PRODUCT SPECIFICATION

Part

Number

Product

Description

Doc

Number

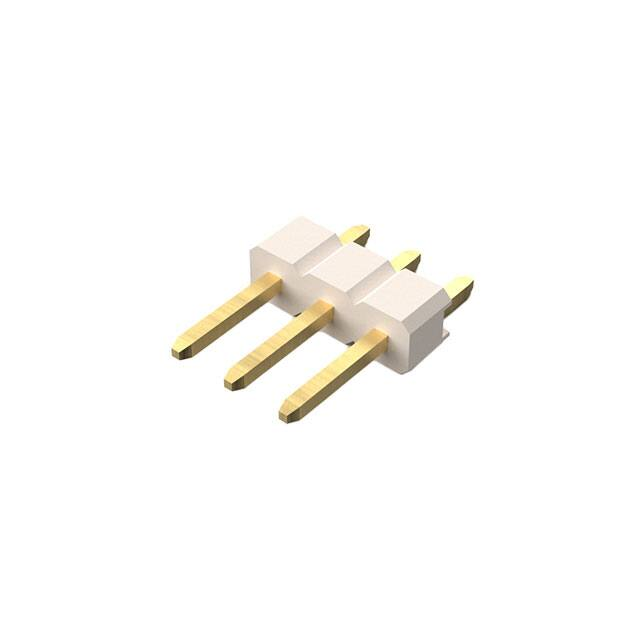

BG 2.54mm Series

C

Rev

2.54mm Board to Board Header Connectors

BG Series

Prepared

By:

Checked

By:

SA

AE

Date

22/03/10

Page

1

Approved

By:

DR

1.0 SCOPE

This specifies Pitch 2.54mm Headers Connectors. The connector shall meet the performances,

specified here under the condition with the plug connector and the receptacle connector mated.

This specification covers the product standards, requirements and qualification provisions.

2.0 APPLICABLE DOCUMENTS

At the time of this specifications release, the latest revisions of the following documents were used.

These documents shall form a part of this specification as described within this document.

2.1 Industry Specifications / Standards

UL-94 Flammability.

ASTM B-103 Phosphor Bronze or Brass Plate, Rod, Sheet, Strip and Rolled Bar.

2.2 EIA Specifications

EIA-364-D Electrical Connector / Socket Test Procedures Including Environmental Classifications.

3.0 REQUIREMENTS

3.1 Dimensional

Connectors shall meet the physical dimensions specified on the applicable product drawing.

3.2 Material

Each component shall be constructed of the materials specified within this document. Substitute materials

must meet the performance requirements of this specification.

3.2.1 Contacts

Copper Alloy

3.2.2 Housings

PBT, Nylon 6T or LCP, flame retardant 94V-0 per UL-94; or other high performance resin.

www.gct.co

�PRODUCT SPECIFICATION

Part

Number

Product

Description

Doc

Number

BG 2.54mm Series

C

Rev

2.54mm Board to Board Header Connectors

BG Series

Prepared

By:

Checked

By:

SA

AE

Date

22/03/10

Page

2

Approved

By:

DR

3.3 Plating

3.3.1 Contact Under Plate and Finish

• Finish: Gold Flash All Over (A) – Under plate: Nickel 30-50µ”

• Finish: Selective gold flash contact area/tin on tail (B) – Under plate: Nickel 50-100µ”

• Finish: Tin All Over (C) – 80µ” minimum – Under plate: Nickel 30-50µ”

• Finish: Gold 10µ” (G) or 30µ” (I) on contact area. Tin 80µ” min. on Tail – Under plate: Nickel 50-100µ”

3.4 Design

3.4.1 Mating

The connector shall be capable of mating and unmating manually with the test board.

3.5 Mechanical Requirements

3.5.1 Workmanship

The product shall be uniform in quality and free from defects (burrs, scratches, cracks, voids, etc.) that will

adversely affect the product performance.

3.5.2 Contact Retention Force

The end of a post shall be pushed in a perpendicular to base housing at a constant speed of

25.4 mm / minute. Min. Retention Force for 5N / Pin.

3.5.3 Durability

When measured in accordance with EIA-364-09C, the following details shall apply:

100 mating cycles at a rate of 25.4 mm / minute, contact resistance 30 mΩ Max.

www.gct.co

�PRODUCT SPECIFICATION

Part

Number

Product

Description

Doc

Number

BG 2.54mm Series

C

Rev

2.54mm Board to Board Header Connectors

BG Series

Prepared

By:

Checked

By:

SA

AE

Date

22/03/10

Page

3

Approved

By:

DR

3.6 Electrical Requirements

3.6.1 Current Rating

3.0A, When measured in accordance with EIA-364-70, 3.0 A Max., based on a 30°C rise over ambient.

3.6.2 Voltage Rating

250V AC / DC. When measured in accordance with EIA-364-20B.

3.6.3 Low Level Circuit Resistance

≤20mΩ, measured in accordance with EIA-364-23B, Initial: ≤20 mΩ, after environmental test: ≤30mΩ.

The following details shall apply:

(a). Current: 10 mA Max.

(b). Max. Open Circuit Voltage: 20 mV DC.

3.6.4 Dielectric Withstanding Voltage

There shall be of no evidence of flashover when the mated header and socket are tested in accordance with

EIA-364-20B, The following details shall apply:

(a). Voltage: 600V AC at 50 Hz,

(b). Duration: 60 sec,

(c). Measurement Points: Measure across a Min. of 10 adjacent and 10 opposing contacts.

3.6.5 Insulation Resistance

Shall be a Min. of 1000 MΩ before conditioning and a Min. of 500 MΩ after conditioning. When

measured in accordance with EIA-364-21C, the following details shall apply:

(a). Voltage: 500 V DC / 1 min.

(b). Measurement Points: Measure between 10 adjacent and 10 opposing contacts per header and socket.

3.6.6 Capacitance

Measure the capacitance between adjacent unmated contacts. The capacitance shall not exceed a Max.

of 2 pF at 1 KHz.

www.gct.co

�PRODUCT SPECIFICATION

Part

Number

Product

Description

Doc

Number

BG 2.54mm Series

C

Rev

2.54mm Board to Board Header Connectors

BG Series

Prepared

By:

Checked

By:

SA

AE

Date

22/03/10

Page

4

Approved

By:

DR

3.7 Environmental Requirements

3.7.1 Operating Temperature Range

-40°C~105°C.

3.7.2 Temperature Life

After exposure of the unmated connector to a high temperature operating environment, the contact

resistance shall not exceed the value specified in paragraph 3.6.3. Test shall be in accordance

with EIA-364-17B. The following details shall apply:

(a). Test Condition: 105°C, 96hours.

3.7.3 Thermal Shock Test

There shall be no evidence of physical damage when the mated header and socket are subjected to

transient acceleration. During and after each shock, the test shall show no evidence of discontinuity greater

than 1 microsecond.

The test shall be in accordance with EIA-364-32C, Test Condition a, b:

(a). Temperature: -40°C to +105°C, 5 cycles.

(b). Initial, After Test THERMAL: Max. Circuit Resistance: 30 mΩ or below.

3.7.4 Humidity Test

After exposure of the plug and receptacle to a high humidity environment, the insulation resistance shall not

be less than 500 MΩ. The dielectric withstanding voltage shall be greater than 500V AC for 1 minute.

The test shall be in accordance with EIA-364-31B.

(a). Test Condition: (40±2°C, 90-95% RH, 96 hrs).

3.7.5 Salt Spray

After exposure, the contact resistance shall not exceed that specified (see paragraph 3.6.3). The insulation

resistance shall not be less than 500 MΩ (see paragraph 3.6.5). The dielectric withstanding voltage

shall be greater than 600V AC for 1 minute (see paragraph 3.6.4).

The test shall be in accordance with EIA-364-26B, The following details shall apply:

(a). Test Condition: 35±2°C, 16 hrs, 5% NaCL.

(b). Special Handling: The mated headers shall be mildly rinsed in water to remove salt residue and allowed

to dry for 24 hours at room temperature before measurements are to be taken.

www.gct.co

�PRODUCT SPECIFICATION

Part

Number

Product

Description

Doc

Number

BG 2.54mm Series

C

Rev

2.54mm Board to Board Header Connectors

BG Series

Prepared

By:

Checked

By:

SA

AE

Date

22/03/10

Page

5

Approved

By:

DR

3.7.6 Resistance to Soldering Heat

There shall be no evidence of physical damage to the insulator or finished product when the unmated header

is subjected to the reflow soldering process. After exposure, the contact resistance shall not exceed that

specified in paragraph 3.6.3.

The following details shall apply:

(a). Test Condition: Test connector shall be placed on the PCB.

(b). Pre-Heat Temperature: 100~150°C for 60 seconds Max.

(c). Temperature: Min. 210°C for 30 seconds Max.

(d). Peak Temperature: 260±5°C, 10±5sec.

3.7.7 Solderability Test

After exposure, the contact solder tails shall have a minimum of 95% solder coverage. The covered

area must not show any evidence of voids or pinholes.

The test shall be in accordance with EIA-364-71B, the contact solder tails must have solder coverage

of 95% up. The plastics have no damaged.

The following details shall apply:

(a). Solder Dwell Time: Contacts shall be held above the solder for 3 to 5 seconds before being immersed in

the solder

(b). Test Temperature : 245±3°C, 3~5sec.

www.gct.co

�PRODUCT SPECIFICATION

Part

Number

Product

Description

Doc

Number

BG 2.54mm Series

C

Rev

2.54mm Board to Board Header Connectors

BG Series

Prepared

By:

Checked

By:

SA

AE

Date

22/03/10

Page

6

Approved

By:

4.0 QUALITY ASSURANCE PROVISIONS

4.1 Inspection Conditions

Unless otherwise specified, all inspections shall be performed under the following ambient conditions.

(a) Temperature: 25±5°C.

(b) Relative Humidity: 30% to 70%.

(c) Barometric Pressure: Local Ambient.

4.2 Qualification Inspection

Qualification inspections shall be performed on sample units produced with production equipment.

4.2.1 Sample Selection

Connectors shall be prepared according to applicable instruction sheets. Samples shall be selected at

random from current production. A total of 26 samples are required for the specified test sequence.

4.2.2 Test Sequence

The sample connectors shall be subjected to the inspections specified in the order shown.

Test Item

Sample Size

A

3

B

3

C

3

D

3

E

3

F

3

G

3

H

3

Examination of Product

1,5

1,5

1,9

1,7

1,9

1,3

1,3

1,3

Terminal Resistance

2,4

2,4

2,8

2,8

Insulation Resistance

3,7

2,5

Dielectric Withstanding Voltage

4,6

3,6

Temperature Life

3

Humidity Test

Thermal Shock

4

3

Solderability

2

Resistance to Soldering Heat

2

Insertion Force

3,6

Unmating Force

4,7

Contact Resistance Force

2

Durability

Salt Spray

5

5

www.gct.co

DR

�PRODUCT SPECIFICATION

Part

Number

Product

Description

Doc

Number

BG 2.54mm Series

C

Rev

2.54mm Board to Board Header Connectors

Prepared

By:

BG Series

Checked

By:

SA

AE

Date

22/03/10

Page

7

Approved

By:

Revision details :Revision

Information

Page

Release Date

A

Specification released.

-

22/03/10

B

Clarified underplating information.

2

16/08/13

C

Amended tin plating thickness.

2

07/10/13

www.gct.co

DR

�