HL-EMC-3030D46W-2C-S1-HR3 数据手册

Under Development

Mass production

RoHS

Specification

规 格 书

Customer Name:

客户名称:

Customer P/N:

客户品号:

Factory P/N: HL-EMC-3030D46W-2C-S1-HR3

公司品号:

Sending Date:

Client approval

客户审核

Approval

核准

Hongli approval

鸿利智汇审核

Audit

确认

Approval

核准

Audit

确认

Confirmation

制作

林德顺

□ Qualified

接受

□ Disqualified

不接受

翦桂云

DATE:

日期:

Adr:No.1,Xianke Yi Road,Huadong Town,Huadu District,Guangzhou,China

地址:中国广州市花都区花东镇先科一路1号

Tel/电话:020-86733333

Fax/传真:020-86733883 86733938

86733265

Web/网址:www.honglitronic.com

注:1.此规格书以中英文方式书写,若有冲突以中文版本为准文本.

2.此规格书的最终解释权归鸿利智汇集团股份有限公司

3.此规格书的有效期限为两年,自盖章或签字之日起计算,期满时双方可以续签协议,但应采用书面形式

SPEC NO:B-17-A-1605

REV NO: A/1

DATE: July/13/2018

PAGE: 1 OF 11

●

�Under Development

Mass production

HL-EMC-3030D46W-2C-S1-HR3

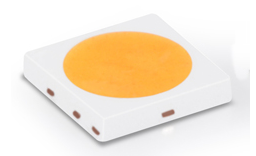

Features( 特征)

PLCC-2 Package.(PLCC-2 封装)

Extremely wide viewing angle.(宽的发光角度)

Suitable for all SMT assembly and solder process.(适用于所有的SMT组装和焊接工艺)

Available on tape and reel.(适用于载带及卷轴)

Moisture sensitivity level: Level 4.(防潮等级 Level 4)

Package:4500pcs/reel..(包装每卷4500PCS)

RoHS compliant. (RoHS 认证)

ATTENTION

Description(描述)

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

DISCHARGE

SENSITIVE

DEVICES

The White LED which was fabricated using a blue chip and the phosphor

白光LED由蓝光芯片与荧光粉激发而成

注意:操作时应注意静电敏感

释放设备装置

Applications(应用)

Package Dimensions(封装尺寸)

■ Portable lighting(便携照明)

■ Decorative lighting(装饰照明)

■ OA equipment(办公照明)

■ Backlighting of full color LCD(液晶背光)

■ Bulbs and fluorescent lamps(家居照明)

Recommended Soldering Pattern

(建议焊盘尺寸图)

Notes:(备注)

1. All dimension units are millimeters.(所有标注尺寸单位为毫米)

2.All dimension tolerance is ±0.15mm unless otherwise noted.(除特别标注外,所有尺寸允许公差±0.15mm )

SPEC NO:B-17-A-1605

REV NO: A/1

DATE: July/13/2018

PAGE: 2 OF 11

●

�Under Development

Mass production

HL-EMC-3030D46W-2C-S1-HR3

Selection Guide(选择指南)

Part No. 型号

Chip Materials 芯片材料

Lens Type 胶体类型

InGaN

Yellow Diffused

HL-EMC-3030D46W-2C-S1-HR3

Mass Production list(批量生产目录)

Part No. 型号

CCT(K)

Min

CCT(K)

Typ

CCT(K)

Max

Φ(lm)

Min

Φ(lm)

Typ

Test Conditions

测试条件

2600

2720

2800

110

120

IF=150mA

2850

2950

3150

120

130

IF=150mA

3300

3460

3700

120

130

IF=150mA

3800

4010

4200

130

140

IF=150mA

4700

4970

5300

130

140

IF=150mA

5700

6000

6300

130

140

IF=150mA

6150

6430

6850

130

140

IF=150mA

HL-EMC-3030D46W-2C-S1HR3

Electrical / Optical Characteristics at Ta=25°C

Parameter(参数)

Symbol

(符号)

Min.

(最小)

Forward Voltage

正向电压

VF

5.6

Viewing Angle

角度

2θ1/2

--

Color Rendering Index

显色性指数

Ra

Thermal Resistance

热阻

Rθjc

Typ.

(平均)

电性与光学特性

Max.

(最大)

Units

(单位)

Test Conditions

测试条件

6.8

V

IF=150mA

120

--

Deg

IF=150mA

80

--

--

--

IF=150mA

--

12.5

--

℃/W

IF=150mA

--

Note:(备注)

21/2 is the angle from optical centerline where the luminous intensity is 1/2 the optical centerline value.

21/2 是半值角,指光强是光学中心线光强的1/2处到光学中心线的角度

2. The above luminous flux measurement allowance tolerance is ±10%.

上述光通量的测试允许公差为±10%

3. The above Color Rendering Index measurement allowance tolerance is ±2

以上显色性指数的测试允许公差为±2

4. The above forward voltage measurement allowance tolerance is ±2%.

以上所示电压测量误差±2%

5. The above color coordinates measurement allowance tolerance is ±0.01.

以上所示坐标测量误差±0.01

SPEC NO:B-17-A-1605

REV NO: A/1

DATE: July/13/2018

PAGE: 3 OF 11

●

�Under Development

Mass production

HL-EMC-3030D46W-2C-S1-HR3

Absolute Maximum Ratings at Ta=25°C

绝对最大额定值

Parameter(参数)

Symbol(符号)

Rating(值)

Units(单位)

Power Dissipation(功耗)

Pd

1156

mW

Forward Current(正向电流)

IF

170

mA

Peak Forward Current [1](峰值正向电流)

IFP

250

mA

Vr

10

V

Reverse Current

反向电流

IR

10

μA

Operating Temperature(操作温度)

Topr

-35 ~ +100

℃

Storage Temperature(保存温度)

Tstg

-35 ~ +85

℃

Junction Tempetatue(结温)

Tj

125

℃

Electrostatic Discharge (HBM)(静电)

ESD

2000

V

Power dissipation Reverse voltage (功耗反向电

压)

Note:(备注)

1. 1/10 Duty cycle, 0.1ms pulse width.(脉宽0.1ms,周期1/10)

SPEC NO:B-17-A-1605

REV NO: A/1

DATE: July/13/2018

PAGE: 4 OF 11

●

�Under Development

Mass production

HL-EMC-3030D46W-2C-S1-HR3

Bin Range of Chromaticity Coordinate Bin区分类及色坐标范围

SPEC NO:B-17-A-1605

REV NO: A/1

DATE: July/13/2018

PAGE: 5 OF 11

●

�Under Development

Mass production

HL-EMC-3030D46W-2C-S1-HR3

SPEC NO:B-17-A-1605

REV NO: A/1

DATE: July/13/2018

PAGE: 6 OF 11

●

�Under Development

Mass production

HL-EMC-3030D46W-2C-S1-HR3

SMT Reflow Soldering Instructions SMT回流焊说明

1.Reflow soldering should not be done more than two times. 回流焊不可以做两次以上。

2.When soldering , do not put stress on the LEDs during heating

当焊接时,不要在材料受热时用力压胶体表面。

Soldering iron 烙铁焊接

1.When hand soldering, keep the temperature of iron below less 300℃ less than 3 seconds

当手工焊接时,烙铁的温度必须小于300℃,时间不可超过3秒。

2.The hand solder should be done only one times

手工焊接只可焊接一次。

Repairing 修补

Repair should not be done after the LEDs have been soldered. When repairing is unavoidable,

a double-head soldering iron should be used (as below figure). It should be confirmed in advance

whether the characteristics of LEDs will or will not be damaged by repairing.

LED回流焊后不应该修复,当修复是不可避免时,必须使用双头烙铁(如下图),但必须事先确认此种方式会或不会

损坏LED本身的特性。

Cautions 注意事项

The encapsulated material of the LEDs is silicone. Therefore the LEDs have a soft surface on

the top of package. The pressure to the top surface will be influence to the reliability of the LEDs.

Precautions should be taken to avoid the strong pressure on the encapsulated part. So when use

the picking up nozzle, the pressure on the silicone resin should be proper.

LED封装为硅胶,故LED胶体表面较软,用力按压胶体表面会影响LED可靠性,因此应有预防措施避免在封装的零件上的

强大压力,当使用吸嘴时,胶体表面的压力应是恰当的。

SPEC NO:B-17-A-1605

REV NO: A/1

DATE: July/13/2018

PAGE: 7 OF 11

●

�Under Development

Mass production

HL-EMC-3030D46W-2C-S1-HR3

Handling Precautions 处理防备措施

Compare to epoxy encapsulant that is hard and brittle, silicone is softer and flexible. Although its

characteristic significantly reduces thermal stress, it is more prone to damage by external mechanical force . As a result, Special handling precautions must be observed during assembling using silicone encapsulated LED products, Failure to comply might leads to damage and premature failure of

the LED.

相对环氧树脂较脆较硬而言,硅胶封装较柔软且有弹性,虽然它的特性大大减少了热应力,但易受机械外力损坏,因此

在手工处理方面须要对硅胶封装材料做预防措施,若未按要求操作,可能会导致LED损坏和光衰。

1.Handle the component along the side surface by using forceps or appropriate tools; do not directly

touch or Handle the silicone lens surface, it may damage the internal circuitry.

通过使用适当的工具从材料侧面夹取,不可直接用手或尖锐金属压胶体表面,它可能会损坏内部电路。

2.The outer diameter of the SMD pickup nozzle should not exceed the size

of the LED to prevent air leaks. The inner diameter of the nozzle should be

as large as possible. A pliable material is suggested for the nozzle tip to avoid

scratching or damaging the LED surface during pickup. The dimensions of the

component must be accurately programmed in the pick-and-place machine to

insure precise pickup and avoid damage during production.

为防止气压泄漏,SMD吸咀外径不可以超过LED尺寸,吸咀内径尺寸应尽可能大,吸咀顶端材

质建议采用柔软材料以防在吸取期间刮伤或损坏LED胶体表面,元件的尺寸必须在取放机里准

确的编程好,以确保精确的吸取和避免生产过程中的损害。

3.Do not stack together assembled PCBs containing

LEDs. Impact may scratch the silicone lens or damage

the internal circuitry

4.Not suitable to operate in acidic environment, PH

HL-EMC-3030D46W-2C-S1-HR3 价格&库存

很抱歉,暂时无法提供与“HL-EMC-3030D46W-2C-S1-HR3”相匹配的价格&库存,您可以联系我们找货

免费人工找货