Q40 Sensors dc-Voltage Series

Datasheet

Self-contained, dc-operated sensors

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel

protection. Doing so could lead to serious injury or death.

This device does not include the self-checking redundant circuitry

necessary to allow its use in personnel safety applications. A

sensor failure or malfunction can cause either an energized or deenergized sensor output condition.

Models

Model1

Sensing Mode

Range

LED

Output

Infrared, 950 nm

NPN

Q406E

-

Q40SN6R

Opposed

OPPOSED

Q40SP6R

Q40SN6LP

Q40SP6LP

60 m (200 ft)

P

PNP

NPN

Polarized Retroreflective

6 m (20 ft)

Visible red, 680 nm

PNP

POLAR RETRO

Q40SN6FF200

Q40SN6FF400

Q40SP6FF400

NPN

200 mm (8 in) cutoff

Q40SP6FF200

Fixed Field

400 mm (16 in) cutoff

FIXED-FIELD

Q40SN6FF600

Q40SP6FF600

600 mm (24 in) cutoff

PNP

Infrared, 880 nm

NPN

PNP

NPN

PNP

Fixed-Field Mode Overview

Q40 Series self-contained fixed-field sensors are small, powerful, infrared diffuse mode sensors with far-limit cutoff. The

high excess gain of these sensors makes it possible for them to detect objects of low reflectivity. The fixed-field design

makes them ideal for detecting a part or surface that is directly in front of another surface, while ignoring the surface in

the background.

Installation

In the drawings and discussion in Excess Gain on page 4 and in Background Reflectivity and Placement on page 2,

the letters E, R1, and R2 identify how the sensor’s three optical elements (Emitter “E,” Near Detector “R1,” and Far

Detector “R2”) line up across the face of the sensor. In Figure 1 on page 2, Figure 2 on page 2, and Figure 3 on

page 2, these elements align vertically; in Figure 4 on page 2, they align horizontally. Note how the pattern on the

sensor’s lens helps to define the sensing axis of the sensor (Figure 6 on page 4). The sensing axis becomes important

in situations like those illustrated in Figure 3 on page 2 and Figure 4 on page 2.

1 Standard 2 m (6.5 ft) cable models are listed.

•

To order 9 m (30 ft) cable: add suffix "W/30" (for example, Q406E W/30).

•

To order 4-pin Euro-style QD models: add suffix "Q" (for example, Q406EQ). A model with a QD connector requires a mating cable.

Original Document

116167 Rev. B

14 November 2016

116167

�Q40 Sensors dc-Voltage Series

Background Reflectivity and Placement

Avoid mirror-like backgrounds that produce specular reflections. A false sensor response occurs if a background surface

reflects the sensor’s light more to the near detector (R1) than to the far detector (R2). The result is a false ON condition

(Figure 1 on page 2). To correct this problem, use a diffusely reflective (matte) background, or angle either the sensor

or the background (in any plane) so the background does not reflect light back to the sensor (see Figure 2 on page 2).

Position the background as far beyond the cutoff distance as possible.

An object beyond the cutoff distance, either stationary (and when positioned as shown in Figure 3 on page 2), or

moving past the face of the sensor in a direction perpendicular to the sensing axis, may cause unwanted triggering of the

sensor if more light is reflected to the near detector than to the far detector. The problem is easily remedied by rotating

the sensor 90° (Figure 4 on page 2) to align the sensing axis horizontally. The object then reflects the R1 and R2 fields

equally, resulting in no false triggering. A better solution, if possible, may be to reposition the object or the sensor.

Unwanted triggering of the sensor from an object beyond the cutoff can also be caused by attempting to sense a small

object that is moving perpendicular to the sensor face, or by an object moving through the off-center position shown in

Figure 3 on page 2. Making the object larger, centering the sensor relative to the object, or rotating the sensor to place

the sensing axis perpendicular to the longer dimension of the object (Figure 4 on page 2) will solve the problem.

Cutoff

Distance

Cutoff

Distance

Reflective

Background

R1 = Near Detector

R2 = Far Detector

E = Emitter

Cutoff

Reflective

Background

Fixed Sensing Field

Q40 sensor

Strong

Direct

Reflection

to R1

R1

R2

Core of

Emitted

Beam

E

Q40 sensor

R1

R2

E

Core of

Emitted

Beam

Strong Direct

Reflection

Away

From Sensor

Fixed Sensing Field

Figure 1. Reflective background - problem

R1 = Near Detector

R2 = Far Detector

E = Emitter

Figure 2. Reflective background - solution

Cutoff

Distance

Cutoff

Distance

Q40 sensor

Q40 sensor

R1

R2

E, R2, R1

E

Fixed

Sensing

Field

R1 = Near Detector

R2 = Far Detector

E = Emitter

E = Emitter

R2 = Far Detector

R1 = Near Detector

Reflective

Background

or

Moving Object

Fixed

Sensing

Field

Reflective

Background

or

Moving Object

Figure 4. Object beyond cutoff - solution

Figure 3. Object beyond cutoff - problem

Wiring Diagrams

Cabled Emitters

3

1

2

NPN (Sinking) Outputs

PNP (Sourcing) Outputs

Standard Hookup

Standard Hookup

3

–

10-30V dc

+

–

10-30V dc

+

1

4

2

Load

Load

www.bannerengineering.com - Tel: +1-763-544-3164

1

+

10-30V dc

–

3

4

2

Load

Load

P/N 116167 Rev. B

�Q40 Sensors dc-Voltage Series

Alarm Hookup

NOTE: QD

hookups are

functionally

identical.

1

2

3

–

10-30V dc

+

3

4

Alarm Hookup

+

10-30V dc

–

1

4

Load

2

Alarm

Load

Alarm

Specifications

Output Protection Circuitry

Protected against false pulse on power-up and continuous overload or

short circuit of outputs

Supply Voltage and Current

10 to 30 V dc (10% max. ripple)

Supply current (exclusive of load current):

Emitters: 25 mA

Receivers: 20 mA

Polarized Retroreflective: 30 mA

Fixed-Field: 35 mA

Output Response Time

Opposed mode: 3 ms ON, 1.5 ms OFF

Retro and Fixed-Field: 3 ms ON and OFF

NOTE: 100 ms delay on power-up; outputs

do not conduct during this time.

Supply Protection Circuitry

Protected against reverse polarity and transient voltages

Output Configuration

SPDT solid-state dc switch; Choose NPN (current sinking) or PNP

(current sourcing) models

Light Operate: N.O. output conducts when sensor sees its own (or the

emitter's) modulated light

Dark Operate: N.C. output conducts when the sensor sees dark; the

N.C. (normally closed) output may be wired as a normally open

marginal signal alarm output, depending upon hookup to power supply

(U.S. patent 5087838)

Output Rating

150 mA maximum (each) in standard hookup.

When wired for alarm output, the total load may not exceed 150 mA.

OFF-state leakage current: < 1 microamp at 30 V dc

ON-state saturation voltage: < 1V at 10 mA dc; < 1.5 V at 150 mA

dc

Required Overcurrent Protection

WARNING: Electrical connections must be

made by qualified personnel in accordance

with local and national electrical codes and

regulations.

Overcurrent protection is required to be provided by end product

application per the supplied table.

Overcurrent protection may be provided with external fusing or via

Current Limiting, Class 2 Power Supply.

Supply wiring leads < 24 AWG shall not be spliced.

For additional product support, go to www.bannerengineering.com.

Supply Wiring (AWG)

Required Overcurrent Protection (Amps)

20

5.0

22

3.0

24

2.0

26

1.0

28

0.8

30

0.5

P/N 116167 Rev. B

Repeatability

Opposed mode: 375 μs

Retro and Fixed-Field: 750 μs

Repeatability and response are independent of signal strength

Indicators

Two LEDs (Green and Amber)

Green ON steady: power to sensor is ON

Green flashing: output is overloaded

Amber ON steady: N.O. output is conducting

Amber flashing: excess gain marginal (1 to 1.5x) in light condition

Construction

PBT polyester housing; acrylic lens

Environmental Rating

Leakproof design rated NEMA 6P, IEC IP67. QD Models rated IEC IP69K

per DIN 40050-9.

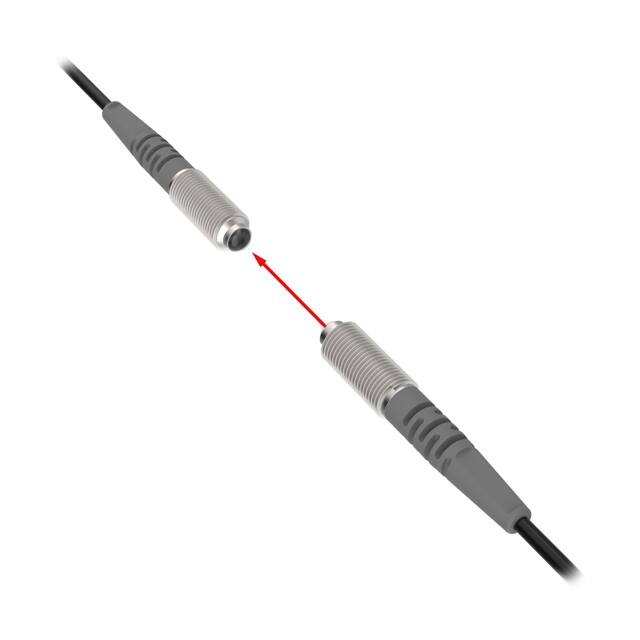

Connections

2 m (6.5 ft) or 9 m (30 ft) attached cable, or 4-pin Euro-style quickdisconnect fitting

Operating Conditions

Temperature: −40 °C to +70 °C (−40 °F to +158 °F)

90% at +50 °C maximum relative humidity (non-condensing)

Vibration and Mechanical Shock

All models meet Mil. Std. 202F requirements. Method 201A (Vibration;

frequency 10 Hz to 60 Hz, max., double amplitude 0.06 inch

acceleration 10G). Method 213B conditions H&I. Shock: 75G with unit

operating; 100G for non-operation

Certifications

www.bannerengineering.com - Tel: +1-763-544-3164

3

�Q40 Sensors dc-Voltage Series

Dimensions

Cabled Models

40.1 mm

(1.58")

50.0 mm

(1.97")

QD Models

46.0 mm

(1.81")

Green LED

Power Indicator

Lens Centerline

50.0 mm

(1.97")

20.1 mm

(0.79")

19.8 mm

(0.78")

Yellow LED

Output Indicator

(Jam Nut Supplied)

19.8 mm

(0.78")

82.5 mm

(3.25")

M30 x 1.5 Thread

2 m (6.5') Cable

M30 x 1.5 Thread

(Jam Nut Supplied)

All measurements are listed in millimeters [inches], unless noted otherwise.

Excess Gain

The excess gain curves for these products are available on the

Banner website. They show excess gain versus sensing distance

for sensors with 200 mm, 400 mm, and 600 mm (8 in, 16 in, and

24 in) cutoffs. Maximum excess gain for all models occurs at a

lens-to-object distance of about 40 mm (1.57 in). Sensing at or

near this distance makes maximum use of each sensor’s available

sensing power.

Receiver

Elements

Near R1

Detector

Cutoff

Distance

Object B

or

Background

Object

A

Lenses

Far

R2

Detector

Backgrounds and background objects must always be placed

beyond the cutoff distance.

The excess gain curves were generated using a white test card of

90% reflectance. Objects with reflectivity of less than 90% reflect

less light back to the sensor, and thus require proportionately

more excess gain in order to be sensed with the same reliability

as more reflective objects. When sensing an object of very low

reflectivity, it may be especially important to sense it at or near

the distance of maximum excess gain.

Emitter

Sensing

Range

Object is sensed if amount of light at R1

is greater than the amount of light at R2

Figure 5. Fixed-field Concept

The effects of object reflectivity on cutoff distance, though small,

may be important for some applications. Sensing of objects of

less than 90% reflectivity causes the cutoff distances to be

“pulled” slightly closer to the sensor. For example, an excess gain

of 1 for an object that reflects 1/10 as much light as the 90%

white card is represented by the heavy horizontal graph line at

excess gain = 10. An object of this reflectivity results in far limit

cutoffs of approximately 190 mm, 250 mm, and 390 mm (7.48

in, 9.84 in, and 15.4 in) for the 200 mm, 400 mm, and 600 mm

(8 in, 16 in, and 24 in) cutoff models, respectively.

For highest sensitivity, the sensor-to-object distance should be

such that the object will be sensed at or near the point of

maximum excess gain. The background must be placed beyond

the cutoff distance. Following these two guidelines makes it

possible to detect objects of low reflectivity, even against close-in

reflective backgrounds.

4

E

R1

R2

Sensing

Axis

E

As a general rule, the most reliable sensing of an

object approaching from the side occurs when the

line of approach is parallel to the sensing axis.

Figure 6. Fixed-field sensing axis

www.bannerengineering.com - Tel: +1-763-544-3164

P/N 116167 Rev. B

�Q40 Sensors dc-Voltage Series

Quick-Disconnect (QD) Cables

4-Pin Threaded M12/Euro-Style Cordsets

Model

Length

MQDC-406

1.83 m (6 ft)

MQDC-415

4.57 m (15 ft)

MQDC-430

9.14 m (30 ft)

MQDC-450

15.2 m (50 ft)

MQDC-406RA

1.83 m (6 ft)

MQDC-415RA

4.57 m (15 ft)

MQDC-430RA

9.14 m (30 ft)

Style

Dimensions

44 Typ.

Straight

M12 x 1

ø 14.5

15.2 m (50 ft)

2

1

3

4

32 Typ.

[1.26"]

30 Typ.

[1.18"]

Right-Angle

MQDC-450RA

Pinout (Female)

1

2

3

4

=

=

=

=

Brown

White

Blue

Black

M12 x 1

ø 14.5 [0.57"]

Banner Engineering Corp. Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of shipment. Banner Engineering Corp.

will repair or replace, free of charge, any product of its manufacture which, at the time it is returned to the factory, is found to have been defective during the warranty

period. This warranty does not cover damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION,

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE

OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL BANNER ENGINEERING CORP. BE

LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER

ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or liabilities relating to any product

previously manufactured by Banner Engineering Corp. Any misuse, abuse, or improper application or installation of this product or use of the product for personal protection

applications when the product is identified as not intended for such purposes will void the product warranty. Any modifications to this product without prior express approval

by Banner Engineering Corp will void the product warranties. All specifications published in this document are subject to change; Banner reserves the right to modify product

specifications or update documentation at any time. Specifications and product information in English supersede that which is provided in any other language. For the most

recent version of any documentation, refer to: www.bannerengineering.com.

©

Banner Engineering Corp. All rights reserved

�