DA9313

High Efficiency Dual Cell Switched Capacitor Divider

General Description

DA9313 is a high-voltage power converter with a maximum output current of 10 A, suitable for

applications supplied from a dual (2S) Li-ion or Li-polymer stacked cell battery pack, or any input

voltage between 5 V and 10.5 V. The converter operates with efficiency during conversion of up to

98 %. Master/slave operation is offered, where a pair of devices can combine to double the peak

output current to 20 A.

Low profile external components and a minimum PCB footprint allow small circuit implementation in

compact applications. The pass devices are fully integrated therefore no external FETs are needed.

DA9313 utilizes a programmable soft start to limit the inrush current from the input node and secure

a slope controlled activation of the rails. It also implements integrated over-temperature and overcurrent protection for increased system reliability without the need for external sensing components.

Enable, low power mode entry and exit, and power good signals are available at configurable ports

flexibly supporting different applications and power-up or power-down scenarios.

Key Features

■ 2S to 1S power voltage converter

■ VOUT = ½ VIN

■ 5 V to 10.5 V input voltage (2S Li-ion stacked ■ High and flat efficiency, up to 98 %

battery pack)

■ Typical 55 μA quiescent current (standalone)

■ 10 A total output current (standalone)

□ Typical 70 μA total quiescent current in

■ 20 A total output current (master/slave)

master/slave configuration

■ 1.0 mm max external components height

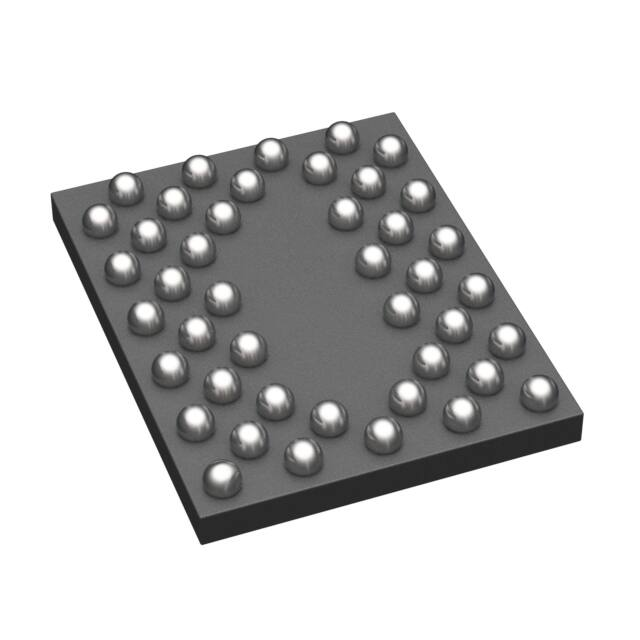

■ Package 43 WLCSP (RouteEasy™ equivalent

to 0.65 mm pitch)

■ Integrated power switches

■ I2C compatible interface

Applications

■

■

■

■

■

Ultrabooks™

Notebook computers

Chromebooks™

Tablets

■

■

■

■

DSLR and mirrorless cameras

Camcorders

Power banks

2S battery applications

Smartphone direct charging

Datasheet

CFR0011-120-00

Revision 3.4

1 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

Contents

General Description ............................................................................................................................ 1

Key Features ........................................................................................................................................ 1

Applications ......................................................................................................................................... 1

Contents ............................................................................................................................................... 2

Figures .................................................................................................................................................. 3

Tables ................................................................................................................................................... 4

1

Terms and Definitions ................................................................................................................... 5

2

References ..................................................................................................................................... 5

3

Functional Block Diagrams .......................................................................................................... 6

4

Pinout ........................................................................................................................................... 10

5

Absolute Maximum Ratings ....................................................................................................... 12

6

Recommended Operating Conditions ....................................................................................... 12

7

Electrical Characteristics ........................................................................................................... 13

7.1 Power-On-Reset, Reference Generation and Supervision ................................................. 13

7.2 Internal Oscillator ................................................................................................................ 14

7.3 Power Voltage Converter .................................................................................................... 14

7.4 VCORE................................................................................................................................ 15

7.5 VDDIO ................................................................................................................................. 16

7.6 Digital I/O Characteristics.................................................................................................... 16

8

I2C Control Bus ............................................................................................................................ 18

9

Typical Characteristics ............................................................................................................... 19

9.1 Standalone Operation ......................................................................................................... 19

9.2 Master/Slave Operation ...................................................................................................... 20

10 Functional Description ............................................................................................................... 22

10.1 Start Up ............................................................................................................................. 22

10.1.1 Standalone Operation .......................................................................................... 22

10.1.2 Master/Slave Operation ....................................................................................... 22

10.2 Interface Functions .............................................................................................................. 23

10.2.1 GPIOs .................................................................................................................. 23

10.2.2 nONKEY .............................................................................................................. 25

10.3 Power Voltage Converter .................................................................................................... 27

10.3.1 PVC Output Voltage ............................................................................................ 27

10.3.2 PVC Start-Up ....................................................................................................... 27

10.3.3 PVC Operating Modes ......................................................................................... 28

10.3.4 PVC Power Down ................................................................................................ 29

10.3.5 PVC Current Limit ................................................................................................ 29

11 Operating Modes ......................................................................................................................... 30

11.1 OFF Mode (HARDRESET) ................................................................................................. 31

11.2 POWER_DOWN Mode ....................................................................................................... 31

11.3 ACTIVE Mode ..................................................................................................................... 31

11.4 SLEEP Mode ....................................................................................................................... 31

11.5 FAULT RECOVERY Mode.................................................................................................. 32

Datasheet

CFR0011-120-00

Revision 3.4

2 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

11.5.1 Input Under-Voltage............................................................................................. 32

11.5.2 Over-Temperature ............................................................................................... 33

11.5.3 PVC Current Limit ................................................................................................ 33

11.5.4 PVC Start-Up Failure ........................................................................................... 33

11.6 VCORE Voltage Regulator ................................................................................................. 33

11.7 VDDIO Generation .............................................................................................................. 33

11.8 Internal Oscillator ................................................................................................................ 34

11.8.1 Internal Temperature Supervision ....................................................................... 34

12 Control Interface .......................................................................................................................... 35

12.1 I2C Communication ............................................................................................................. 35

12.2 I2C Control Bus Protocol ..................................................................................................... 35

13 Register Definitions .................................................................................................................... 38

14 Package Information ................................................................................................................... 50

14.1 Package Outline .................................................................................................................. 50

14.2 Moisture Sensitivity Level.................................................................................................... 51

14.3 WLCSP Handling ................................................................................................................ 51

14.4 Soldering Information .......................................................................................................... 51

15 Layout Guidelines ....................................................................................................................... 52

15.1 Suggested PCB Layout ....................................................................................................... 52

15.2 RouteEasyTM Technology Chart ........................................................................................ 52

16 Application Information .............................................................................................................. 53

16.1 Recommended Capacitors ................................................................................................. 53

17 Ordering Information .................................................................................................................. 53

Figures

Figure 1: Functional Block Diagram Standalone (I2C Not Connected) ................................................. 6

Figure 2: Functional Block Diagram Master/Slave Operation (I2C Not Connected) .............................. 7

Figure 3: Functional Block Diagram Standalone (I2C Connected) ........................................................ 8

Figure 4: Functional Block Diagram Master/Slave Operation (I2C Connected) .................................... 9

Figure 5: Connection Diagram ............................................................................................................ 10

Figure 6: I2C Bus Timing ..................................................................................................................... 18

Figure 7: DA9313 Efficiency Automatic Mode Standalone ................................................................. 19

Figure 8: DA9313 Efficiency Fixed Frequency Mode Standalone....................................................... 19

Figure 9: DA9313 Output Voltage Drop Automatic Mode Standalone ................................................ 20

Figure 10: DA9313 Efficiency Automatic Mode Master/Slave ............................................................. 20

Figure 11: DA9313 Efficiency Fixed Frequency Mode Master/Slave .................................................. 21

Figure 12: DA9313 Output Voltage Drop Automatic Mode Master/Slave ........................................... 21

Figure 13: Master Slave Timing in Automatic Frequency Mode ......................................................... 28

Figure 14: Operating Modes ................................................................................................................ 30

Figure 15: Timing of I2C START and STOP Condition ........................................................................ 36

Figure 16: I2C Byte Write (SDA Line) .................................................................................................. 36

Figure 17: I2C Byte Read (SDA Line) .................................................................................................. 36

Figure 18: I2C Page Read (SDA Line) ................................................................................................. 37

Figure 19: I2C Page Write (SDA Line) ................................................................................................. 37

Figure 20: I2C Repeated Write (SDA Line) .......................................................................................... 37

Figure 21: 43 WLCSP Package Outline Drawing ................................................................................ 50

Figure 22: Suggested PCB Layout ...................................................................................................... 52

Datasheet

CFR0011-120-00

Revision 3.4

3 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

Tables

Table 1: Pin Description ...................................................................................................................... 10

Table 2: Pin Type Definition ................................................................................................................ 11

Table 3: Absolute Maximum Ratings ................................................................................................... 12

Table 4: Recommended Operating Conditions ................................................................................... 12

Table 5: Power-on-Reset, Reference and Supervision Characteristics .............................................. 13

Table 6: Internal Oscillator Characteristics.......................................................................................... 14

Table 7: Power Voltage Converter Characteristics ............................................................................. 14

Table 8: VCORE Characteristics ......................................................................................................... 15

Table 9: VDDIO Characteristics .......................................................................................................... 16

Table 10: Digital I/O Characteristics .................................................................................................... 16

Table 11: I2C Control Bus Characteristics ........................................................................................... 18

Table 12: GPIO Configuration Overview ............................................................................................. 23

Table 13: SLEEP_CTRL Register Configuration ................................................................................ 31

Table 14: Register Map ....................................................................................................................... 38

Table 15: VENDORID 0x01 ................................................................................................................. 38

Table 16: MODE_CTRL 0x02 ............................................................................................................. 39

Table 17: SLEEP_CTRL 0x03 ............................................................................................................. 39

Table 18: PVC_CTRL 0x04 ................................................................................................................. 40

Table 19: GPIO_CTRL 0x05 ............................................................................................................... 40

Table 20: GPIO_CTRL_2 0x06 ........................................................................................................... 41

Table 21: INTERFACE_CTRL 0x07 .................................................................................................... 42

Table 22: NONKEY_CTRL 0x08 ......................................................................................................... 42

Table 23: MASK 0x09.......................................................................................................................... 43

Table 24: STATUS 0x0A ..................................................................................................................... 43

Table 25: EVENT 0x0B ....................................................................................................................... 44

Table 26: FAULT_LOG 0x0C .............................................................................................................. 44

Table 27: LOCK_REG 0x0D................................................................................................................ 44

Table 28: PVC_CONFIG_1 0x0E ........................................................................................................ 45

Table 29: PVC_CONFIG_2 0x0F ........................................................................................................ 45

Table 30: PVC_CONFIG_3 0X10 ........................................................................................................ 46

Table 31: CONFIG_A 0x11 ................................................................................................................. 47

Table 32: CONFIG_C 0x13 ................................................................................................................. 47

Table 33: CONFIG_D 0x14 ................................................................................................................. 48

Table 34: VARIANT_ID 0x30............................................................................................................... 48

Table 35: DEVICE_ID 0x31 ................................................................................................................. 48

Table 36: CUSTOMER_ID 0x32 ......................................................................................................... 48

Table 37: CONFIG_ID 0x33 ................................................................................................................ 49

Table 38: MSL Classification ............................................................................................................... 51

Table 39: Recommended Capacitor Types ......................................................................................... 53

Table 40: Ordering Information ........................................................................................................... 53

Datasheet

CFR0011-120-00

Revision 3.4

4 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

1

Terms and Definitions

CCM

DCM

HBM

OTP

PCB

PG

PMIC

POR

PVC

PWC

2

[1]

Continuous Conduction Mode

Discontinuous Conduction Mode

Human Body Model

One Time Programmable

Printed Circuit Board

Power Good

Power Management Integrated Circuit

Power On Reset

Power Voltage Converter

Power Cycle

References

UM10204 I2C Bus Specification and User Manual

Datasheet

CFR0011-120-00

Revision 3.4

5 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

3

Functional Block Diagrams

CBS_PVC CFLY

BS1

C1P

CFLY

C2N

C1N

CBS_PVC

C2P

BS2

VBAT

VBAT (2S)

VOUT_S

VIN

VOUT

Power

Voltage

Converter

CIN_PVC

CO_PVC

VBAT/2 (1S)

CLOAD

PGND

DA9313

nONKEY/IC_EN

VCORE

ON/OFF

CTRL

PWC/PVC_EN/SLEEP_EN/

GPIO_1

PG/nIRQ/Ext_Clk_Inp/SLAVE_ID

PWC/PVC_EN/SLEEP_EN/

PG/nIRQ/MS_IF

Digital Core

CO_VCORE

OTP

IN/OUT

GPIO_0

IN/OUT

Bias,

Supervision,

Oscillator

AGND

SCL SDA

Figure 1: Functional Block Diagram Standalone (I2C Not Connected)

Datasheet

CFR0011-120-00

Revision 3.4

6 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

CBS_PVC

BS1

C1P

CFLY

CFLY

CBS_PVC

C1N

C2N

C2P

BS2

VBAT

VBAT (2S)

VIN

VOUT_S

CIN_PVC

VBAT/2 (1S)

VOUT

Power

Voltage

Converter

CLOAD

CO_PVC

PGND

SLAVE

nONKEY/IC_EN

nONKEY

PWC/PVC_EN/SLEEP_EN/

PG/nIRQ/Ext_Clk_Inp/SLAVE_ID

DA9313

VCORE

ON/OFF

CTRL

CBS_PVC

CFLY

CFLY

CBS_PVC

CO_VCORE

GPIO_1

IN/OUT

Digital core

BS1

OTP

C1P

C1N

C2N

BS2

C2P

VBAT

GPIO_0

AGND

Bias,

Supervision,

Oscillator

MS_IF

OUT

VOUT_S

VIN

CIN_PVC

VOUT

Power

Voltage

Converter

SCL SDA

CO_PVC

PGND

MASTER

NC

nONKEY

VCORE

GPIO_1

DA9313

VCORE

ON/OFF

CTRL

IN/OUT

Digital core

CO_VCORE

OTP

GPIO_0

IN

AGND

Bias,

Supervision,

Oscillator

SCL SDA

Figure 2: Functional Block Diagram Master/Slave Operation (I2C Not Connected)

Datasheet

CFR0011-120-00

Revision 3.4

7 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

CBS_PVC

BS1

C1P

CFLY

C1N

CFLY

CBS_PVC

C2N

C2P

BS2

VBAT

VBAT (2S)

VOUT_S

VIN

CIN_PVC

VOUT

Power

Voltage

Converter

VBAT/2 (1S)

CO_PVC

CLOAD

PGND

nONKEY/IC_EN

VCORE

DA9313

ON/OFF

CTRL

CO_VCORE

PWC/PVC_EN/SLEEP_EN/ GPIO_1

PG/nIRQ/Ext_Clk_Inp/SLAVE_ID

Digital Core

OTP

Memory

Bias,

Supervision,

Oscillator

Register

Space

IN/OUT

GPIO_0

PWC/PVC_EN/SLEEP_EN/

PG/nIRQ/MS_IF

IN/OUT

AGND

SCL

INOUT

IN

2-Wire Interface

SDA

SCL

SDA

Figure 3: Functional Block Diagram Standalone (I2C Connected)

Datasheet

CFR0011-120-00

Revision 3.4

8 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

CBS_PVC

BS1 C1P

Cfly

Cfly

C2N

C1N

CBS_PVC

C2P

BS2

VBAT

VBAT (2S)

VOUT_S

VIN

CIN_PVC

VOUT

Power

Voltage

Converter

VBAT/2 (1S)

Co_pvc

PGND

nONKEY/IC_EN

VCORE

DA9313

nONKEY

ON/OFF

CTRL

PWC/PVC_EN/SLEEP_EN/PG/nIRQ/

Ext_Clk_Inp/SLAVE_ID

GPIO_1

CLOAD

SLAVE

CBS_PVC Cfly

Co_vcore

Digital

Core

OTP

Memory

BS1 C1P

IN/OUT

GPIO_0

Register

Space

C2N

C1N

C2P

BS2

VOUT_S

VIN

MS_IF

Bias,

Supervision,

Oscillator

CBS_PVC

VBAT

AGND

OUT

Cfly

CIN

IN

INOUT

SCL

VOUT

Power

Voltage

Converter

2-Wire Interface

CO_PVC

PGND

SDA

VCORE

DA9313

NC

nONKEY

MASTER

VCORE

ON/OFF

CTRL

GPIO_1

Digital Core

OTP

Memory

CO_VCORE

Bias,

Supervision,

Oscillator

Register

Space

AGND

IN/OUT

GPIO_0

IN

SCL

SDA

SCL

INOUT

IN

2-Wire Interface

SDA

Figure 4: Functional Block Diagram Master/Slave Operation (I2C Connected)

Datasheet

CFR0011-120-00

Revision 3.4

9 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

4

Pinout

1

2

3

4

5

6

7

8

9

10

11

12

A

VIN

C1P

C1P

BS1

C1N

C1N

B

VIN

C1P

VOUT

VOUT

C1N

PGND

C

nONKEY

VIN

VOUT

VOUT

VOUT

PGND

D

SCL

VCORE

E

GPIO_0

AGND

F

SDA

VOUT_S

VBAT

G

GPIO_1

VIN

VOUT

VOUT

VOUT

PGND

H

VIN

C2P

VOUT

VOUT

C2N

PGND

J

VIN

C2P

C2P

BS2

C2N

C2N

Top View

Power supply

Analog signal

Digital signal

Ground

Figure 5: Connection Diagram

Table 1: Pin Description

Location

Pin Name

Pin Type

(Table 2)

F12

VBAT

AI/P

VBAT input for voltage supervision and supply input voltage for power

voltage converter controller

A1, B2, C3

J1, H2, G3

VIN

PWR

Supply input voltage for power path

A3, B4, A5

C1P

AIO

Flying capacitance 1 positive terminal

A9, B10,

A11

C1N

AIO

Flying capacitance 1 negative terminal

A7

BS1

AIO

Boot strap capacitor positive terminal for power voltage converter

J3, H4, J5

C2P

AIO

Flying capacitance 2 positive terminal

J9, H10, J11

C2N

AIO

Flying capacitance 2 negative terminal

J7

BS2

AIO

Boot strap capacitor positive terminal for power voltage converter

B6, B8, C5,

C7, C9, G5,

G7,G9, H6,

H8

VOUT

AO

Power voltage converter output voltage

Datasheet

CFR0011-120-00

Description

Revision 3.4

10 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

Location

Pin Name

Pin Type

(Table 2)

Description

F10

VOUT_S

AI

Power voltage converter output sense

D12

VCORE

AIO

Main internal supply

C1

nONKEY

AIO

On key signal (active low)

E1

GPIO_0

DIO

General purpose input/output

G1

GPIO_1

DIO

General purpose input/output

F2

SDA

DIO

I2C data. Must be connected to GND if no I2C interface

D2

SCL

DI

I2C clock. Must be connected to GND if no I2C interface

E11

AGND

GND

Analog quiet ground

B12, C11,

G11, H12

PGND

GND

Power ground for power voltage converter

Table 2: Pin Type Definition

Pin Type

Description

Pin Type

Description

DI

Digital Input

AI

Analog Input

DO

Digital Output

AO

Analog Output

DIO

Digital Input/Output

AIO

Analog Input/Output

PWR

Power Supply

GND

Ground

Datasheet

CFR0011-120-00

Revision 3.4

11 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

5

Absolute Maximum Ratings

Table 3: Absolute Maximum Ratings

Parameter

Description

TSTG

Min

Max

Unit

Storage temperature

-65

+165

°C

TA

Operating temperature

-40

+85

°C

TJ

Junction temperature

-40

+125

°C

VDD_LIM

Limiting supply voltage

VBAT, VIN,

-0.3

20

V

VVOUT_LIM

Limiting output voltage

converter voltage

-0.3

5.5

V

VC1P_LIM,

VC2P_LIM

Limiting flying cap positive

pin voltage

C1P, C2P

-0.3

VO_PVC

+ 5.5

V

VC1N_LIM,

VC2N_LIM

Limiting flying cap negative

pin voltage

C1N, C2N

-0.3

+ 5.5

V

VBS1_LIM,

VBS2_LIM

Limiting bootstrap voltage

converter pin voltage

BS1, BS2

-0.3

VC1P/C2P

+ 5.5

V

VCORE_LIM

Limiting VCORE voltage

-0.3

5.5

V

VSDA_LIM

Limiting voltage at SDA

-0.3

5.0

V

VSCL_LIM

Limiting voltage at SCL

-0.3

5.0

V

VPIN_LIM

Limiting voltage at all pins

-0.3

VO_VCORE

+ 0.3

V

RTH

Thermal resistance

(junction to ambient θJA)

36.8

ºC/W

2

kV

VESD_HBM

Note 1

6

Electrostatic discharge

voltage

Conditions (Note 1)

PVC_EN =0

and VBAT, VIN ramp < 1 V/µs

When the voltage converter is

off VC1P = VC2P = VVOUT = 0

Human Body Model (HBM)

Stresses beyond those listed under absolute maximum ratings (Table 3) may cause permanent

damage to the device. These are stress ratings only, so functional operation of the device at these or

any other conditions beyond those indicated in the operational sections of the specification are not

implied. Exposure to absolute maximum rating conditions for extended periods may affect device

reliability.

Recommended Operating Conditions

Table 4: Recommended Operating Conditions

Parameter

Description

Conditions

Min

Typ

Max

Unit

5

7.4

10.5

V

VDD = VBAT

VDD

Supply voltage

IO_MAX_PVC_DC

PVC maximum

continuous output

current

Datasheet

CFR0011-120-00

PVC_EN =1

and VBAT, VIN ramp <

1 V/µs

8.2

Revision 3.4

12 of 54

A

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

7

Electrical Characteristics

7.1

Power-On-Reset, Reference Generation and Supervision

Table 5: Power-on-Reset, Reference and Supervision Characteristics

Unless otherwise noted, the following is valid for TJ = -40 ºC to +125 ºC, VIN = 5 V to 10.5 V for

standalone/master device

Parameter

Description

IDD_PD

Quiescent current in

POWER_DOWN mode

IDD_ACT

Quiescent current in

ACTIVE/SLEEP mode

(standalone)

IDD_ACT_MASTER

Conditions

Min

Typ

Max

Unit

6

µA

PVC enabled in auto.

frequency mode

no load

VDDIO disabled

55

µA

Quiescent current in

ACTIVE mode (master)

PVC enabled in auto.

frequency mode

no load

VDDIO disabled

60

µA

IDD_ACT_SLAVE

Quiescent current (slave)

Master PVC in auto.

frequency mode

no load

VDDIO disabled

10

µA

VTH_LO_POR

Power on reset lower

threshold

Measured @VCORE

VDD decreasing

VTH_HI_POR

Power on reset higher

threshold

Measured @VCORE

VDD increasing

VTH_UVLO_VDD

Under voltage lockout

threshold @ VDD

VDD decreasing

Configurable in 50 mV

steps (Note 1)

(VBAT_UV_CRIT)

VTH_UVLO_ACC

Under voltage lockout

threshold accuracy

VHYST_UVLO_VDD

Under voltage lockout

hysteresis @ VDD

Configurable in 50 mV

steps (VBAT_UV_HYS)

50

VTH_WARN

Under voltage warning

threshold

VDD decreasing

Configurable in 200 mV

steps (VBAT_UV_WARN)

VTH_WARN_ACC

Under voltage warning

threshold accuracy

VTH_PG_PVC

Power voltage converter

power good threshold

VTH_PG_ACC

Power voltage converter

power good threshold

accuracy

VHYST_PG_PVC

Power voltage converter

power good hysteresis

TTH_WARN

(Note 2)

Thermal warning

threshold temperature

110

125

140

°C

TTH_CRIT

(Note 2)

Thermal critical threshold

temperature

125

140

155

°C

tACTIVE

Time to ACTIVE from

3.5

ms

Datasheet

CFR0011-120-00

2.8

V

3.7

V

6.15

V

+2

%

400

mV

5.2

6.6

V

-2

+2

%

5.0

V

+2

%

4.6

5.0

-2

Configurable in 100 mV

steps (PVC_PG_ADJ)

2.5

200

3.0

-2

100

NONKEY_MODE= 0

Revision 3.4

13 of 54

1.5

mV

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

Parameter

tEN

Description

Conditions

OFF mode

AUTOBOOT = 1

Time to ACTIVE from

POWER_DOWN mode

NONKEY_MODE= 1

after IC_EN asserted

NONKEY_DEBOUNCE =

001

Note 1

PVC requires 5.0 V minimum setting for correct operation.

Note 2

Thermal thresholds are non-overlapping.

7.2

Min

Typ

Max

Unit

500

µs

Internal Oscillator

Table 6: Internal Oscillator Characteristics

Unless otherwise noted, the following is valid for TJ = -40 ºC to +125 ºC, VDD = 5 V to 10.5 V

Parameter

Description

fOSC

Internal oscillator frequency

fOSC_ACC

Internal oscillator frequency

accuracy

7.3

Conditions

Min

Typ

Max

6

After trimming

-5

Unit

MHz

+5

%

Power Voltage Converter

Table 7: Power Voltage Converter Characteristics

Unless otherwise noted, the following is valid for TJ = -40 ºC to +125 ºC, VDD = 5 V to 10.5 V and

typical external components

Parameter

Description

Conditions

Min

VDD

Supply voltage

VDD = VBAT

5.0

VO_PVC

Power voltage converter

output voltage

IOUT = 0

IO_MAX_PVC

Power voltage converter

maximum output current

ILIM_PVC

Power voltage converter

current limit

ILIM_ACC

Power voltage converter

current limit accuracy

Typ

Max

Unit

10.5

V

50

%

10

11.55

Configurable in 450 mA

steps (PVC_ILIM)

4.8

IO = ILIM_PVC trimming

range

-20

+20

IO = 10 A

-10

+10

A

A

%

80 %

ILIM_PVC

A

2 * 47

µF

4.7

µF

IALARM

Current alarm

CFLY

External flying

capacitors

Nominal (Note 1)

CO_PVC

External output

capacitor

Nominal

CLOAD

External load capacitor

CBS_PVC

External boot strap

capacitors 1 and 2

Nominal

10

nF

CIN_PVC

External decoupling

capacitor

Nominal

2 * 4.7

µF

ISTUP_PVC

Power voltage converter

start-up current

Configurable in 500 mA

steps (I_STUP_PVC)

Datasheet

CFR0011-120-00

47

Revision 3.4

14 of 54

500

470

2000

µF

mA

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

Parameter

Description

Conditions

fSW_PVC

Power voltage converter

switching frequency

Fixed frequency mode

500

kHz

ηpeak

Power converter peak

efficiency

VDD = 7.4 V

fixed frequency mode /

auto. frequency mode

98

%

ηPVC

Power voltage converter

efficiency

VDD = 7.4 V

IOUT = 30 mA to 3 A,

Min

Typ

Max

97.5

Unit

%

auto. frequency mode

VDD = 7.4 V

IOUT = 500 mA to 8 A,

Power voltage converter

efficiency

ηPVC

fixed frequency mode

95

%

95

%

13

µA

IOUT = 10 mA to 5.5 A

auto. frequency mode

VDD = 7.4 V

IOUT = 1 A to 15 A,

Power voltage converter

efficiency (master/slave)

ηPVCMS

fixed frequency mode

IOUT = 10 mA to 10 A

auto. frequency mode

IQ_PVC

PVC quiescent current

VDD = 7.4 V

no load

auto. frequency mode

Effective capacitance must be CFLY ≥ 18 µF @ 5 V, IRMS = 8 A

Note 1

7.4

VCORE

Table 8: VCORE Characteristics

Unless otherwise noted, the following is valid for TJ = -40 ºC to +125 ºC, VDD = 5 V to 10.5 V

Parameter

Description

Conditions

Min

VDD

Supply voltage

VDD = VBAT

5.0

VO_VCORE

Output voltage @

VCORE

IO_VCORE

Max load on VCORE

VO_VCORE_ACC

Accuracy of output

voltage at VCORE

CO_VCORE

External output

capacitance @

VCORE (Note 1)

Note 1

Typ

Max

Unit

10.5

V

4.0

-5

Including voltage and

temperature coefficient

2.2

V

20

mA

+5

%

µF

Effective external capacitance should be min 0.5 μF, max 1.3 μF and is typically 1.0 μF.

Datasheet

CFR0011-120-00

Revision 3.4

15 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

7.5

VDDIO

Table 9: VDDIO Characteristics

Unless otherwise noted, the following is valid for TJ = -40 ºC to +125 ºC, VDD = 5 V to 10.5 V

Parameter

Description

Conditions

Min

Typ

Max

Unit

VDDIO

Internal VDDIO

voltage rail

Internally generated, no

external capacitor

Configurable via

VDDIO_CONF

1.5

1.8

3.3

V

VDDIO_ACC

Accuracy of internal

VDDIO voltage rail

+5

%

7.6

-5

Digital I/O Characteristics

Table 10: Digital I/O Characteristics

Unless otherwise noted, the following is valid for TJ = -40 ºC to +125 ºC, VDD = 5 V to 10.5 V, VDDIO

enabled

Parameter

Description

VIH_ONKEY

HIGH level input

voltage @ pin

nONKEY

VIL_ONKEY

LOW level input

voltage @ pin

nONKEY

VHYS_ONKEY

Conditions

Min

Typ

Max

1.1

V

0.4

Hysteresis voltage

@

Unit

100

V

mV

pin nONKEY

VIH_IC_EN

VIL_IC_EN

RO_PU_GPO

IC_EN

Input HIGH voltage

IC_EN

Input LOW voltage

0.7*VCO

RE

0.3*

VCOR

E

GPO

Pull-down resistor

@ GPI

RI_PU_ONKEY

Pull-up resistor @

nONKEY

V

NONKEY_MODE = 0x1

Pull-up resistor @

RI_PD_GPI

VIH

NONKEY_MODE = 0x1

To VCORE

GPI_0-1, SCL,

SDA,

V

24

kΩ

210

kΩ

21

kΩ

0.7*VDDIO

V

Input HIGH voltage

VIL

GPI_0-1, SCL,

SDA,

Input LOW voltage

VOH

GPO_0-1

Output HIGH

voltage

Datasheet

CFR0011-120-00

0.3*

VDDIO

Push-pull mode

@1 mA

Revision 3.4

16 of 54

0.8*

(VCORE or

VDDIO)

V

V

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

Parameter

Description

Conditions

VOL1

GPO_0-1, SDA,

Output LOW

voltage

VOL3

Max

Unit

@IOL = 1 mA

0.1

V

SDA,

Output LOW

voltage

@IOL = 3 mA

0.24

V

VOL20

SDA

Output LOW

voltage

@IOL = 20 mA

0.4

V

CGPO_LOAD

GPO_0-1

Maximum

capacitive load

50

pF

CIN_I2C

CLK, SDA

Input capacitance

10

pF

tSP

CLK, SDA

Spike suppression

pulse width

50

10

ns

Datasheet

CFR0011-120-00

Min

Typ

2.5

Fast-mode / Fast-mode Plus

High-speed (Hs) mode

Revision 3.4

17 of 54

0

0

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

8

I2C Control Bus

tF

tR

tSU_D

tBUF

70%

SDA

30%

tSU_STA

tH_D

tH_STA

tR

tW_CH

tSP

tF

tSU_STO

70%

SCL

30%

1/fSCL

P

tW_CL

S

Figure 6: I2C Bus Timing

Table 11: I2C Control Bus Characteristics

Unless otherwise noted, the following is valid for TJ = -40 ºC to +125 ºC

Parameter

Description

tBUF

Bus free time from STOP to

START condition

Cb

Bus line capacitive load

Conditions

Min

Max

0.5

Unit

µs

150

pF

1000

kHz

Standard-mode / Fast-mode / Fast-mode Plus

fSCL

Clock frequency @ pin SCL

0 (Note 1)

tSU_STA

START condition set-up time

0.26

µs

tH_STA

START condition hold time

0.26

µs

tW_CL

Clock LOW duration

0.5

µs

tW_CH

Clock HIGH duration

0.26

µs

tR

Rise time @ pin SCL and SDA

Input requirement

1000

ns

tF

Fall time @ pin SCL and SDA

Input requirement

300

ns

tSU_D

Data set-up time

50

ns

tH_D

Data hold time

0

ns

High-Speed Mode

fCLK_HS

Clock frequency @ pin SCL

0 (Note 1)

tSU_STA_HS

START condition set-up time

160

ns

tH_STA_HS

START condition hold time

160

ns

tW_CL_HS

Clock LOW duration

160

ns

tW_CH_HS

Clock HIGH duration

60

ns

tR_HS

Rise time @ pin SCL and SDA

Input requirement

160

ns

tF_HS

Fall time @ pin SCL and SDA

Input requirement

160

ns

tSU_D_HS

Data set-up time

10

ns

tH_D_HS

Data hold time

0

ns

tSU_STO_HS

STOP condition set-up time

160

ns

Note 1

3400

kHz

Maximum clock period is 38 ms if OTP control I2C_TO_EN is enabled.

Datasheet

CFR0011-120-00

Revision 3.4

18 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

9

Typical Characteristics

9.1

Standalone Operation

ηPVC (%)

100

98

96

94

92

90

88

86

84

82

80

1

10

VDD = 5.0V

100

VDD = 7.4V

1000

10000 IO (mA)

VDD = 10.5V

Figure 7: DA9313 Efficiency Automatic Mode Standalone

ηPVC (%)

100

90

80

70

60

50

40

30

20

10

0

1

10

VDD = 5.0V

100

1000

VDD = 7.4V

VDD = 10.5V

10000 I (mA)

O

Figure 8: DA9313 Efficiency Fixed Frequency Mode Standalone

Datasheet

CFR0011-120-00

Revision 3.4

19 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

VO_PVC (V)

3.70

3.65

3.60

3.55

3.50

3.45

1

10

100

1000

10000 ILOAD (mA)

VDD = 7.4V

Figure 9: DA9313 Output Voltage Drop Automatic Mode Standalone

9.2

Master/Slave Operation

ηPVC (%)

100

98

96

94

92

90

88

86

84

82

80

1

10

VDD = 5.0V

100

VDD = 7.4V

1000

10000

IO (mA)

VDD = 10.5V

Figure 10: DA9313 Efficiency Automatic Mode Master/Slave

Datasheet

CFR0011-120-00

Revision 3.4

20 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

ηPVC (%)

100

90

80

70

60

50

40

30

20

10

0

1

10

VDD = 5.0V

100

1000

VDD = 7.4V

VDD = 10.5V

10000

IO (mA)

Figure 11: DA9313 Efficiency Fixed Frequency Mode Master/Slave

VO_PVC (V)

3.70

3.65

3.60

3.55

3.50

3.45

1

10

100

1000

IO (mA)

10000

VDD = 7.4V

Figure 12: DA9313 Output Voltage Drop Automatic Mode Master/Slave

Datasheet

CFR0011-120-00

Revision 3.4

21 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

10 Functional Description

DA9313 is a 2S compliant high-voltage power converter that generates an unregulated 1S output

voltage (VOUT) of half of VIN using a capacitive interleaved charge-pump divider. VOUT is a 10 A peak

current output in standalone configuration and 20 A peak current when driven from two DA9313

chips paired in master/slave configuration.

Host communication is not required for operation with OTP loading to configure DA9313 on start-up.

However, an I2C interface is available for host configuration of the register map if required. In

addition, the GPIOs can be configured as nIRQ for fault signaling and recovery. An internal LDO can

be enabled to supply VDDIO if required.

10.1 Start Up

DA9313 is OTP configured as a standalone or master/slave variant. The OTP variants are described

in a separate document.

10.1.1

Standalone Operation

DA9313 starts as a standalone device as default, when master/slave operation is not enabled

(MSTSLV_IF_EN bit is set to 0).

On battery insertion the full OTP content is loaded to the register map. DA9313 self-checks that the

system is stable and then proceeds to ACTIVE Mode or POWER_DOWN Mode as configured by the

AUTOBOOT bit.

POWER_DOWN mode is an ultra-low power state of the system implemented to extend the shelf life

of applications with a battery connected during shipping and before first user boot. DA9313 can be

brought from POWER_DOWN mode to ACTIVE mode via a user press of the nONKEY pin (the user,

or external IC, activated power on/off button). Once in ACTIVE mode the system will perform as

configured in either automatic or fixed frequency mode, see section 10.3.3.

To ensure minimal quiescent current requirements the oscillator is enabled only on demand, see

section 11.8. If necessary, the system can safely transfer clocking from the internal oscillator to an

external clock (within the specified operating frequency, see Table 6) via GPIO configuration, see

section 10.2.1.4.

DA9313 responds to critical faults by power cycling the device to protect circuitry, see section 11.5.

10.1.2

Master/Slave Operation

DA9313 starts in master/slave mode when MSTSLV_IF_EN bit is set to 1. GPIO_0 operates as the

master/slave interface (MS_IF) and is pulled down internally. On the master device, GPIO_1 should

not be driven externally. To configure the device as slave, GPIO_1 should be tied to VCORE of the

slave device, see Figure 2. DA9313 will remain in this state unless a cold boot is performed by

removing the battery.

The master takes control over the slave in such a way that the slave always operates in

POWER_DOWN Mode.

Datasheet

CFR0011-120-00

Revision 3.4

22 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

10.1.2.1

Master Operation

In master operation, GPIO_0 operates as the master slave interface (MS_IF) and provides the PVC

phase and enable/disable sequencing controls from the master to the slave. The start-up time is

extended to ensure that the slave device completes the cold boot to POWER_DOWN mode

sequence. Once the slave device has entered POWER_DOWN Mode, the master device enters

ACTIVE Mode and GPIO_0 is configured as a push-pull GPO for use as a master/slave interface

(MS_IF).

After the master device has entered ACTIVE mode, the master PVC triggers the slave PVC over the

MS_IF. GPIO_1 is functional in the master and can be configured via I2C.

NOTE

All master IOs, GPIO_1 and I2C, are supplied from VCORE in master mode not VDDIO. Thus I2C

communications are only possible if host I2C IOs also run from a 4 V supply, or are externally level shifted.

10.1.2.2

Slave Operation

When the device is operating as slave, it goes directly to POWER_DOWN Mode. There is no

communication to the slave (slave I2C lines are grounded) and the master controls the slave PVC

directly via MS_IF.

10.2 Interface Functions

DA9313 incorporates two general purpose input/output pins (GPIOs) and a dual mode onkey

(nONKEY) pin. Functions are assigned to the GPIOs via GPIO_CTRL and GPIO_CTRL_2 registers

and to nONKEY via NONKEY_MODE in the MODE_CTRL register.

Table 12: GPIO Configuration Overview

GPIO

Input Functionality

Output Functionality

Alternative Functionality

GPIO_1

GPI (Note 1)

PVC_EN

GPO (Note 1)

PG

Digital clock input (Ext_Clk_Inp)

SLAVE_ID

SLEEP_EN

PWC

nIRQ (Note 1)

GPI (Note 1)

PVC_EN

GPO (Note 1)

PG

SLEEP_EN

PWC

nIRQ (Note 1)

GPIO_0

Note 1

10.2.1

Master/slave control interface (MS_IF)

Valid when I2C is enabled

GPIOs

A power good (PG) indicator can be routed to either GPIO for host power up sequencing. The power

voltage converter enable, disable, and status field, PVC_EN, can be controlled via I2C or GPI. The

system controller can also be moved to a configurable SLEEP mode via I2C or GPI control.

NOTE

When DA9313 is in master/slave mode all GPI’s must be referenced to VCORE.

10.2.1.1

PVC Enable

The PVC can be disabled by an external PMIC (supplied from a different rail to the DA9313 PVC

output). This function is only provided in ACTIVE Mode and SLEEP Mode when VDDIO_EN bit is

high.

Either GPIO_1 or GPIO_0 can be configured as a PVC_EN pin via the GPIO_CTRL register,

GPIO_1_PIN and GPIO_0_PIN. The PVC_EN pin controls the PVC_EN bit in the PVC_CTRL

Datasheet

CFR0011-120-00

Revision 3.4

23 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

register, allowing read-back of the current setting. The PVC_EN bit can also be controlled over I2C

when not set to be driven from GPIO_1 or GPIO_0.

10.2.1.2

SLEEP Enable

In order to reduce power consumption to a minimum, the host processor can send DA9313 into

SLEEP Mode. SLEEP mode is a configurable mode with configuration via the SLEEP_CTRL register.

This function is available in ACTIVE Mode and SLEEP mode when VDDIO_EN bit is high.

Any GPI pin can be configured as SLEEP_EN via the GPIO_1_PIN and GPIO_0_PIN bits. The

SLEEP_EN pin controls the SLEEP status bit in the MODE_CTRL register allowing read-back of the

current setting. The SLEEP bit can also be controlled over I2C when not set to be driven from GPI,

see section 11.4.

10.2.1.3

Power Cycle

The power cycle (PWC) input allows the host to perform a power cycle of DA9313 with OTP reload.

This function is provided in ACTIVE Mode and SLEEP Mode when VDDIO_EN bit is high.

Any GPI pin can be configured as PWC via the GPIO_1_PIN and GPIO_0_PIN bits. After PWC

assertion DA9313 de-asserts the power good (PG) pin for 10 µs and then initiates a power cycle.

The GPI_RESET bit is set in the FAULT_LOG for host read-back following power cycle back to

ACTIVE mode.

10.2.1.4

Clock Input

GPIO_1 supports the connection of an external oscillator delivering the target 6 MHz, see Table 6, to

the system. This requires that GPIO_1 is selected for external clock input (Ext_Clk_Inp) via

GPIO_1_PIN. The GPI does not generate any event in this case.

The switch over from the internal to external clock occurs on the falling edge of the clock. If the

external clock is not present, a clock detect switches control to the internal clock. In this case, I 2C

communication is possible.

CAUTION

Removing an external clock without first reverting the internal clocking GPI setting may damage the device.

10.2.1.5

Output Ports

Output ports (GPOs) are supplied from the internal rail (VCORE or VDDIO) and can be configured to

be open drain or push-pull (selected via GPIO_1_MODE or GPIO_0_MODE). If a GPO is used as a

push-pull driver VDDIO has to be enabled. GPOs can also be supplied from an external rail by

disabling the internal 20 kΩ pull-up resistor in open-drain mode.

If the output ports are defined as general purpose outputs (GPOs), the low/high level is defined in

register bits GPIO_1_TYPE or GPIO_0_TYPE. If the output ports are associated to power good

(PG), defined by GPIO_1_PIN and GPIO_0_PIN, the GPIO_1_TYPE or GPIO_0_TYPE fields

indicates the active low/high characteristics.

NOTE

In master/slave mode, with GPIO_1 operating in open drain with an external pull-up, the pull-up resistor must

be > 820 kΩ to prevent a false SLAVE_ID recognition.

Datasheet

CFR0011-120-00

Revision 3.4

24 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

10.2.1.6

Power Good Indication

Power good (PG) voltage monitoring at the PVC output can be enabled. The PG function monitors

the VOUT rail and informs the host processor about a power cycle in advance of the power cycle

occurring. PG indication is selected via GPIO_1_PIN or GPIO_0_PIN .

The voltage monitoring threshold can be configured between 2.5 V and 5 V in 100 mV steps via

PVC_PG_ADJ. When the voltage drops below the VTH_PG_PVC threshold, the event E_PVC_PG is

generated and the PG pin is de-asserted. Active level is configurable via GPIO_0_TYPE.

After an under voltage condition has been triggered, the indicator will return back to PG after the

output voltage has recovered above VTH_PG_PVC + VHYS_PG_PVC, see Table 5.

When a power cycle is initiated the PG will be always be de-asserted for 10 µs in advance of the

power cycle occurring before exiting ACTIVE or SLEEP mode.

10.2.1.7

nIRQ

GPIO_0 and GPIO_1 both support an nIRQ function that indicates that an interrupt causing event

has occurred. The related event and status information, such as warnings about temperature and

voltages, over-current fault conditions or status changes at GPI ports, is available in the EVENT and

STATUS registers.

The nIRQ output is enabled via GPIO_1_PIN or GPIO_0_PIN.

nIRQ can be push-pull or open drain, selected via GPIO_1_TYPE or GPIO_0_TYPE, and can be

active LOW or active HIGH.

The EVENT registers hold information about the events that have occurred. Events are triggered by

a status change at the monitored signals. When an event bit is set the nIRQ signal is asserted,

unless this interrupt is masked by the appropriate in MASK register.

The masked bits only mask the nIRQ assertion, and do not suppress the event generation. The nIRQ

is not released until all event bits are cleared by writing a 1 to the appropriate EVENT register bits.

New events which have occurred during the reading of the EVENT register are held until the register

has been cleared; ensuring that host processor does not miss them.

10.2.2

nONKEY

The nONKEY pin can be configured via the NONKEY_MODE register. It can operate as a user

power button or as a level sensitive IC_EN pin, which allows the DA9313 state to be controlled from

the GPO of another device.

The nONKEY input port is always enabled to ensure that activities which should generate an

application wake-up or power down are always captured. The level of the debounced signal is

provided by the status flag nONKEY.

NOTE

The nONKEY port should be never externally overdriven to a voltage higher than VCORE.

10.2.2.1

Event Generation

In ACTIVE or SLEEP modes a press of nONKEY causes an IRQ assertion if not suppressed via the

interrupt mask M_nONKEY.

The event can be generated from either the rising or the falling edge of the nONKEY pin via

NONKEY_PIN setting:

0: An E_nONKEY event is generated when the debounced signal from port nONKEY goes low

(asserting edge). If not masked, an interrupt is signaled to the host via nIRQ.

1: An E_nONKEY event is generated when the debounced signal from port nONKEY goes high (de

asserting edge). If not masked, an interrupt is signaled to the host via nIRQ.

Datasheet

CFR0011-120-00

Revision 3.4

25 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

10.2.2.2

Press Detection

Host notification of button presses via a maskable interrupt is available from the STATUS register,

field nONKEY. A configurable long press can be used to trigger a power cycle of the device as a

blue-screen lock up escape.

10.2.2.3

Wake Up

When DA9313 is in POWER_DOWN mode a user press of the nONKEY, for longer than the

configured debounce setting in NONKEY_DEBOUNCE, triggers a transition to ACTIVE mode.

NOTE

Subsequent de-asserting edges of the nONKEY following a wake-up from POWER_DOWN require a release of

the external button and new assertion to generate subsequent events.

10.2.2.4

Long Press

When DA9313 is in ACTIVE mode, a user press of the nONKEY, for longer than the configured

debounce setting in NONKEY_DEBOUNCE plus the KEY_DELAY and SHUT_DELAY settings,

triggers a power cycle which results in the device entering ACTIVE or POWER_DOWN mode

(depending on the settings in NONKEY_CYCLE). If a long press of nONKEY has been detected,

DA9313 will power cycle in 1 s unless this bit is cleared by the host, see E_KEY_RESET.

10.2.2.5

External IC Enable

The operation of the pin as an external IC enable (IC_EN) is configured in OTP via

NONKEY_MODE. In this mode, the pin must be driven externally to VCORE or pulled to ground. The

level of the nONKEY port controls transitions between ACTIVE (IC_EN high) and POWER_DOWN

(IC_EN low).

● For MSTSLV_IF_EN = 0 and 1, if NONKEY_MODE = 1 (IC_EN mode) then AUTOBOOT must be

set to 0.

● For MSTSLV_IF_EN = 1, if NONKEY_MODE = 1 (IC_EN mode) then the nONKEY pin of the

slave must be connected to PGND.

During cold boot it is the responsibility of the host processor and the external application to make

sure that the level of IC_EN is correct. There should be external resistors, in the 100 kΩ range,

defining the correct level when the port is not actively driven.

The FAULT_TIME system controller state is bypassed when moving from ACTIVE to

POWER_DOWN due to IC_EN de assertion but is still enabled for fault handling.

NOTE

When NONKEY is set as IC_EN, SLEEP mode has a restricted usage. System behavior is only guaranteed if

SLEEP mode is entered / exited via I2C/GPI while IC_EN is high, using SL_nONKEY_CONT as SLEEP mode

exit is invalid as this will bring chip to POWER_DOWN on the de-asserting edge of IC_EN

Datasheet

CFR0011-120-00

Revision 3.4

26 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

10.3 Power Voltage Converter

The high efficiency 2S to 1S power voltage converter (PVC) is capable of supplying multiple 1S

voltage rails with up to 10 A output current. The dual phase interleaved operation ensures an almost

constant input current, thereby highly improving the application design against noise.

10.3.1

PVC Output Voltage

The PVC can be configured via OTP or I2C and outputs a non-regulated voltage which is nominally

half of the input voltage, in the case where no load is applied. When a current (I OUT) is drawn at the

VOUT node and the PVC is switching at frequency of fSW_PVC, the output voltage is determined as:

VOUT =

V IN

− R EQ I OUT

2

Where:

● REQ is a function of the sum of all resistances in the input/output power path (including the power

device’s on-resistance and the PCB routing resistance) as well as the switching frequency, C FLY

and PCB parasitics.

The voltage ripple at VOUT can be first order approximated as the voltage drop due to the discharge of

the CFLY capacitor in half of the period at an fSW_PVC switching frequency, plus the discharge voltage

of the output VOUT capacitor during a typical 30 ns short dead time for phase switch. In addition, the

PVC provides an optional hardware enable/disable via selectable GPI, configured via the PVC_EN

register field, see section 10.2.1.1.

10.3.2

PVC Start-Up

The PVC can be OTP configured to enable on entry to ACTIVE mode and to run in automatic (mixed

DCM and CCM based on load sensing) or in fixed frequency (CCM). Alternatively the PVC can be

set to CCM in ACTIVE mode and to run in automatic in SLEEP mode. See section 10.3.3.

During PVC start-up, the PVC does not switch and the flying capacitors CFLY are connected in

parallel to the output capacitor CLOAD. An internal current source charges the capacitors up to a

voltage value close to the target average in normal operation. The internal current source can be

configured from 500 mA to 2000 mA via I_STUP_PVC.

At the end of the start-up phase the normal switching operation of the PVC is restored.

NOTE

A start-up phase with an output load greater than I_STUP_PVC will not be successful. The PVC has a ramp-up

timer which checks the ramp-up happens in approx. 20 ms. If the output voltage has not reached a value close

to VDD/2 at this time this indicates a failure condition and the regular switching is not started. This is reported as

PVC_RAMPUP in FAULT_LOG.

CAUTION

To avoid damage to the device, the PVC output must reach VDD/2 – 80 mV before a load greater than half of

I_STUP_PVC can be applied to its output.

Datasheet

CFR0011-120-00

Revision 3.4

27 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

10.3.3

PVC Operating Modes

10.3.3.1

Standalone Mode

When the PVC is enabled, the operating mode is defined by the PVC_MODE register field. The PVC

operates either in fixed frequency (PVC_MODE= 0) or in automatic frequency mode (PVC_MODE=

1).

In automatic frequency mode, the switching frequency is not always constant, see Figure 13. The

PVC operates in continuous conduction mode (CCM) at high loads and moves to discontinuous

conduction mode (DCM) as soon as the load becomes lower than a certain threshold.

● When the load decreases, the VOUT voltage increases over the VPVC_DROP threshold and the PVC

moves from CCM to DCM.

● When the load increases again and the VOUT voltage decreases by VPVC_HYST below VPVC_DROP

and the PVC moves back from DCM to CCM.

Operating in automatic frequency mode extends the efficiency range to low levels of output loads,

enabling the PVC to supply a low voltage PMIC in low power mode over a long period.

VBAT/2

Load Decreasing

Sudden Load

Applied

Light Load

Load Decreasing

Vpvc_drop

DCM threshold

VOUT

DCM request

skip

Sudden Load

skip

Vpcv_hyst

Vpvc_ms_drop

skip

Unloading

CCM Request

Vpvc_ms_hyst

MSI

Master :CCM

Slave : OFF

Master :DCM

Slave : OFF

Master: CCM

Slave: OFF

Master : CCM

Slave : ON

Master: CCM

Slave: OFF

Master: DCM

Slave : OFF

Figure 13: Master Slave Timing in Automatic Frequency Mode

10.3.3.2

Master/Slave Operation

The master device behaves in the same way as a standalone device, see section 10.3.3.1, with

additional VOUT monitoring at VMSI level (see Note below). This monitoring is used to trigger the slave

device via the master/slave interface (MS_IF). The level at which the master triggers the slave is

defined in PVC_MS_DROP.

When the VOUT voltage decreases beyond VMSI due to progressive output loading, the master

DA9313 enables the slave DA9313 over MS_IF.

When the VOUT voltage increases above VMSI + VPVC_MS_HYST (defined in PVC_MS_HYST), the master

DA9313 disables the slave DA9313 over MS_IF.

Disabling the master PVC triggers a shutdown of the slave PVC over MS_IF.

NOTE

VMSI = VCCM – VPVC_MS_DROP

Where:

●

●

VCCM = (VBAT/2 - VPVC_DROP - VPVC_HYSTMAX)

VPVC_HYSTMAX is a constant value of 30 mV

Datasheet

CFR0011-120-00

Revision 3.4

28 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

10.3.4

PVC Power Down

During PVC power down, the PVC does not switch and the flying capacitors C FLY are connected in

parallel to the output capacitor CLOAD. An internal pull-down is used to ensure the PVC is in a defined

start condition. When the output voltage drops below the threshold of 1 V, the PVC can accept a restart.

In master/slave configuration, power down is synchronized by the master/slave interface (MS_IF) in a

way where both devices connect the flying capacitors (CFLY) in parallel to the output capacitor (CLOAD)

at the same time. These capacitors are discharged by the master.

10.3.5

PVC Current Limit

The configurable integrated current limit is aimed to protect DA9313’s power stages and the external

components from excessive current.

When hitting the current limit ILIM_PVC (configured in PVC_ILIM) DA9313 enters FAULT RECOVERY.

DA9313 provides an indication that the system current is approaching the critical limit, before hitting

the current limit itself, allowing an active host processor to take some countermeasures.

When the warning threshold IALARM is reached the event E_PVC_OC_WARN is generated. The status

of the over-current alarm comparator can be read back on FAULT_LOG via the I2C control interface.

Datasheet

CFR0011-120-00

Revision 3.4

29 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

11 Operating Modes

OFF mode

VCORE ≥ VTH_HI_POR

Fault no longer present

Power cycle to

POWER_DOWN from ACTIVE

or SLEEP mode?

FAULT RECOVERY

mode

Yes

No

REGMAP_RESET

Safety pause complete

OTP_LOAD

Cold boot &

AUTOBOOT = 0?

FAULT_TIME

Yes

POWER_DOWN

mode

No

Power cycle from:

critical fault

SOFT_RESET

or LONGPRESS

ACTIVE mode

SLEEP_EN

!IC_EN

!SLEEP_EN

SLEEP mode

IC_EN or

NONKEY WAKE press

Figure 14: Operating Modes

Datasheet

CFR0011-120-00

Revision 3.4

30 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

11.1 OFF Mode (HARDRESET)

DA9313 is in OFF mode without being supplied or with a low supply, when VO_VCORE ≤ VTH_LO_POR.

The only circuitry enabled is the VCORE regulator and its voltage supervision. The digital core is kept

reset in OFF mode.

When VO_VCORE ≥ VTH_HI_POR DA9313 transitions from OFF mode to ACTIVE mode or to

POWER_DOWN mode, depending on the AUTOBOOT setting.

11.2 POWER_DOWN Mode

The POWER_DOWN mode is the lowest quiescent current operating mode with a valid input voltage.

It can support a shelf mode for applications with integrated battery packs, which allows connecting

pre-charged batteries before the user enables the device for the first time.

PVC, oscillator, and analog references are disabled, only the nONKEY sense circuit is left running on

VCORE. A nONKEY wake press will transition the system to ACTIVE, see section 10.2.2.3.

11.3 ACTIVE Mode

ACTIVE mode is the main operating mode of DA9313 and is entered into after OTP load. The PVC is

then automatically turned on and operates in the configured mode.

NOTE

The host processor should wait for DA9313 to reach the ACTIVE mode following a start-up from OFF or

POWER_DOWN before starting the I2C communication with DA9313, see Table 5 for timing details.

After the application starts up, the host processor should always read the FAULT_LOG register to

determine which one of the following sequences occurred before ACTIVE mode was enabled:

●

●

●

●

●

from a fault condition (dedicated fault bit)

from OFF during cold boot (POR bit)

from power cycle due to long press of nONKEY

from power cycle initiated via SOFTRESET write

from power cycle initiated by PWC

11.4 SLEEP Mode

SLEEP mode is used to support application low power modes with lower quiescent current. The

mode can be entered into and exited from by register write or via GPI. An optional exit via nONKEY

is also supported when VDDIO has been disabled in SLEEP mode.

SLEEP mode is configurable via the SLEEP_CTRL register, see Table 13 for configuration options.

● To enter SLEEP mode via I2C, assert the SLEEP bit in the MODE_CTRL register.

● To enter SLEEP mode via GPI, configure GPIO_1_PIN or GPIO_0_PIN to SLEEP_EN. The level

of the GPI controls entry into SLEEP mode and exit back to ACTIVE mode.

ACTIVE configuration settings are re-applied on exit of SLEEP mode.

Table 13: SLEEP_CTRL Register Configuration

Control bit

Block

PVC_SL

PVC operation in SLEEP mode:

0: no change

1: automatic frequency mode

The PVC is changed to automatic frequency mode (variable frequency).

PVC_MODE setting is overwritten (old value restored at the exit of SLEEP

mode)

Datasheet

CFR0011-120-00

Revision 3.4

31 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

Control bit

Block

PVC_DIS_SL

PVC enable control, in SLEEP mode:

0: no change

1: PVC disabled

The PVC is disabled

PVC_EN setting is overwritten (old value restored at the exit of SLEEP mode)

VDDIO_DIS_SL

Control VDDIO supply enable, in SLEEP mode:

0: no change

1: VDDIO rail disabled.

11.5 FAULT RECOVERY Mode

DA9313 responds to critical under-voltage, over-current, and over-temperature conditions and safely

power cycles the device through FAULT RECOVERY mode. Fault events are captured in the

FAULT_LOG register for host interrogation on reboot and warning levels generate maskable interrupt

events.

FAULT RECOVERY is a temporary mode and is automatically entered and exited depending on fault

condition presence. DA9313 enters FAULT RECOVERY mode from ACTIVE or SLEEP mode. In

POWER_DOWN mode there is no supervision therefore FAULT RECOVERY mode cannot be

entered.

The device waits for a configurable FAULT_TIME, when the PVC is disabled, to ensure discharge of

all critical nodes in the application before any attempt to reboot. DA9313 automatically exits FAULT

RECOVERY mode when the fault condition has expired.

The FAULT_LOG register can be reset by a register write of 1 to the appropriate register bit.

11.5.1

Input Under-Voltage

VBAT voltage is continuously sensed, except in RESET and POWER_DOWN modes, by dedicated

analog circuitry based on two configurable levels: a warning level, VTH_WARN and a shutdown level,

VTH_UVLO_VDD.

The upper comparator triggers a warning if VBAT drops below VTH_WARN. The lower comparator

triggers a fault condition if VBAT drops below VTH_UVLO_VDD.

The VTH_UVLO_VDD voltage threshold is configurable and can be set via VBAT_UV_CRIT_THRSH from

4.6 V to 6.15 V (5.0 V default) in steps of 50 mV.

The VHYST_UVLO_VDD hysteresis can be also be configured via VBAT_UV_HYS from 50 mV to 400 mV

(200 mV default) in steps of 50 mV.

The VTH_WARN voltage threshold is configurable and can be set via VBAT_UV_WARN from 5.2 V to

6.6 V in steps of 200 mV.

To reduce the current consumption of the block only the warning comparator is permanently on, the

shutdown comparator is enabled on demand in the interval where VBAT is below the warning

threshold.

The critical under voltage threshold comparator is also debounced, this guarantees that short spikes

do not trigger the application power-down.

When the warning comparator triggers, the status bit VBAT_WARN is asserted and the event

E_VBAT_WARN is generated. If not masked via M_VBAT_WARN, the output port nIRQ is asserted

(providing a GPIO is configured as nIRQ). The host processor is then informed that the input voltage

level is close to critical and it can take action such as powering down the application.

If the input voltage keeps dropping and the shutdown comparator is triggered the PVC is disabled

and the VBAT_UV_CRIT bit is asserted in FAULT_LOG. When the VBAT voltage recovers over

VTH_UVLO_VDD + VHYST_UVLO_VDD, DA9313 enters ACTIVE mode after having performed an OTP read.

Datasheet

CFR0011-120-00

Revision 3.4

32 of 54

14-Aug-2020

© 2020 Dialog Semiconductor

�DA9313

High Efficiency Dual Cell Switched Capacitor Divider

11.5.2

Over-Temperature

FAULT RECOVERY mode is entered when TJ ≥ TTH_CRIT and is exited when TJ < TTH_CRIT. The

TEMP_CRIT bit is asserted in FAULT_LOG.

11.5.3

PVC Current Limit

When the PVC hits the current limit, FAULT RECOVERY mode is entered and is immediately exited,

because the root cause (current limit reached) is removed when the PVC is disabled. The

PVC_OC_CRIT bit is asserted in FAULT_LOG.

11.5.4

PVC Start-Up Failure

FAULT RECOVERY mode is entered when the PVC has failed its start-up procedure. This occurs

when the output voltage has not reached a voltage close to VDD/2 within approximately 20 ms.