| P1J

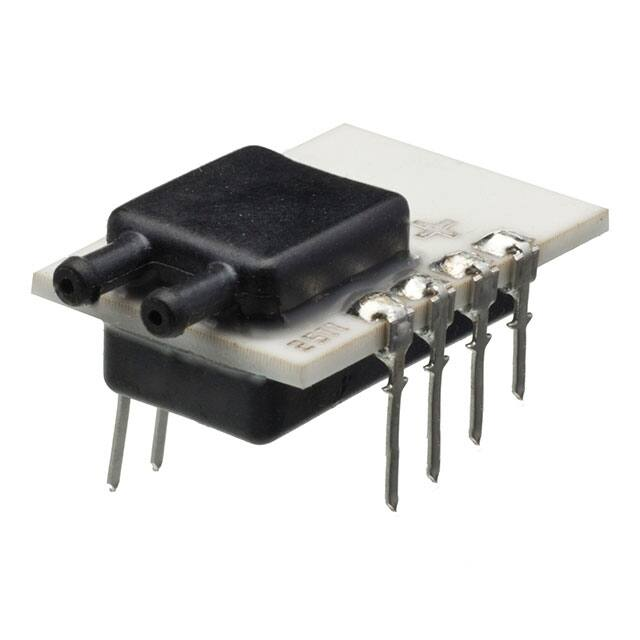

Pressure Sensor

Description

The P1J series of pressure sensors incorporates a piezo-resistive sensing element in a compact package. Using a 2.7 to 5.5 VDC supply voltage, the P1J

provides a SPI or I2C digital output as required by your application. Internal temperature compensation provides and accurate, easy to use sensor. The

industry standard terminal pins provides ease of use for your printed circuit board designs.

Features

• Compact Package

• Amplified Temperature Compensated Digital Output

• No Position Sensitivity above 0-2”H2O

• EMI/RFI and ESD Protected

• Superior Output Signal Stability

• Printed Circuit Board through Hole Mounting

Applications

• Variable Air Volume Systems

• Filter Pressure Monitoring

• Duct Air Flow

• Modulated Furnace Controls

• Combustion Airflow

• Gaseous Leak Detection

• Medical Applications:

Oxygen Concentrators, Ventilators, Anesthesia Equipment, CPAP,

Wound Therapy.

MAIN FEATURES

Pressure Ranges

2, 5, 10, +/-2, +/- 5, +/- 10 inches of water; 5, 12.5, 25, +/- 5, +/- 6, +/- 12.5, +/- 25 mbar

Electrical Connection

PCB thru hole terminal pins, 2.54 mm [.100 inch] pitch

Pressure Connection

Barbed port, 1.9[.08] diameter

Housing Material

PPS, 40% glass filled, black

Terminal Pin Material

Phosphor bronze, tin plated

Supply Voltage

2.7 to 5.5 VDC

Output Signal

14 Bit Digital Output Count – Digital count at null (0% FS): 1638

Digital count at full scale (100% FS) 14745

Page 1

Copyright © 2018 Sensata Technologies, Inc.

www.sensata.com

�TECHNICAL SPECIFICATIONS

Pressure Ranges

from 0 to...

2” H2O

5” H2O

10” H2O

+/- 2” mBar

+/- 5” mBar

from 0 to...

5mbar

12.5mbar

20mbar

+/- 5mbar

+/- 12.5 mbar

Proof Pressure Factor

1.0 PSI/

(70mbar)

1.0 PSI/

(70mbar)

1.0 PSI/

(70mbar)

1.0 PSI/

(70mbar)

1.0 PSI/

(70mbar)

Burst Pressure Factor

1.8 PSI/

(125mbar)

1.8 PSI/

(125mbar)

1.8 PSI/

(125mbar)

1.8 PSI/

(125mbar)

1.8 PSI/

(125mbar)

Physical

Expected Operating Life

10 million full pressure life cycles

Shelf Life

10 years minimum

Stability

+/- 0.5% of full scale span for 1 year

Vibration

10 G’s peak to peak sinusoidal (20 to 1600Hz)

Shock Resistance

Weight

50 G’s ½ Sinewave, 11 mSec pulse, 18 pulses (6 per axis)

3.5g max.

Operating Temperature

-20°C to 85°C

Storage Temperature

-40°C to 85°C

Humidity

Media

Up to 92% RH in a non-condensing environment

Dry air

Performance

Accuracy

0.25% Max (% of full scale span) (RSS of linearity, hysteresis and repeatability)

Temp. Error

0.05%/ C [% of full scale span]

Temp. Error

5% full scale span within temperature range -20° to 0°C and 60° to 85°C 0 to 60°C

Electrical

Input Voltage Protection

Excitation Current

-0.3 to 6 VDC on Vin PIN, -0.3 to Vs+0.3 on all other pins

< 2.5mA

Minimum Load

25k Ohms between output and ground

Response Time

0.5 ms

Page 2

Copyright © 2018 Sensata Technologies, Inc.

www.sensata.com

�DIMENSIONS

Dimensions in mm [Inch]

Page 3

Copyright © 2018 Sensata Technologies, Inc.

www.sensata.com

�I2C COMMUNICATION

Acknowledge (ACK)

Output

Signal Resolution

12 Bits (11 bits minimum for 0-2” H2O and 0-5 mBar range)

Update Rate

0.5 ms

Digital Count at 0% Pressure

Digital Count at 100% Pressure

Sensor Slave Addresses

1638 (10% of 2^14 counts or 0x666)

14745 (90% of 2^14 counts or 0x3999)

40 (0x28), 56 (0x38), 72 (0x48), 88 (0x58), 104 (0x68), 120 (0x78)

SYMBOL

MIN

MAX

UNITS

Analog Supply Voltage to Gnd

VDD

2.7

5.5

V

High-level input voltage

VIH

0.8 × VDD

VDD

V

Low-level input voltage

VIL

0

0.2 × VDD

V

High-level output voltage

VOH

VDD - 0.2

-

V

Low-level output voltage

VOL

-

0.2

V

Output Sourcing Current

IOH_SDA

-1.9

-4.8

mA

Output Sink Current

IOL_SDA

2.3

6.2

mA

200

pF

PARAMETER

Load Capacitance at SDA (@ 400 kHz)

CSDA

Pull-up Resistor

RI2C_PU

Input Capacitance (each pin)

CI2C_IN

Ω

500

10

pF

fSCL

100

400

kHz

tHDSTA

0.1

-

µs

Minimum SCL clock low width 1)

tLOW

0.6

µs

Minimum SCL clock high width 1)

tHIGH

0.6

µs

Start condition setup time relative to

SCL edge

tSUSTA

0.1

µs

Data hold time on SDA relative to SCL

edge

tHDDAT

0

µs

Data setup time on SDA relative to SCL

edge

tSUDAT

0.1

µs

Stop condition setup time on SCL

tSUSTO

0.1

µs

tBUS

2

µs

SCL clock frequency

START condition hold time relative to

SCL range

Bus free time between stop condition

and start condition

1) Combined low and high widths must equal or exceed minimum SCLK period.

Page 4

Copyright © 2018 Sensata Technologies, Inc.

www.sensata.com

�I2C TIMING DIAGRAM

Note

There are three adjustments to the I2C implementation compared with the original I2C™ protocol:

• Sending a start-stop condition without any transitions on the CLK line (no clock pulses in between) creates a communication error for the next

communication, even if the next start condition is correct and the clock pulse is applied. An additional start condition must be sent, which results in

restoration of proper communication.

• The restart condition—a falling SDA edge during data transmission when the CLK clock line is still high—creates the same situation. The next

communication fails, and an additional start condition must be sent for correct communication.

• A falling SDA edge is not allowed between the start condition and the first rising SCL edge. If using an I2C™ address with the first bit 0, SDA must

be held low from the start condition through the first bit.

Page 5

Copyright © 2018 Sensata Technologies, Inc.

www.sensata.com

�SPI COMMUNICATION

Output Packet with Positive Edge Sampling

Packet = [ {S(1:0), B(13:8)}, {B(7:0)}, {T(10:3)}, {T(2:0),xxxxx}] Where

S(1:0) = Status bits of packet (normal, command, busy, diagnostic)

B(13:8) = Upper 6 bits of 14-bit bridge data

B(7:0) = Lower 8 bits of 14-bit bridge data

T(10:0) = NOT corrected temperature data (mask out or terminate read early)

Output

Signal Resolution

12 Bits (11 bits minimum for 0-2” H2O and 0-5 mBar range)

Update Rate

0.5 ms

Digital Count at 0% Pressure

Digital Count at 100% Pressure

1638 (10% of 214 counts or 0x666)

14746 (90% of 214 counts or 0x3999)

SYMBOL

MIN

MAX

UNITS

Analog Supply Voltage to Gnd

VDD

2.7

5.5

V

High-Level Input Voltage

VIH

0.8 × VDD

VDD

V

Low-Level Input Voltage

VIL

0

0.2 × VDD

V

High-Level Output Voltage

VOH

VDD - 0.2

-

V

Low-Level Output Voltage

VOL

-

0.2

V

IOH_MISO

1.9

-4.8

mA

IOH_SS

-0.63

-1.9

mA

IOL_MISO

2.3

6.2

mA

IOL_SS

0.85

3.0

mA

10

pF

PARAMETER

Output Sourcing Current @ VOH

Output Sink Current @ VOL

Input Capacitance (Each Pin)

CI2C_IN

SCLK Clock Frequency (4 MHz clock)

fSCL

50

800

kHz

SCLK Clock Frequency (1 MHz clock)

tSCL

50

200

kHz

SS Drop to First Clock Edge

tHDSS

2.5

µs

Minimum SCL Clock Low Width 1)

tLOW

0.6

µs

Minimum SCL Clock High Width 1)

tHIGH

0.6

µs

Clock Edge to Data Transition

tCLKD

0

Rise of SS Relative to Last Clock Edge

tSUSS

0.1

µs

Bus Free Time Between Rise and Fall of SS

tBUS

2

µs

0.1

µs

1) Combined low and high widths must equal or exceed minimum SCLK period.

Page 6

Copyright © 2018 Sensata Technologies, Inc.

www.sensata.com

�SPI TIMING DIAGRAM

Note

The MISO line is setup to change state on the falling edge of the SCLK clock. Accordingly, the master should sample the data on the rising edge of the

SCLK signal.

I2C/SPI DIAGNOSTIC FEATURES

The P1J offers a full suite of diagnostic features to ensure robust system operation. The diagnostic states are indicated by a transmission of the status

of the 2 MSBs of the bridge high byte data or by a saturated output at 3FFFH.

STATUS BITS (2 MSB’S OF OUTPUT PACKAGE)

Signal resolution

Update rate

Digital count at 0% pressure

Digital count at 100% pressure

DEFINITION

12 Bits (11 bits minimum for 0-2” H2O and 0-5 mBar range)

0.5 ms

1638 (10% of 214 counts or 0x666)

14746 (90% of 214 counts or 0x3999)

When the two MSBs are 11, one of the following faults listed below is indicated.

• Invalid EEPROM signature

• Loss of bridge positive or negative

• Bridge input short

• Loss of bridge source

• Loss of bridge sink

All diagnostics are detected in the next measurement cycle and reported in the subsequent data fetch. Once a diagnostic is reported, the diagnostic

status bits will not change unless both the cause of the diagnostic is fixed and a power-on-reset is performed.

Page 7

Copyright © 2018 Sensata Technologies, Inc.

www.sensata.com

�Example : P1J-2-AX16PA

ORDERING OPTIONS

P1J Pressure sensor 0 -1” H20, I2C 28 Hex digital output, no internal material

seal, barbed tube fitting port with PCB Terminal Pin connection, no external

material seal.

P1J

Family

2

A

X

16

P

A

P1J

Pressure Ranges

2:

2B:

5:

5B:

10:

10B:

5MB:

5MBB:

6MBB:

12.5MB:

12.5MBB:

25MB:

25MBB

0-2” H2O

+/- 2” H2O

0-5” H2O

+/- 5” H2O

0-10” H2O

+/- 10” H2O

0-5 mbar

+/- 5 mbar

+/- 6 mbar

0-12.5 mbar

+/-12.5 mbar

0-25 mbar

+/- 25 mbar

Output Type

8: SPI

A: l2C, 28 HEX

B: l2C, 38 HEX

C: l2C, 48 HEX

D: l2C, 58 HEX

E: l2C, 68 HEX

F: l2C, 78 HEX

Seal Material

X: None

Pressure Connection

16: Barb or Tube Fitting

Built-in Connector

P: PCB Terminal Pins

Seal Material

A: None

Page 8

Copyright © 2018 Sensata Technologies, Inc.

www.sensata.com

�AGENCY APPROVALS & CERTIFICATIONS

Page 9

Revised 2/16/18

Sensata Technologies, Inc. (“Sensata”) data sheets are solely intended to assist designers (“Buyers”) who are developing systems that

incorporate Sensata products (also referred to herein as “components”). Buyer understands and agrees that Buyer remains responsible

for using its independent analysis, evaluation and judgment in designing Buyer’s systems and products. Sensata data sheets have

been created using standard laboratory conditions and engineering practices. Sensata has not conducted any testing other than that

specifically described in the published documentation for a particular data sheet. Sensata may make corrections, enhancements,

improvements and other changes to its data sheets or components without notice.

Buyers are authorized to use Sensata data sheets with the Sensata component(s) identified in each particular data sheet. HOWEVER, NO

OTHER LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE TO ANY OTHER SENSATA INTELLECTUAL PROPERTY RIGHT, AND

NO LICENSE TO ANY THIRD PARTY TECHNOLOGY OR INTELLECTUAL PROPERTY RIGHT, IS GRANTED HEREIN. SENSATA DATA SHEETS

ARE PROVIDED “AS IS”. SENSATA MAKES NO WARRANTIES OR REPRESENTATIONS WITH REGARD TO THE DATA SHEETS OR USE

OF THE DATA SHEETS, EXPRESS, IMPLIED OR STATUTORY, INCLUDING ACCURACY OR COMPLETENESS. SENSATA DISCLAIMS

ANY WARRANTY OF TITLE AND ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, QUIET

ENJOYMENT, QUIET POSSESSION, AND NON-INFRINGEMENT OF ANY THIRD PARTY INTELLECTUAL PROPERTY RIGHTS WITH REGARD

TO SENSATA DATA SHEETS OR USE THEREOF.

All products are sold subject to Sensata’s terms and conditions of sale supplied at www.sensata.com SENSATA ASSUMES NO LIABILITY

FOR APPLICATIONS ASSISTANCE OR THE DESIGN OF BUYERS’ PRODUCTS. BUYER ACKNOWLEDGES AND AGREES THAT IT IS SOLELY

RESPONSIBLE FOR COMPLIANCE WITH ALL LEGAL, REGULATORY AND SAFETY-RELATED REQUIREMENTS CONCERNING ITS PRODUCTS,

AND ANY USE OF SENSATA COMPONENTS IN ITS APPLICATIONS, NOTWITHSTANDING ANY APPLICATIONS-RELATED INFORMATION

OR SUPPORT THAT MAY BE PROVIDED BY SENSATA.

Mailing Address: Sensata Technologies, Inc., 529 Pleasant Street, Attleboro, MA 02703, USA.

Copyright © 2018 Sensata Technologies, Inc.

CONTACT US

Americas

+1 (800) 350 2727

sensors@sensata.com

switches@sensata.com

Europe, Middle East & Africa

+359 (2) 809 1826

pressure-info.eu@sensata.com

Asia Pacific

sales.isasia@list.sensata.com

China +86 (21) 2306 1500

Japan +81 (45) 277 7117

Korea +82 (31) 601 2004

India +91 (80) 67920890

Rest of Asia +886 (2) 27602006

ext 2808

www.sensata.com

�