INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

G530 Series

Embedded Multimedia Card

e•MMC™ 5.0 HS400

Engineering Specification

Document Number: 401-0410-00

Revision: F

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

1

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

TABLE OF CONTENTS

1. Introduction ............................................................................................................................ 5

2. Specification ........................................................................................................................... 5

2.1. System Performance ............................................................................................................. 5

2.2. Power Consumption .............................................................................................................. 6

2.3. Capacity by Partition ............................................................................................................. 6

2.4. User Density .......................................................................................................................... 6

3. e•MMC™ Device and System ................................................................................................. 7

3.1. e•MMC™ System Overview ................................................................................................... 7

3.2. Memory Addressing .............................................................................................................. 7

3.3. e•MMC™ Device Overview .................................................................................................... 8

3.3.1 Clock (CLK) .................................................................................................................... 8

3.3.2 Data Strobe (DS) ............................................................................................................ 8

3.3.3 Command (CMD) ........................................................................................................... 8

3.3.4 Input/Outputs (DAT0-DAT7) ........................................................................................... 8

3.4. Bus Protocol ........................................................................................................................ 10

3.5. Bus Speed Modes ............................................................................................................... 10

3.5.1 HS200 Bus Speed Mode .............................................................................................. 10

3.5.2 HS200 System Block Diagram ..................................................................................... 11

3.5.3 HS400 Bus Speed mode .............................................................................................. 12

3.5.4 HS400 System Block Diagram ..................................................................................... 12

4. e•MMC™ Functional Description ......................................................................................... 13

4.1 e•MMC™ Overview .............................................................................................................. 13

4.2 Boot Operation Mode .......................................................................................................... 13

4.3 Device Identification Mode .................................................................................................. 13

4.4 Interrupt Mode ..................................................................................................................... 13

4.5 Data Transfer Mode ............................................................................................................ 13

4.6 Inactive Mode ...................................................................................................................... 14

4.7 H/W Reset Operation .......................................................................................................... 14

4.8 Noise Filtering Timing for H/W Reset .................................................................................. 15

4.9 Field Firmware Update(FFU) ............................................................................................... 16

4.10 Power off Notification for sleep ............................................................................................ 17

5. Register Settings .................................................................................................................. 19

5.1. OCR Register ...................................................................................................................... 19

5.2. CID Register ........................................................................................................................ 19

5.3. CSD Register ...................................................................................................................... 19

5.4. Extended CSD Register ...................................................................................................... 19

5.5. RCA Register ...................................................................................................................... 19

5.6. DSR Register ...................................................................................................................... 19

6. The e•MMC™ bus .................................................................................................................. 20

6.1 Power-up ............................................................................................................................. 21

6.1.1 e•MMC™ power-up ....................................................................................................... 21

6.1.2 e•MMC™ Power Cycling ............................................................................................... 22

6.2 Bus Operating Conditions.................................................................................................... 23

6.2.1 Power supply: e•MMC™................................................................................................ 23

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

2

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

6.2.2 e•MMC™ Power Supply Voltage ................................................................................... 24

6.2.3 Bus Signal Line Load ................................................................................................... 25

6.2.4 HS400 reference load .................................................................................................. 26

6.3 Bus Signal Levels ................................................................................................................ 27

6.3.1 Open-drain Mode Bus Signal Level .............................................................................. 27

6.3.2 Push-pull mode bus signal level— e•MMC™ ................................................................ 27

6.3.3 Bus Operating Conditions for HS200 & HS400 ............................................................ 28

6.3.4 Device Output Driver Requirements for HS200 & HS400 ............................................ 28

6.4 Bus Timing .......................................................................................................................... 28

6.4.1 Device Interface Timing................................................................................................ 29

6.5 Bus Timing for DAT Signals During Dual Data Rate Operation ........................................... 30

6.6 Bus Timing Specification in HS200 Mode............................................................................ 31

6.7 Bus Timing Specification in HS400 mode............................................................................ 35

6.7.1 HS400 Device Input Timing.......................................................................................... 35

6.7.2 HS400 Device Output Timing ....................................................................................... 36

7. Package Connections .......................................................................................................... 38

7.1. Package Mechanical .......................................................................................................... 38

7.1.1. 11.5 x 13.0 x 1mm 153 Ball Package ........................................................................... 38

8. Ball Assignments ................................................................................................................. 40

8.1. 153 Ball Package ............................................................................................................... 40

9. Temperature.......................................................................................................................... 41

10. Ordering Information ........................................................................................................... 41

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

3

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

Product Features:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Packaged NAND flash memory with e•MMC™ 5.0 interface

Compliant with e•MMC™ Specification Ver.4.4, 4.41,4.5 and 5.0

Bus mode

High-speed e•MMC™ protocol

Clock frequency: 0-200MHz.

Ten-wire bus (clock, 1 bit command, 8 bit data bus) and a hardware reset.

Supports three different data bus widths : 1 bit(default), 4 bits, 8 bits

Data transfer rate: up to 52Mbyte/s (using 8 parallel data lines at 52 MHz)

Single data rate : up to 200Mbyte/s @ 200MHz

Dual data rate : up to 400Mbytes/s @200MHz

Operating voltage range :

VCCQ = 1.8 V/3.3 V

VCC = 3.3 V

Error free memory access

Internal error correction code (ECC) to protect data communication

Internal enhanced data management algorithm

Solid protection of sudden power failure safe-update operations for data content

Security

Supports secure bad block erase commands

Enhanced Write Protection with permanent and partial protection options

Quality

RoHS compliant (for detailed RoHS declaration, please contact your Delkin representative.)

Supports Field Firmware Update (FFU)

Enhanced Device Life Time

Supports pre EOL information

Supports Production State Awareness

Supports Power Off Notification for Sleep

Supports HS400

Temperature Range:

Operating: -40 to +85°C

Storage: -40 to +85°C

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

4

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

1. Introduction

Delkin Devices e•MMC™ products comply with the JEDEC e•MMC™ 5.0 standard and are an ideal

universal storage solution for many embedded devices. E•MMC™ combines MLC NAND and an

e•MMC™ controller inside one JEDEC standard package, providing a standard interface to the host.

Delkin offers the 153 ball (11.5 x 13 x 1.0mm package), in MLC and pSLC configurations. The e•MMC™

controller directly manages NAND flash, including ECC, wear-leveling, IOPS optimization and read

sensing.

Table 1 – Device Summary

Flash Configuration Available Capacities

Package

FBGA153

MLC

4GB – 8GB

11.5 x 13 x 1.0mm

pSLC

FBGA153

2GB – 4GB

(single user partition)

11.5 x 13 x 1.0mm

Refer to part number table in Section 10.

Operating Voltage

VCC=3.3V,

VCCQ=1.8V/3.3V

2. Specification

2.1. System Performance

Product Configuration

4GB MLC

Table 2- Read/Write Performance

Typical Value

Read Sequential

Write Sequential

(MB/s)

(MB/s)

14

8GB MLC

25

250

2GB pSLC

30

4GB pSLC

80

Note 1: Values given for an 8-bit bus width, running HS400 mode from proprietary tool, VCC=3.3V,VCCQ=1.8V.

Note 2: For performance numbers under other test conditions, please contact Delkin.

Note 3: Performance numbers might be subject to change without notice.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

5

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

2.2. Power Consumption

Products

4GB MLC or 2GB pSLC

Table 3–Device Power Consumption

Read (mA)

Write mA)

VCCQ (1.8V)

Vcc(3.3V)

VCCQ (1.8V)

Vcc(3.3V)

100

80

50

30

8GB MLC or 4GB pSLC

160

50

100

40

Standby (mA)

Typ

0.12

0.16

Note 1; Values given for an 8-bit bus width, a clock frequency of 200MHz DDR mode, VCC= 3.3V±5%, VCCQ=1.8V±5%.

Note 2: Standby current is measured at Vcc = 3.3V ±5%, 8-bit bus width without clock frequency

Note 2: Current numbers might be subject to change without notice.

2.3. Capacity by Partition

Device

Boot Partition 1

4GB MLC or 2GB pSLC

8GB MLC or 4GB pSLC

2048 KB

4096 KB

Boot Partition 2

2048 KB

4096 KB

RPMB

512KB

4096 KB

2.4. User Density

Device

4GB MLC

User Density

3,901,415,424 Bytes

8GB MLC

7,802,871,808 Bytes

2GB pSLC

4GB pSLC

1,954,217,984 Bytes

3,901,415,424 Bytes

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

6

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

3. e•MMC™ Device and System

3.1. e•MMC™ System Overview

The e•MMC™ specification covers the behavior of the interface and the Device controller. As part

of this specification, the existence of a host controller and a memory storage array are implied but

the operation of these pieces is not fully specified.

Delkin’s NAND device consists of a single chip MMC controller and NAND flash memory module.

The micro-controller interfaces with a host system allowing data to be written to and read from the

NAND flash memory module. The controller allows the host to be independent from details of

erasing and programming the flash memory.

Figure 1– e•MMC™ System Overview

3.2. Memory Addressing

Previous implementations of the e•MMC™ specification follow byte addressing with 32 bit field. This

addressing mechanism is permitted for e•MMC™ densities up to and including 2 GB.

To support larger densities the addressing mechanism was updated to support sector addresses

(512 B sectors). The sector addresses shall be used for all devices with capacity larger than 2 GB.

To determine the addressing mode use the host should read bit [30:29] in the OCR register.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

7

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

3.3. e•MMC™ Device Overview

The e•MMC™ device transfers data via a configurable number of data bus signals. The

communication signals are:

3.3.1 Clock (CLK)

Each cycle of this signal directs a one bit transfer on the command and either a one bit (1x) or

two bit transfer (2x) on all the data lines. The frequency may vary between zero and the

maximum clock frequency.

3.3.2 Data Strobe (DS)

This signal is generated by the device and used for output in HS400 mode. The frequency of

this signal follows the frequency of CLK. For data output each cycle of this signal directs two

bits transfer (2x) on the data - one bit for positive edge and the other bit for negative edge. For

CRC status response output and CMD response output (enabled only HS400 enhanced strobe

mode), the CRC status is latched on the positive edge only, and ignores the negative edge.

3.3.3 Command (CMD)

This signal is a bidirectional command channel used for Device initialization and transfer of

commands. The CMD signal has two operation modes: open-drain for initialization mode, and

push-pull for fast command transfer. Commands are sent from the e•MMC™ host controller to

the e•MMC™ Device and responses are sent from the Device to the host.

3.3.4 Input/Outputs (DAT0-DAT7)

These are bidirectional data channels. The DAT signals operate in push-pull mode. Either the

Device or the host is driving these signals at any given time. By default, after power up or reset,

only DAT0 is used for data transfer. A wider data bus can be configured for data transfer, using

either DAT0-DAT3 or DAT0-DAT7, by the e•MMC™ host controller. The e•MMC™ Device

includes internal pull-ups for data lines DAT1-DAT7. Immediately after entering 4-bit mode, the

Device disconnects the internal pull ups of lines DAT1, DAT2, and DAT3. Correspondingly,

immediately after entering 8-bit mode, the Device disconnects the internal pull-ups of lines

DAT1–DAT7.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

8

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

Table 4– Communication Interface

Type1

I

I/O/PP

Name

CLK

DAT0

DAT1

DAT2

DAT3

DAT4

DAT5

DAT6

DAT7

CMD

RST_n

VCC

VCCQ

VSS

VSSQ

DS

Description

Clock

Data

Data

Data

Data

Data

Data

Data

Data

Command/Response

Hardware reset

Supply voltage for Core

Supply voltage for I/O

Supply voltage ground for Core

Supply voltage ground for I/O

Data strobe

I/O/PP

I/O/PP

I/O/PP

I/O/PP

I/O/PP

I/O/PP

I/O/PP

I/O/PP/OD

I

S

S

S

S

O/PP

Note1:I: input; O: output; PP: push-pull; OD: open-drain; NC: Not connected (or logical high); S: power supply.

Table 5– e•MMC™ Registers

Name

Width

(Bytes)

CID

16

RCA

2

DSR

2

CSD

16

OCR

4

EXT_CSD

512

Description

Device Identification number, an individual number for

identification.

Relative Device Address is the Device system address,

dynamically assigned by the host during initialization.

Driver Stage Register, to configure the Device’s output drivers.

Device Specific Data, information about the Device operation

conditions.

Operation Conditions Register. Used by a special broadcast

command to identify the voltage type of the Device.

Extended Device Specific Data. Contains information about the

Device capabilities and selected modes. Introduced in standard

v4.0

Implementation

Mandatory

Mandatory

Optional

Mandatory

Mandatory

Mandatory

The host may reset the device by:

•

•

•

Switching the power supply off and back on. The device shall have its own power-on detection

circuitry which puts the device into a defined state after the power-on Device.

A reset signal

By sending a special command

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

9

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

3.4. Bus Protocol

After a power-on reset, the host must initialize the device by a special message-based e•MMC™

bus protocol. For more details, refer to section 5.3.1 of the JEDEC Standard Specification

No.JESD84-B51.

3.5. Bus Speed Modes

e•MMC™ defines several bus speed modes as shown in Table 6.

Table 6— Bus Speed Mode

Data Rate

IO Voltage

Bus Width

Frequency

Max Data Transfer

(implies x8 bus width)

Single

3.3/1.8V

1, 4, 8

0-26MHz

26MB/s

Single

3.3/1.8V

4, 8

0-52MHz

52MB/s

Dual

3.3/1.8V

4, 8

0-52MHz

104MB/s

HS200

Single

1.8V

4, 8

0-200MHz

200MB/s

HS400

Dual

1.8V

8

0-200MHz

400MB/s

Mode Name

Backwards

Compatibility with

legacy MMC card

High Speed SDR

High Speed DDR

3.5.1 HS200 Bus Speed Mode

The HS200 mode offers the following features:

•

•

•

•

•

•

SDR Data sampling method

CLK frequency up to 200MHz Data rate – up to 200MB/s

8-bits bus width supported

Single ended signaling with 4 selectable Drive Strength

Signaling levels of 1.8V

Tuning concept for Read Operations

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

10

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

3.5.2 HS200 System Block Diagram

Figure 2 shows a typical HS200 Host and Device system. The host has a clock generator,

which supplies CLK to the Device. For write operations, clock and data direction are the

same, write data can be transferred synchronous with CLK, regardless of transmission line

delay. For read operations, clock and data direction are opposite; the read data received by

Host is delayed by round-trip delay, output delay and latency of Host and Device. For reads,

the Host needs to have an adjustable sampling point to reliably receive the incoming data

Figure 2— System Block Diagram

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

11

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

3.5.3 HS400 Bus Speed mode

The HS400 mode has the following features

•

DDR Data sampling method

•

CLK frequency up to 200MHz, Data rate is – up to 400MB/s

•

Only 8-bit bus width supported

•

Signaling levels of 1.8V

•

Support up to 5 selective Drive Strength

• Data strobe signal is toggled only for Data out and CRC response

3.5.4 HS400 System Block Diagram

Figure 3 shows a typical HS400 Host and Device system. The host has a clock generator, which

supplies CLK to the Device. For read operations, Data Strobe is generated by device output

circuit. Host receives the data which is aligned to the edge of Data Strobe.

Figure 3- HS400 Host and Device block diagram

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

12

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

4. e•MMC™ Functional Description

4.1 e•MMC™ Overview

All communication between the host and device are controlled by the host (main chip). The host

sends a command, which results in a device response. For more details, refer to section 6.1 of

the JEDEC Standard Specification No.JESD84-B50.

Five operation modes are defined for the e•MMC™ system:

•

•

•

•

•

Boot operation mode

Device identification mode

Interrupt mode

Data transfer mode

Inactive mode

4.2 Boot Operation Mode

In boot operation mode, the master (e•MMC™ host) can read boot data from the slave (e•MMC™

device) by keeping CMD line low or sending CMD0 with argument + 0xFFFFFFFA, before issuing

CMD1. The data can be read from either boot area or user area depending on register setting. For

more details, refer to section 6.3 of the JEDEC Standard Specification No.JESD84-B50.

4.3 Device Identification Mode

While in device identification mode the host resets the device, validates operation voltage range

and access mode, identifies the device and assigns a Relative device Address (RCA) to the device

on the bus. All data communication in the Device Identification Mode uses the command line (CMD)

only. For more details, refer to section 6.4 of the JEDEC Standard Specification No.JESD84-B50.

4.4 Interrupt Mode

The interrupt mode on the e•MMC™ system enables the master (e•MMC™ host) to grant the

transmission allowance to the slaves (Device) simultaneously. This mode reduces the polling load

for the host and hence, the power consumption of the system, while maintaining adequate

responsiveness of the host to a Device request for service. Supporting e•MMC™ interrupt mode is

an option, both for the host and the Device. For more details, refer to section 6.5 of the JEDEC

Standard Specification No.JESD84-B50.

4.5 Data Transfer Mode

When the Device is in Stand-by State, communication over the CMD and DAT lines will be

performed in push-pull mode. For more details, refer to section 6.6 of the JEDEC Standard

Specification No.JESD84-B50.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

13

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

4.6 Inactive Mode

The device will enter inactive mode if either the device operating voltage range or access mode is

not valid. The device can also enter inactive mode with GO_INACTIVE_STATE command

(CMD15). The device will reset to Pre-idle state with power cycle. For more details, refer to section

6.1 of the JEDEC Standard Specification No.JESD84-B50.

4.7

H/W Reset Operation

Figure 4– H/W Reset Waveform

Note1: Device will detect the rising edge of RST_n signal to trigger internal reset sequence

Table 7– H/W Reset Timing Parameters

Symbol

Comment

tRSTW

RST_n pulse width

tRSCA

RST_n to Command time

tRSTH

RST_n high period (interval time)

Min

Max

Unit

1

[us]

2001

[us]

1

[us]

Note1:74 cycles of clock signal required before issuing CMD1 or CMD0 with argument 0xFFFFFFFA

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

14

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

4.8

401-0410-00 Rev F

Noise Filtering Timing for H/W Reset

Device must filter out 5ns or less pulse width for noise immunity

Figure 5– Noise Filtering Timing for H/W Reset

Device must not detect the rising edge.

Device must not detect 5ns or less of positive or negative RST_n pulse.

Device must detect more than or equal to 1us of positive or negative RST_n pulse width.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

15

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

4.9

401-0410-00 Rev F

Field Firmware Update(FFU)

Field Firmware Updates (FFU) enables features enhancement in the field. Using this

mechanism the host downloads a new version of the firmware to the e.MMC device and, following

a successful download, instructs the e.MMC device to install the new downloaded firmware into

the device.

In order to start the FFU process the host first checks if the e.MMC device supports FFU

capabilities by reading SUPPPORTED_MODES and FW_CONFIG fields in the EXT_CSD. If the

e.MMC device supports the FFU feature the host may start the FFU process. The FFU process

starts by switching to FFU Mode in MODE_CONFIG field in the EXT_CSD. In FFU Mode host

should use closed-ended or open ended commands for downloading the new firmware and

reading vendor proprietary data. In this mode, the host should set the argument of these

commands to be as defined in FFU_ARG field. In case these commands have a different

argument the device behavior is not defined and the FFU process may fail. The host should set

Block Length to be DATA_SECTOR_SIZE. Downloaded firmware bundle must be

DATA_SECTOR_SIZE size aligned (internal padding of the bundle might be required).Once in

FFU Mode the host may send the new firmware bundle to the device using one or more write

commands.

The host could regain regular functionality of write and read commands by setting

MODE_CONFIG field in the EXT_CSD back to Normal state. Switching out of FFU Mode may

abort the firmware download operation. When host switched back to FFU Mode, the host should

check the FFU Status to get indication about the number of sectors which were downloaded

successfully by reading the NUMBER_OF_FW_SECTORS_CORRECTLY_PROGRAMMED in

the extended CSD. In case the number of sectors downloaded successfully is zero, the host

should re-start downloading the new firmware bundle from its first sector. In case the number of

sectors which were downloaded successfully is positive, the host should continue the download

from the next sector, which would resume the firmware download operation.

In case MODE_OPERATION_CODES field is not supported by the device, the host sets to

NORMAL state and initiates a CMD0/HW_Reset/Power cycle to install the new firmware. In such

case the device doesn’t need to use NUMBER_OF_FW_SECTORS_CORRECTLY_PROGRAMMED.

In both cases, occurrence of a CMD0/HW_Reset/Power before the host successfully downloaded

the new firmware bundle to the device may cause the firmware download process to be aborted.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

16

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

4.10 Power off Notification for sleep

The host should notify the device before it powers the device off – by turning off all of its power

supplies. This allows the device to better prepare itself for power down. In particular, the host

should issue a power off notification (POWER_OFF_LONG, POWER_OFF_SHORT ) if it intends

to turn off both VCC and VCCQ power I or it may use a power off notification

(SLEEP_NOTIFICATION ) if it intends to turn-off VCC after moving the device to Sleep state.

To indicate to the device that power off notification is supported by the host, a supporting host

shall first set the POWER_OFF_NOTIFICATION byte in EXT_CSD [34] to POWERED_ON

(0x01). To execute a power off, before powering the device down, the host will change the value

to either POWER_OFF_SHORT (0x02) or POWER_OFF_LONG (0x03). The host should wait for

the busy line to be de-asserted. Once the setting has changed to either 0x02 or 0x03, host may

safely power off the device.

The host may issue SLEEP_AWAKE (CMD5) to enter or to exit from Sleep state if

POWER_OFF_NOTIFICATION byte is set to POWERED_ON. Before moving to Standby state

and then to Sleep state, the host sets POWER_OFF_NOTIFICATION to SLEEP_NOTIFICATION

and waits for the DAT0 line de-assertion. While in Sleep (slp) state, VCC (Memory supply) may

be turned off as defined in 4.1.6. Removing power supplies other than VCC while the device is in

the Sleep (slp) state may result in undefined device behavior. Before removing all power supplies,

the host should transition the device out of Sleep (slp) state back to Transfer state using CMD5

and CMD7 and then execute a power off notification setting POWER_OFF_NOTIFICATION byte

to either POWER_OFF_SHORT or POWER_OFF_LONG.

If host continues to send commands to the device after switching to the power off setting (PO

WER_OFF_LONG, POWER_OFF_SHORT or SLEEP_NOTIFICATION) or performs HPI during t

he busy condition, the device shall restore the POWER_OFF_NOTIFICATION byte to POWERED

_ON.

If the host tries to change POWER_OFF_NOTIFICATION to 0x00 after writing another value ther

e, a SWITCH_ERROR is generated.

The difference between the two power-off modes is the urgency with which the host wants to

turn power off. The device should respond to POWER_OFF_SHORT quickly under the generic

CMD6 timeout. If more time is acceptable, POWER_OFF_LONG may be used and the device

shall respond to it within the POWER_OFF_LONG_TIME timeout.

While POWER_OFF_NOTIFICATION is set to POWERED_ON, the device expects the host to

host shall:

•Keep the device power supplies alive (both VCC and VCCQ) and in their active mode

•Not power off the device intentionally before changing POWER_OFF_NOTIFICATION to

either POWER_OFF_LONG or POWER_OFF_SHORT

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

17

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

•Not power off VCC intentionally before changing POWER_OFF_NOTIFICATION to

SLEEP_NOTIFICATION and before moving the device to Sleep state

Before moving to Sleep state, hosts may set the POWER_OFF_NOTIFICATION byte to

SLEEP_NOTIFICATION (0x04) if aware that the device is capable of autonomously initiating

background operations for possible performance improvements. Host should wait for the busy

line to be de-asserted. Busy line may be asserted up the period defined in

SLEEP_NOTIFICATION_TIME byte in EXT_CSD [216]. Once the setting has changed to 0x04

host may set the device into Sleep mode (CMD7+CMD5). After exiting from Sleep, the

POWER_OFF_NOTIFICATION byte will restore its value to POWERED_ON. HPI may interrupt

the SLEEP_NOTIFICATION operation. In that case POWER_OFF_NOTIFICATION byte will

restore to POWERED_ON.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

18

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

5. Register Settings

Within the Device interface six registers are defined: OCR, CID, CSD, EXT_CSD, RCA and

DSR. These can be accessed only by corresponding commands (see Section 6.10 of JESD84B50).

5.1. OCR Register

The 32-bit operation conditions register (OCR) stores the VDD voltage profile of the Device and the

access mode indication. In addition, this register includes a status information bit. This status bit is

set if the Device power up procedure has been finished. The OCR register shall be implemented

by all Devices.

5.2. CID Register

The Card Identification (CID) register is 128 bits wide. It contains the Device identification

information used during the Device identification phase (e•MMC™ protocol). For details, refer to

JEDEC Standard Specification No.JESD84-B50.

5.3. CSD Register

The Card-Specific Data (CSD) register provides information on how to access the contents stored

in e•MMC™. The CSD registers are used to define the error correction type, maximum data access

time, data transfer speed, data format…etc. For details, refer to section 7.3 of the JEDEC Standard

Specification No.JESD84-B50.

5.4. Extended CSD Register

The Extended CSD register defines the Device properties and selected modes. It is 512 bytes long.

The most significant 320 bytes are the Properties segment, which defines the Device capabilities

and cannot be modified by the host. The lower 192 bytes are the Modes segment, which defines

the configuration the Device is working in. These modes can be changed by the host by means of

the SWITCH command. For details, refer to section 7.4 of the JEDEC Standard Specification

No.JESD84-B50.

5.5. RCA Register

The writable 16-bit Relative Device Address (RCA) register carries the Device address assigned

by the host during the Device identification. This address is used for the addressed host-Device

communication after the Device identification procedure. The default value of the RCA register is

0x0001. The value 0x0000 is reserved to set all Devices into the Stand-by State with CMD7. For

detailed register setting value, please refer to appendix or contact Delkin.

5.6. DSR Register

The 16-bit driver stage register (DSR) is described in detail in Section 7.6 of the JEDEC Standard

Specification No.JESD84-B50. It can be optionally used to improve the bus performance for

extended operating conditions (depending on parameters like bus length, transfer rate or number

of Devices). The CSD register carries the information about the DSR register usage. For detailed

register setting value, please refer to appendix or contact Delkin.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

19

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

6. The e•MMC™ bus

The e•MMC™ bus has ten communication lines and three supply lines:

• CMD: Command is a bidirectional signal. The host and Device drivers are operating in

two modes, open drain and push/pull.

• DAT0-7: Data lines are bidirectional signals. Host and Device drivers are operating in

push-pull mode

• CLK: Clock is a host to Device signal. CLK operates in push-pull mode

• Data Strobe: Data Strobe is a Device to host signal. Data Strobe operates in push-pull

mode.

Figure 6– Bus Circuitry Diagram

The ROD is switched on and off by the host synchronously to the open-drain and push-pull mode

transitions. The host does not have to have open drain drivers, but must recognize this mode to

switch on the ROD. RDAT and RCMD are pull-up resistors protecting the CMD and the DAT lines

against bus floating device when all device drivers are in a high-impedance mode.

A constant current source can replace the ROD by achieving a better performance (constant

slopes for the signal rising and falling edges). If the host does not allow the switchable ROD

implementation, a fixed RCMD can be used). Consequently, the maximum operating frequency in

the open drain mode has to be reduced if the used RCMD value is higher than the minimal one

given.

RData strobe is pull-down resistor used in HS400 device .

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

20

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

6.1 Power-up

6.1.1 e•MMC™ power-up

An e•MMC™ bus power-up is handled locally in each device and in the bus master. Figure7

shows the power-up sequence and is followed by specific instructions regarding the powerup sequence. Refer to section 10.1 of the JEDEC Standard Specification No.JESD84-B50 for

specific instructions regarding the power-up sequence.

Figure 7 – e•MMC™ Power-up Diagram

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

21

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

6.1.2 e•MMC™ Power Cycling

The master can execute any sequence of VCC and VCCQ power-up/power-down. However, the

master must not issue any commands until VCC and VCCQ are stable within each operating

voltage range. After the slave enters sleep mode, the master can power-down VCC to reduce

power consumption. It is necessary for the slave to be ramped up to VCC before the host

issues CMD5 (SLEEP_AWAKE) to wake the slave unit. For more information about power

cycling see Section 10.1.3 of the JEDEC Standard Specification No.JESD84-B50.

Figure 8– The e•MMC™ Power Cycle

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

22

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

6.2

401-0410-00 Rev F

Bus Operating Conditions

Table 8– General Operating Conditions

Parameter

Symbol Min

Peak voltage on all lines

All Inputs

Input Leakage Current (before initialization sequence and/or the

internal pull up resistors connected)

Input Leakage Current (after initialization sequence and the

internal pull up resistors disconnected)

All Outputs

Output Leakage Current (before initialization sequence)

Output Leakage Current (after initialization sequence)

Note1:Initialization sequence is defined in section 10.1

Max.

Unit

-0.5

VCCQ +

0.5

V

-100

100

μA

-2

2

μA

-100

-2

100

2

μA

μA

Remark

6.2.1 Power supply: e•MMC™

In the e•MMC™, VCC is used for the NAND flash device and its interface voltage; V CCQ is for

the controller and the MMC interface voltage as shown in Figure 9. The core regulator is

optional and only required when internal core logic voltage is regulated from V CCQ. A CReg

capacitor must be connected to the VDDi terminal to stabilize regulator output on the system.

Figure 9– e•MMC™ Internal Power Diagram

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

23

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

6.2.2 e•MMC™ Power Supply Voltage

The e•MMC™ supports one or more combinations of VCC and VCCQ as shown in Table9. The

VCCQ must be defined at equal to or less than VCC.

Table 9– e•MMC™ Operating Voltage

Symbol

MIN

MAX

VCC

2.7

3.6

2.7

3.6

VCCQ

1.7

1.95

tPRUH

35

tPRUL

25

Parameter

Supply voltage (NAND)

Supply voltage (I/O)

Supply power-up for 3.3V

Supply power-up for 1.8V

Unit

V

V

V

ms

ms

Remarks

The e•MMC™ must support at least one of the valid voltage configurations, and can

optionally support all valid voltage configurations (see Table ).

Table 10 – e•MMC™ Voltage Combinations

VCCQ

Vcc

2.7V-3.6V

1.7V–1.95V

Valid

2.7V–3.6V1

Valid

Note1:VCCQ (I/O) 3.3 volt range is not supported in HS200 /HS400 devices

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

24

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

6.2.3 Bus Signal Line Load

The total capacitance CL of each line of the e•MMC™ bus is the sum of the bus master

capacitance CHOST, the bus capacitance CBUS itself and the capacitance CDEVICE of e•MMC™

connected to this line:

CL = CHOST + CBUS + CDEVICE

The sum of the host and bus capacitances must be under 20pF.

Table 11– Signal Line Load

Parameter

Pull-up resistance for

CMD

Pull-up resistance for

DAT0–7

Pull-up resistance for

RST_n

Bus signal line

capacitance

Single Device

capacitance

Maximum signal line

inductance

Impedance on CLK /

CMD / DAT0~7

Serial’s resistance on

CLK line

Serial’s resistance on

CMD / DAT0~7 line

Symbol

Min

Max

RCMD

4.7

50

Kohm to prevent bus floating

RDAT

10

50

Kohm to prevent bus floating

50

It is not necessary to put pull-up resistance on

RST_n (H/W rest) line

Kohm

if host does not use H/W reset. (Extended

CSD register [162] = 0 b )

RRST_n

4.7

CL

30

pF

CBGA

12

pF

16

nH

Remark

Single Device

45

55

ohm Impedance match

SRCLK

0

47

ohm

SRCMD

SRDAT0~7

0

47

ohm

2.2+0.1

4.7+0.22

VCCQ decoupling

capacitor

μF

CH1

VCC capacitor value

VDDi capacitor value

Unit

CREG

1

2.2

1+0.1

4.7+0.22

μF

1

4.7+0.1

μF

It should be located as close as possible to the

balls defined in order to minimize connection

parasitics

CH1 is only for HS200. It should be placed

adjacent to VCCQ-VSSQ balls (#K6 and #K4

accordingly, next to DAT [7..0] balls). It should

be located as close as possible to the balls

defined in order to minimize connection

parasitic.

It should be located as close as possible to the

balls defined in order to minimize connection

parasitic

To stabilize regulator output to controller core

logics. It should be located as close as

possible to the balls defined in order to

minimize connection parasitic

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

25

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

6.2.4 HS400 reference load

The circuit in Figure 10 shows the reference load used to define the HS400 Device Output

Timings and overshoot / undershoot parameters.

The reference load is made up by the transmission line and the CREFERENCE capacitance.

The reference load is not intended to be a precise representation of the typical system

environment nor a depiction of the actual load presented by a production tester.

System designers should use IBIS or other simulation tools to correlate the reference load to

system environment. Manufacturers should correlate to their production test conditions.

Delay time (td) of the transmission line has been introduced to make the reference load

independent from the PCB technology and trace length.

Figure 10 – HS400 reference load

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

26

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

6.3

401-0410-00 Rev F

Bus Signal Levels

As the bus can be supplied with a variable supply voltage, all signal levels are related to the

supply voltage.

Figure 11 – Bus Signal Levels

6.3.1

Open-drain Mode Bus Signal Level

Parameter

Output HIGH voltage

Output LOW voltage

Table 12– Open-drain Bus Signal Level

Symbol

Min

Max.

Unit

VOH

VDD – 0.2

V

VOL

0.3

V

Conditions

IOH = -100 μA

IOL = 2 mA

The input levels are identical with the push-pull mode bus signal levels.

6.3.2 Push-pull mode bus signal level— e•MMC™

The device input and output voltages shall be within the following specified ranges for any

VDD of the allowed voltage range

For 2.7V-3.6V VCCQ range (compatible with JESD8C.01)

Parameter

Output HIGH voltage

Output LOW voltage

Input HIGH voltage

Input LOW voltage

Table 13– Push-pull Signal Level—High-voltage e•MMC™

Symbol

Min

Max.

Unit

Conditions

VOH

0.75 * VCCQ

V

IOH = -100 μA @ VCCQ min

VOL

0.125 * VCCQ

V

IOL = 100 μA @ VCCQ min

VIH

0.625 * VCCQ

VCCQ + 0.3

V

VIL

VSS – 0.3

0.25 * VCCQ

V

For 1.70V – 1.95V VCCQ range (: Compatible with EIA/JEDEC Standard “EIA/JESD8-7

Normal Range” as defined in the following table.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

27

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

Table 14– Push-pull Signal Level—1.70 -1.95 VCCQ Voltage Range

Parameter

Symbol

Min

Output HIGH voltage

VOH

VCCQ – 0.45V

Output LOW voltage

VOL

Input HIGH voltage

VIH

Input LOW voltage

VIL

Max.

Unit

Conditions

V

IOH = -2mA

0.45V

V

IOL = 2mA

0.65 * VCCQ 1

VCCQ + 0.3

V

VSS – 0.3

0.35 * VDD2

V

Note1:0.7 * VDD for MMC™4.3 and older revisions.

Note2:0.3 * VDD for MMC™4.3 and older revisions.

6.3.3 Bus Operating Conditions for HS200 & HS400

The bus operating conditions for HS200 devices is the same as specified in sections 10.5.0

of JESD84-B51through 10.5.2 of JESD84-B50. The only exception is that VCCQ=3.3v is not

supported.

6.3.4 Device Output Driver Requirements for HS200 & HS400

Refer to section 10.5.4 of the JEDEC Standard Specification No.JESD84-B50.

6.4 Bus Timing

Figure 12– Timing Diagram

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

28

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

6.4.1 Device Interface Timing

Parameter

Table 15– High-speed Device Interface Timing

Symbol

Min

Max.

Unit

Clock CLK1

Clock frequency Data Transfer Mode

fPP

(PP)2

Clock frequency Identification Mode

fOD

(OD)

Clock high time

tWH

Clock low time

tWL

Clock rise time4

tTLH

Clock fall time

tTHL

Inputs CMD, DAT (referenced to CLK)

Input set-up time

tISU

Input hold time

tIH

Outputs CMD, DAT (referenced to CLK)

Output delay time during data transfer tODLY

Output hold time

tOH

Signal rise time5

tRISE

Signal fall time

tFALL

Remark

0

523

MHz

CL ≤ 30 pF

Tolerance:+100KHz

0

400

kHz

Tolerance: +20KHz

3

3

ns

ns

ns

ns

CL ≤ 30 pF

CL ≤ 30 pF

CL ≤ 30 pF

CL ≤ 30 pF

ns

ns

CL ≤ 30 pF

CL ≤ 30 pF

ns

ns

ns

ns

CL ≤ 30 pF

CL ≤ 30 pF

CL ≤ 30 pF

CL ≤ 30 pF

6.5

6.5

3

3

13.7

2.5

3

3

Note1:CLK timing is measured at 50% of VDD.

Note2: eMMC™ shall support the full frequency range from 0-26Mhz or 0-52MHz

Note3:Device can operate as high-speed Device interface timing at 26 MHz clock frequency.

Note4:CLK rise and fall times are measured by min (VIH) and max (VIL).

Note5:Inputs CMD DAT rise and fall times are measured by min (VIH) and max (VIL) and outputs CMD DAT rise and fall times are measured by min (VOH) and

max (VOL). “

Parameter

Table16– Backward-compatible Device Interface Timing

Symbol

Min

Max.

Unit

Clock CLK2

Clock frequency Data Transfer Mode (PP)3

Clock frequency Identification Mode (OD)

Clock high time

Clock low time

Clock rise time4

Clock fall time

Inputs CMD, DAT (referenced to CLK)

Input set-up time

Input hold time

Outputs CMD, DAT (referenced to CLK)

Output set-up time5

Output hold time5

fPP

fOD

tWH

tWL

tTLH

tTHL

0

0

10

10

tISU

tIH

tOSU

tOH

Remark1

CL ≤ 30 pF

26

400

MHz

kHz

10

10

ns

ns

ns

CL ≤ 30 pF

CL ≤ 30 pF

CL ≤ 30 pF

CL ≤ 30 pF

3

3

ns

ns

CL ≤ 30 pF

CL ≤ 30 pF

11.7

8.3

ns

ns

CL ≤ 30 pF

CL ≤ 30 pF

Note1:The Device must always start with the backward-compatible interface timing. The timing mode can be switched to high-speed interface timing by the host

sending the SWITCH command (CMD6) with the argument for high-speed interface select.

Note2:CLK timing is measured at 50% of VDD.

Note3:For compatibility with Devices that support the v4.2 standard or earlier, host should not use > 26 MHz before switching to high-speed interface timing.

Note4:CLK rise and fall times are measured by min (VIH) and max (VIL).

Note5:tOSU and tOH are defined as values from clock rising edge. However, there may be Devices or devices which utilize clock falling edge to output data in

backward compatibility mode. Therefore, it is recommended for hosts either to settWL value as long as possible within the range which will not go over tCKtOH(min) in the system or to use slow clock frequency, so that host could have data set up margin for those devices. In this case, each device which utilizes

clock falling edge might show the correlation either between tWL and tOSU or between tCK and tOSU for the device in its own datasheet as a note or its

application notes.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

29

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

6.5

401-0410-00 Rev F

Bus Timing for DAT Signals During Dual Data Rate Operation

This timing applies to the DAT[7:0] signals only when the device is configured for dual data mode

operation. In this dual data mode, the DAT signals operate synchronously from both the rising

and the falling edges of CLK. The CMD signal still operates synchronously of the rising edge of

CLK and therefore complies with the bus timing specified in section 10.5, therefore there is no

timing change for the CMD signal.

Figure13– Timing Diagram: Data Input/Output in Dual Data Rate Mode

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

30

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

6.5.1 Dual Data Rate Interface Timing

Parameter

Table 17– High-speed Dual Data Rate Interface Timing

Symbol

Min

Max.

Unit

Remark

Input CLK1

Clock duty cycle

45

Input DAT (referenced to CLK-DDR

mode)

Input set-up time

Input hold time

Output DAT (referenced to CLK-DDR

mode)

Output delay time during data transfer

Signal rise time (all signals)2

Signal fall time (all signals)

tISUddr

tIHddr

2.5

2.5

tODLYddr

tRISE

tFALL

1.5

55

7

2

2

%

Includes jitter, phase

noise

ns

ns

CL ≤ 20 pF

CL ≤ 20 pF

ns

ns

ns

CL ≤ 20 pF

CL ≤ 20 pF

CL ≤ 20 pF

Note1:CLK timing is measured at 50% of VDD.

Note2:Inputs CMD, DAT rise and fall times are measured by min (VIH) and max (VIL), and outputs CMD, DAT rise and fall times are measured

by min (VOH) and max (VOL)

6.6 Bus Timing Specification in HS200 Mode

6.6.1 HS200 Clock Timing

Host CLK Timing in HS200 mode shall conform to the timing specified in Figure and Table18.

CLK input shall satisfy the clock timing over all possible operation and environment conditions.

CLK input parameters should be measured while CMD and DAT lines are stable high or low,

as close as possible to the Device.

The maximum frequency of HS200 is 200MHz. Hosts can use any frequency up to the

maximum that HS200 mode allows.

Figure 14– HS200 Clock Signal Timing

Note1:VIH denote VIH(min.) and VIL denotes VIL(max.).

Note2:VT=0.975V – Clock Threshold, indicates clock reference point for timing measurements.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

31

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

Symbol

tPERIOD

Min.

5

tTLH, tTHL

-

Duty Cycle

30

401-0410-00 Rev F

Table18– HS200 Clock Signal Timing

Unit

Remark

ns

200MHz (Max.), between rising edges

tTLH, tTHL < 1ns (max.) at 200MHz, CBGA=12pF, The

0.2*

ns

absolute maximum value of tTLH, tTHL is 10ns regardless of

tPERIOD

clock frequency.

70

%

Max.

-

6.6.2 HS200 Device Input Timing

Figure 15– HS200 Device Input Timing

Note1: tISU and tIH are measured at VIL(max.) and VIH(min.).

Note2: VIH denote VIH(min.) and VIL denotes VIL(max.).

Table 19 – HS200 Device Input Timing

Symbol

tISU

tIH

Min.

1.4

0.8

Max.

-

Unit

ns

ns

Remark

CBGA ≤ 6pF

CBGA ≤ 6pF

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

32

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

6.6.3 HS200 Device Output Timing

tPH parameter is defined to allow device output delay to be longer than t PERIOD. After

initialization, the tPH may have random phase relation to the clock. The Host is responsible to

find the optimal sampling point for the Device outputs, while switching to the HS200 mode.

Figure 16 and Table 20 define Device output timing.

While setting the sampling point of data, a long term drift, which mainly depends on

temperature drift, should be considered. The temperature drift is expressed by ΔT PH. Output

valid data window (tVW) is available regardless of the drift (ΔTPH) but position of data window

varies by the drift, as described in Figure 17.

Figure 16 – HS200 Device Output Timing

Note: VOH denotes VOH(min.) and VOL denotes VOL(max.).

Table 20– Output Timing

Symbol

Min.

Max.

Unit

tPH

0

2

UI

ΔTPH

TVW

-350

+1550

(ΔT=-20°C) (ΔT=90°C)

0.575

-

ps

UI

Remark

Device output momentary phase from CLK input to CMD or DAT lines output.

Does not include a long term temperature drift.

Delay variation due to temperature change after tuning. Total allowable shift of

output valid window (TVW) from last system Tuning procedure ΔTPH is 2600ps

for ΔT from -25°C to 125°C during operation.

tVW=2.88ns at 200MHz Using test circuit in Figure 15 including skew among

CMD and DAT lines created by the Device. Host path may add Signal Integrity

induced noise, skews, etc. Expected TVW at Host input is larger than 0.475UI.

Note:Unit Interval (UI) is one bit nominal time. For example, UI=5ns at 200MHz.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

33

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

Figure 17– ΔTPH consideration

Implementation Guide: Host should design to avoid sampling errors that may be caused by the Δ TPH

drift. It is recommended to perform tuning procedure while Device wakes up, after sleep. One simple

way to overcome the ΔTPH drift is by reduction of operating frequency.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

34

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

6.7

401-0410-00 Rev F

Bus Timing Specification in HS400 mode

6.7.1

HS400 Device Input Timing

The CMD input timing for HS400 mode is the same as CMD input timing for HS200

mode.

Figure 18 and Table 21 show Device input timing

Figure 18 - HS400 Device Data input timing

Table 21- HS400 Device input timing

Parameter

Symbol

Min

Max

Unit

Remark

Input CLK

Cycle time data

transfer mode

Slew rate

tPERIOD

5

SR

1.125

Duty cycle

tCKDCD

0.0

distortion

Minimum pulse

width

tCKMPW

2.2

200MHz(Max), between rising edges with respect to VT.

0.3

V/ns

With respect to VIH/VIL.

ns

Allowable deviation from an ideal 50% duty cycle with

respect to VT. Includes jitter, phase noise

ns

With respect to VT.

Input DAT (referenced to CLK)

Input set-up time

tISUddr

0.4

ns

CDevice ≤ 6pF with respect to VIH/VIL

Input hold time

tIHddr

0.4

ns

CDevice ≤ 6pF with respect to VIH/VIL

Slew rate

SR

1.125

V/ns

With respect to VIH/VIL

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

35

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

6.7.2

401-0410-00 Rev F

HS400 Device Output Timing

The Data Strobe is used to read data in HS400 mode. The Data Strobe is toggled only during

data read or CRC status response.

Figure 19- HS400 Device output timing

Table 22 – HS400 Device Output timing

Parameter

Symbol

Min

Max

Unit

Remark

Data Strobe

Cycle time data transfer

mode

Slew rate

tPERIOD

5

SR

1.125

Duty cycle distortion

tDSDCD

0.0

V/ns

0.2

ns

200MHz(Max), between rising edges With respect to

VT

With respect to VOH/VOL and HS400 reference load

Allowable deviation from the input CLK duty

cycle distortion (tCKDCD) with respect to VT

Includes jitter, phase noise

Minimum pulse width

tDSMPW

2.0

ns

With respect to VT

Read pre-amble

tRPRE

0.4

Read post-amble

tRPST

Output skew

tRQ

0.4

ns

With respect to VOH/VOL and HS400 reference load

Output hold skew

tRQH

0.4

ns

With respect to VOH/VOL and HS400 reference load

Slew rate

SR

V/ns

With respect to VOH/VOL and HS400 reference load

tPERIOD Max value is specified by manufacturer. Value up

to infinite is valid

0.4

tPERIOD Max value is specified by manufacturer. Value up

to infinite is valid

Output DAT (referenced to Data Strobe)

1.125

-

NOTE 1 : Measured with HS400 reference load(6.2.4)

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

36

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

Table 23 – HS400 Capacitance

Parameter

Symbol

Min

Pull-up resistance for CMD

RCMD

Pull-up resistance for DAT0-7

Pull-down resistance for Data

Strobe

Internal pull up resistance

DAT1-DAT7

Single Device capacitance

Max

Unit

4.7

100(1)

Kohm

RDAT

10

100(1)

Kohm

RDS

10

100(1)

Kohm

Rint

10

150

Kohm

6

pF

CDevice

Type

Remark

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

37

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

7. Package Connections

7.1. Package Mechanical

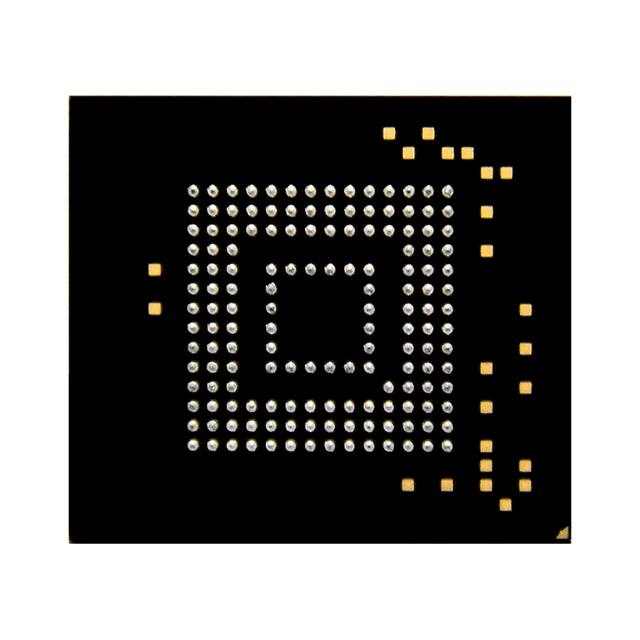

7.1.1. 11.5 x 13.0 x 1mm 153 Ball Package

11.5 ± 0.1 mm

13 ± 0.1 mm

0.5 BSC. (mm)

Min 0.15mm

Max 0.92mm

1.0mm Max

Figure 20 – 153 Ball Package Outline Drawing

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

38

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

Figure 21 – 153 Ball Package Outline Drawing (Bottom)

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

39

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

8. Ball Assignments

8.1. 153 Ball Package

Figure 24 – 153 ball assignment

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

40

�INDUSTRIAL EMBEDDED MULTIMEDIA CARD (EMMC)

401-0410-00 Rev F

9. Temperature

Parameter

Rating

Units

Operating temperature

-40 ~ +85

°C

Storage temperature

-40 ~ +85

°C

10. Ordering Information

Capacity/Type

Package Type

Delkin Part Number

Packaging

EM04APYD3-BA000-2

Trays

8GB MLC

EM08APGD3-BA000-2

1520 per box

10 trays of 152

MOQ 1 box

2GB pSLC

EM02APYD4-BA000-2

Trays

EM04APGD4-BA000-2

1520 per box

10 trays of 152

MOQ 1 box

4GB MLC

153 Ball

11.5x13x1.0

153 Ball

11.5x13x1.0

4GB pSLC

WARNING: This product may contain chemicals known to the State of California to cause cancer,

birth defects, or other reproductive harm. For more information go to www.p65warnings.ca.gov.

___________________________________________________________________________________________________________________

© 2020 | Delkin Devices Inc.

41

�