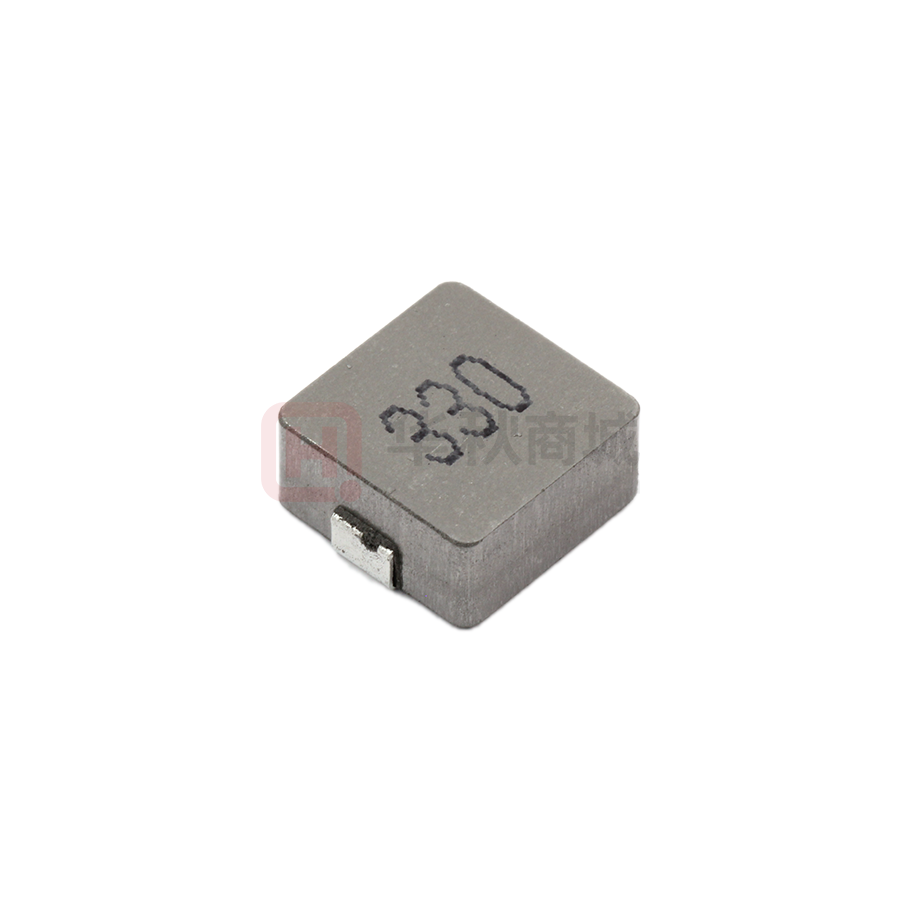

1. 物料型号:SLO1365H330MTT

2. 器件简介:

- 该电感器采用磁性金属粉末材料制成。

- 设计紧凑,具有高电流、低直流电阻(DCR)和高效率。

- 非常低的声学噪声和漏磁噪声。

- 高可靠性。

- 100%无铅且符合RoHS标准。

3. 引脚分配:文档中未明确提供引脚分配信息,但通常这类电感器为表面贴装元件,具体引脚分配需参考产品规格书或数据手册。

4. 参数特性:

- 典型电感值(LO Inductance):33uH,最大40uH。

- 直流电阻(DCR):最大48mΩ。

- 额定直流电流(Idc):5.0A,当温度上升约40°C时。

- 饱和直流电流(Isat):9.0A,此时电感值下降约35%。

5. 功能详解:

- 电感值随直流电流变化的曲线图显示了在不同直流电流下的电感值变化。

- 温度上升与直流电流的关系图显示了在不同直流电流下的温升情况。

6. 应用信息:

- 工作温度范围:-55°C至+125°C。

- 存储温度:-10°C至+40°C,相对湿度50-60%(未封装产品)。

7. 封装信息:

- 外形尺寸:最大14.40mm x 12.80mm,高度6.50mm,端头宽度2.50mm。

- 推荐焊盘尺寸:长度4.50mm,宽度3.40mm,间距14.10mm。

8. 可靠性和测试条件:

- 包括高温暴露、低温寿命测试、偏置湿度测试、热冲击测试、振动测试和回流测试等。

9. 焊接条件推荐:

- 推荐使用回流焊,提供了焊接温度曲线和高温耐热性描述。

10. 包装信息:

- 提供了不同包装类型的尺寸和数量信息。