CRYSTAL OSCILLATOR

SERIES 6N, SEAM SEALED CERAMIC 7.0X5.0MM SURFACE MOUNT PACKAGE

深圳市晶科鑫实业有限公司

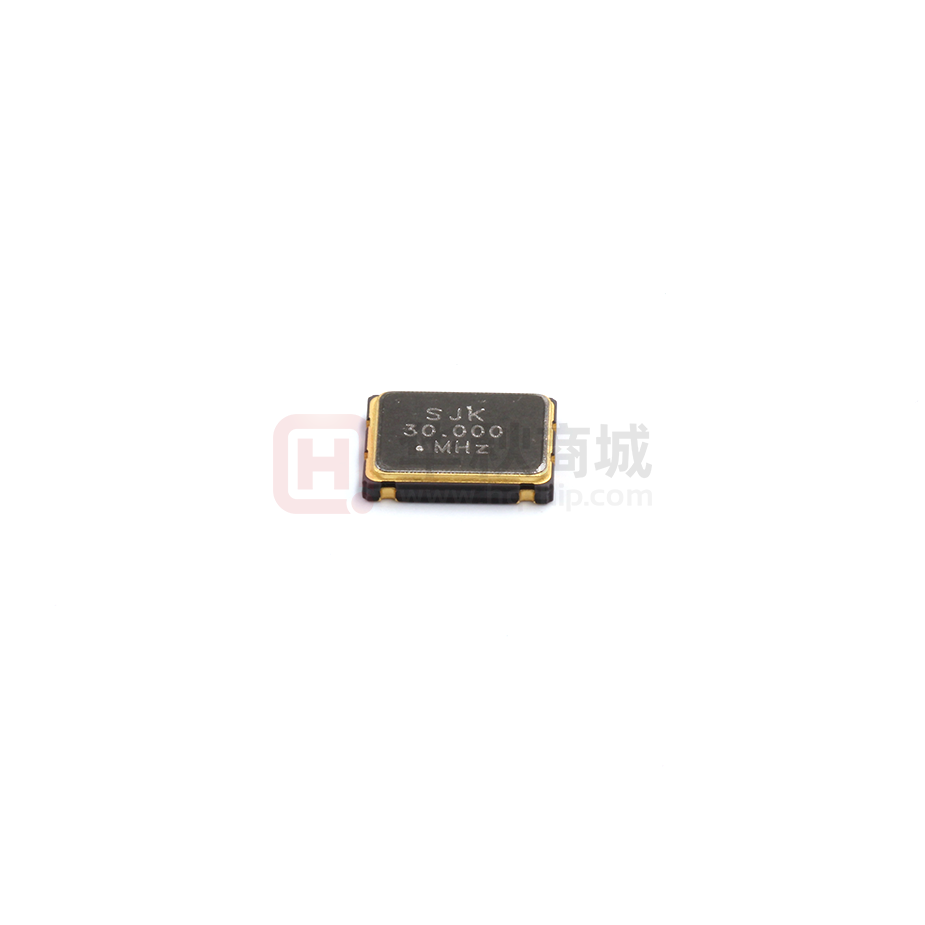

Shenzhen Crystal Technology Industrial Co., Ltd

APPROVAL SHEET

CUSTOMER P/N:

TYPE:

SMD CRYSTAL

DESCRIPTION:

P N/ SJK:

MSL:

LVCMOS -40~85℃

6N30000G33YC

ENVIRONMENTAL:

REVISION:

SMD7050 OSC 30.000MHZ 3.3V

■RoHS

A1

■REACH

■HF

□PAHS

□other

2017-5-10

Levels 1

SIGNATURE

SUPPLIER

Issue

Check

CUSTOMER

Approve

QA

SJK

Signature

FAE_EMAIL

Date

Date

Check

Approve: □accept

Approve

□unaccepted

Note:

Tel:0755-88352810-837(Mr.huang) Fax:0755-88353718

http://www.q-crystal.com

ADD: Room 1204~1206,Building 3C, TianAn Cloud Park Phase 1,Bantian, Longgang District, Shenzhen

1 /5

�CRYSTAL OSCILLATOR

SERIES 6N, SEAM SEALED CERAMIC 7.0X5.0MM SURFACE MOUNT PACKAGE

1. ELECTRICAL SPECIFICATIONS

Standard atmospheric conditions

Unless otherwise specified, the standard range of atmospheric conditions for making measurement

and tests are as follow:

Ambient temperature : 25±5℃

Relative humidity : 40%~70%

If there is any doubt about the results, measurement shall be made within the following limits:

Ambient temperature : 25±3℃

Relative humidity : 40%~70%

Measure equipment

Electrical characteristics measured by MD 37WX-05M or equivalent.

Crystal cutting type

The crystal is using AT CUT (thickness shear mode).

Parameters

1

2

SYM

Electrical Spec.

MIN

Nominal Frequency

Frequency

Stability

TYPE

MAX

Notes

UNITS

30.000000

MHZ

AT 25℃

±10

PPM

Over Operating

Temperature range

±20

PPM

3

Operating Temperature

Topr

-40

25

85

℃

4

Storage Temperature

Tstg

-55

~

125

℃

5

Supply Voltage

VDD

6

Input Current

Icc

7

Enable Control

8

Output Load : CMOS

3.3 / ±10%

-40~85℃

V

5

mA

Yes

CL

Pad1

15

pF

90%

Vdd

9

Output Voltage High

VoH

10

Output Voltage Low

VoL

10%

Vdd

V

11

Rise Time

Tr

5

ns

12

Fall Time

Tf

5

ns

13

Symmetry (Duty ratio)

TH/T

55

%

14

Start-up Time

Tosc

10

ms

15

Enable Voltage High

Vhi

16

Disable Voltage Low

Vlo

17

Aging

18

Output Disable Delay Time

T off

150

us

19

Output Enable Delay Time

T on

150

us

20

Phase Jitter (12KHZ~20MHZ)

1.0

ps

45

V

~

70%

Vdd

10%→90%VDD

Level

90%→10%VDD

Level

V

30%

Vdd

±3

0.5

V

ppm/yr.

1st. Year at 25℃

Tel:0755-88352810-837(Mr.huang) Fax:0755-88353718

http://www.q-crystal.com

ADD: Room 1204~1206,Building 3C, TianAn Cloud Park Phase 1,Bantian, Longgang District, Shenzhen

2 /5

�CRYSTAL OSCILLATOR

SERIES 6N, SEAM SEALED CERAMIC 7.0X5.0MM SURFACE MOUNT PACKAGE

2. DIMENSIONS

(Units :mm)

3. MARKING

4. TEST CIRCUIT

Control input (output

enable/disable)

Logic 1 or open on pad 1:

Oscillator output

Logic 0 on pad 1 : Disable

output to high impedance

Tel:0755-88352810-837(Mr.huang) Fax:0755-88353718

http://www.q-crystal.com

ADD: Room 1204~1206,Building 3C, TianAn Cloud Park Phase 1,Bantian, Longgang District, Shenzhen

3 /5

�CRYSTAL OSCILLATOR

SERIES 6N, SEAM SEALED CERAMIC 7.0X5.0MM SURFACE MOUNT PACKAGE

5. WAVEFORM CONDITIONS

Waveform measurement

system should

have a min. bandwidth of 5

times the

frequency being tested.

6. OUTPUT ENABLE / DISABLE DELAY

The following figure shows the oscillator timing during normal operation . Note that when the device is in

standby,

the oscillator stops. When standby is released, the oscillator starts and stable oscillator output occurs after a

short delay

7. SUGGESTED REFLOW PROFILE

Total time : 200 sec. Max / Solder melting point :220 ℃

Tel:0755-88352810-837(Mr.huang) Fax:0755-88353718

http://www.q-crystal.com

ADD: Room 1204~1206,Building 3C, TianAn Cloud Park Phase 1,Bantian, Longgang District, Shenzhen

4 /5

�CRYSTAL OSCILLATOR

SERIES 6N, SEAM SEALED CERAMIC 7.0X5.0MM SURFACE MOUNT PACKAGE

8. RELIABILITY TEST SPECIFICATION

1.Mechanical Endurance

No.

Test Item

Test Methods

REF. DOC

1

Drop Test

JIS C6701

2

Mechanical Shock

3

Vibration

4

Gross Leak

75 cm height,3 times on concrete floor .

Device are shocked to half sine wave ( 1000

G ) three mutually

perpendicular axes each 3 times. 0.5m sec.

duration time

Frequency range 10 ~ 2000 Hz

Amplitude 1.52 mm/20G

Sweep time 20 minutes

Perpendicular axes each test time 4 Hrs

(Total test time 12 Hrs)

Standard Sample For Automatic Gross Leak

Detector, Test Pressure: 2kg / cm2

5

Fine Leak

Helium Bomging 4.5 kgf / cm 2 for 2 Hrs

Solderability

Temperature 245 ℃ ± 5℃

Immersing depth 0.5 mm minimum

Immersion time 5 ± 1 seconds

Flux Rosin resin methyl alcohol

solvent ( 1 : 4 )

6

MIL-STD-202F

MIL-STD-883E

MIL-STD-883E

MIL-STD-883E

2.Environmental Endurance

No.

Test Item

1

Resistance To

Soldering Heat

2

3

High Temp.

Storage

Low Temp.

Storage

Test Methods

Pre-heat temperature 125 ℃

Pre-heat time 60 ~ 120 sec.

Test temperature 260 ± 5 ℃

Test time 10 ± 1 sec.

REF. DOC

MIL-STD-202F

+ 125 ℃ ± 3 ℃ for 1000 ± 12 Hrs

MIL-STD-883E

- 40 ℃ ± 3 ℃ for 1000 ± 12 Hrs

Total 100 cycles of the following temperature cycle

4

5

6

Thermal Shock

Pressure Cooker

Storage

High Temp&

Humidity

MIL-STD-883E

121 ± 3℃ , RH100% , 2 bar , 240 Hrs

JIS C6701

85℃ ± 3℃, RH 85% , 1000 Hrs

JIS C5023

备注

Tel:0755-88352810-837(Mr.huang) Fax:0755-88353718

http://www.q-crystal.com

ADD: Room 1204~1206,Building 3C, TianAn Cloud Park Phase 1,Bantian, Longgang District, Shenzhen

5 /5

�

很抱歉,暂时无法提供与“6N30000G33YC”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 1+5.06520

- 10+4.08240

- 30+3.59640

- 100+3.11040

- 500+2.66760

- 1000+2.51640

- 国内价格

- 1+2.75655

- 10+2.65880

- 100+2.42420

- 500+2.30690