

Item

Soldertechnique

simulation

Temperature

(℃)

Time(s)

1

Solder iron

350±10

(solder irno temp)

4~5

2

Vapor phase reflow

215±5

(vapor temp)

60±5

3

IR/convection reflow

255±5

(component temp)

30±5

Temperature ramp/immersion

and emersion rate

1℃/s~4℃/s time above 183℃

90s~120s

Note:The curve includes recommended value only, please adjust your equipment to make sure the solder

process.Details please refers to the standard J-STD-020.

6. Reliability Test Criteria:

6.1 Terminal strength: Pull test withstand 9.8N 60+/-0.5S no looseness or movement.

6.2 Solderbility: Dipped in 245℃+/-5℃ molten solder for 3+/-0.5 seconds,95% min shall be smooth any and

bright.

6.3 Resistance to soldering heat : Convection reflow condition setting: peak temperature at 260℃+0/-5℃

above 217℃ for 90-180 seconds, ramp-up rate 2-3℃/s. Ramp-down rate 6℃/s Max. No mechanical problem

found. No electrical failure found per our specification.

6.4 Vibration: 1.5mm amplitude total excursion 10-55-10 Hz traversed in 1minute, x.y.z, axis for 2 hours. Shall

not be any abnormality.

6.5 Random drop (Packing condition): Height 60cm, 3 times on the wood floorboard ,shall not be any

abnormality.

6.6 Dry heat: 100+/-2℃ 96 hours.

6.7 Cold: -20+/-2℃ 96 hours.

6.8 Damp Heat: 60+/-2℃, 93+/-3% RH 96 hours.

6.9 Change of temperature: exposed 5 cycle; each consisting of 30 minutes at -20+/-2℃,2-3minutes at 20+/2℃,30 minutes at 85+/-2℃, 2-3 minutes at 20+/-2℃.

�

很抱歉,暂时无法提供与“B2009D”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 5+1.65063

- 50+1.27256

- 140+1.11967

- 500+0.92884

- 2500+0.84389

- 5000+0.79290

- 国内价格

- 1+1.14750

- 10+1.10500

- 100+1.00300

- 500+0.95200