Datasheet – epc901

CCD line sensor 1024x1 pixel

General Description

Features

The epc901 is a high-performance CCD line sensor capable of

storing a total of 4 frames in the frame store elements for ultra

high-speed image acquisition. The acquisition of the image is controlled by a control signal SHUTTER. The epc901 flags when a

frame is ready for read-out by asserting the DATA_RDY signal.

The transmission of the frame over the video amplifier is controlled

by the external control signal READ. When a read-out is initiated

by a pulse on the READ signal, it is sampled by a CDS stage. After

a fixed delay the frame can be shifted out through the video amplifier by applying the appropriate amount of read clock edges.

■ Photosensitive CCD array backside illuminated with 1024x1 pixel

■ Very high frame rate

■ Very high sensitivity due to 100% fill factor and ESPROS' unique

OHC15L process technology

■ Pixel size 7.5 x 120μm

■ On-chip correlated-double sampling

■ Single-ended or differential analog output

■ Simple 5-pin control interface for acquisition and read-out

■ I2C bus interface

■ Internal clock source, trimmable

■ Two on-chip temperature sensors

■ Single supply voltage

■ 32 Pin space saving CSP package

■ Chip size L x W x T: 8.0 x 1.3 x 0.23 mm

The device offers various configuration options:

■ Gain of the read-out stage selectable of 1, 2 or 4

■ Transmission direction left to right and right to left

■ Region of interest (ROI) center region (pixel 256 to 767)

■ Binning of 2 or 4 pixels to reduce transmission time and noise

■ Single- or multi-frame acquisition

■ Clearing of frames stored and periodic flushing of pixel array to

avoid blooming

Applications

■ Linear and rotary encoder

■ Triangulation light barrier / distance measurement

■ Line sensor / camera

■ Business card readers & portable scanners

■ Multi-touch displays / electronic white boards

■ Finger print readers

■ Spectrometers

■ Check & ticket readers

■ Speed measurement

■ Bar code readers

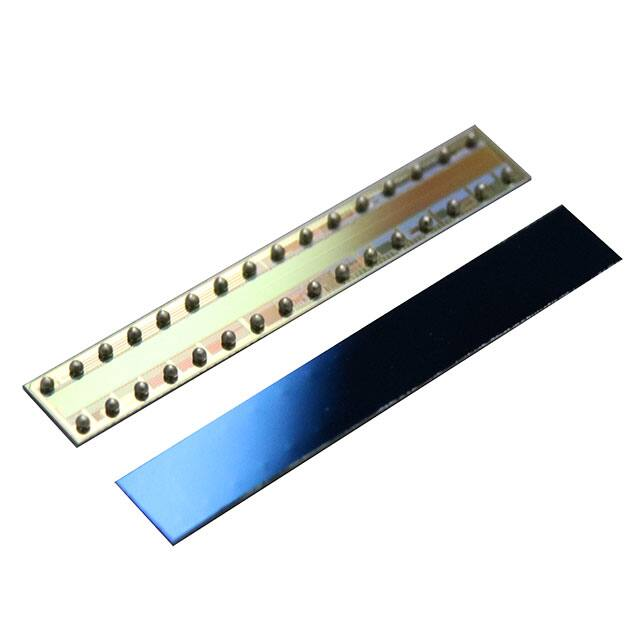

Figure 1: Backside illuminated CMOS/CCD imager

CCD 1024x1

Configuration

Inputs

Logic

Frame store 1

Frame store 2

Frame store 3

Frame store 4

Configuration

I2C-bus

I2C-Interface

1024 : 1 MUX

Analog output

Figure 2: Block diagram

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

1 / 32

Datasheet_epc901-V7.00

www.espros.com

�Table of Contents

1. Block diagram.....................................................................................................................................................3

2. Pin-out................................................................................................................................................................3

2.1. Power domains....................................................................................................................................................................................5

3. Electrical, optical and timing characteristics............................................................................................................6

3.1. Electrical and other characteristics......................................................................................................................................................6

3.2. Temperature sensor characteristics....................................................................................................................................................7

3.3. Timing parameters...............................................................................................................................................................................7

3.4. Absolute maximum ratings..................................................................................................................................................................8

3.5. Optical characteristics..........................................................................................................................................................................9

3.6. Frequency response..........................................................................................................................................................................10

3.7. Video amplifier frequency response..................................................................................................................................................10

4. Configuration.................................................................................................................................................... 11

5. Imager operation................................................................................................................................................12

5.1. General remarks................................................................................................................................................................................12

5.2. Single frame acquisition.....................................................................................................................................................................12

5.3. Multi frame acquisition.......................................................................................................................................................................13

5.4. Image readout....................................................................................................................................................................................13

5.5. ROI / binning read clock....................................................................................................................................................................14

5.6. Flush..................................................................................................................................................................................................14

6. Various features.................................................................................................................................................15

6.1. Temperature sensor..........................................................................................................................................................................15

6.2. Power-down.......................................................................................................................................................................................15

6.3. Oscillator clock trimming....................................................................................................................................................................15

6.4. Reset..................................................................................................................................................................................................15

7. I2C interface......................................................................................................................................................16

7.1. I2C communication............................................................................................................................................................................16

7.1.1. Device addressing..........................................................................................................................................................................16

7.1.2. Single-byte write.............................................................................................................................................................................16

7.1.3. Multi-byte write................................................................................................................................................................................16

7.1.4. Single-byte read..............................................................................................................................................................................17

7.1.5. Multi-byte read................................................................................................................................................................................17

7.1.6. Software reset.................................................................................................................................................................................17

7.1.7. Device address sampling...............................................................................................................................................................17

7.1.8. Setup latency..................................................................................................................................................................................17

7.2. I2C bus timing....................................................................................................................................................................................18

8. Register description...........................................................................................................................................19

8.1. Binning, amplifier gain, ROI, read direction.......................................................................................................................................19

8.2. Video Amplifier bandwidth.................................................................................................................................................................20

8.3. Video amplifier bandwidth, noise and current consumption..............................................................................................................20

8.4. Configuration control, video amplifier on/off......................................................................................................................................20

8.5. Video amplifier SE/Diff, charge pump on/off, 5V regulator on/off.....................................................................................................21

8.6. Oscillator trimming (fine)....................................................................................................................................................................21

8.7. Oscillator trimming (coarse)...............................................................................................................................................................22

8.8. Temperature sensors read................................................................................................................................................................22

8.8.1. Left temperature sensor.................................................................................................................................................................22

8.8.2. Right temperature sensor...............................................................................................................................................................22

8.9. Temperature sensors control.............................................................................................................................................................23

8.10. I2C error flag....................................................................................................................................................................................23

8.11. Chip revision....................................................................................................................................................................................23

9. Application information......................................................................................................................................24

9.1. Differential mode................................................................................................................................................................................24

9.2. Single ended mode............................................................................................................................................................................25

9.3. External components.........................................................................................................................................................................25

9.4. Low noise operation...........................................................................................................................................................................25

9.4.1. Charge pump noise........................................................................................................................................................................25

9.4.2. Video amplifier noise......................................................................................................................................................................25

9.4.3. Layout recommendations...............................................................................................................................................................26

10. Power consumption considerations....................................................................................................................27

10.1. General considerations....................................................................................................................................................................27

10.2. Low power operation.......................................................................................................................................................................27

11. Layout and packaging information......................................................................................................................28

11.1. Mechanical dimensions...................................................................................................................................................................28

11.2. PCB design and SMD manufacturing process considerations.......................................................................................................29

11.3. Tape & Reel Information..................................................................................................................................................................29

11.4. Soldering and IC handling...............................................................................................................................................................29

12. Self-test mode by fill-and-spill............................................................................................................................30

13. Ordering Information........................................................................................................................................31

14. IMPORTANT NOTICE........................................................................................................................................32

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

2 / 32

Datasheet_epc901-V7.00

www.espros.com

�1. Block diagram

CCD

Control

CCD pixel field 1024 x 1

FS4

FS3

FS2

FS1

CCD frame store buffer FS1..4

Floating diffusion / source follower / CDS

Shift

Control

1024:4 multiplexer

4:1 multiplexer

VDD_OA

analog in

VIDEO_P

VIDEO_CM

VIDEO_N

AMP

CLR_DATA

digital control

SHUTTER

READ

GND_OA

DATA_RDY

Control

ROI_SEL

VDD

Charge pump

RD_DIR

HOR_BIN

VDD_7V0

AGND

Oscillator

I2C Interface

CS0

TEST_MODE

ANA_TEST_0

PWR_DOWN

I_BIAS

GAIN

BW0

BW1

DGND

Temperature

Sensor

1&2

Test

Control

AMP

Control

Power supply /

Power on

Reset

ANA_TEST_1

AGND

SCL

1.8V regulator

CS1

5V regulator

VDD_1V8

SDA

VDD_5V0

Figure 3: Block diagram

2. Pin-out

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

11

12

13

14

15

16

epc901

1

2

3

4

5

6

7

8

9

10

Figure 4: Pin-out, view to the photo-sensitive side (top-view)

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

3 / 32

Datasheet_epc901-V7.00

www.espros.com

�Pin no. Pin name

Digital pins

2

PWR_DOWN

3

CLR_DATA

5

CLR_PIX

6

SHUTTER

12

READ

4

DATA_RDY

13

SDA

14

SCL

15

ROI_SEL

17

CS1

19

CS0

21

GAIN

22

BW0

23

BW1

24

RD_DIR

25

HOR_BIN

30

TEST_MODE

Analog pins

8

VIDEO_N

9

VIDEO_P

11

VIDEO_CM

27

I_BIAS

28

ANA_TEST_1

29

ANA_TEST_0

Supply pins

26

VDD

10

VDD_OA

32

VDD_1V8

18

VDD_5V0

20

VDD_7V0

16

AGND

1

AGND

7

GND_OA

31

DGND

Pin type

DI

DI

DI

DI

DI

Default [V] Description

0

0

0

0

0

DO

DIOD

DIOD

DI

TER

TER

TER

TER

TER

DI

TER

DI

AO

AO

AI

AI

AIO

AIO

Supply

Supply

AO / Supply

Supply

Supply

Supply

Supply

VDD

VDD

0

VDD/2

VDD/2

VDD/2

VDD/2

VDD/2

0

VDD/2

0

Power-down mode enable

Clear internal data memory controller

Rising edge resets pixels and its controller

Exposure active when SHUTTER set

Read-out control and read clock

Flag when data on video interface is ready. Used as a strap pin to turn on/off

the charge pump

I2C serial data (open drain)

I2C serial clock (open drain)

Region of interest selection

I2C chip select 1

I2C chip select 0

Select gain of read-out path

LSB of bandwidth of video amplifier

MSB of bandwidth of video amplifier

Read-out direction

Horizontal binning selection

Chip test

Negative terminal of video output

Positive terminal of video output

VDD/2 or 0 Voltage to set video output common-mode

Bias current

0

Analog test in-/output 1

0

Analog test in-/output 0, rising edge indicates the last pixel in a frame

Positive chip supply voltage

Positive supply of video amplifier

Decoupling

Decoupling / external 5V supply for low power consumption (refer to 10.2.)

Decoupling

Analog ground

Analog ground

Video amplifier ground

Digital ground

Definitions:

■ DI:

■ DO:

■ DIOD:

■ AO:

■ AI:

■ AIO:

■ TER:

Digital input pin, with an internal pull-down resistor of approx. 100-250kΩ

Digital output pin

General purpose bidirectional digital pin with open-drain output, requires external pull-up resistor

Analog output

Analog input

Analog input and output

Ternary input pin, with a pull-down and an equal pull-up resistor of approx. 100-250kΩ which tie the pin to the VDD/2 state.

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

4 / 32

Datasheet_epc901-V7.00

www.espros.com

�2.1. Power domains

VDD

VDD_5V0

VDD_7V0

VDD_OA

VDD_1V8

The epc901 chip has internally 5 different power domains and 3 ground references which are interconnected with ESD protection diodes.

All pins are also equipped with ESD protection diodes. Figure 5 shows this functional circuit. The diodes have a breakthrough voltage of

0.3V. The designer has to take care that none of these diodes become conductive either at power-up, power-down or normal operation.

epc 901

VIDEO_P

VIDEO_N

VIDEO_CM

I_BIAS

ANA_TEST_0

ANA_TEST_1

analog pins

DGND

all others

TEST_MODE

GND_OA

digital pins

AGND

GND_OA

DGND

AGND

Figure 5: ESD protection diode circuit

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

5 / 32

Datasheet_epc901-V7.00

www.espros.com

�3. Electrical, optical and timing characteristics

(TA = 25°C, VDD = 3.0V unless otherwise noted)

3.1. Electrical and other characteristics

Parameter

Description

Min

Typ

Max

Unit

VDD Nominal

Nominal supply voltage on VDD and VDD_OA

2.70

3.00

3.45

V

Supply voltage on VDD and VDD_OA

with Read Clock of max. 1 MHz.

2.45

PSRR

Power supply rejection ratio VDD and VDD_OA.

Differential

13

dB

IDD+IDD_OA 1

Total current consumption on pins VDD and VDD_OA

(refer to section 10.)

Single ended

9

dB

Differential mode,

full video bandwidth, 46kfps 2,

Charge pump:

ON

Temperature sensors:

ON

Idle mode (READ = L)

26

39

mA

Peak, during read-out

48

72

mA

Differential mode,

full video bandwidth, 46kfps 2,

external VDD5V0 supply 3

Charge pump:

OFF

Temperature sensors:

OFF

Idle mode (READ = L)

10

15

mA

Peak, during read-out

16

24

mA

Differential mode,

low video bandwidth, 1kfps 4,

external VDD5V0 supply 3

Charge pump:

OFF

Temperature sensors:

OFF

Idle mode (READ = L)

6.0

9.0

mA

Peak, during read-out

6.0

9.0

mA

Single-ended mode,

low video bandwidth, 1kfps 4

Charge pump:

ON

Temperature sensors:

ON

Idle mode (READ = L)

21

30

mA

Peak, during read-out

40

60

mA

Single-ended mode,

low video bandwidth, 1kfps 4,

external VDD5V0 supply 3

Charge pump:

OFF

Temperature sensors:

OFF

Idle mode (READ = L)

5.0

10.0

mA

Peak during read-out

5.0

10.0

mA

Power-Save mode (POWR_DOWN = H, shutter still working),

external VDD5V0 supply 3

Charge pump:

OFF

Temperature sensors:

OFF

1.3

2

mA

In-rush current at power-up during approximately 5ms

Charge pump:

ON

60

90

mA

In-rush current at power-up during approximately 2ms,

external VDD5V0 supply 3

Charge pump:

OFF

50

75

mA

1.2

2.5

mA

0.2*VDD

V

IDD_5V

Current consumption on pin VDD_5V0 3,

Differential/single-ended mode, full video bandwidth, 46kfps

external VDD5V0 supply 3)

Charge pump:

OFF

VDIL

Low voltage level on binary digital inputs 5 (Level L)

VDIH

High voltage level on binary digital inputs (Level H)

VDOL, VTERIL

Low voltage level on binary and ternary digital outputs (Level L)

VDOH, VTERIH

High voltage level on binary and ternary digital outputs (Level H)

0.8*VDD

VTERIM

Centre voltage level on ternary digital inputs (Level M)

0.4*VDD

IDI

Sink current at digital inputs

RDI

Internal pull-down resistor

RTER

Internal voltage dividing resistors which force the input to VDD/2

IDO

Sink / source current at digital outputs

VVDD1V8

Internally generated voltage on pin VDD1V8

1.62

1.8

VVDD5V0

Internally generated voltage on pin VDD5V0

4.5

5.0

5.5

V

VVDD7V0

Internally generated voltage on pin VDD7V0

6.0

6.5

7.0

V

VVIDEO_P,N

Voltage range at output of video amplifier (@ gain 1)

0.25

VDD-0.25

V

VCM_SE

Voltage at VIDEO_CM to select single-ended mode

0.4

V

2

5

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

6 / 32

0.5*VDD

V

0.2*VDD

V

V

0.6*VDD

V

10

μA

100

250

kΩ

100

250

kΩ

3

mA

1.98

V

Datasheet_epc901-V7.00

www.espros.com

�Parameter

Description

Min

Typ

Max

Unit

VCM_D

Common-mode voltage in differential mode, set on pin

VIDEO_CM. Note: For VCM_D>1V, differential mode is detected automatically by default. For VCM_D Frame Store Buffers --> CDS

VIDEO_CM

GND_OA

I_BIAS

7

27

DGND

31

AGND

16

1

AGND

VIDEO_N

RBIAS

9

ADC

11

8

Pins 8 and 11:

Can be left not

connected.

Refer to the note

below.

Figure 16: Single ended mode application diagram

If VIDEO_N and VIDEO_CM are tied to GND at power-up or RESET, single-ended mode is enabled. The output signal is available at

VIDEO_P.

Note:

If the pins VIDEO_N and VIDEO_CM are not connected, the epc901 is in differential mode after power-up or RESET. In this case, singleended mode can be selected via I2C register setting FORCE_ANA_CTRL_SIGS, bit AMP_OVR (see Table 14 and Table 15).

Illumination

VIDEO_P (typ.)

Dark voltage

0.4V

Maximum video output

2.0V

Table 28: Video amplifier output in single-ended mode

9.3. External components

The external components in Figure 15 and Figure 16 shall be as follows:

Parameter

Description

Value

Units

Tolerance Comments

RBIAS

Bias resistor

56k

kΩ

±1%

Temperature coefficient max. ±100ppm/K

CVDD1V8

Decoupling capacitor

1.0

μF

±20%

low ESR

CVDD5V0, CVDD7V0 Decoupling capacitors

2.2

μF

±20%

low ESR

CVDD, CVDD_OA

Decoupling capacitors

1.0

μF

±20%

low ESR

L

Decoupling inductor

600

Ω

@100MHz, e.g. Taiyo Yuden BK1005HR601-T

9.4. Low noise operation

9.4.1. Charge pump noise

The internal charge pump generates some noise, especially in single-ended mode. The noise performance can be optimized by turning off

the charge pump and supplying the chip with an external 5V supply. Refer to section 10.2.

9.4.2. Video amplifier noise

Another noise source is the video amplifier which can be used in two different modes. Single ended mode is the lower noise operation

mode. Thus, use the chip in single ended mode for low noise applications. In addition, operate the video amplifier at lowest possible band width and lowest current consumption. Refer to 8.2. and 8.3.

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

25 / 32

Datasheet_epc901-V7.00

www.espros.com

�9.4.3. Layout recommendations

The epc901 line imager is a very high sensitivity analog/digital chip. Due to its high conversion gain, just a few electrons collected by

coupling to signal lines close to the chip generate a significant voltage at the output. Thus, do not place any signal lines underneath the

chip without shielding. It is highly recommended to place a stable AGND plane underneath the epc901 chip (on the top layer of the PCB)

and not to place any signal tracks close to the chip.

Also very important is a clean noise-free power supply. Especially decouple the VDD from VDD_OA with capacitor so the output modula tion of the video amplifier does not modulate the VDD of the chip. Make sure all the capacitors used for decoupling are low ESR types.

The READ signal line can also be a major source of noise or coupling to the output signal. Figure 17 shows a scope screen shot of such a

coupling problem.

VIDEO_P

READ

Figure 17: READ signal coupling to the output by a ground loop

The source of such problems is usually a ground loop. Especially if there is a significant distance 'd' as shown in Figure 18 (starting from a

few cm only) between the video output of the epc901 chip and the input of the ADC. Care has to be taken that the layout of the GND lines

is exactly like shown in Figure 18. Make sure that the digital GND has a separate track as shown by the blue ground line!

d

VDD

VDD_OA

VDD_5V0

VIDEO_P

31

1

GND_OA

epc 901

VDD_7V0

GNDD

20

VDD_1V8

GNDA

18

GNDA

32

12

READ

10

VDD

26

16

VIDEO_N

VDD

9

ADC

8

AGND

7

GND

Common AGND

connection

Digital

control

Common GND

connection

READ

DGND

Figure 18: Recommended ground and power supply connections

Make also sure that the thick lines in Figure 18 are as short and as thick as possible.

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

26 / 32

Datasheet_epc901-V7.00

www.espros.com

�10. Power consumption considerations

10.1. General considerations

There are several options to control the power consumption. However, a trade-off between performance and power consumption has to be

considered. The following section describes the various options. The most power-consuming blocks are

•

Temperature sensors (approx. 3mA)

•

Video amplifier (approx. 3.5mA)

•

Charge pump and 5V regulator (approx. 13.5mA)

The wake-up time of the video amp is typ. 3µs only. Thus, in most applications it can be turned off during illumination in order to reduce the

average power consumption.

10.2. Low power operation

The lowest possible power consumption of the epc901 can be achieved if it is supplied with 3V and 5V since the highest power consumption is the internal charge pump which generates the 5V from VDD. In this case, the chip-internal charge pump and the internal 5V regu lator shall be turned off. The power consumption in this configuration is less than 20mW compared to 80mW in the standard mode. The

following application information shows how this can be achieved. Follow carefully the instructions in order to avoid damage of the chip.

Use protection diodes according to circuit diagram below. The diodes have to be low voltage Schottky devices with a forward current of at

least 100mA (i.e. BAT74).

IN_+3.0V

Ext. supply

+3.0V

VDD

26

epc 901

D1

VDD_OA

DGND

VDD_7V0

31

GND_OA

20

D2

10

VDD_5V0

AGND

18

D3

AGND

Ext. supply

+5.0V

IN_+5.0V

32

VDD_1V8

1

16

7

GND

Common GND

connection

Common AGN

connection

Make sure that external 5V supply (VDD_5V0) is delayed by at least 100µs to the VDD.

1. Power up VDD (3V)

2.

3.

Wait for at least 100µs

Power up VDD_5V0

VDD

VDD_5V0

>100µs

Figure 19: Power up sequence in low power configuration

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

27 / 32

Datasheet_epc901-V7.00

www.espros.com

�11. Layout and packaging information

11.1. Mechanical dimensions

(0.050)

The packaging technology is a CSP with a uBGA. All measures which do not have an explicit tolerance are meant +/-0.001mm.

Photosensitive side

(top view)

Solder balls Sn96.5Ag3.0Cu0.5

(SAC305)

0.190 ±0.020

PCB side

8.080 ±0.040

4.080 ±0.020

1024 x 0.0075 = 7.680

0.0075

photosensitive area

center of pixel-field

17

0.618

Pixel #1023

top view (view to photosensitive side)

(ball size: 0.200)

(0.232 ±0.020)

1

(0.330 ±0.020)

0.860

Pixel #0

0.850 ±0.020

1.324 ±0.040

0.120

32

16

0.090

0.500

3.750

15 x 0.500 = 7.500

Weight: 4.57 mg

- dimensions in mm

- not specified tolerances ±0.001

The photosensitive area is not marked neither on the front nor on the backside of the IC. As a visible reference, the metal ring of the IC can

be used which is visible from the back side (solder ball side). Also from the front side (photosensitive area) it can be seen with a camera

which is sensitive in the near infrared wavelength domain (950 .. 1150nm).

Figure 20 shows the epc901 chip from the bottom side with view to the solder balls. Please note the location of pin 1.

Pin 1

Figure 20: Bottom view

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

28 / 32

Datasheet_epc901-V7.00

www.espros.com

�11.2. PCB design and SMD manufacturing process considerations

The epc901 chip comes in a very small 32 pin chip scale package, the PCB layout should be made with special care. The silicon chip is

small and light weight compared to its solder balls. It is highly recommended that all tracks to the chip should come straight from the side.

A consequent symmetrical PCB layout design is highly recommended to achieve high production yield.

The pads and the tracks should also have exactly the same width. The tracks shall be covered by a solder resist mask in order to avoid

drain of the solder tin alloy to the track.

solder resist mask opening

solder resist mask

1.324

ø0.3

min. 0.25

solder paste resist coverage

8.000

track

(straight only for 0.25mm!)

landing pad

max. 0.15

ø0.4

chip perimeter

all measures in mm

Figure 21: Recommended PCB layout

Underfill of the components reduces stress to the solder pads caused by e.g. temperature cycling or mechanical bending. The thermal and

mechanical fatigue will be reduced and the longterm reliability will be increased. Underfill and underfill selection is application specific. It

shall follow JEDEC-STD JEP150: Stress-Test-Driven Qualification of and Failure Mechanisms Associated with Assembled Solid State

Surface- Mount Components.

Please refer to the application note AN08_Process-Rules_CSP_Assembly. Please follow carefully the recommendations in this application

note to achieve a high manufacturing yield.

11.3. Tape & Reel Information

The devices are packed in tape on reel for automatic placement systems. The tape is wound on 178 mm (7 inch) or 330 mm (13 inch)

reels and individually packaged for shipment. General tape-and-reel specification data are available in a separate data sheet and indicate

the tape sizes for various package types. Further tape-and-reel specifications can be found in the Electronic Industries Association (EIA)

standard 481-1, 481-2, 481-3.

CSP32 Tape

12

Pin 1

4

ESPROS does not guaranteeCSP6

that there

Thus, the pick-and-place

machine should check the presence of a chip dur Tape are no empty cavities.

QFN16 Tape

Pin 1

Pin 1

ing picking.

8

11.4. Soldering and IC handling

12

Since the chip is only 50μm thick and has a high aspect ratio (length to width), a careful handling during the surface mount assembly

process shall be taken in order to avoid mechanical damage. In addition to that, careful PCB layout is needed in order to achieve reliable

assembly results with a high yield. Please refer to the application note AN08_Process-Rules_CSP_Assembly which contains most up to

date and comprehensive information to these topics. This application note can be downloaded at www.espros.com/application-notes.

4

8

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

29 / 32

Datasheet_epc901-V7.00

www.espros.com

�12. Self-test mode by fill-and-spill

The CCD and the readout chain functionality of the epc901 chip can be tested without optical stimulation. This function is useful in a factory test of the final product or in safety applications. The concept is to inject electrically stimulated charge into the pixel instead of photon

generated charge by the as-called fill-and-spill circuitry.

The basic behavior of the IC by the fill-and-spill circuitry is exactly the same as when the IC is illuminated. I.e. also when fill-and-spill is

used, the acquisition is controlled by SHUTTER, the internal flush and shift operation are similar and the signal DATA_RDY is asserted at

the end of the internal shift operation.

If the CCD is stimulated by the fill-and-spill, the on-chip test controller coordinates the operation of the fill-and-spill and the CCD.

Fill-and-spill procedure:

1. Select differential readout mode.

2. Apply the following voltages:

TEST_MODE = VDD

ROI_SEL = 0V or VDD

RD_DIR = 0V or VDD

3. Access the test mode configuration registers. Write access remains available until next reset:

Addr 0xD0: 0x4A

Addr 0xD1: 0x66

Addr 0xD2: 0x02

Addr 0xD4: 0x20

Addr 0xD5: 0x21

4. Select the pattern of pixels to be stimulated by writing to register Addr 0xD3 (see Table 29):

Bit select

Stimulation

7

not used

6

all odd pixels

5

pixels 2, 6, 10 etc.

4

pixels 4, 12, 20 etc.

3

pixels 0, 8, 16 etc.

2:0

Set these bits to 0x1

Table 29: Bit select description of register Addr 0xD3 in fill-and-spill test mode

5. Apply the following voltages to the test pins. Note that Vout varies from production lot to lot:

ANA_TEST_0 = 1 VDC

ANA_TEST_1 (VIDEO_P – VIDEO_N):

◦

◦

3.0 VDC for Vout of approx. -0.3V

3.6 VDC for Vout of approx. +0.5V

6. Wait 10 µs

7. Acquire a frame by using a 20µs SHUTTER signal. A different integration time is not allowed.

8. Read the frame as described in section 5.4.

9. Disconnect external voltage sources from pins ANA_TEST_0/1.

10. Configure test mode registers to their initial values:

Addr 0xD4: 0x00

Addr 0xD5: 0x01

Addr 0xD2: 0x00

Addr 0xD3: 0x00

11. Apply the following voltages:

TEST_MODE = 0V

ROI_SEL → application dependent

RD_DIR → application dependent

Important notes:

■ The chip does not operate correctly if the procedure and the write sequences described above are not exactly executed.

■ ANA_TEST* are bi-directional pins, by default output pins. Thus, the voltages V IN and VDC may only be applied once the chip is in fill-andspill mode. Otherwise, it can get damaged!

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

30 / 32

Datasheet_epc901-V7.00

www.espros.com

�13. Ordering Information

Part Number

Part Name

Package

RoHS

Packaging

Method

P100 401

epc901-CSP32-033

CSP32

Yes

Reel

P100 208

epc901 Evaluation Board V2

PCB 70.00 x 65.00 mm

Yes

Anti static bag

P100 209

epc901 Chip Carrier Board V2

PCB 36.00 x 42.75 mm

Yes

Anti static bag

Table 30: Ordering information

Application notes can be downloaded from the ESPROS website at www.espros.com/downloads/09_Application_notes.

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

31 / 32

Datasheet_epc901-V7.00

www.espros.com

�14. IMPORTANT NOTICE

ESPROS Photonics AG and its subsidiaries (ESPROS) reserve the right to make corrections, modifications, enhancements, improvements, and other changes to its products and services at any time and to discontinue any product or service without notice. Customers

should obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are sold subject to ESPROS’ terms and conditions of sale supplied at the time of order acknowledgment.

ESPROS warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with epc’s stan dard warranty. Testing and other quality control techniques are used to the extent ESPROS deems necessary to support this warranty. Except where mandated by government requirements, testing of all parameters of each product is not necessarily performed.

ESPROS assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using ESPROS components. To minimize the risks associated with customer products and applications, customers should

provide adequate design and operating safeguards.

ESPROS does not warrant or represent that any license, either express or implied, is granted under any ESPROS patent right, copyright,

mask work right, or other ESPROS intellectual property right relating to any combination, machine, or process in which ESPROS products

or services are used. Information published by ESPROS regarding third-party products or services does not constitute a license from ESPROS to use such products or services or a warranty or endorsement thereof. Use of such information may require a license from a third

party under the patents or other intellectual property of the third party, or a license from ESPROS under the patents or other intellectual

property of ESPROS.

Resale of ESPROS products or services with statements different from or beyond the parameters stated by ESPROS for that product or

service voids all express and any implied warranties for the associated ESPROS product or service. ESPROS is not responsible or liable

for any such statements.

ESPROS products are not authorized for use in safety-critical applications (such as life support) where a failure of the ESPROS product

would reasonably be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their appli cations, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning

their products and any use of ESPROS products in such safety-critical applications, notwithstanding any applications-related information or

support that may be provided by epc. Further, Buyers must fully indemnify ESPROS and its representatives against any damages arising

out of the use of ESPROS products in such safety-critical applications.

ESPROS products are neither designed nor intended for use in military/aerospace applications or environments unless the ESPROS prod ucts are specifically designated by ESPROS as military-grade. Only products designated by ESPROS as military-grade meet military spec ifications. Buyers acknowledge and agree that any such use of ESPROS products which ESPROS has not designated as military-grade is

solely at the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with

such use.

ESPROS products are neither designed nor intended for use in automotive applications or environments unless the specific ESPROS

products are designated by ESPROS as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any

non-designated products in automotive applications, ESPROS will not be responsible for any failure to meet such requirements.

© 2020 ESPROS Photonics Corporation

Characteristics subject to change without notice

32 / 32

Datasheet_epc901-V7.00

www.espros.com

�