SPECIFICATION FOR APPROVAL

CUSTOMER

CUST. PART NO.

CUST. DOC. REV.

DESCRIPTION

SAMPLE LOT NO.

PART NO.

DOC. REV.

DATE

HIGH CURRENT POWER CHOKE(ROHS+H.F)

S201809-0056

MCS0530-XXXMN2

ORIG

9/18/’18

Once you approve this part, please sign and return this page to the following marked location.

Customer Signature:___________________

Date:_________________

□This part currently development section.

□Production line can produce this series of products.

■Sales Office-Headquarter

No. 566-1, Kao-Shi Rd., Yangmei, Taoyuan 32668,

Taiwan

TEL: +886-3-475-3355

FAX: +886-3-485-4959

□Yong Zhou Plant

Tao-Yuan Rd., Fenghuang Park, Lengshuitan

District, Yongzhou, Hunan 425000, P.R.C.

TEL: +86-746-8610-180

FAX: +86-746-8610-181

□Sales Office-Dong Guan,China

No.638,Mei Jing West Road Xiniupo Administrative

Zone Dalang Town,Dong Guan City,GuangDong

Province,China.

TEL: +86-769-8555-0979

FAX: +86-769-8555-0972

TESTED BY

CHECKED BY

APPROVED BY

Zhikai Deng

Tieqiao Gong

Shengjun Zhou

PROSPERITY DIELECTRICS CO., LTD.

�TABLE OF CONTENTS

INDEX

Page

■ Engineering Change Notice - Record ……………………….

2

■ Product Identification ………….…………….………………….

3

■ Product Dimension

3

……….…………….…………………….

■ Marking and Date code

….…………….……………………...

3

■ Electrical Spec. ……………………………………………...……

4

■ Reliability Performance

……………………………………….

5

……………………………………………………..

6

■ Package Form …………………………………………………….

7

■ Reflow Chart

■ Test Report ………………………………………………………..

Rev.D

.

P1

.Prosperity Dielectrics Co., Ltd.

�SPECIFICATION FOR APPROVAL

CUSTOMER P/N

CUSTOMER

REV.

SPL. LOT NO.

S201809-0056

-

PART NAME

PART NO.

HIGH CURRENT POWER

CHOKE(ROHS+H.F)

REV.

MCS0530-XXXMN2

DATE OF ISSUE

ORIG

Q'TY

9/18/’18

0 PCS

ENGINEERING CHANGE NOTICE - RECORD

REVISION

NO.

ORIG

Rev.D

REVISION DESCRIPTION

P2

Prosperity Dielectrics Co., Ltd.

AUTHOR

DATE

Zhikai Deng

9/18/’18

REMARK

�SPECIFICATION FOR APPROVAL

※This is a RoHS and REACH compliant product whose related documents are available on request.

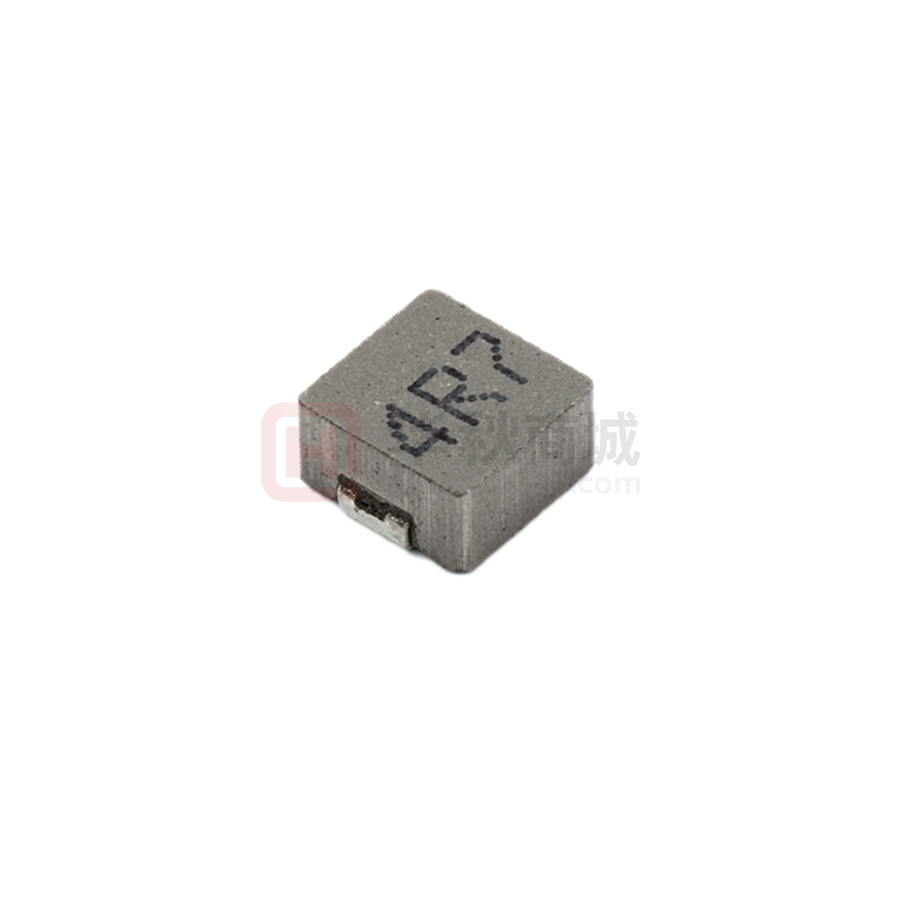

※Graphic is only for dimensionally application.

1. PRODUCT IDENTIFICATION

2. PRODUCT DIMENSION

UNIT:

3. MARKING AND DATE CODE

Marking ex:2.2uH 2R2

Rev.D

P3

Prosperity Dielectrics Co., Ltd.

mm

DIM.

TOL.

M1

5.4

±0.3

M2

5.2

±0.3

M3

3.0

Max

M4

2.2

±0.3

M5

1.2

±0.2

�SPECIFICATION FOR APPROVAL

4. ELECTRICAL SPEC.

PART NO.

MCS0530-R20MN2

MCS0530-R47MN2

MCS0530-R68MN2

MCS0530-1R0MN2

MCS0530-1R2MN2

MCS0530-1R5MN2

MCS0530-2R2MN2

MCS0530-3R3MN2

MCS0530-4R7MN2

MCS0530-6R8MN2

MCS0530-100MN2

Inductance

(uH)±20%

0.20

0.47

0.68

1.0

1.2

1.5

2.2

3.3

4.7

6.8

10

DCR mΩ

Typical 25℃

3.5

7.4

11

13

15

20

25

32

50

75

110

DCR mΩ

MAX.25℃

3.9

8.5

12

14

16

25

29

38

60

90

125

Rated Current

Typical (A)

18.0

13.5

8.5

7.0

6.5

6.0

5.5

5.0

3.5

3.0

2.5

I sat

Typical (A)

14.5

12.0

14.0

11.0

11.0

8.5

7.5

6.0

5.0

4.0

3.5

TEST INSTRUMENT: CHROMA 16502 、Zentech1320+Zentech3305

(1). Test Freq : 100KHz , 0.5V

(2). All test data is referenced to 25℃ ambient.

(3). Operating Temperature Range -55℃ to +125℃.

(4). Rated Current: DC current(A)that will cause an approximate△T of 40℃.

(5). I sat: DC current(A)that will cause Lo to drop approximately 30%.

(6). The part temperature(ambient +temp rise)should not exceed

125℃ under worst case operating conditions. Circuit design, component placement, PWB trace size and

thickness, airflow and other cooling provisions all affect the part temperature Part temperature should be verified

Rev.D

P4

Prosperity Dielectrics Co., Ltd.

�SPECIFICATION FOR APPROVAL

5. RELIABILITY PERFORMANCE

Reliability Experiment For Electrical

Test Item

Test Condition

Standard Source

Humidity Test

+40℃± 2℃, humidity of 90% ± 5% (total 96 hours).

MIL-STD-202G

Method 103B

Test Condition B

High Temperature Test

1.Temperature: +125℃±2℃

2.Test time: 48±2hrs

IEC 68-2

Test Condition B

Low Temperature Test

1.Temperature: -40℃±2℃

2.Test time: 48±2hrs

IEC 68-2

Test Condition A

Thermal Shock

+125℃±5℃ (30 minutes) ~ -40 ± 5℃ (30 minutes),

temperature switch time: 5 minutes (total 50 cycles).

MIL-STD-202G

Method 107G

Test Condition B-2

Life Test

+70℃±5℃ (250Hours)

MIL-STD-202G

Method 108A

Test Condition B

Reliability Experiment For Physical

Test Item

Test Condition

Standard Source

Vibration Test

10-55-10HZ, amplitude: 1.5mm, direction: X, Y, Z axes,

each axis 2 hours (total 6 hours).

MIL-STD-202G

Method 201A

Solder Heat Resistance

Test

IR/convection reflow:Peak Temp 260±5℃ for 30Sec in air,

Through 2 Cycle. Temperature Ramp:+1~4°C/sec; Above

217°C, must keep 90 s - 120 s.

J-STD-020D

Classification

Reflow Profiles

Solder Ability Test

Soak in 245 ℃ solder pot of 3Sec, PAD must have 95%

above coverage.

J-STD-003B

Rev.D

P5

Prosperity Dielectrics Co., Ltd.

�SPECIFICATION FOR APPROVAL

6. TYPICAL RoHS REFLOW PROFILE

Rev.D

P6

Prosperity Dielectrics Co., Ltd.

�SPECIFICATION FOR APPROVAL

7. PACKAGING

THE FORCE FOR TEARING OFF

130 GRAMS IN THE ARROW

THICKNESS (t)

0.10 MAX

165 TO 180°

TOP COVER TAPE

EMBOSSED CAVITY

BASE TAPE

EMBOSSED CARRIER

START

END

NO COMPONENTS

NO COMPONENTS

COMPONENTS

160 (mm) MIN

MIN. 390 (mm)

MAX. 560 (mm)

COVER TAPE

USER DIRECTION OF FEED

DIMENSIONS OF CARRIER TAPE (mm)

CARRIER TAPE REELS (mm)

MATERIAL:

PLASTIC

E

2.0±0.1

4.0±0.1

1.75±0.1

A

B

1.5 +0.1-0

W

N

C

P

C

※ 10 sprocket hole pitch cumulative tolerance ±0.20

2000 Parts per Reel

UNIT : mm

Rev.D

A

B

C

E

N

P

W

t

A0

B0

K0

DIM.

330

25.0

13.0

12.5

100

8.0

12.0

0.4

5.7

5.9

3.6

TOL.

0.2

0.5

0.5

0.5

MIN

0.1

0.3

0.05

0.1

0.1

0.1

P7

Prosperity Dielectrics Co., Ltd.

�

很抱歉,暂时无法提供与“MCS0530-4R7MN2”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 5+0.53448

- 20+0.48732

- 100+0.44016

- 500+0.39300

- 1000+0.37099

- 2000+0.35527