HuBei TKD Electronic Technology Co.,LTD

湖北泰晶电子科技股份有限公司

Page 1 of 9

CRYSTAL SPECIFICATION

客户

:

客户料号

泰晶料号

:

:

产品类别

日期

:

CS13K032768DDE

M8-32.768-6-20

2019.1.7

:

CUSTOMER’S APPROVAL

地址:湖北省武汉市东湖新技术开发区光谷二路219号光谷新动力15号楼

电话:027-65521137,FAX:027-65521932

(PLEASE RETURN A COPY WITH APPOVAL

Hubei TKD Electronic Technology Co.,LTD

湖北泰晶电子科技股份有限公司

DESIGNER

APPROVED

何金玲

代 伟

SALE Department :TEL :0722-3309660

FAX :0722-3309768

QCD Department :TEL :0722-3308231

FAX :0722-3309768

FAE Department :TEL :0755-27328651

FAX :0755-27328001

�HuBei TKD Electronic Technology Co.,LTD

湖北泰晶电子科技股份有限公司

Page 2 of 9

REV.

Description of Revision History

Date

Designer

Checked By

A

New revision

2019 年 1 月 7 日

HE JIN LING

Dai Wei

�HuBei TKD Electronic Technology Co.,LTD

湖北泰晶电子科技股份有限公司

Page 3 of 9

CRYSTAL SPECIFICATION

1.

2.

3.

4.

5.

6.

Description:

Tuning Fork Quartz Crystal

Nominal Frequency:

32.768KHz

Oscillation Mode:

Fundamental

Cutting Mode:

X-2° cut

Measurement Instrument: S&A 250B(Calculated FL)

Electrical Characteristics:

[1]Operation Conditions:

Item

Symbol

MIN.

Operating Temperature Range

Topt

Storage Temperature Range

Tstg

TYP.

MAX.

Unit

-40

85

℃

-55

125

℃

Load Capacitance

CL

6

pF

Drive Level

DL

0.1

uW

Condition

[2]Frequency Stability:

Item

Symbol

MIN.

Tolerance

dF/Fo

-20

Stability Over Temperature

dF/F25

Aging

dF/F25

TYP.

MAX.

Unit

Condition

20

ppm

Refer to Center Frequency@25±3℃

ppm/℃2

-0.036

-5

5

ppm

Refer to Operating Temperature

Per Year

dF/Fo:Frequency Deviation Refer to Center Frequency

dF/F25:Frequency Deviation Refer to 25℃ Frequency

[3]Electrical Performance:

Item

MAX.

Unit

ESR

50

KΩ

Shunt Capacitance

C0

5

pF

Insulation Resistance

IR

Equivalent Series Resistance

Symbol

MIN.

TYP.

500

MΩ

Condition

@Series

@DC 100 Volt

7.

Marking:Laser

Marking Generally:32.768. Refer to with Customer’s requirement.

32.768

�HuBei TKD Electronic Technology Co.,LTD

湖北泰晶电子科技股份有限公司

Page 4 of 9

8.

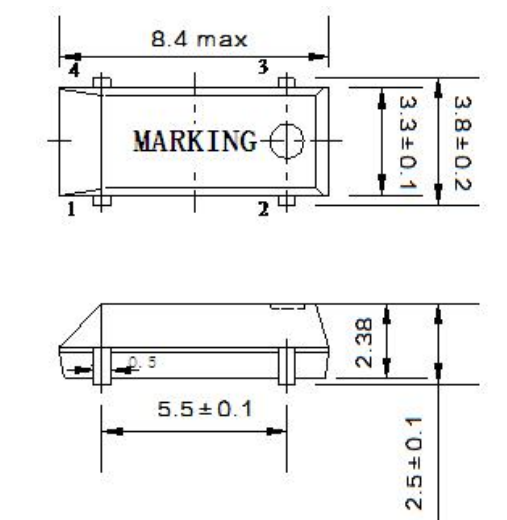

Outline drawing (unit:mm)

Recommended soldering pattern

�HuBei TKD Electronic Technology Co.,LTD

湖北泰晶电子科技股份有限公司

Page 5 of 9

9. Reliability Specification

Test Items

Test Method and Condition

Vibration

(1)Vibration Frequency

10 to 55Hz

(2)Vibration Amplitude

1.5mm

(3)

Cycle Time

1-2min(10-55-10Hz)

(4)Direction

(5)Duration

Shock

Hermetic seal

Solder ability

High temperature

X.Y.Z

3 Times free drop from 75cm height to hard wooden

board of thickness more than 30mm

Helium leak detector

Checked:before the molded crystal uints

Temperature cycle

Resistance Change:±15% or 5kohm Max.

Frequency Change:±10ppm Max.

Resistance Change:±15% or 5kohm Max.

less than 1 × 10 EXP(–7) mbar.l/sec.

Dip the leads of crystal units into the solution (7-10%) of

The dipped surface of the leads should be at

rosin 3±0.5s,then dip it into the tank 5-10s.

least 95% covered with continuous new solder

Temperature of solder melted tank is

coating

245℃±5℃

240 hours at +85℃±2℃

After 1-2hours past at room temperature from following

After 1-2hours past at room temperature from following

test.

Humidity

Frequency Change:±10ppm Max.

2h/each direction

240 hours at -40℃±2℃

Low temperature

Requirements

240 hours at +40℃±2℃,relative humidity 90-95%

After 1-2hours past at room temperature from following

Frequency Change:±10ppm Max.

Resistance Change:±25% or 10kohm Max.

Frequency Change:±10ppm Max.

Resistance Change:±15% or 5kohm Max.

Frequency Change:±10ppm Max.

Resistance Change:±25% or 10kohm Max.

After supplying the following temperature cycle

Frequency Change:±10ppm Max.

(50cycles)

Resistance Change:±25% or 10kohm Max.

�HuBei TKD Electronic Technology Co.,LTD

湖北泰晶电子科技股份有限公司

Page 6 of 9

After 24h past from frequency test,

F

Reflow soldering

Frequency Change:±10ppm Max.

Resistance Change:±25% or 10kohm Max.

Notice:

1、Using the infrared lamp at soldering

process may cause uneven temperature

rise on plastic surface of the parts,so

that

please keep the package temperature

within left conditions.

2、DO NOT dip the plastic part into

solder

�HuBei TKD Electronic Technology Co.,LTD

湖北泰晶电子科技股份有限公司

Page 7 of 9

10. Handling Notice for Standard Tuning Fork Crystal (Cylindrical Type)

10.1. Shock resistance

It may deteriorate the characteristics or cause of no oscillation if excess physical shock given. Please be

careful not to drop. Please use under condition to minimize the shocks as much as possible.

Please review the conditions if it is used by auto mounting or after the conditions are changed.

10.2. Heat and humidity resistance in storage

Storing the crystal products under higher or lower temperature or high humidity for a long period may

deteriorate the characteristics of crystal units. Please store and use the crystal products at the normal

temperature and humidity.

10.3 Solder heat resistance

Please review the condition or consult us about flow solder process.

Our soldering condition is under 265ºC within 15±5sec .

�HuBei TKD Electronic Technology Co.,LTD

湖北泰晶电子科技股份有限公司

Page 8 of 9

10.4. Mounting metho

When the crystal products need to be lay down please fix to PCB securely.

If the crystal is used with mechanical vibration location, please put cushion in between PCB or fix with

elasticity glue (Silicon etc) as shown in below figure. Please don’t gluing hermetic seal grass.

10.5.Ultrasonic cleaning and ultrasonic soldering

Soldered by ultrasonic cannot be guaranteed, because crystal may be sympathetic vibrated and may damage.

Please study at your side about ultrasonic cleaning.

10.6. Drive level

Applying excessive drive level to the crystal units may cause deterioration of characteristics or damage. Less

then 1.0μW is recommended to this products. More than 2.0μW cannot be guaranteed.

10.7.Solder paste should be more than 150μm thickness.

10.8.Storage environment

10.8.1 To storage the reel at +15℃ to +35℃,25%RH to 65%RH of Humidity.

10.8.2 To open the packing just before using.

10.8.3 Not to expose the sun.

10.8.4 Not to storage with some erosive chemicals.

10.8.5 Nothing is allowed to put on the reel or carton to prevent mechanical damage.

�HuBei TKD Electronic Technology Co.,LTD

湖北泰晶电子科技股份有限公司

Page 9 of 9

11.PACKING

�

很抱歉,暂时无法提供与“CS13K032768DDE”相匹配的价格&库存,您可以联系我们找货

免费人工找货