1. 物料型号: TMPA0402SP系列,有多种型号,包括R10MN、R22MN、R47MN等,每种型号具有不同的电感值和公差。

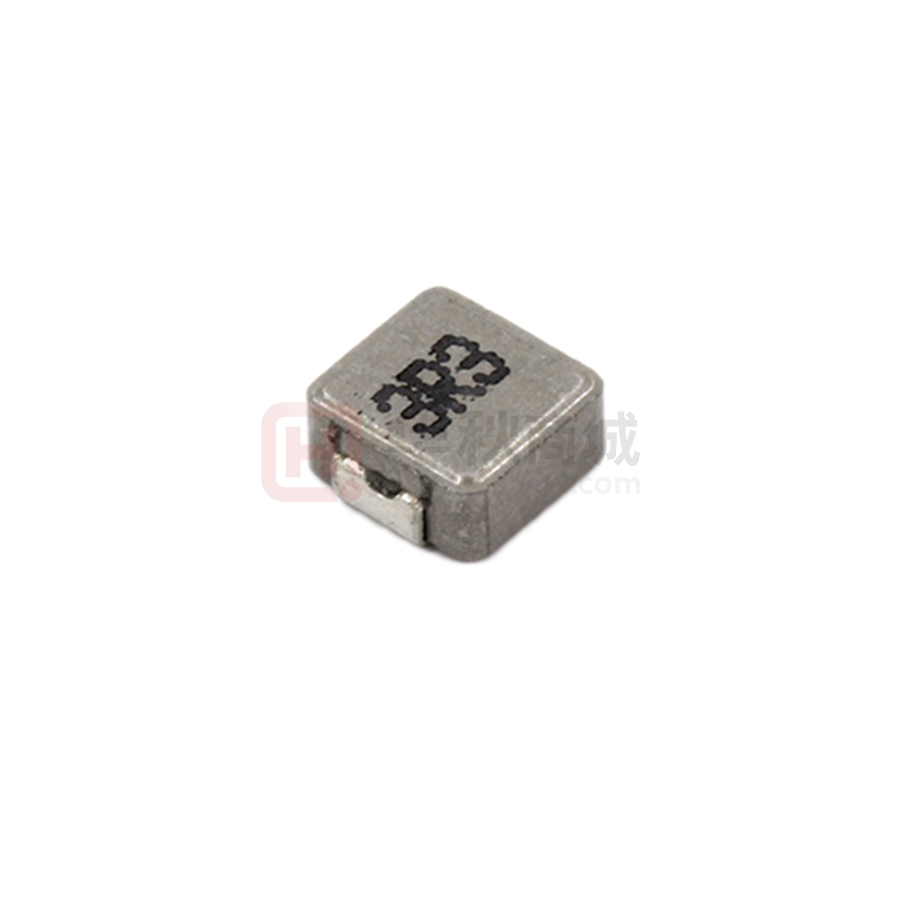

2. 器件简介: 该系列电感器具有屏蔽结构,能够应对高频应用,低直流电阻(DCR)实现低损耗,采用金属粉末芯实现高性能(Isat),无卤素、无铅,超低噪音,符合RoHS标准,工作温度范围为-40~+125℃。

3. 引脚分配: 引脚分配的详细信息在文档中未明确列出,但提到了PCB布局推荐,包括焊盘尺寸和推荐焊膏厚度。

4. 参数特性: 提供了详细的规格参数,包括电感值、额定直流电流、饱和直流电流、直流电阻等。

5. 功能详解: 电感器适用于多种应用,包括分布式电源系统中的DC/DC转换器、FPGA的DC/DC转换器、电池供电设备、交换机的薄型板载电源模块、服务器的VRM、高电流低剖面POL转换器等。

6. 应用信息: 列出了电感器的推荐应用领域,如上所述。

7. 封装信息: 提供了封装尺寸和推荐的PCB布局图案。

8. 材料清单: 列出了制造电感器使用的材料,包括合金粉末芯、聚酯线或等效物、无铅焊料(Ni+Sn---镀层)、无卤素酮油墨。

9. 可靠性和测试条件: 包括工作温度、储存温度、电气性能测试、寿命测试、负载湿度测试、耐湿性测试、热冲击测试、振动测试等。

10. 焊接和安装: 提供了焊接推荐,包括使用温和活性助焊剂、再流焊接温度曲线、烙铁焊接的注意事项等。

11. 包装信息: 包括卷轴尺寸、胶带尺寸、包装数量和撕离力。

12. 存储条件和运输: 提供了产品存储和运输的推荐条件。

13. 典型性能曲线: 文档最后提供了电感器的性能曲线,但具体曲线未在摘要中列出。