BR Series

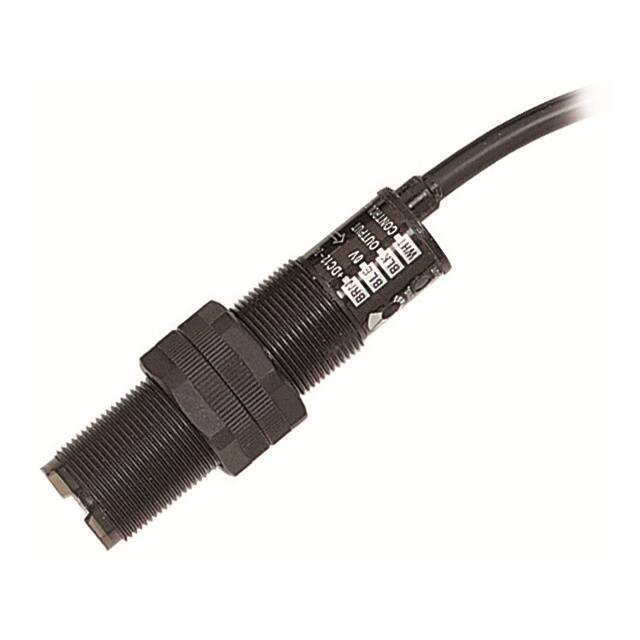

Cylindrical (Ø18mm) Type

Features

SENSORS

● Realizes long sensing distance (20m) (through-beam type)

● Superior noise resistance with digital signal processing

● High-speed response time under 1ms

● �Power reverse polarity protection circuit,

output short over current protection circuit

● Suitable for sensing in narrow space (narrow beam type)

● External sensitivity adjustment (except through-beam type)

● Light ON, Dark ON switchable by control wire

(except through-beam type)

● Excellent environment-resistance performance with glass lens(BR4M)

● Protection structure IP66 (IEC standard)

Please read “Safety Considerations”

in the instruction manual before using.

model

BR100DDT

BR100

DDT-C

BR100

DDT-P

BR100

DDT-C-P

Metal

BRP400

DDT

BRP400

DDT-C

BRP400

DDT-P

BRP400

DDT-C-P

Plastic

BR400DDT

BR400

DDT-C

BR400

DDT-P

BR400

DDT-C-P

Metal

Diffuse reflective type

Sensing distance

100mm

Sensing target

Opaque, translucent materials

400mm

Cable type

SOFTWARE

(MS-2)

Connector Type

※The model name with ‘-C’ is connector type.

※MST- is sold separately.

Sensing type

※1

MOTION DEVICES

(MST- )

Specifications

BRP100NPN open collector DDT

output

BRP100

DDT-C

BRP100

PNP open collector DDT-P

output

BRP100

DDT-C-P

Case

Plastic

CONTROLLERS

※2

BRP200 BR200

DDTN

DDTN

BRP200 BR200

DDTN-C DDTN-C

BRP200 BR200

DDTN-P DDTN-P

BRP200 BR200

DDTN-C-P DDTN-C-P

Plastic

Metal

Narrow beam

reflective type

※2

200mm

BR4MBR20M- BR4MBR20MTDTD

TDTD

TDTL

TDTL

BR4MBR20M- BR4MBR20MTDTD-C TDTD-C TDTL-C TDTL-C

BR4MBR20M- BR4MBR20MTDTD-P TDTD-P TDTL-P TDTL-P

BR4MBR20M- BR4MBR20MTDTD-C-P TDTD-C-P TDTL-C-P TDTL-C-P

Metal

4m

20m

4m

(B)

Fiber Optic

Sensors

(C)

LiDAR

(D)

Door/Area

Sensors

20m

Opaque materials of min. Ø15mm

Ambient temperature -10 to 60℃, storage: -25 to 75℃

Ambient humidity

Protection structure

(A)

Photoelectric

Sensors

Through-beam type

Max. 20% at rated sensing distance

Max. 1ms

12-24VDCᜡ±10% (ripple P-P: max. 10%)

Max. 45mA

Infrared LED (940nm) Infrared LED (850nm)

Red LED (660nm) Infrared LED (850nm)

Sensitivity adjuster

Fixed

Selectable Light ON or Dark ON by control wire (white)

Dark ON

Light ON

NPN

or

PNP

open

collector

output

Control output

●Load voltage: max. 30VDCᜡ ●Load current: max. 200mA ●Residual voltage - NPN: max. 1VDCᜡ, PNP: max. 2.5VDC

Protection circuit

Power reverse polarity protection circuit, output short over current protection circuit

Indicator

Operation indicator: red LED, power indicator: red LED (only for emitter of through-beam type)

Connection

Cable type, connector type

Insulation resistance Over 20MΩ (at 500VDC megger)

Noise immunity

±240V the square wave noise (pulse width: 1㎲) by the noise simulator

Dielectric strength

1000VAC 50/60Hz for 1 minute

Vibration

1.5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Shock

500m/s² (approx. 50G) in each X, Y, Z direction for 3 times

Ambient illumination Sunlight: max. 11,000lx, incandescent lamp: max. 3,000lx (receiver illumination)

Environment

Hysteresis

Response time

Power supply

Current consumption

Light source

Sensitivity adjustment

Operation mode

BRP3M- BR3MMDT

MDT

BRP3M BR3MMDT-C MDT-C

BRP3M BR3M-

MDT-P MDT-P

BRP3M- BR3M-

MDT-C-P MDT-C-P

Plastic Metal

Retroreflective

type

※3

3m

Opaque materials

of min. Ø60mm

-

35 to 85%RH, storage: 35 to 85%RH

IP66 (IEC standard) (BR20M Series: IP67)

●Case - BRP:

●Case - brass, ni-plate

polyamide (black) ●�Sensing part - �BR4M: glass lens

Material

BR: brass, ni-plate

BR20M: �polycarbonate

●Sensing part lens

acrylic lens

Ø5mm,

4-wire,

2m

(emitter

of

through-beam

type:

Ø5mm,

2-wire,

2m

/

receiver:

Ø5mm,

3-wire,

2m)

Cable type

(AWG22, core diameter: 0.08mm, number of cores: 60, insulator out diameter: Ø1.25mm)

Cable

Connector type M12 connector

Adjustment

Individual

Adjustment screwdriver

screwdriver,

AcceReflector (MS-2)

ssory

● BR: M18 fixing nut: 2, washer: 1

● BR: M18 fixing nut: 4, washer: 2

Common

● BRP: M18 fixing nut: 2

● BRP: M18 fixing nut: 4

Approval

※4

●BRP:

approx.

140g

(approx.

100g)

●BR:

approx.

160g

(approx.

120g)

●BR: a

� pprox. 340g (approx. 300g)

Weight

●BRP-C: approx. 70g (approx. 30g)

●BR-C: approx. 90g (approx. 50g) ●BR-C:�approx. 150g (approx.110g)

※1: Non-glossy white paper 50×50mm.

※2: Non-glossy white paper 100×100mm.

※3: �The sensing distance is specified with using the MS-2 reflector. The distance between the sensor and the reflector should be set over

0.1m. When using reflective tapes, the reflectivity will vary by the size of the tape. Please refer to the catalog or website.

※4: The weight includes packaging. The weight in parenthesis is for unit only.

※Tightening torque for connector is 0.39 to 0.49N.m.

※The temperature or humidity mentioned in Environment indicates a non freezing or condensation.

●Case - �BRP: polyamide (black)

BR: brass, ni-plate

●Sensing part - polycarbonate lens

A-101

(E)

Vision

Sensors

(F)

Proximity

Sensors

(G)

Pressure

Sensors

(H)

Rotary

Encoders

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

�BR Series

Feature Data

Diffuse reflective type / Narrow beam reflective type

Sensing area characteristic

Sensing area characteristic

Measuring method Data

Measuring method

Measuring method Data

Standard sensing

target:Non-glossy

white paper

50×50mm

Standard sensing

target:Non-glossy

white paper

50×50mm

L

Sensing distance L (mm)

ℓ1

100

Data

ℓ1

70

40

L

10

0

Diffuse

reflective

20

10

0

ℓ1

Left

10

ℓ1

Center

20

400

ℓ1

300

200

L

100

0

20

Diffuse

reflective

Right

Sensing area ℓ1 (mm)

Standard sensing

target:Non-glossy

white paper

50×50mm

10

0

ℓ1

Left

Center

10

Sensing distance L (mm)

●BR200-DDTN- (-P)/BRP200-DDTN- (-P)

Sensing area characteristic

Sensing distance L (mm)

●BR100-DDT- (-P)/BRP100-DDT- (-P) ●BR400-DDT- (-P)/BRP400-DDT- (-P)

200

150

100

50

0

20

20

ℓ1

Diffuse

reflective

Right

Sensing area ℓ1 (mm)

10

0

ℓ1 ℓ1

Left

Center

10

20

Right

Sensing area ℓ1 (mm)

Retroreflective type

● BR3M-MDT- (-P) / BRP3M-MDT- (-P)

Parallel shifting characteristic

Parallel shifting characteristic

Parallel shifting characteristic

Measuring method

Measuring method

Measuring method Data

Reflector (MS-2)

L

4

3

θ

2

1

0

120 80

40

0

ℓ1

40

80 120

ℓ1

Center

Left

Retroreflective

L

Right

Reflector (MS-2)

Sensing distance L (m)

Sensing distance L (m)

Reflector (MS-2)

ℓ1

Data

4

3

2

L

1

0

10°

5°

0

Center

Left

5°

10°

4

3

2

1

0

60° 40° 20°

Left

Right

Operation angle θ

Retroreflective

Sensing area ℓ1 (mm)

θ

Sensing distance L (m)

Data

Angle characteristic

Measuring method

Measuring method

Receiver

L

ℓ1

L

Sensing distance L (m)

Data

4

Receiver

3

2

θ

L

1

0

200

Emitter

100

ℓ1

0

100

ℓ1

Center

Left

200

4

3

2

1

0

20°

10°

0

Center

Left

Right

Sensing area ℓ1 (mm)

● BR20M-TDT -

Data

Sensing distance L (m)

/ BR4M-TDT - -P

Parallel shifting characteristic

/ BR20M-TDT - -P

Parallel shifting characteristic

Angle characteristic

Measuring method

Measuring method

Data

10

20°

Right

Operation angle θ

Emitter

Data

Emitter

L

20

Receiver

15

10

θ

5

0

800 600 400 200 0 200 400 600 800

ℓ1

Left

Center

Right

A-102

15

10

5

0

15° 10°

ℓ1

Sensing area ℓ1 (mm)

L

Sensing distance L (m)

ℓ1

Sensing distance L (m)

20

Receiver

Emitter

Left

5°

0°

Center

20° 40° 60°

Right

Operation angle θ

Retroreflective

Through-beam type

● BR4M-TDT -

0

Center

5° 10°

Right

Operation angle θ

15°

�Cylindrical Type

Dimensions

(unit: mm)

Diffuse reflective/Narrow beam reflective/Retroreflective type

BR100-DDT(-P)

BR400-DDT(-P)

Ø29

24

BR200-DDTN(-P)

SENSORS

BR3M-MDT(-P)

CONTROLLERS

4

47

74.3

18.3

Sensitivity

adjuster

4

48

75.3

18.3

M18×1

4

�BR100-DDT-C(-P)

�BR400-DDT-C(-P)

Ø29

24

3

48

4

Lens

Ø5, 2m

17.6

M18×1

Sensitivity

adjuster

Operation

indicator (red)

M18×1

4

�BR200-DDTN-C(-P)

78.6

MOTION DEVICES

Operation

indicator (red)

Operation

indicator (red)

Lens

Sensitivity

adjuster

SOFTWARE

Ø5, 2m

BR3M-MDT-C(-P)

4

M12×1

79.6

48

17.6

M18×1

4

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

Sensitivity

adjuster

Operation

indicator (red)

(C)

LiDAR

(D)

Door/Area

Sensors

M12×1

(E)

Vision

Sensors

BRP100-DDT(-P)

BRP400-DDT(-P)

Ø26.5

24

3

BRP200-DDTN(-P)

48

44

Lens

BRP100-DDT-C(-P)

BRP400-DDT-C(-P)

Ø26.5

24

3

74.3

18.3

M18×1

Sensitivity

adjuster

Operation

indicator (red)

4

Ø5, 2m

78.6

17.6

Sensitivity

adjuster

48

44

BRP200-DDTN-C(-P)

48

75.3

18.3

M18×1

44

M18×1

M12×1

(G)

Pressure

Sensors

Sensitivity

adjuster

(H)

Rotary

Encoders

Operation

indicator (red)

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

Ø5, 2m

BRP3M-MDT-C(-P)

4

48

79.6

17.6

Sensitivity

adjuster

Operation

indicator (red)

Operation

indicator (red)

Lens

(F)

Proximity

Sensors

BRP3M-MDT(-P)

44

M18×1

M12×1

A-103

�BR Series

Through-beam type

(unit: mm)

BR4M-TDTD(-P) / BR4M-TDTL(-P)

Ø29

24

68.5

2.5

67

Operation

indicator (red)

48

Lens

Operation

indicator (red)

46.5

2.5

Lens

Ø5, 2m

M18×1

4

Ø5, 2m

M18×1

4

BR4M-TDTD-C(-P) / BR4M-TDTL-C(-P)

Ø29

24

74.1

Lens

2.5

17.6

44

Operation

indicator (red)

72.6

2.5

Lens

17.6

42.5

M12×1

4

M18×1

Power indicator

(red)

M12×1

4

M18×1

BR20M-TDTD(-P) / BR20M-TDTL(-P)

Ø29

24

3

62

41

11.5

Power indicator

(red)

Lens

M18×1

4

Ø5, 2m

62

41

3

11.5

Operation

indicator (red)

Lens

Ø5, 2m

M18×1

4

BR20M-TDTD-C(-P) / BR20M-TDTL-C(-P)

Ø29

24

3

Lens

M18×1

37

67.6

17.6

M12×1

4

37

3

Power indicator

(red)

Lens

M18×1

67.6

17.6

M12×1

4

Operation

indicator (red)

Connection cable (sold separately)

CIDH4-

CLDH4-

Ø6

Ø14.8

32

Ø14.8

L(m)※

※�Specifi cation of connector cable: Ø6mm, 4-wire, 2m/3m/5m/7m

(AWG22, core diameter: 0.08mm, number of cores: 60, insulator out diameter: Ø1.65mm)

A-104

Ø6

27.5

40

L(m)※

�Cylindrical Type

● Reflector

M18 fixing nut

4

24

M18×1

A

2-Ø3.8

0.38

SENSORS

4.2

24

24

4

Reflective tape (sold separately)

MS-2

52

60.5

(unit: mm)

M18×1

34

40.5

Model

3.25

8.5

2.5

CONTROLLERS

A

MST-50-10

50

MST-100-5

100

MST-200-2

200

MOTION DEVICES

SOFTWARE

Operation Mode

Operation mode

Light ON

Receiver operation

Dark ON

Received light

Received light

Interrupted light

Interrupted light

ON

ON

OFF

OFF

ON

ON

OFF

OFF

Operation indicator

(red LED)

Transistor output

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

※The transistor output will be held OFF for 0.5 sec after supplied power in order to prevent malfunction of this photoelectric

sensor (except through-beam type).

Connections

● Diffuse reflective type /

Narrow beam reflective type

Sensitivity adjuster

Sensitivity adjuster

+ 12-24VDC

-

Dark ON

Light ON

MS-2 (reflector)

Reflective tape

(MST Series)

(brown) +V

Operation indicator

(red)

Sensing target

(blue) 0V

Dark ON

(white) Control

Light ON

(brown) +V

+ 12-24VDC

(blue) 0V

(white) Control

Operation indicator

(red)

Sensing target

(brown) +V

(brown) +V

+

12-24VDC

-

(blue) 0V

12-24VDC

+

-

(blue) 0V

(black) Output

Connections for Connector Part

1

Pin No.

2

3

4

M12 Connector pin

1

2

3

4

Cable

color

Brown

White

Blue

Black

Application

Diffuse/

Narrow beam reflective/

Retroreflective type

24VDC

CONTROL

GND

OUTPUT

Through-beam type

Emitter

Receiver

24VDC

N.C

GND

N.C

24VDC

GND

GND

OUTPUT

(G)

Pressure

Sensors

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

● Through-beam type

Power indicator

(red)

(F)

Proximity

Sensors

(H)

Rotary

Encoders

(black) Output

(black) Output

(D)

Door/Area

Sensors

(E)

Vision

Sensors

● Retroreflective type

Operation indicator

(red)

Sensing target

(C)

LiDAR

● Connector cable (sold separately)

※�Please refer to the

connector cable section.

A-105

�BR Series

Control Output Diagram

● NPN open collector output

● PNP open collector output

Through-beam type (receiver)

Through-beam type (receiver)

Connection

Main circuit

1

4

Output short

over current

protection circuit

Photoelectric sensor circuit

1.5Ω

3

(brown) +V

1

Load

(black) Output

+

-

Max. 200mA

39V

Connection

(brown) +V

12-24VDC

Main circuit

Photoelectric sensor circuit

Output short

over current

protection circuit

1.5Ω

39V

Max. 200mA

4

(blue) 0V

3

(black) Output

(blue) 0V

+

-

12-24VDC

Load

Diffuse reflective/Narrow beam reflective/Retroreflective type

Diffuse reflective/Narrow beam reflective/Retroreflective type

Photoelectric sensor circuit

Photoelectric sensor circuit

Connection

Main circuit

4

Output short

over current

protection circuit

39V

1.5Ω

3

10kΩ

2

1

Load

(black) Output

+

Max. 200mA

(blue) 0V

Connection

Dark ON

-

12-24VDC

Main circuit

1

(brown) +V

Light ON

Output short

over current

protection circuit

Dark ON

1.5Ω

39V

Max. 200mA

4

3

10kΩ

(white) Control

(brown) +V

2

(black) Output

(blue) 0V

Load

+

-

12-24VDC

Light ON

(white) Control

※Before using this unit, select Light ON/Dark ON with control wire. (light on: connect control wire 0V / dark on: connect control wire with +V)

※Control wire is only for Diffuse reflective/Narrow beam reflective/Retroreflective type.

※�If short-circuit the control output terminal or supply current over the rated specification, normal control signal is not output due to the

output short over current protection circuit.

Installation and Sensitivity Adjustment

Install the sensor to the desired place and check the connections. Supply the power to the sensor and adjust the optical

axis and the sensitivity as following.

When using photoelectric sensors closely over two units, it may result in malfunction due to mutual interference.

When installing the product, tighten the screw with a tightening torque of 0.39N.m for BRP and to 14.7N.m for BR.

Diffuse reflective/Narrow beam reflective type

1. The sensitivity should be adjusted depending on a

sensing target or mounting place.

※Be sure that it can be different by size, surface and gloss

of target.

ⓐ

Optimal

position

ⓑ

Photoelectric sensor

Sensing target

2. Set the target at a position to be detected by the beam,

then turn the sensitivity adjuster until position ⓐ where

the operation indicator turns ON from min. position of the

sensitivity adjuster.

3. Take the target out of the sensing area, then turn the

sensitivity adjuster until position ⓑ where the operation

indicator turns ON. If the indicator dose not turn ON,

max. position is ⓑ.

4. Set the sensitivity adjuster at the center of two switching

position ⓐ, ⓑ.

A-106

MAX

MIN

SENS

�Cylindrical Type

Through-beam type

1. Supply the power to the photoelectric sensor, after

setting the emitter and the receiver facing each other.

2. Set the receiver in center of position in the middle of the

operation range of indicator by adjusting the receiver or

the emitter right and left, up and down.

3. After the adjustment, check the stability of operation

putting the object at the optical axis.

※If the sensing target is translucent body or smaller than

Ø15, it can be missed by sensor cause light penetrate it.

Adjust

Right/Left

Emitter

Receiver

Reflectivity by Reflective Tape

Model

MST-50-10 (50×50mm)

80%

MST-100-5 (100×100mm)

120%

MST-200-2 (200×200mm)

140%

SENSORS

CONTROLLERS

※This reflectivity is based on the reflector (MS-2).

※Reflectivity may vary depending on usage environment

and installation conditions.

The sensing distance and minimum sensing target size

increase as the size of the tape increases.

Please check the reflectivity before using reflective

tapes.

※For using reflective tape, installation distance should be

min. 20mm.

MOTION DEVICES

SOFTWARE

Adjust

Up/Down

(A)

Photoelectric

Sensors

Retroreflective type

1. Supply the power to the photoelectric sensor, after

setting the photoelectric sensor and the reflector (MS-2)

or reflective tape face to face.

2. Set the photoelectric sensor in the position which

indicator turns on, as adjusting the reflector or the

sensor right and left, up and down.

3. Fix both units tightly after checking that the unit detects

the target.

Adjust

Right/Left

(C)

LiDAR

(D)

Door/Area

Sensors

(E)

Vision

Sensors

Reflector (MS-2)

Reflective tape

(MST Series)

Optical axis

Photoelectric

sensor

(B)

Fiber Optic

Sensors

(F)

Proximity

Sensors

(G)

Pressure

Sensors

Adjust Up/Down

(H)

Rotary

Encoders

※If using more than 2 photoelectric sensors in parallel,

the space among them should be more than 30cm.

※If reflectance of target is higher than non-glossy white

paper, it might cause malfunction by reflection from

the target when the target is near to photoelectric sensor.

Therefore put enough space between the target and the

photoelectric sensor or the surface of the target should

be installed at angle of 30 to 45° against optical axis.

(when a sensing target with high reflectance near by,

photoelectric sensing with the polarizing filter should be

used.)

※Sensitivity adjustment: R

� efer to the diffuse reflective/

narrow beam reflective type’s.

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

30 to 45°

L

Sensing

target

※If the mounting place is too

narrow, please use MS-4 instead

of MS-2.

※Please use reflective tape (MST

Series) for where a reflector is not

installed.

Reflector (MS-2)

Reflective tape

(MST Series)

A-107

�