IS31LT3954

CONSTANT-CURRENT 3-AMPERE PWM DIMMABLE BUCK

REGULATOR LED DRIVER WITH OUTPUT FAULT REPORTING

September 2021

GENERAL DESCRIPTION

FEATURES

The IS31LT3954 is a DC-to-DC switching converter

that integrates an N-channel MOSFET to operate in a

buck configuration. The device can operate from a

wide input voltage between 4.5V and 38V and

provides a constant current of up to 3A for driving a

single LED or multiple series connected LEDs.

The external resistor, RISET, is used to set a constant

LED output current, while allowing the output voltage

to be automatically adjusted for a variety of LED

configurations.

The IS31LT3954 operates in a fixed frequency mode

during switching. There is an external resistor

connected between the VCC and TON pins used to

configure the on-time (switching frequency). The

switching frequency is dithered for spread spectrum

operation which will spread the electromagnetic

energy into a wider frequency band. This function is

helpful for optimizing EMI performance.

A logic input PWM signal applied to the enable (EN)

pin will adjust the average LED current. The LED

brightness is proportional to the duty cycle of the

PWM signal.

True average output current operation is achieved

with fast transient response by using cycle-by-cycle,

controlled on-time method.

The IS31LT3954 is available in an SOP-8-EP

package with an exposed pad for enhanced thermal

dissipation. It operates from 4.5V to 38V over the

temperature range of -40°C to +125°C.

Wide input voltage supply from 4.5V to 38V

- Withstand 40V load dump

True average output current control

3A maximum output over operating temperature

range

Cycle-by-cycle current limit

Integrated high-side MOSFET switch

Dimming via direct logic input or power supply

voltage

Internal control loop compensation

Under-voltage lockout (UVLO) and thermal

shutdown protection

2μA low power shutdown

Spread spectrum to optimize EMI

Robust fault protection and reporting function:

- Pin-to-GND short

- Component open/short faults

- Adjacent pin-to-pin short

- LED open/short

- Thermal shutdown

APPLICATIONS

General high brightness LED lighting

Architecture lighting

Dimmable lights

Pool lighting

TYPICAL APPLICATION CIRCUIT

Figure 1

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

Typical Application Circuit

1

�IS31LT3954

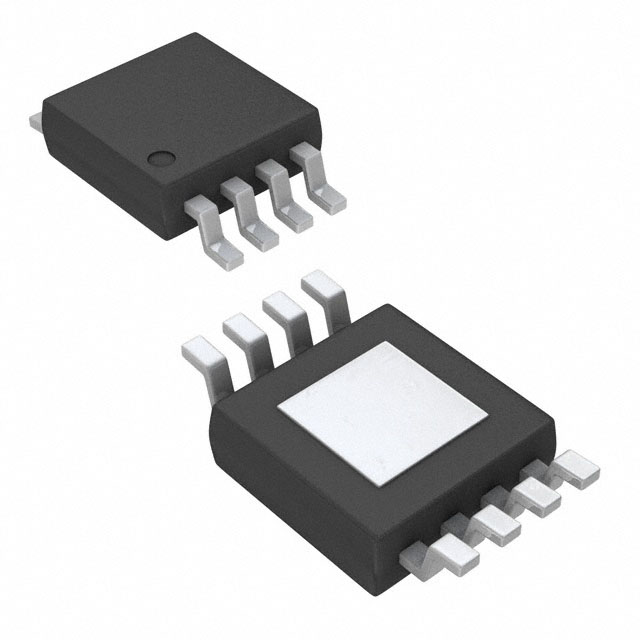

PIN CONFIGURATION

Package

Pin Configuration (Top View)

SOP-8-EP

PIN DESCRIPTION

No.

Pin

Description

1

VCC

Power supply input. Connect a bypass capacitor CIN to ground.

The path from CIN to GND and VCC pins should be as short as

possible.

2

TON

On-time setting. Connect a resister from this pin to VCC pin to

set the regulator controlled on-time.

3

EN/PWM

Logic input for enable and PWM dimming. Pull up above 1.4V to

enable and below 0.4V to disable. Input a 100Hz~20kHz PWM

signal to dim the LED brightness.

4

FB

Drive output current sense feedback. Set the output current by

connecting a resister from this pin to the ground.

5

FAULTB

Open drain diagnostic pin. Active low to indicate fault

conditions.

6

GND

Ground.

7

BOOT

Internal MOSFET gate driver bootstrap. Connect a 0.1µF X7R

ceramic capacitor from this pin to LX pin.

8

LX

Internal high-side MOSFET switch output. Connect this pin to

the inductor and Schottky diode.

Thermal Pad

Connect to GND.

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

2

�IS31LT3954

ORDERING INFORMATION

Industrial Range: -40°C to +125°C

Order Part No.

Package

QTY/Reel

IS31LT3954-GRLS4-TR

SOP-8-EP, Lead-free

2500

Copyright © 2021 Lumissil Microsystems. All rights reserved. Lumissil Microsystems reserves the right to make changes to this specification and its

products at any time without notice. Lumissil Microsystems assumes no liability arising out of the application or use of any information, products or

services described herein. Customers are advised to obtain the latest version of this device specification before relying on any published information and

before placing orders for products.

Lumissil Microsystems does not recommend the use of any of its products in life support applications where the failure or malfunction of the product can

reasonably be expected to cause failure of the life support system or to significantly affect its safety or effectiveness. Products are not authorized for use in

such applications unless Lumissil Microsystems receives written assurance to its satisfaction, that:

a.) the risk of injury or damage has been minimized;

b.) the user assume all such risks; and

c.) potential liability of Lumissil Microsystems is adequately protected under the circumstances

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

3

�IS31LT3954

ABSOLUTE MAXIMUM RATINGS (Note 1)

Input voltage, VCC (Note 2)

Bootstrap to switching voltage, (VBOOT-VLX)

Switching voltage, VLX (Steady state)

Switching voltage, VLX (Transient< 10ns)

EN/PWM, TON and FAULTB voltage, VEN/PWM, VTON and VFAULTB

Current sense voltage, VFB

Power dissipation, PD(MAX)

Operating temperature, TA=TJ

Storage temperature, TSTG

Junction temperature, TJMAX

Package thermal resistance, junction to ambient (4 layer standard

test PCB based on JESD 51-2A), θJA

Package thermal resistance, junction to thermal PAD (4 layer

standard test PCB based on JESD 51-8), θJP

ESD (HBM)

ESD (CDM)

-0.3V ~ +42V

-0.3V ~ +6.0V

-0.6V ~ VCC +0.3V

-3.0V

-0.3V ~ VCC +0.3

-0.3V ~ 6.0V

2.29W

-40°C ~ +125°C

-65°C ~ +150°C

+150°C

43.7 °C/W

1.41 °C/W

±2kV

±750V

Note 1: Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress

ratings only and functional operation of the device at these or any other condition beyond those indicated in the operational sections of the

specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

Note 2: A maximum of 44V can be sustained at this pin for a duration of ≤ 2s.

ELECTRICAL CHARACTERISTICS

VCC= 24V, TJ= TA= 25°C, unless otherwise noted. (Note 3)

Symbol

VCC

VUVLO

Parameter

Conditions

Input supply voltage

VCC undervoltage lockout threshold

VUVLO_HY VCC undervoltage lockout hysteresis

Min.

Typ.

4.5

VCC increasing

4.05

4.25

VCC decreasing

250

Max.

Unit

38

V

4.45

V

mV

ICC

VCC pin supply current

VFB = 0.5V, VEN/PWM = high

1.2

2

mA

ISD

VCC pin shutdown current

EN/PWM shorted to GND

2

10

µA

4.5

5.5

A

ISWLIM

tOCP

Buck switch current limit threshold

3.5

Over Current Protection (OCP) hiccup

(Note 4)

time

1

ms

RDS_ON

Buck switch on-resistance

VBOOT= VCC+4.3V, ILX= 1A

0.2

VBTUV

BOOT undervoltage lockout threshold

VBOOT to VLX increasing

3.3

V

VBTUV_HY BOOT undervoltage lockout hysteresis

VBOOT to VLX decreasing

400

mV

tOFF_MIN

Switching minimum off-time

VFB = 0V

110

150

ns

tON_MIN

Switching minimum on-time

120

150

ns

tON

Selected on-time

0.4

Ω

VCC= 24V, VOUT= 12V,

RTON= 420kΩ

800

1000

1200

ns

VFB decreasing, LX turns on

195

200

205

mV

Regulation Comparator and Error Amplifier

VFB

Load current sense regulation

threshold

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

4

�IS31LT3954

ELECTRICAL CHARACTERISTICS (CONTINUE)

VCC= 24V, TA= TJ = 25°C, unless otherwise noted. (Note 3)

Symbol

Parameter

Conditions

Min.

Typ.

Max.

Unit

0.1

0.2

V

1

µA

FAULT OUTPUT

VFAULTB

FAULTB pin pull down voltage

ILK_FAULTB FAULTB pin leakage current

Fault condition, sink current

IOL = 5mA

No fault condition, pull up to

12V

tDELAY1

Fault detect to fault report delay time

10

ms

tDELAY2

Fault recover to fault report delay time

10

ms

Enable Input

VIH

Logic high voltage

VEN/PWM increasing

VIL

Logic low voltage

VEN/PWM decreasing

RPWMPD

EN/PWM pin pull-down resistance

VEN/PWM= 5V

tPWML

Duration EN/PWM pin kept low to

shutdown the device

tPWMH

tPWMSW

1.4

V

0.4

V

100

200

300

kΩ

55

65

80

ms

Duration EN/PWM pin kept high to quit

(Note 4)

from shutdown mode

16

25

µs

The latency of EN/PWM pull high to IC

(Note 4)

starts switching

120

150

µs

Thermal Shutdown

TSD

Thermal shutdown threshold

(Note 4)

165

°C

TSDHYS

Thermal shutdown hysteresis

(Note 4)

25

°C

Note 3: Production testing of the device is performed at 25°C. Functional operation of the device specified over -40°C to +125°C temperature

range, is guaranteed by design, characterization and process control.

Note 4: Guaranteed by design.

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

5

�IS31LT3954

TYPICAL PERFORMANCE CHARACTERISTICS

2

2

1.8

Supply Current (mA)

Supply Current (mA)

RTON = 200kΩ

TJ = 25°C

EN/PWM = High

1.5

1

1.6

VCC = 12V

RTON = 200kΩ

EN/PWM = High

1.4

1.2

1

0.8

0.6

0.5

0.4

0.2

0

0

10

20

30

0

-40

40

-25

-10

5

Figure 3

ICC vs. VCC

3

50

65

80

95

110

125

80

95

110

125

80

95

110

125

ICC vs. Temperature

2

RTON = 200kΩ

TJ = 25°C

EN/PWM = Low

2.5

1.8

Shutdown Current (µA)

Shutdown Current (µA)

35

Temperature (°C)

Supply Voltage (V)

Figure 2

20

2

1.5

1

1.6

VCC = 12V

RTON = 200kΩ

EN/PWM = Low

1.4

1.2

1

0.8

0.6

0.4

0.5

0.2

0

0

10

20

30

0

-40

40

-25

-10

5

35

50

65

Temperature (°C)

Supply Voltage (V)

Figure 4

20

Figure 5

ISD vs. VCC

ISD vs. Temperature

0.4

0.3

TJ = 25°C

VCC = 12V

0.35

0.25

0.3

RDS_ON (Ω)

RDS_ON (Ω)

0.2

0.15

0.25

0.2

0.15

0.1

0.1

0.05

0

0.05

0

10

20

30

40

0

-40

-25

-10

RDS_ON vs. VCC

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

20

35

50

65

Temperature (°C)

Supply Voltage (V)

Figure 6

5

Figure 7

RDS_ON vs. Temperature

6

�IS31LT3954

100

1600

3LED

95

1560

1540

1520

1500

1480

1460

RISET = 0.13Ω

RTON = 200kΩ

L1 = 10µH

TJ = 25°C

1LED ~ 10LED

1440

1420

1400

4LED 5LED 6LED 7LED 8LED 9LED 10LED

2LED

90

Efficiency (%)

Output Current (mA)

1580

5

10

1LED

85

80

75

70

RISET = 0.13Ω

RTON = 200kΩ

L1 = 10µH

TJ = 25°C

65

15

20

25

30

35

60

40

5

10

15

IOUT vs. VCC

Figure 9

3200

95

3000

2950

2900

RISET = 0.067Ω

RTON = 200kΩ

L1 = 10µH

TJ = 25°C

1LED ~ 9LED

2800

2750

5

10

25

30

35

9LED

RISET = 0.067Ω

RTON = 200kΩ

L1 = 10µH

TJ = 25°C

5

10

15

Supply Voltage (V)

Figure 10

7LED 8LED

75

60

40

5LED 6LED

80

65

20

40

85 1LED

70

15

35

2LED

90

3050

Efficiency (%)

Output Current (mA)

3LED 4LED

3100

2850

30

Efficiency vs. VCC

100

3150

2700

25

Supply Voltage (V)

Supply Voltage (V)

Figure 8

20

20

25

30

35

40

Supply Voltage (V)

IOUT vs. VCC

Figure 11

4.5

Efficiency vs. VCC

220

4.4

VCC = 12V

UVLO_H

4.3

210

UVLO_L

4.1

VFB (mV)

VUVLO (V)

4.2

4

3.9

200

3.8

190

3.7

3.6

3.5

-40

-25

-10

5

20

35

50

65

80

95

110

125

180

-40

10

Temperature (°C)

Figure 12

VUVLO vs. Temperature

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

60

110

160

Temperature (°C)

Figure 13

VFB vs. Temperature

7

�IS31LT3954

3500

2500

Output Current (mA)

Output Current (mA)

3000

3000

VCC = 12V

RISET = 0.067Ω

TJ = -40°C

PWM = 500Hz, 1kHz, 5kHz, 10kHz

2500

2000

1500

1000

2000

1500

1000

500

500

0

0

VCC = 12V

RISET = 0.067Ω

TJ = 25°C

PWM = 500Hz, 1kHz, 5kHz, 10kHz

10

20

30

40

50

60

70

80

90

100

0

0

10

20

30

Duty Cycle (%)

Figure 14

Output Current (mA)

50

60

70

80

90

100

Duty Cycle (%)

IOUT vs. Duty Cycle

Figure 15

3000

2500

40

IOUT vs. Duty Cycle

VCC = 12V

RTON = 200kΩ

TJ = -40°C

VCC = 12V

RISET = 0.067Ω

TJ = 125°C

PWM = 500Hz, 1kHz, 5kHz, 10kHz

2000

VCC

10V/Div

1500

1000

VEN/PWM

10V/Div

500

0

0

10

20

30

40

50

60

70

80

90

100

IL1

1A/Div

Duty Cycle (%)

Figure 16

Time (100µs/Div)

IOUT vs. Duty Cycle

Figure 17

VCC = 12V

RTON = 200kΩ

TJ = 25°C

VCC = 12V

RTON = 200kΩ

TJ = 125°C

VCC

10V/Div

VCC

10V/Div

VEN/PWM

10V/Div

VEN/PWM

10V/Div

IL1

1A/Div

IL1

1A/Div

Time (100µs/Div)

Figure 18

EN/PWM Enable Time

Time (100µs/Div)

EN/PWM Enable Time

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

Figure 19

EN/PWM Enable Time

8

�IS31LT3954

VCC = 12V

PWM = 5V, 1kHz

RTON = 200kΩ

TJ = -40°C

VCC = 12V

PWM = 5V, 1kHz

RTON = 200kΩ

TJ = -40°C

VCC

10V/Div

VCC

10V/Div

VEN/PWM

5V/Div

VEN/PWM

5V/Div

IL1

500mA/Div

IL1

500mA/Div

Time (4µs/Div)

Figure 20

Time (4µs/Div)

PWM Off

Figure 21

VCC = 12V

PWM = 5V, 1kHz

RTON = 200kΩ

TJ = 25°C

VCC = 12V

PWM = 5V, 1kHz

RTON = 200kΩ

TJ = 25°C

VCC

10V/Div

VCC

10V/Div

VEN/PWM

5V/Div

VEN/PWM

5V/Div

IL1

500mA/Div

IL1

500mA/Div

Time (4µs/Div)

Figure 22

Time (4µs/Div)

PWM Off

Figure 23

VCC = 12V

PWM = 5V, 1kHz

RTON = 200kΩ

TJ = 125°C

PWM On

VCC = 12V

PWM = 5V, 1kHz

RTON = 200kΩ

TJ = 125°C

VCC

10V/Div

VCC

10V/Div

VEN/PWM

5V/Div

VEN/PWM

5V/Div

IL1

500mA/Div

IL1

500mA/Div

Time (4µs/Div)

Figure 24

PWM On

Time (4µs/Div)

PWM Off

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

Figure 25

PWM On

9

�IS31LT3954

FUNCTIONAL BLOCK DIAGRAM

BOOT

VCC

VREG 5.3V

VDD

UVLO

Average

On-Time

Current

Generator

TON

On-Time

Timer

Off-Time

Timer

Gate Drive

UVLO

SD

Level

Shift

EN/PWM

VIL=0.4V

VIH=1.4V

LX

IC and Driver

Control Logic

FB

Current Limit

Off-time Timer

VDD UVLO

0.2V

CCOMP

Thermal

Shutdown

Buck Switch

Current Sense

ILIM

Fault

Detection

FAULTB

GND

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

10

�IS31LT3954

APPLICATION INFORMATION

DESCRIPTION

OUTPUT CURRENT SETTING

The IS31LT3954 is a buck regulator with wide input

voltage, low reference voltage, quick output response

and excellent PWM dimming performance, which is

ideal for driving a high-current LED string. It uses

average current mode control to maintain constant

LED current and consistent brightness.

The LED current is configured by an external sense

resistor, RISET, with a value determined as follows

Equation (1):

UNDER VOLTAGE LOCKOUT (UVLO)

The device features an under voltage lockout (UVLO)

function on VCC pin. This is a fixed value which cannot

be adjusted. The device is enabled when the VCC

voltage rises to exceed VUVLO (Typ. 4.25V), and

disabled when the VCC voltage falls below (VUVLO –

VUVLO_HY) (Typ. 4.0V).

BOOTSTRAP CIRCUIT

The gate driver of the integrated high-side MOSFET

requires a voltage above VCC as power supply. As

below circuit diagram, there is an internal 5.3V LDO

which is the power supply of the gate driver. The

BOOT pin is internally connected to the output of the

5.3V LDO. Connect a ceramic capacitor between

BOOT and SW pins. The VCC supplies the power to

the 5.3V LDO which charges the CBOOT capacitor

during high-side MOSFET off cycles. Then in high-side

MOSFET on cycles, the CBOOT charge voltage is used

to boost the BOOT pin to 5.3V higher than LX pin.

VCC

Bootstrap

Circuit

5.3V LDO

BOOT

Gate Drive

UVLO

SD

Level

Shift

Gate

Drive

CBOOT

0.1µF

Internal

MOSFET

LX

Figure 26

Bootstrap Circuit

A 0.1µF X7R ceramic capacitor will work well in most

applications. The gate driver also has an under voltage

lockout detection. The gate driver is enabled when the

voltage on the CBOOT rises to above VBTUV (Typ. 3.3V),

and disabled when the voltage on the CBOOT drops

below (VBTUV – VBTUV_HY) (Typ. 2.9V).

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

I LED VFB / RISET

(1)

Where VFB = 0.2V (Typ.).

Note that RISET= 0.0667Ω is the minimum allowed

value for the sense resistor in order to maintain the

switch current below the specified maximum value.

Table 1

RISET Resistance Versus Output Current

RISET (Ω)

Nominal Average Output Current (mA)

0.2

1000

0.1

2000

0.0667

3000

The resistor RISET should be a 1% resistor with enough

power tolerance and good temperature characteristic

to ensure accurate and stable output current.

ENABLE AND PWM DIMMING

A high logic signal on the EN/PWM pin will enable the

IC. The buck converter ramps up the LED current to a

target level which is set by external resistor, RISET.

When the EN/PWM pin goes from high to low, the buck

converter will turn off, but the IC remains in standby

mode for up to tPWML. When the EN/PWM pin goes high

within this period, the LED current will turn on

immediately. Sending a PWM (pulse-width modulation)

signal to the EN/PWM pin will result in dimming of the

LED. The resulting LED brightness is proportional to

the duty cycle (tON /T) of the PWM signal. A practical

range for PWM dimming frequency is between 100Hz

and 20kHz.

There is an inherent PWM turn on delay time of about

1µs during continuous PWM dimming. A high

frequency PWM signal has a shorter period time that

will degrade the PWM dimming linearity. Therefore, a

low frequency PWM signal is good for achieving better

dimming contrast ratio. At a 200Hz PWM frequency,

the dimming duty cycle can be varied from 100% down

to 1% or lower.

If the EN/PWM pin is kept low for at least tPWML, the IC

enters shutdown mode to reduce power consumption.

The next high signal on EN/PWM will initialize a full

startup sequence, which includes a shutdown quit time,

tPWMH, and a startup latency, tPWMSW. This startup

sequence does not exist in a typical PWM operation.

11

�IS31LT3954

and capacitance of the capacitor contribute to the

output current ripple. Therefore, a low-ESR X7R type

capacitor should be used.

tPWMSW

tPWML

tPWMH

VEN/PWM

IC

shutdown

IC

enabled

IC starts

switching

IL

Figure 27 Device Shutdown and Enable

INPUT CAPACITOR

The input capacitor provides the transient pulse

current, which is approximately equal to ILED, to the

inductor of the converter when the high-side MOSFET

is on. An X7R type ceramic capacitor is a good choice

for the input bypass capacitor to handle the ripple

current since it has a very low equivalent series

resistance (ESR) and low equivalent series inductance

(ESL). Use the following equation to estimate the

approximate capacitance:

C IN _ MIN

I t

LED ON

VCC

(2)

Where, ∆VCC is the acceptable input voltage ripple,

generally choose 5%-10% of input voltage. TON is

on-time of the high-side MOSFET in µs. A minimum

input capacitance of 2X CIN_MIN is recommended for

most applications.

OUTPUT CAPACITOR

The IS31LT3954 control loop can accept a voltage

ripple on the FB pin, this means it can operate without

an output capacitor to save cost. The FB pin needs a

certain amount of voltage ripple to keep control loop

stability. A capacitor can be added across the LEDs but

excluding the FB resistor. This capacitor will reduce the

LED current ripple while keep the same average

current in some application cases. The reduction of the

LED current ripple by the capacitor depends on

several factors: capacitor value, inductor current ripple,

operating frequency, output voltage, etc. A several µF

capacitor is sufficient for most applications. However,

the output capacitor brings in more delay time of LED

current during PWM dimming that will degrade the

dimming contrast.

The output capacitor is used to filter the LED current

ripple to an acceptable level. The equivalent series

resistance (ESR), equivalent series inductance (ESL)

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

Figure 28 Adding Output Capacitor

FREQUENCY SELECTION

During switching the IS31LT3954 operates in a

constant on-time mode. The on-time is adjusted by the

external resistor, RTON, which is connected between

the VCC and TON pins.

2.2

2

1.8

1.6

fSW (MHz)

The EN/PWM pin is high-voltage tolerant and can be

connected directly to a power supply. However, a

series resistor (10kΩ) is required to limit the current

flowing into the EN pin if PWM is higher than the VCC

voltage at any time. If PWM is driven from a logic input,

this series resistor is not necessary.

1.4

1.2

1

0.8

0.6

0.4

0.2

0

0

100

200

300

400

500

600

700

800

900 1000 1100

RTON (kΩ)

Figure 29

Operating Frequency vs. RTON Resistance

The approximate operating frequency

calculated by below Equation (3) and (4):

t ON

k RTON RINT VOUT

VCC

f SW

1

k RTON RINT

can

be

(3)

(4)

Where k= 0.00458, with fSW in MHz, tON in µs, and RTON

and RINT (internal resistance, 20kΩ) in kΩ.

Higher frequency operation results in smaller

component size but increases the switching losses. It

may also increase the high-side MOSFET gate driving

current and may not allow sufficient high or low duty

cycle. Lower frequency gives better performance but

results in larger component size.

12

�IS31LT3954

SPREAD SPECTRUM

A switch mode controller can be troublesome when the

EMI is concerned. To optimize the EMI performance,

the IS31LT3954 includes a spread spectrum feature,

which is a 500Hz with ±10% operating frequency jitter.

The spread spectrum can spread the total

electromagnetic emitting energy into a wider range that

significantly degrades the peak energy of EMI. With

spread spectrum, the EMI test can be passed with

smaller size and lower cost filter circuit.

MINIMUM AND MAXIMUM OUTPUT VOLTAGE

The output voltage of a

approximately given as below:

buck

VOUT VCC D

converter

is

(5)

Assume the forward voltage of each LED is 3.2V, the

device can drive up to 3 LEDs in series.

The minimum output voltage is limited by the switching

minimum on-time, about 150ns, since the frequency is

set. For example, if the input voltage is 12V and the

operating frequency fSW=1MHz, the minimum output

voltage is:

VOUT 12V 150ns 1MHz 1.8V

(9)

This means the device can drive a low forward voltage

LED, such as a RED color LED. So under the condition

of VCC=12V and fSW=1MHz, the output voltage range is

1.8V~10.2V. Exceeding this range, the operation will

be clamped and the output current cannot reach the

set value.

In a typical application, the output voltage is affected

by other operating parameters, such as output current,

RDS_ON of the high-side MOSFET, DRC of the inductor,

parasitic resistance of the PCB traces, and the forward

voltage of the diode. Therefore, the output voltage

range could vary from the calculation. The more

precision equation is given by:

Where D is the operating duty cycle.

VOUT (VCC I LED RDS _ ON ) D RL I LED VD (1 D) (10)

Where, RDS_ON is the static drain-source on resistance

of the high-side MOSFET, and RL is the inductor DC

resistance.

Figure 30

D

So, VOUT VCC

Operating Waveform

t ON

t ON t OFF

(6)

tON

VCC tON f SW

t ON tOFF

(7)

Where tON and tOFF are the turn-on and turn off time of

high-side MOSFET. Note that due to the spread

spectrum, the fSW should use the maximum of the

operating frequency, 110%×fSW.

According to above equation, the output voltage

depends on the operating frequency and the high-side

MOSFET turn on time. When the frequency is set, the

maximum output voltage is limited by the switching

minimum off-time tOFF_MIN, about 150ns. For example, if

the input voltage is 12V and the operating frequency

fSW=1MHz, the maximum output voltage is:

VOUT 12V (1s 150ns ) 1MHz 10.2V

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

Figure 31 shows how the minimum and maximum

output voltages vary with the operating frequency at

12V and 24V input. Figure 32 shows how the minimum

and maximum output voltages vary with the LED

current at 9V input (assuming RDS_ON = 0.4Ω, inductor

DCR RL= 0.1Ω, and diode VD = 0.6V). Note that due to

spread spectrum the fSW should use the maximum

operating frequency, 110%×fSW.

When the output voltage is lower than the minimum tON

time of the device, the device will automatically extend

the operating tOFF time to maintain the set output LED

current all the time. However, the operating frequency

will decrease accordingly to lower level to keep the

duty cycle in correct regulating.

To achieve wider output voltage range and flexible

output configuration, a lower operating frequency

could be considered.

(8)

13

�IS31LT3954

24

L

22

20

18

16

VOUT (V)

VCC= 24V (Max. VOUT)

ILED= 2A

RL= 0.1Ω

RDSON= 0.4Ω

VD= 0.6V

12

VCC= 12V (Max. VOUT)

8

VCC= 24V (Min. VOUT)

6

4

VCC= 12V (Min. VOUT)

2

0

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

fSW (MHz)

Since the IS31LT3954 is a Continuous Conduction

Mode (CCM) buck driver which means the valley of the

inductor current, IMIN, should not drop to zero at any

time, the ∆IL must be smaller than 200% of the average

output current.

Figure 31 Minimum and Maximum Output Voltage versus

Operating Frequency (minimum tON and tOFF = 150ns)

I MIN I LED

8

VCC= 9V

fSW= 1MHz

RL= 0.1Ω

RDSON= 0.4Ω

VD= 0.6V

Max.

I MAX I LED

4

2

Min.

1

0

(12)

I L

I SWLIM

2

(13)

To ensure system stability, the ∆IL must be higher than

10% of the average output current. For the better

performance, choose an inductor current ripple ∆IL

between 10% and 50% of the average output current.

3

0.1 I LED I L 0.5 I LED

0

0.5

1

1.5

2

2.5

3

3.5

ILED (A)

Figure 32 Minimum and Maximum Output Voltage versus LED

Current (minimum tON and tOFF = 150ns)

PEAK CURRENT LIMIT

To protect itself, the IS31LT3954 integrates an Over

Current Protection (OCP) detection circuit to monitor

the current through the high-side MOSFET during

switching on. Whenever the current exceeds the OCP

current threshold, ISWLIM, the device will immediately

turn off the high-side MOSFET for tOCP and restart

again. The device will remain in this hiccup mode until

the current drops below ISWLIM.

INDUCTOR

Inductor value involves trade-offs in performance. A

larger inductance reduces inductor current ripple,

however it also brings in unwanted parasitic resistance

that degrades the efficiency. A smaller inductance has

compact size and lower cost, but introduces higher

ripple in the LED string. Use the following equation to

estimate the approximate inductor value:

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

(14)

Figure 33 shows inductor selection based on the

operating frequency and LED current at 30% inductor

current ripple. If a lower operating frequency is used,

either a larger inductance or current ripple should be

used.

2

1.8

VCC= 12V

VOUT= 6.4V

L= 10µH

1.6

1.4

fSW (MHz)

VOUT (V)

5

I L

0

2

Besides, the peak current of the inductor, IMAX, must be

smaller than ISWLIM to prevent the IS31LT3954 from

triggering OCP, especially when the output current is

set to a high level.

7

6

(11)

Where VCC is the minimum input voltage in volts, VLED

is the total forward voltage of LED string in volts, fSW is

the operation frequency in hertz and ∆IL is the current

ripple in the inductor. Select an inductor with a rated

current greater than the output average current and

the saturation current over the Over Current Protection

(OCP) current threshold ISWLIM.

14

10

(VCC VLED ) VLED

f SW I L VCC

L= 15µH

1.2

L= 22µH

1

0.8

0.6

0.4

L= 33µH

0.2

0

L= 47µH

0

0.5

1

1.5

2

2.5

3

ILED (A)

Figure 33 Inductance Selection Based On 30% Current Ripple

14

�IS31LT3954

DIODE

The IS31LT3954 is a non-synchronous buck driver that

requires a recirculating diode to conduct the current

during the high-side MOSFET off time. The best choice

is a Schottky diode due to its low forward voltage, low

reverse leakage current and fast reverse recovery time.

The diode should be selected with a peak current

rating above the inductor peak current and a

continuous current rating higher than the maximum

output load current. It is very important to consider the

reverse leakage of the diode when operating at high

temperature. Excess leakage will increase the power

dissipation on the device.

The higher input voltage and the voltage ringing due to

the reverse recovery time of the Schottky diode will

increase the peak voltage on the LX output. If a

Schottky diode is chosen, care should be taken to

ensure that the total voltage appearing on the LX pin

including supply ripple, does not exceed its specified

maximum value.

Please check Table 2 for the details of the fault

actions.

Note that the FAULTB pin is an open drain structure. If

it is monitored by a host, an external pull up resistor

RPU from the supply of the host to FAULTB pin is

needed. The recommended value is 47kΩ.

CALCULATING RANGE OF RPU

The ideal value for RPU range needs to take into

account the number of IS31LT3954 devices

connected to the same host. The resulting RPU voltage

level should not interfere with the VIH_HOST and VIL_HOST

detection levels of the host. For no-fault detected

operation, the sum of the leakage current(s) for the

open drain (if more than one device interconnected)

multiplied with the value of RPU must be greater than

VIH_HOST. For fault detected operation, the pull down

voltage must be below VIL_HOST. Then

RPU _ MAX

THERMAL SHUTDOWN PROTECTION

To protect the IC from damage due to high power

dissipation, the temperature of the die is monitored. If

the die temperature exceeds the thermal shutdown

temperature of 165°C (Typ.) then the device will shut

down, and the output current is shut off and FAULTB

pin pulls low. After a thermal shutdown event, the

IS31LT3954 will not try to restart until its temperature

has reduced to less than 140°C (Typ.). Once restart

the FAULTB pin will recover.

RPU _ MIN

Pin open

Pin-to-ground short (except LX pin)

Pin-to-neighboring pin short

Output LED string open and short

External component open or short (except diode)

Thermal shutdown

Lumissil Microsystems – www.lumissil.com

Rev. F, 09/01/2021

N I LK _ FAULTB

(15)

(VHOST VIL _ HOST ) VFAULTB

N VIL _ HOST I OL

(16)

Where N is the number of IS31LT3954 devices

connected to the same host. IOL is the test condition of

FAULTB pin pull down capability. It can be found in

the EC table.

VHOST

FAULT HANDLING

The IS31LT3954 is designed to detect the following

faults and report via open drain FAULTB pin:

VHOST VIH _ HOST

RPU

HOST

IS31LT3954

FAULTB

Figure 34 Host Monitors The Fault Reporting

15

�IS31LT3954

Table 2 Fault Actions

Fault Type

LED

String

Inductor

shorted

Dim

Trigger OCP. Turn off high-side MOSFET Pull Low after second

immediately. Retry after 1ms.

OCP cycle.

RISET short

Dim

Trigger OCP. Turn off high-side MOSFET Pull Low after second

immediately. Retry after 1ms.

OCP cycle.

RISET open

Off

LED string

open

Off

LED string

shorted

Off

LED string

shorted to

GND

Off

BOOT

capacitor

open

Dim

BOOT

capacitor

shorted

Off

RTON resistor

open

Dim

RTON resistor

shorted

Dim

EN short to

RISET

Off

Thermal

Shutdown

Off

Detect Condition

FAULTB Pin

Fault Recovering

Inductor shorted removed. No

OCP triggered and FAULTB pin

recover after 10ms.

RISET shorted removed. No OCP

triggered and FAULTB pin recover

after 10ms.

RISET open removed. The FB pin

voltage drops below 1.55V and

FAULTB pin recover after 10ms.

The FB pin voltage exceeds 2V. Turn off

high-side MOSFET immediately. Retry

Pull Low immediately.

after 1ms.

No PWM FB pin average voltage drops No PWM Pull Low after

dimming: below 0.2V for 10ms.

dimming: 10ms.

Pull low after LED open removed. FB average

FB pin average voltage drops

voltage keep at 0.2V for 10ms and

128 PWM

PWM

below 0.2V after 25µs

PWM

cycles or the FAULTB pin recover.

dimming: deglitch time and keeps for dimming:

on-time over

128 PWM cycles.

20µs.

No PWM

dimming:

Filter VLX to get VOUT, if

VOUT1V for

10ms and FAULTB pin recover.

Shorted removed. No OCP

triggered and FAULTB pin recover

after 10ms.

BOOT capacitor open removed,

VCC-VSW