Boya Microelectronics

Memory Series

BY25Q40AL

4M BIT SPI NOR FLASH

Features

● Serial Peripheral Interface (SPI)

- Standard SPI: SCLK, /CS, SI, SO, /WP, /HOLD

- Dual SPI: SCLK, /CS, IO0, IO1, /WP, /HOLD

- Quad SPI: SCLK, /CS, IO0, IO1, IO2, IO3

- Software Reset

● Read

- Normal Read Data: 33MHz clock rate

- others Read Data: 85MHz clock rate

● Program

- Serial-input Page Program up to 256bytes

- Dual-input Page Program up to 256bytes

- Quad-input Page Program up to 256bytes

- Program Suspend and Resume

● Erase

- Page erase (256-byte)

- Block erase (64/32 KB)

- Sector erase (4 KB)

- Chip erase

- Erase Suspend and Resume

● Program/Erase Speed

- Page Program time: 2ms typical

- Page Erase time: 8ms typical

- Sector/Block Erase time: 8ms typical

- Chip Erase time: 8ms typical

● Flexible Architecture

- Sector of 4K-byte

- Block of 32/64K-byte

● Low Power Consumption

- 3mA maximum active current

- 0.6uA maximum power down current

● Software/Hardware Write Protection

- 3x512-Byte Security Registers with OTP Lock

- Enable/Disable protection with WP Pin

- Write protect all/portion of memory via software protect

- Top or Bottom, Sector or Block selection

● Single Supply Voltage

- Full voltage range: 1.65~2.0V

● Temperature Range

- Commercial (0℃ to +70℃)

- Industrial (-40℃ to +85℃)

● Cycling Endurance/Data Retention

- Typical 100k Program-Erase cycles on any sector

- Typical 20-year data retention

August 2019

Rev 1.4

1 / 75

�BY25Q40AL

Contents

Contents

1. Description ................................................................................. 4

2. Signal Description ...................................................................... 6

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

Input/Output Summary ................................................................................. 6

Chip Select (/CS) .......................................................................................... 6

Serial Clock (SCLK) ..................................................................................... 6

Serial Input (SI)/IO0 ..................................................................................... 6

Serial Data Output (SO)/IO1......................................................................... 7

Write Protect (/WP)/IO2 ............................................................................... 7

HOLD (/HOLD)/IO3 .................................................................................... 7

VCC Power Supply ....................................................................................... 7

VSS Ground .................................................................................................. 7

3. Block/Sector Addresses ............................................................. 8

4. Function Descriptions ................................................................. 9

4.1

4.2

4.3

Standard SPI Instructions .............................................................................. 9

Dual SPI Instructions .................................................................................... 9

Quad SPI Instructions ................................................................................... 9

5. Operation Features .................................................................. 10

5.1

Supply Voltage ............................................................................................ 10

5.1.1 Operating Supply Voltage ............................................................... 10

5.1.2 Power-up Conditions ....................................................................... 10

5.1.3 Device Reset .................................................................................... 10

5.1.4 Power-down ...................................................................................... 10

5.2

Active Power and Standby Power Modes ................................................... 10

5.3

Hold Condition............................................................................................ 10

5.4

Status Register............................................................................................. 12

5.4.1 The Status and Control Bits ........................................................... 12

5.4.2 Status Register Memory Protection .............................................. 14

6. Device Identification ................................................................. 16

7. Instructions Description ............................................................ 17

7.1

Configuration and Status Instructions ......................................................... 20

7.1.1 Write Enable (06H) .......................................................................... 20

7.1.2 Write Enable for Volatile Status Register (50h) ........................... 20

7.1.3 Write Disable (04h) .......................................................................... 21

7.1.4 Read Status Register-1 (05h), Status Register-2 (35h)............. 22

7.1.5 Active Status Interrupt (25h) .......................................................... 23

7.1.6 Write Status Register (01h) ............................................................ 24

7.2

Read Instructions......................................................................................... 25

7.2.1 Normal Read Data (03H) ................................................................ 25

7.2.2 Fast Read (0BH) .............................................................................. 26

7.2.3 Fast Read Dual Output (3Bh) ........................................................ 27

7.2.4 Fast Read Quad Output (6Bh) ....................................................... 28

7.2.5 Fast Read Dual I/O (BBh)............................................................... 29

7.2.6 Fast Read Quad I/O (EBh) ............................................................. 31

7.2.7 Set Burst with Wrap (77h) .............................................................. 33

7.3

ID and Power Instructions........................................................................... 34

7.3.1 Deep Power-down (B9h) ................................................................ 34

7.3.2 Release Power-down / Device ID (ABh) ...................................... 35

7.3.3 Read Manufacturer / Device ID (90h) ........................................... 36

7.3.4 Read Manufacturer / Device ID Dual I/O (92h) ........................... 37

August 2019

Rev 1.4

2 / 75

�BY25Q40AL

Contents

7.3.5 Read Manufacturer / Device ID Quad I/O (94h) ......................... 38

7.3.6 Read JEDEC ID (9Fh)..................................................................... 39

7.3.7 Read Unique ID Number (4Bh).......................................................... 40

7.4

Program / Erase and Security Instructions .................................................. 41

7.4.1 Page Program (02h) ........................................................................ 41

7.4.2 Dual Page Program (A2h) .............................................................. 42

7.4.3 Quad Page Program (32h) ............................................................. 43

7.4.4 Page Erase (81h/DBh) .................................................................... 44

7.4.5 Sector Erase (20h)........................................................................... 45

7.4.6 32KB Block Erase (52h) ................................................................. 46

7.4.7 64KB Block Erase (D8h) ................................................................. 47

7.4.8 Chip Erase (C7h / 60h) ................................................................... 48

7.4.9 Program/Erase Suspend (75h) ...................................................... 49

7.4.10

Program/Erase Resume (7Ah) ............................................... 51

7.4.11

Erase Security Registers (44h) ............................................... 52

7.4.12

Program Security Registers (42h) .......................................... 53

7.4.13

Read Security Registers (48h)................................................ 54

7.4.14

Enable Reset (66h) and Reset Device (99h)........................ 55

7.4.15

Read Serial Flash Discoverable Parameter (5AH) .............. 56

8. Electrical Characteristics .......................................................... 61

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

8.10

8.11

Absolute Maximum Ratings ....................................................................... 61

Operating Ranges ........................................................................................ 61

Power-up Timing......................................................................................... 62

DC Electrical Characteristics ...................................................................... 63

AC Measurement Conditions ...................................................................... 64

AC Electrical Characteristics ...................................................................... 65

AC Electrical Characteristics (cont’d) ........................................................ 66

Serial Output Timing ................................................................................... 67

Serial Input Timing ..................................................................................... 67

/HOLD Timing ............................................................................................ 67

/WP Timing ................................................................................................. 67

9. Package Information ................................................................ 68

9.1

9.2

9.3

9.4

9.5

Package 8-Pin SOP 150-mil ........................................................................ 68

Package 8-Pin SOP 208-mil ........................................................................ 69

Package 8-Pin TSSOP 173-mil ................................................................... 70

Package USON8 (2*3-0.50mm) ................................................................. 71

Package USON8 (2*3-0.55mm) ................................................................. 72

10. Order Information ..................................................................... 73

10.1

10.2

Valid part Numbers and Top Side Marking................................................. 74

Minimum Packing Quantity (MPQ) ........................................................... 74

11. Document Change History ....................................................... 75

August 2019

Rev 1.4

3 / 75

�Description

BY25Q40AL

1. Description

The BY25Q40AL is 4M-bit Serial Peripheral Interface (SPI) Flash memory, designed for using in a wide

variety of high-volume consumer based applications in which program code is shadowed from Flash

memory into embedded or external RAM for execution. The flexible erase architecture of the device, with

its page erase granularity it is ideal for data storage as well, eliminating the need for additional data

storage devices.

The erase block sizes of the device have been optimized to meet the needs of today's code and data

storage applications. By optimizing the size of the erase blocks, the memory space can be used much

more efficiently. Because certain code modules and data storage segments must reside by themselves in

their own erase regions, the wasted and unused memory space that occurs with large sectored and large

block erase Flash memory devices can be greatly reduced. This increased memory space efficiency

allows additional code routines and data storage segments to be added while still maintaining the same

overall device density.

The device uses a single low voltage power supply, ranging from 1.65 Volt to 2.0 Volt, and supports

JEDEC standard manufacturer and device ID, a 128-bit Unique Serial Number and three 512-bytes

Security Registers.

August 2019

Rev 1.4

4 / 75

�Description

BY25Q40AL

Figure 1. Logic diagram

VCC

SCLK

SO

SI

/CS

BY25QXX

/WP

/HOLD

VSS

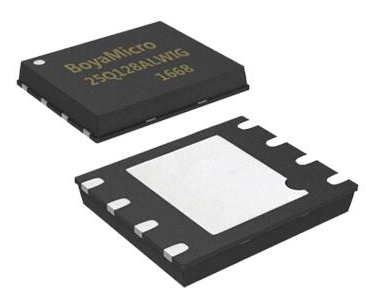

Figure 2. Pin Configuration SOP8/TSSOP8

Top View

/CS

1

SO

2

8

VCC

7

HOLD

SOP8/TSSOP8

/WP

3

6

SCLK

VSS

4

5

SI

Figure 3. Pin Configuration DFN 2*3mm

/CS

1

8

VCC

SO

2

7

/HOLD

Top View

August 2019

/WP

3

6

SCLK

VSS

4

5

SI

Rev 1.4

5 / 75

�BY25Q40AL

Signal Description

2. Signal Description

During all operations, VCC must be held stable and within the specified valid range: VCC(min) to

VCC(max).

All of the input and output signals must be held High or Low (according to voltages of VIH, VOH,

VIL or VOL, see Section 8.4, DC Electrical Characteristics). These signals are described next.

2.1 Input/Output Summary

Table 1. Signal Names

Pin Name

I/O

/CS

I

SO (IO1)

I/O

/WP (IO2)

I/O

VSS

Chip Select

Serial Output for Standard SPI mode

IO1 for Dual or Quad SPI mode

Write Protect in Standard SPI mode or Dual SPI mode

IO2 in Quad SPI mode.

The signal has an internal pull-up resistor and may be left unconnected in the

host system if not used for Quad SPI mode.

Ground

SI (IO0)

I/O

SCLK

I

/HOLD (IO3)

I/O

VCC

Description

Serial Input for Standard SPI mode.

IO0 for Dual or Quad SPI mode.

Serial Clock

Hold (pause) serial transfer in Standard SPI mode or Dual SPI mode.

IO3 in Quad SPI mode.

The signal has an internal pull-up resistor and may be left unconnected in the

host system if not used for Quad SPI mode.

Core and I/O Power Supply

2.2 Chip Select (/CS)

The chip select signal indicates when an instruction for the device is in process and the other

signals are relevant for the memory device. When the /CS signal is at the logic high state, the

device is not selected and all input signals are ignored and all output signals are high impedance.

Unless an internal Program, Erase or Write Status Registers embedded operation is in progress,

the device will be in the Standby Power mode. Driving the /CS input to logic low state enables the

device, placing it in the Active Power mode. After Power Up, a falling edge on /CS is required prior

to the start of any instruction.

2.3 Serial Clock (SCLK)

This input signal provides the synchronization reference for the SPI interface. Instructions,

addresses, or data input are latched on the rising edge of the SCLK signal. Data output changes

after the falling edge of SCLK.

2.4 Serial Input (SI)/IO0

This input signal is used to transfer data serially into the device. It receives instructions, addresses,

and data to be programmed. Values are latched on the rising edge of serial SCK clock signal.

SI becomes IO0 an input and output during Dual and Quad SPI mode for receiving instructions,

addresses, and data to be programmed (values latched on rising edge of serial SCK clock signal)

as well as shifting out data (on the falling edge of SCK).

August 2019

Rev 1.4

6 / 75

�BY25Q40AL

Signal Description

2.5 Serial Data Output (SO)/IO1

This output signal is used to transfer data serially out of the device. Data is shifted out on the

falling edge of the serial SCK clock signal.

SO becomes IO1 an input and output during Dual and Quad SPI mode for receiving instructions,

addresses, and data to be programmed (values latched on rising edge of serial SCK clock signal)

as well as shifting out data (on the falling edge of SCK).

2.6 Write Protect (/WP)/IO2

When /WP is driven Low (VIL), while the Status Register Protect bits (SRP1 and SRP0) of the

Status Registers (SR2[0] and SR1[7]) are set to 0 and 1 respectively, it is not possible to write to

the Status Registers. This prevents any alteration of the Status Registers. As a consequence, all

the data bytes in the memory area that are protected by the Block Protect, BP4, BP3 bits in the

status registers, are also hardware protected against data modification while /WP remains Low.

The /WP function is not available when the Quad mode is enabled (QE) in Status Register 2

(SR2[1]=1).

The /WP function is replaced by IO2 for input and output during Quad mode for receiving

addresses, and data to be programmed (values are latched on rising edge of the SCK signal) as

well as shifting out data (on the falling edge of SCK). /WP has an internal pull-up resistance; when

unconnected; /WP is at VIH and may be left unconnected in the host system if not used for Quad

mode.

2.7 HOLD (/HOLD)/IO3

The /HOLD signal goes low to stop any serial communications with the device, but doesn’t stop

the operation of write status register, programming, or erasing in progress.

The operation of HOLD, need /CS keep low, and starts on falling edge of the /HOLD signal, with

SCLK signal being low (if SCLK is not being low, HOLD operation will not start until SCLK being

low). The HOLD condition ends on rising edge of /HOLD signal with SCLK being low (If SCLK is

not being low, HOLD operation will not end until SCLK being low).

When QE=0, the IO3 pin can be configured either as a /HOLD pin. When QE=1, the /HOLD

function is not available.

The HOLD function is replaced by IO3 for input and output during Quad mode for receiving

addresses, and data to be programmed (values are latched on rising edge of the SCK signal) as

well as shifting out data (on the falling edge of SCK).

2.8 VCC Power Supply

VCC is the supply voltage. It is the single voltage used for all device functions including read,

program, and erase.

2.9 VSS Ground

VSS is the reference for the VCC supply voltage.

August 2019

Rev 1.4

7 / 75

�Block/Sector Addresses

BY25Q40AL

3. Block/Sector Addresses

Table 2. Block/Sector Addresses of BY25Q40AL

Memory

Density

Block(64k

byte)

Block(32k

byte)

Sector 0

Sector

Size(KB)

4

000000h-000FFFh

:

:

:

Sector 7

4

007000h-007FFFh

Sector 8

4

008000h-008FFFh

:

4

:

Sector 15

4

00F000h-00FFFFh

Sector 16

4

010000h-010FFFh

:

:

:

Sector 23

4

017000h-017FFFh

Sector 24

4

018000h-018FFFh

:

:

:

Sector 31

4

01F000h-01FFFFh

:

:

:

Sector 96

4

060000h-060FFFh

:

:

:

Sector 103

4

067000h-067FFFh

Sector 104

4

068000h-068FFFh

:

4

:

Sector 111

4

06F000h-06FFFFh

Sector 112

4

070000h-070FFFh

:

:

:

Sector 119

4

077000h-077FFFh

Sector 120

4

078000h-078FFFh

:

:

:

Sector 127

4

07F000h-07FFFFh

Sector No.

Half block

0

Block 0

Half block

1

Half block

2

Block 1

Half block

3

4Mbit

:

:

Half block

12

Block 6

Half block

13

Half block

14

Block 7

Half block

15

Address range

Notes:

1. Block = Uniform Block, and the size is 64K bytes.

2. Half block = Half Uniform Block, and the size is 32k bytes.

3. Sector = Uniform Sector, and the size is 4K bytes.

August 2019

Rev 1.4

8 / 75

�Function Descriptions

BY25Q40AL

4. Function Descriptions

4.1 Standard SPI Instructions

The BY25Q40AL features a serial peripheral interface on 4 signals bus: Serial Clock (SCLK), Chip

Select (/CS), Serial Data Input (SI) and Serial Data Output (SO). Both SPI bus mode 0 and 3 are

supported.

4.2 Dual SPI Instructions

The BY25Q40AL supports Dual SPI operation when using the “Dual Output Fast Read” and “Dual

I/O Fast Read” (3Bh and BBh) instructions. These instructions allow data to be transferred to or

from the device at two times the rate of the standard SPI. When using the Dual SPI instruction the

SI and SO pins become bidirectional I/O pins: IO0 and IO1

4.3 Quad SPI Instructions

The BY25Q40AL supports Quad SPI operation when using the “Quad Output Fast Read”, “Quad

I/O Fast Read”, (6Bh, EBh,) instructions. These instructions allow data to be transferred to or from

the device at four times the rate of the standard SPI. When using the Quad SPI instruction the SI

and SO pins become bidirectional I/O pins: IO0 and IO1, and /WP and /HOLD pins become IO2

and IO3. Quad SPI instructions require the non-volatile Quad Enable bit (QE) in Status Register-2

to be set to 1.

All of the above three SPI mode (Standard SPI, Dual SPI and Quad SPI) have input bits

(including instructions, addresses, data, M7~M0, W6~W4 etc.) latched on the rising edge of SCLK

and output bits shifted out on the falling edge of SCLK.

August 2019

Rev 1.4

9 / 75

�Operation Features

BY25Q40AL

5. Operation Features

5.1 Supply Voltage

5.1.1

Operating Supply Voltage

Prior to selecting the memory and issuing instructions to it, a valid and stable VCC voltage within

the specified [VCC(min), VCC(max)] range must be applied (see operating ranges). In order to

secure a stable DC supply voltage, it is recommended to decouple the VCC line with a suitable

capacitor (usually of the order of 10 nF to 100 nF) close to the VCC/VSS package pins. This

voltage must remain stable and valid until the end of the transmission of the instruction and, for a

Write instruction, until the completion of the internal write cycle.

5.1.2

Power-up Conditions

When the power supply is turned on, VCC rises continuously from VSS to VCC. During this time,

the Chip Select (/CS) line is not allowed to float but should follow the VCC voltage, it is therefore

recommended to connect the /CS line to VCC via a suitable pull-up resistor.

In addition, the Chip Select (/CS) input offers a built-in safety feature, as the /CS input is edge

sensitive as well as level sensitive: after power-up, the device does not become selected until a

falling edge has first been detected on Chip Select (/CS). This ensures that Chip Select (/CS) must

have been High, prior to going Low to start the first operation.

5.1.3

Device Reset

In order to prevent inadvertent Write operations during power-up (continuous rise of VCC), a

power on reset (POR) circuit is included. At Power-up, the device does not respond to any

instruction until VCC has reached the power on reset threshold voltage (this threshold is lower

than the minimum VCC operating voltage defined in operating ranges).

When VCC has passed the POR threshold, the device is reset.

5.1.4

Power-down

At Power-down (continuous decrease in VCC), as soon as VCC drops from the normal operating

voltage to below the power on reset threshold voltage, the device stops responding to any

instruction sent to it. During Power-down, the device must be deselected (Chip Select (/CS) should

be allowed to follow the voltage applied on VCC) and in Standby Power mode (that is there should

be no internal Write cycle in progress).

5.2 Active Power and Standby Power Modes

When Chip Select (/CS) is Low, the device is selected, and in the Active Power mode. The device

consumes ICC. When Chip Select (/CS) is High, the device is deselected. If a Write cycle is not

currently in progress, the device then goes in to the Standby Power mode, and the device

consumption drops. to ICC1.

5.3 Hold Condition

The /HOLD signal goes low to stop any serial communications with the device, but doesn’t stop

the operation of write status register, programming, or erasing in progress.

The operation of HOLD, need /CS keep low, and starts on falling edge of the /HOLD signal, with

SCLK signal being low (if SCLK is not being low, HOLD operation will not start until SCLK being

August 2019

Rev 1.4

10 / 75

�Operation Features

BY25Q40AL

low). The HOLD condition ends on rising edge of /HOLD signal with SCLK being low (If SCLK is

not being low, HOLD operation will not end until SCLK being low).

The SO is high impedance, both SI and SCLK don’t care during the HOLD operation, if /CS drives

high during HOLD operation, it will reset the internal logic of the device to Standby Mode. To

re-start communication with chip, the /HOLD must be at high and the /CS must be at low.

Figure 5.1. Hold condition activation

/CS

SCLK

/HOLD

HOLD

HOLD

August 2019

Rev 1.4

11 / 75

�Status Register

BY25Q40AL

5.4 Status Register

5.4.1

The Status and Control Bits

SR2

Default value Note1

S15

S14

S13

S12

S11

S10

S9

S8

SUS1

CMP

LB3

LB2

LB1

SUS2

QE

SRP1

n/a

0

0

0

0

n/a

0

0

SR1

Default value Note1

S7

S6

S5

S4

S3

S2

S1

S0

SRP0

BP4

BP3

BP2

BP1

BP0

WEL

WIP

0

0

0

0

0

0

n/a

n/a

Notes:

1. The default value is set by Manufacturer during wafer sort, Marked as Default in following

text

The status and control bits of the Status Register are as follows:

5.4.1.1 WIP bit

The Write in Progress (WIP) bit indicates whether the memory is busy in program / erase / write

status register progress. When WIP bit is set to 1, means that the device is busy in program /

erase / write status register progress, when WIP bit is cleared to 0, means that the device is not in

program / erase / write status register progress.

5.4.1.2 WEL bit

The Write Enable Latch bit indicates the status of the internal Write Enable Latch. When WEL bit is

set to 1 the internal Write Enable Latch is set, when WEL bit is cleared to 0 the internal Write

Enable Latch is reset and no Write Status Register, Program or Erase instruction is accepted.

5.4.1.3 BP4, BP3, BP2, BP1, BP0 bits

The Block Protect (BP4, BP3, BP2, BP1, BP0) bits are non-volatile. They define the size of the

area to be software protected against Program and Erase instructions. These bits are written with

the Write Status Register instruction. When the Block Protect (BP4, BP3, BP2, BP1, BP0) bits are

set to 1, the relevant memory (as defined in Table 4 and Table 5) are became protected against

Page Program, Page Erase, Sector Erase and Block Erase instructions. The Block Protect (BP4,

BP3, BP2, BP1, BP0) bits can be written provided that the Hardware Protected mode has not

been set. The Chip Erase instruction is executed. If the Block Protect (BP2, BP1, and BP0) bits

are 0 and CMP=0 or the Block Protect (BP2, BP1 and BP0) bits are 1and CMP=1.

August 2019

Rev 1.4

12 / 75

�Status Register

BY25Q40AL

5.4.1.4 SRP1, SRP0 bits

The Status Register Protect (SRP1 and SRP0) bits are non-volatile Read/Write bits in the status

register. The SRP bits control the method of write protection: software protection, hardware

protection, power supply lock-down or one time programmable protection.

Table 3. Status Register protect table

SRP1

SRP0

/WP

Status Register

Software

Protected

Hardware

Protected

Hardware

Unprotected

0

0

X

0

1

0

0

1

1

1

0

X

Power Supply

Lock-Down(1)

1

1

X

One Time

Program(2)

Description

The Status Register can be written to after a Write

Enable instruction, WEL=1.(Default)

/WP=0, the Status Register locked and cannot be

written.

/WP=1, the Status Register is unlocked and can be

written to after a Write Enable instruction, WEL=1.

Status Register is protected and cannot be written

to again until the next Power-Down, Power-Up

cycle.

Status Register is permanently protected and

cannot be written to.

Notes:

1. When SRP1, SRP0= (1, 0), a Power-Down, Power-Up cycle will change SRP1, SRP0 to

(0, 0) state.

2. The One time Program feature is available upon special order. Please contact Boya

Microelectronics for details.

5.4.1.5 QE bit

The Quad Enable (QE) bit is a non-volatile Read/Write bit in the Status Register that allows Quad

SPI operation. When the QE bit is set to 0 (Default) the /WP pin and /HOLD pin are enable. When

the QE bit is set to 1, the Quad IO2 and IO3 pins are enabled. (The QE bit should never be set to 1

during standard SPI or Dual SPI operation if the /WP or /HOLD pins directly to the power supply or

ground).

5.4.1.6 LB3/LB2/LB1 bit

The LB bit is a non-volatile One Time Program (OTP) bit in Status Register (S13-S11) that provide

the write protect control and status to the Security Registers. The default state of LB is 0, the

security registers are unlocked. LB can be set to 1 individually using the Write Register instruction.

LB is One Time Programmable, once it’s set to 1, the Security Registers will become read-only

permanently (LB3-1 corresponds to S13-11).

5.4.1.7 SUS1, SUS2 bit

The SUS1 and SUS2 bit are read only bits in the status register2 (S15 and S10) that are set to 1

after executing a Program/Erase Suspend (75H) instruction (The Erase Suspend will set SUS1 to 1.

The Program Suspend will set the SUS2 to 1). The SUS bits are cleared to 0 by Program/Erase

Resume (7AH) instruction. Software reset (66H/99H) instruction as well as a power-down,

power-up cycle.

5.4.1.8 Complement Protect (CMP)

The Complement Protect bit (CMP) is a non-volatile read/write bit in the status register. It is used

in conjunction with BP4, BP3, BP2, BP1 and BP0 bits to provide more flexibility for the array

protection. Please refer to the Status Register Memory Protection table for details. The default

setting is CMP=0.

August 2019

Rev 1.4

13 / 75

�Status Register

5.4.2

BY25Q40AL

Status Register Memory Protection

5.4.2.1 Protect Table

Table 4. BY25Q40AL Status Register Memory Protection (CMP = 0)

STATUS REGISTER(1)

BP4 BP3 BP2

BY25Q40AL (4M-BIT) MEMORY PROTECTION(3)

BP1

BP0

PROTECTED

BLOCK(S)

PROTECTED

ADDRESSES

PROTECTED PROTECTED

DENSITY PORTION(2)

X

X

0

0

0

NONE

NONE

NONE

NONE

0

0

0

0

1

7

070000h – 07FFFFh

64KB

Upper 1/8

0

0

0

0

0

0

1

1

0

1

6 and 7

4 to 7

060000h – 07FFFFh

040000h – 07FFFFh

128KB

256KB

Upper 1/4

Upper 1/2

0

1

0

0

1

0

000000h – 00FFFFh

64KB

Lower 1/8

0

0

0

1

1

X

0

0

1

1

1

X

0

1

X

0 to 1

0 to 3

0 to 7

000000h – 01FFFFh

000000h – 03FFFFh

000000h – 07FFFFh

128KB

256KB

512KB

Lower 1/4

Lower 1/2

ALL

1

0

0

0

1

7

07F000h – 07FFFFh

4KB

U - 1/128

1

0

0

1

0

7

07E000h – 07FFFFh

8KB

U - 1/64

1

0

0

1

1

7

07C000h – 07FFFFh

16KB

U - 1/32

1

0

1

0

X

7

078000h – 07FFFFh

32KB

U - 1/16

1

0

1

1

0

7

078000h – 07FFFFh

32KB

U - 1/16

1

1

0

0

1

0

000000h – 000FFFh

4KB

L - 1/128

1

1

0

1

0

0

000000h – 001FFFh

8KB

L - 1/64

1

1

0

1

1

0

000000h – 003FFFh

16KB

L - 1/32

1

1

1

0

X

0

000000h – 007FFFh

32KB

L - 1/16

1

1

1

1

0

0

000000h – 007FFFh

32KB

L - 1/16

1

X

1

1

1

0 to 7

000000h – 07FFFFh

512KB

ALL

Notes:

1. X = don’t care

2. L = Lower; U = Upper

3. If any Erase or Program instruction specifies a memory region that contains protected data

portion, this instruction will be ignored.

August 2019

Rev 1.4

14 / 75

�Status Register

BY25Q40AL

Table 5. Status Register Memory Protection (CMP = 1)

STATUS REGISTER(1)

BP4 BP3 BP2 BP1 BP0

BY25Q40AL (4M-BIT) MEMORY PROTECTION(3)

PROTECTED

BLOCK(S)

PROTECTED

ADDRESSES

PROTECTED PROTECTED

DENSITY

PORTION(2)

X

X

0

0

0

0 to 7

000000h – 07FFFFh

512KB

All

0

0

0

0

1

0 to 6

000000h – 06FFFFh

448KB

Lower 7/8

0

0

0

1

0

0 and 5

000000h – 05FFFFh

384KB

Lower 3/4

0

0

0

1

1

0 to 3

000000h – 03FFFFh

256KB

Lower 1/2

0

1

0

0

1

1 to 7

010000h – 07FFFFh

448KB

Upper 7/8

0

1

0

1

0

2 to 7

020000h – 07FFFFh

384KB

Upper 3/4

0

1

0

1

1

4 to 7

040000h – 07FFFFh

256KB

Upper 1/2

0

X

1

X

X

NONE

NONE

NONE

NONE

1

0

0

0

1

0 to 7

000000h –07EFFFh

508KB

L - 127/128

1

0

0

1

0

0 to 7

000000h – 07DFFFh

504KB

L - 63/64

1

0

0

1

1

0 to 7

000000h – 07BFFFh

496KB

L - 31/32

1

0

1

0

X

0 to 7

000000h – 077FFFh

480KB

L - 15/16

1

0

1

1

0

0 to 7

000000h – 077FFFh

480KB

L - 15/16

1

1

0

0

1

0 to 7

001000h – 07FFFFh

508KB

U - 127/128

1

1

0

1

0

0 to 7

002000h – 07FFFFh

504KB

U- 63/64

1

1

0

1

1

0 to 7

004000h – 07FFFFh

496KB

U- 31/32

1

1

1

0

X

0 to 7

008000h – 07FFFFh

480KB

U- 15/16

1

1

1

1

0

0 to 7

008000h – 07FFFFh

480KB

U - 15/16

1

X

1

1

1

NONE

NONE

NONE

NONE

Notes:

1. X = don’t care

2. L = Lower; U = Upper

3.If any Erase or Program instruction specifies a memory region that contains protected data

portion, this instruction will be ignored.

August 2019

Rev 1.4

15 / 75

�Device Identification

BY25Q40AL

6. Device Identification

Three legacy Instructions (9Fh/90h/ABh) and two new Instructions (92h/94h) in Dual/Quad SPI

mode are supported to access device identification that can indicate the manufacturer, device type,

and capacity (density). The returned data bytes provide the information as shown in the below

table.

Table 6. BY25Q40AL ID Definition table

Operation Code

M7-M0

ID15-ID8

ID7-ID0

9Fh

68

68

60

13

12

12

90h / 92h /94h

ABh

August 2019

Rev 1.4

16 / 75

�Instructions Description

BY25Q40AL

7. Instructions Description

All instructions, addresses and data are shifted in and out of the device, beginning with the most

significant bit on the first rising edge of SCLK after /CS is driven low. Then, the one byte instruction

code must be shifted in to the device, most significant bit first on SI, each bit being latched on the

rising edges of SCLK.

See Table 7, every instruction sequence starts with a one-byte instruction code. Depending on the

instruction, this might be followed by address bytes, or by data bytes, or by both or none.

For the instruction of Read, Fast Read, Read Status Register-1, Read Status Register-2 or

Release from Deep Power Down, and Read Device ID, the shifted-in instruction sequence is

followed by a data out sequence. /CS can be driven high after any bit of the data-out sequence is

being shifted out.

For the instruction of Page Program, Page Erase, Sector Erase, Block Erase, Chip Erase, Write

Status Register, Write Enable, Write Disable or Deep Power-Down instruction, /CS must be driven

high exactly at a byte boundary, otherwise the instruction is rejected, and is not executed. That is

/CS must drive high when the number of clock pulses after /CS being driven low is an exact

multiple of eight. For Page Program, if at any time the input byte is not a full byte, nothing will

happen and WEL will not be reset.

August 2019

Rev 1.4

17 / 75

�Instructions Description

BY25Q40AL

Table 7. Instruction Set Table 1 (1)

Instruction Name

Byte 1

Write Enable

06h

Volatile SR Write Enable

50h

Write Disable

04h

Read Status Register-1

05h

(S7-S0)(2)

Write Status Register(4)

01h

S7-S0

Read Status Register-2

35h

(S15-S8)(2)

Active Status Interrupt

25h

Chip Erase

C7h/60h

Program/Erase Suspend

75h

Program/Erase Resume

7Ah

Deep Power-down

Release Power-down /

ID

Release Power-down

B9h

ABH

Manufacturer/Device ID

Byte 3

Byte 4

Byte 5

Byte 6

n-Bytes

(continuous)

S15-S8

(continuous)

(ID7-ID0)(2)

Dummy

Dummy

Dummy

90h

Dummy

Dummy

00/01h

Read JEDEC ID

9Fh

(MF7-MF0)

(ID15-ID8)

(ID7-ID0)(2)

Read Unique ID Number

4Bh

Dummy

Dummy

Dummy

Enable Reset

66h

Reset Device

99h

Read Serial Flash

Discoverable

Parameter

5Ah

A23-A16

A15-A8

A7-A0

Dummy

Normal Read Data

03h

A23-A16

A15-A8

A7-A0

(D7-D0)

Fast Read

0Bh

A23-A16

A15-A8

A7-A0

Dummy

(D7-D0)

(continuous)

Dual Output Fast read

3Bh

A23-A16

A7-A0

Dummy

(D7-D0)(7)

(continuous)

BBh

A23-A8(6)

A15-A8

A7-A0

M7-M0(6)

6Bh

Dummy

A15-A8

A15-A8

Dual I/O Fast read

Quad Output Fast read

ABh

Byte 2

Page Program

02h

A23-A16

A23-A0

M7-M0(8)

A23-A16

Dual Page Program

A2h

A23-A16

Quad I/O Fast read

Quad Page Program

Page Erase

EBh

32h

A15-A8

(continuous)

(MF7-MF0)/ (ID7-ID0)(2)/

(continuous)

(ID7-ID0) (MF7-MF0)(2)

(continuous)

Dummy

(ID127-ID0)

(D7-D0)

(Next Byte) (continuous)

(D7-D0)

A7-A0

(D7-D0)

(continuous)

Dummy

(D7-D0)(9)

(10)

A7-A0

(D7-D0)

(Next Byte)

A7-A0

(D7-D0)(3)

(Next Byte)

(3)

(Next Byte)

A15-A8

A7-A0

81h/DBh A23-A16

(D7-D0)

A15-A8

A7-A0

Sector Erase (4KB)

20h

A23-A16

A15-A8

A7-A0

Block Erase (32KB)

52h

A23-A16

A15-A8

A7-A0

Block Erase (64KB)

D8h

A23-A16

A15-A8

A7-A0

Erase Security Registers

44h

A23-A16(5)

A15-A8(5)

A7-A0(5)

42h

A23-A16(5)

A15-A8(5)

A7-A0(5)

D7-D0

Next Byte

48h

A23-A16(5)

A15-A8(5)

A7-A0(5)

Dummy

D7-D0

Set Burst With Wrap

77h

W6-W4

Mftr./Device ID Dual I/O

92h

A23-A8(6)

Mftr./Device ID Quad I/O

94h

A23-A0

M7-M0(8)

Program Security

Registers

Read Security Registers

A7-A0(6)

M7-M0

(M7-M0)

(D7-D0)(10)

(M7-M0)

(D7-D0)

(continuous)

(continuous)

(3)

A23-A16

(continuous)

(continuous)

(continuous)

Notes:

1. Data bytes are shifted with Most Significant Bit first. Byte fields with data in parenthesis

“( )” indicate data output from the device.

2. The Status Register contents and Device ID will repeat continuously until /CS terminates

the instruction.

3. At least one byte of data input is required for Page Program, Dual Page Program, Quad

Page Program and Program Security Registers, up to 256 bytes of data input. If more

than 256 bytes of data are sent to the device, the addressing will wrap to the beginning

of the page and overwrite previously sent data.

August 2019

Rev 1.4

18 / 75

�Instructions Description

BY25Q40AL

4. Write Status Register (01h) can also be used to write Status Register-1&2, see section

7.1.6.

5. Security Register Address:

Security Register 1

A23-16 = 00h

A15-9 = 0001000 A8-0 = byte address

Security Register 2

A23-16 = 00h

A15-9 = 0010000 A8-0 = byte address

Security Register 3

A23-16 = 00h

A15-9 = 0011000 A8-0 = byte address

6. Dual SPI address input format:

IO0 = A22, A20, A18, A16, A14, A12, A10, A8, A6, A4, A2, A0, M6, M4, M2, M0

IO1 = A23, A21, A19, A17, A15, A13, A11, A9, A7, A5, A3, A1, M7, M5, M3, M1

7. Dual SPI data output format:

IO0 = (D6, D4, D2, D0)

IO1 = (D7, D5, D3, D1)

8. Quad SPI address input format:

IO0 = A20, A16, A12, A8, A4, A0, M4, M0

IO1 = A21, A17, A13, A9, A5, A1, M5, M1

IO2 = A22, A18, A14, A10, A6, A2, M6, M2

IO3 = A23, A19, A15, A11, A7, A3, M7, M3

9. Quad SPI data output format:

IO0 = (D4, D0, …..)

IO1 = (D5, D1, …..)

IO2 = (D6, D2, …..)

IO3 = (D7, D3, …..)

10. Fast Read Quad I/O data output format:

IO0 = (x, x, x, x, D4, D0, D4, D0)

IO1 = (x, x, x, x, D5, D1, D5, D1)

IO2 = (x, x, x, x, D6, D2, D6, D2)

IO3 = (x, x, x, x, D7, D3, D7, D3)

August 2019

Rev 1.4

19 / 75

�Instructions Description

BY25Q40AL

7.1 Configuration and Status Instructions

7.1.1

Write Enable (06H)

The Write Enable instruction (Figure 7.1.1) sets the Write Enable Latch (WEL) bit in the Status

Register to a 1. The WEL bit must be set prior to every Page Program, Dual Page Program, Quad

Page Program, Page Erase, Sector Erase, Block Erase, Chip Erase, Write Status Register and

Erase/Program Security Registers instruction. The Write Enable instruction is entered by driving

/CS low, shifting the instruction code “06h” into the Data Input (SI) pin on the rising edge of SCLK,

and then driving /CS high.

Figure 7.1.1. Write Enable Instruction for SPI Mode

/CS

SCLK

Mode 3

Mode 0

0

1

2

3

4

5

6

7

Mode 3

Mode 0

Instruction

SI

06H

SO

High_Z

7.1.2

Write Enable for Volatile Status Register (50h)

The non-volatile Status Register bits described in section 5.4 can also be written to as volatile bits.

This gives more flexibility to change the system configuration and memory protection schemes

quickly without waiting for the typical non-volatile bit write cycles or affecting the endurance of the

Status Register non-volatile bits. To write the volatile values into the Status Register bits, the Write

Enable for Volatile Status Register (50h) instruction must be issued prior to a Write Status Register

(01h) instruction. Write Enable for Volatile Status Register instruction (Figure 7.1.2) will not set the

Write Enable Latch (WEL) bit, it is only valid for the Write Status Register instruction to change the

volatile Status Register bit values.

Figure 7.1.2. Write Enable for Volatile Status Register Instruction for SPI Mode

/CS

SCLK

Mode 3

Mode 0

0

1

2

3

4

5

6

7

Mode 3

Mode 0

Instruction

SI

50H

SO

High_Z

August 2019

Rev 1.4

20 / 75

�Instructions Description

7.1.3

BY25Q40AL

Write Disable (04h)

The Write Disable instruction (Figure 7.1.3) resets the Write Enable Latch (WEL) bit in the Status

Register to 0. The Write Disable instruction is entered by driving /CS low, shifting the instruction

code “04h” into the SI pin and then driving /CS high.

Note that the WEL bit is automatically reset after Power-up and upon completion of the Write Status

Register, Erase/Program Security Registers, Page Program, Dual Page Program, Quad Page

Program, Page Erase, Sector Erase, Block Erase, Chip Erase and Reset instructions.

Figure 7.1.3. Write Disable Instruction for SPI Mode

/CS

SCLK

Mode 3

Mode 0

0

1

2

3

4

5

6

7

Mode 3

Mode 0

Instruction

SI

04H

SO

High_Z

August 2019

Rev 1.4

21 / 75

�Instructions Description

7.1.4

BY25Q40AL

Read Status Register-1 (05h), Status Register-2 (35h)

The Read Status Register instructions allow the 8-bit Status Registers to be read. The instruction is

entered by driving /CS low and shifting the instruction code “05h” for Status Register-1, “35h” for

Status Register -2 into the SI pin on the rising edge of SCLK. The status register bits are then

shifted out on the SO pin at the falling edge of SCLK with most significant bit (MSB) first as shown

in Figure 7.1.4, Refer to section 5.4 for Status Register descriptions.

The Read Status Register instruction may be used at any time, even while a Program, Erase or

Write Status Register cycle is in progress. This allows the WIP status bit to be checked to determine

when the cycle is complete and if the device can accept another instruction. The Status Register

can be read continuously, as shown in Figure 7.1.4 The instruction is completed by driving /CS

high.

Figure 7.1.4. Read Status Register Instruction

/CS

SCLK

Mode 3

Mode 0

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Instruction

SI

05H or 35H

SO

High_Z

Status Register-1/2 out

August 2019

7

MSB

6

5

Rev 1.4

4

3

2

1

Status Register-1/2 out

0

7

6

5

4

3

2

1

0

MSB

22 / 75

7

�Instructions Description

7.1.5

BY25Q40AL

Active Status Interrupt (25h)

To simplify the readout of the WIP bit, the Active Status Interrupt Instruction (25h) may be used. It is

then not necessary to continuously read the status register, it is sufficient to monitor the value of the

SO line. If the SO line is connected to an interrupt line on the host controller, the host controller may

be in sleep mode until the SO line indicates that the device is ready for the next Instruction

The WIP bit can be read at any time, including during an internally self-timed program or erase

operation. To enable the Active Status Interrupt instruction, the /CS pin must first be asserted and

the instruction code of 25h must be clocked into the device. The value of the SI line after the

instruction code being clocked in is of no significance to the operation.

The value of WIP is then output on the SO line, and is continuously updated by the device for as

long as the /CS pin remains asserted. Additional clocks on the SCK pin are not required. That is,

whether the additional clock on the SCK pin exists is independent of the correct output of the value

of WIP. (Figure 7.1.5 shows a case where additional clocks exist). If the WIP bit changes from 1 to

0 while the /CS pin is asserted, the SO line will change from 1 to 0. (The WIP bit cannot change

from 0 to 1 during an operation, so if the SO line already is 0, it will not change.)

De-asserting the /CS pin will terminate the Active Status Interrupt operation and put the SO pin into

a high-impedance state.

The sequence of issuing ASI instruction is: /CS goes low→ sending ASI instruction code→ WIP

data out on SO

Figure 7.1.5. Active Status Interrupt Instruction

/CS

SCLK

Mode 3

Mode 0

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Instruction

SI

25H

SO

High_Z

August 2019

RDY/BSY

Rev 1.4

23 / 75

�Instructions Description

7.1.6

BY25Q40AL

Write Status Register (01h)

The Write Status Register instruction allows the Status Registers to be written. The writable Status

Register bits include: SRP0, BP[4:0] in Status Register-1; CMP, LB[3:1], QE, SRP1 in Status

Register- 2. All other Status Register bit locations are read-only and will not be affected by the

Write Status Register instruction. LB[3:1] are non-volatile OTP bits, once it is set to 1, it cannot be

cleared to 0.

The Write Status Register (WRSR) instruction allows new values to be written to the Status

Register. Before it can be accepted, a Write Enable (WREN) or Write Enable For Volatile SR

instruction must previously have been executed After the Write Enable (WREN) instruction has

been decoded and executed, the device sets the Write Enable Latch (WEL).

The Write Status Register instruction has no effect on S15(SUS1), S10(SUS2), S1(WEL) and

S0(WIP) of the Status Register. /CS must be driven high after the eighth or sixteen bit of the data

byte has been latched in. If not, the Write Status Register (WRSR) command is not executed. If

/CS is driven high after eighth bit of the data byte, the CMP and QE and SRP1 bits will be cleared

to 0. As soon as /CS is driven high, the self-timed Write Status Register cycle (whose duration is

tW) is initiated. While the Write Status Register cycle is in progress, the Status Register may still

be read to check the value of the Write In Progress (WIP) bit. The Write In Progress (WIP) bit is 1

during the self-timed Write Status Register cycle, and is 0 when it is completed. When the cycle is

completed, the Write Enable Latch (WEL) is reset.

The Write Status Register instruction allows the user to change the values of the Block Protect

(BP4, BP3, BP2, BP1, and BP0) bits, to define the size of the area that is to be treated as

read-only, as defined in Table4 and Table5.The Write Status Register (WRSR) instruction also

allows the user to set or reset the Status Register Protect (SRP1 and SRP0) bits in accordance

with the Write Protect (/WP) signal. The Status Register Protect (SRP1 and SRP0) bits and Write

Protect (/WP) signal allow the device to be put in the Hardware Protected Mode. The Write Status

Register instruction is not executed once the Hardware Protected Mode is entered.

The sequence of issuing WRSR instruction is: /CS goes low→ sending WRSR instruction code→

Status Register data on SI→/CS goes high.

The /CS must go high exactly at the 8 bits or 16 bits data boundary; otherwise, the instruction will

be rejected and not executed. The self-timed Write Status Register cycle time (tW) is initiated as

soon as Chip Select (/CS) goes high. The Write in Progress (WIP) bit still can be checked during

the Write Status Register cycle is in progress. The WIP is set 1 during the tW timing, and is set 0

when Write Status Register Cycle is completed, and the Write Enable Latch (WEL) bit is reset.

Figure 7.1.6. Write Status Register Instruction

/CS

SCLK

Mode 3

Mode 0

0

1

2

3

4

5

6

7

8

9

01H

7

MSB

6

5

12

13

14

15

1

0

16

17

4

3

2

18

19

20

21

22

23

9

8

Mode 3

Mode 0

Status Register-2 in

15

14

13

12

11

10

MSB

SO

August 2019

11

Status Register-1 in

Instruction

SI

10

High_Z

Rev 1.4

24 / 75

�Instructions Description

BY25Q40AL

7.2 Read Instructions

7.2.1

Normal Read Data (03H)

The Read Data instruction allows one or more data bytes to be sequentially read from the memory.

The instruction is initiated by driving the /CS pin low and then shifting the instruction code “03h”

followed by a 24-bit address (A23-A0) into the SI pin. The code and address bits are latched on

the rising edge of the SCLK pin. After the address is received, the data byte of the addressed

memory location will be shifted out on the SO pin at the falling edge of SCLK with most significant

bit (MSB) first. The address is automatically incremented to the next higher address after each

byte of data is shifted out allowing for a continuous stream of data. This means that the entire

memory can be accessed with a single instruction as long as the clock continues. The instruction

is completed by driving /CS high.

The Read Data instruction sequence is shown in Figure 7.2.1. If a Read Data instruction is issued

while an Erase, Program or other Write cycle is in progress (WIP=1) the instruction is ignored and

will not have any effects on the current cycle. The Read Data instruction allows clock frequency up

to to a maximum of fR (see AC Electrical Characteristics).

The Normal Read Data (03h) instruction is only supported in Standard SPI mode.

Figure 7.2.1. Read Data Instruction

/CS

SCLK

Mode 3

Mode 0

0

1

2

3

4

5

6

7

8

9

Instruction

SI

03H

10

28

29

30

31

32

33

34

36

37

38

22

21

3

2

1

0

High_Z

7

6

5

Data Out 1

4

3

2

1

MSB

August 2019

39

24-Bit Address

23

MSB

SO

35

Rev 1.4

25 / 75

0

7

�Instructions Description

7.2.2

BY25Q40AL

Fast Read (0BH)

The Fast Read instruction is similar to the Read Data instruction except that it can operate at the

highest possible frequency of fC (see AC Electrical Characteristics). In standard SPI mode, this is

accomplished by adding eight “dummy” clocks after the 24-bit address as shown in Figure 7.2.2.

The dummy clocks allow the devices internal circuits additional time for setting up the initial

address. During the dummy clocks the data value on the SO pin is a “don’t care”.

Figure 7.2.2. Fast Read Instruction

/CS

SCLK

0

Mode 3

Mode 0

1

2

3

4

5

6

7

8

9

29

30

31

24-Bit Address

Instruction

0BH

SI

28

10

23

22

3

21

2

1

0

MSB

High_Z

SO

/CS

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

SCLK

Dummy

SI

Clocks

0

SO

High_Z

7

6

5

Data Out 1

4

3

2

MSB

August 2019

1

0

7

6

5

Data Out 2

4

3

2

1

0

MSB

Rev 1.4

26 / 75

7

�Instructions Description

7.2.3

BY25Q40AL

Fast Read Dual Output (3Bh)

The Fast Read Dual Output (3Bh) instruction is similar to the standard Fast Read (0Bh) instruction

except that data is output on two pins; SI and SO. This allows data to be transferred at twice the

rate of standard SPI devices. The Fast Read Dual Output instruction is ideal for quickly

downloading code from Flash to RAM upon power-up or for applications that cache code-segments

to RAM for execution.

Similar to the Fast Read instruction, the Fast Read Dual Output instruction can operate at the

highest possible frequency of fC (see AC Electrical Characteristics). This is accomplished by

adding eight “dummy” clocks after the 24-bit address as shown in Figure 7.2.3. The dummy clocks

allow the device's internal circuits additional time for setting up the initial address. The input data

during the dummy clocks is “don’t care”. However, the SI pin should be high-impedance prior to the

falling edge of the first data out clock.

Figure 7.2.3. Fast Read Dual Output Instruction

/CS

SCLK

0

Mode 3

Mode 0

1

2

3

4

5

6

7

8

9

10

Instruction

SI

28

29

30

31

24-Bit Address

23

3BH

3

21

22

2

1

0

MSB

High_Z

SO

/CS

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

SCLK

Dummy

SI

6

0

SO

IO0 switches from

Input to Output

Clocks

High_Z

7

MSB

August 2019

4

2

0

6

5

3

1

7

Data Out 1

Rev 1.4

MSB

4

2

0

6

5

3

1

7

Data Out 2

MSB

4

2

0

6

5

3

1

7

Data Out 3

MSB

4

2

0

6

5

3

1

7

Data Out 4

27 / 75

�Instructions Description

7.2.4

BY25Q40AL

Fast Read Quad Output (6Bh)

The Fast Read Quad Output (6Bh) instruction is similar to the Fast Read Dual Output (3Bh)

instruction except that data is output on two pins, SI, SO, /WP, and /HOLD. The Quad Enable (QE)

bit in Status Register-2 must be set to 1 before the device will accept the Fast Read Quad Output

Instruction. The Fast Read Quad Output Instruction allows data to be transferred at four times the

rate of standard SPI devices.

The Fast Read Quad Output instruction can operate at the highest possible frequency of fC (see

AC Electrical Characteristics). This is accomplished by adding eight “dummy” clocks after the

24-bit address as shown in Figure 7.2.4. The dummy clocks allow the device's internal circuits

additional time for setting up the initial address. The input data during the dummy clocks is “don’t

care”. However, the IO pins should be high-impedance prior to the falling edge of the first data out

clock.

Figure 7.2.4. Fast Read Quad Output Instruction

/CS

SCLK

0

Mode 3

Mode 0

1

2

3

4

5

6

7

8

9

10

Instruction

SI

(IO0)

28

29

30

31

24-Bit Address

23

6BH

3

21

22

2

1

0

MSB

High_Z

SO

(IO1)

/WP

(IO2)

/HOLD

(IO3)

High_Z

High_Z

/CS

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

SCLK

Dummy

SI

(IO0)

IO0 switches from

Input to Output

Clocks

0

SO

(IO1)

High_Z

/WP

(IO2)

High_Z

/HOLD

(IO3)

High_Z

4

0

4

0

4

0

4

0

4

5

1

5

1

5

1

5

1

5

6

2

6

2

6

2

6

2

6

7

3

7

3

7

3

7

3

7

Byte1

August 2019

Rev 1.4

Byte2

Byte3

Byte4

28 / 75

�Instructions Description

7.2.5

BY25Q40AL

Fast Read Dual I/O (BBh)

The Fast Read Dual I/O (BBh) instruction allows for improved random access while maintaining

two IO pins, SI and SO. It is similar to the Fast Read Dual Output (3Bh) instruction but with the

capability to input the Address bits (A23-0) two bits per clock. This reduced instruction overhead

may allow for code execution (XIP) directly from the Dual SPI in some applications.

Fast Read Dual I/O with “Continuous Read Mode”

The Fast Read Dual I/O instruction can operate at the highest possible frequency of fC (see AC

Electrical Characteristics). The Fast Read Dual I/O instruction can further reduce instruction

overhead through setting the “Continuous Read Mode” bits (M7-0) after the input Address bits

(A23- 0), as shown in Figure 7.2.5a. The upper nibble of the (M7-4) controls the length of the next

Fast Read Dual I/O instruction through the inclusion or exclusion of the first byte instruction code.

The lower nibble bits of the (M3-0) are don’t care (“x”). However, the IO pins should be

high-impedance prior to the falling edge of the first data out clock.

If the “Continuous Read Mode” bits M5-4 = (1,0), then the next Fast Read Dual I/O instruction

(after /CS is raised and then lowered) does not require the BBh instruction code, as shown in

Figure 7.2.5b. This reduces the instruction sequence by eight clocks and allows the Read address

to be immediately entered after /CS is asserted low. If the “Continuous Read Mode” bits M5-4 do

not equal to (1,0), the next instruction (after /CS is raised and then lowered) requires the first byte

instruction code, thus returning to normal operation. It is recommended to input FFh on SI for the

next instruction (16 clocks), to ensure M4 = 1 and return the device to normal operation.

Figure 7.2.5a. Fast Read Dual I/O Instruction (Initial instruction or previous M5-4≠10)

/CS

SCLK

0

Mode 3

Mode 0

1

2

3

4

5

6

7

8

9

11

12

13

A23-16

Instruction

SI

10

BBH

SO

14

15

16

A15-8

17

18

19

20

22

21

23

M7-0

A7-0

22

20

18

16

14

12

10

8

6

4

2

0

6

4

2

0

23

21

19

17

15

13

11

9

7

5

3

1

7

5

3

1

MSB

MSB

/CS

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

SCLK

IOs

IO0 switch from

Input to Output

SI

0

6

4

2

0

6

4

2

0

6

SO

1

7

5

3

1

7

5

3

1

7

MSB

August 2019

Byte1

MSB

Byte2

MSB

4

2

0

6

4

5

3

1

7

5

Byte3

Rev 1.4

MSB

2

0

6

3

1

7

Byte4

29 / 75

�Instructions Description

BY25Q40AL

Figure 7.2.5b. Fast Read Dual I/O Instruction (Previous instruction set M5-4 = 10)

/CS

0

1

SI

22

20

SO

23

21

SCLK

Mode 3

Mode 0

2

3

4

5

18

16

14

12

10

8

6

4

19

17

15

13

11

9

7

5

A23-16

6

7

8

9

A15-8

10

11

12

13

A7-0

14

15

M7-0

2

0

6

4

2

0

3

1

7

5

3

1

30

31

MSB

MSB

/CS

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

SCLK

IOs

IO0 switch from

Input to Output

SI

0

6

4

2

0

6

4

2

0

6

4

2

0

6

4

2

0

6

SO

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

MSB

August 2019

Byte1

MSB

Byte2

Rev 1.4

MSB

Byte3

MSB

Byte4

30 / 75

�Instructions Description

7.2.6

BY25Q40AL

Fast Read Quad I/O (EBh)

The Fast Read Quad I/O (EBh) instruction is similar to the Fast Read Dual I/O (BBh) instruction

except that address and data bits are input and output through two pins SI, SO, /WP and /HOLD

and four Dummy clocks are required in SPI mode prior to the data output. The Quad I/O

dramatically reduces instruction overhead allowing faster random access for code execution (XIP)

directly from the Quad SPI. The Quad Enable bit (QE) of Status Register-2 must be set to enable

the Fast Read Quad I/O Instruction.

Fast Read Quad I/O with “Continuous Read Mode”

The Fast Read Quad I/O instruction can operate at the highest possible frequency of fC (see AC

Electrical Characteristics). The Fast Read Quad I/O instruction can further reduce instruction

overhead through setting the “Continuous Read Mode” bits (M7-0) after the input Address bits

(A23-0), as shown in Figure 7.2.6a. The upper nibble of the (M7-4) controls the length of the next

Fast Read Quad I/O instruction through the inclusion or exclusion of the first byte instruction code.

The lower nibble bits of the (M3-0) are don’t care (“x”). However, the IO pins should be

high-impedance prior to the falling edge of the first data out clock.

If the “Continuous Read Mode” bits M5-4 = (1,0), then the next Fast Read Quad I/O instruction

(after /CS is raised and then lowered) does not require the EBh instruction code, as shown in

Figure 7.2.6b. This reduces the instruction sequence by eight clocks and allows the Read address

to be immediately entered after /CS is asserted low. If the “Continuous Read Mode” bits M5-4 do

not equal to (1,0), the next instruction (after /CS is raised and then lowered) requires the first byte

instruction code, thus returning to normal operation. It is recommended to input FFh on SI for the

next instruction (8 clocks), to ensure M4 = 1 and return the device to normal operation.

Figure 7.2.6a. Fast Read Quad I/O Instruction (Initial instruction or previous M5-4≠10)

/CS

SCLK

Mode 3

Mode 0

0

1

2

3

4

5

6

7

8

10

A23-16

Instruction

SI

(IO0)

9

11

12

A15-8

13

A7-0

14

15

M7-0

16

17

Dummy

18

19

20

22

21

23

IOs switch from

Input to Output

Dummy

20

16

12

8

4

0

4

0

4

0

4

0

4

SO

(IO1)

21

17

13

9

5

1

5

1

5

1

5

1

5

/WP

(IO2)

22

18

14

10

6

2

6

2

6

2

6

2

6

/HOLD

(IO3)

23

19

15

11

7

3

7

3

7

3

7

3

7

EBH

Byte1

Byte2

Figure 7.2.6b. Fast Read Quad I/O Instruction (Previous instruction set M5-4 = 10 )

/CS

SCLK

Mode 3

Mode 0

0

1

A23-16

2

3

4

A15-8

5

A7-0

6

7

M7-0

8

9

Dummy

10

11

12

13

14

15

IOs switch from

Input to Output

Dummy

SI

(IO0)

20

16

12

8

4

0

4

0

4

0

4

0

4

SO

(IO1)

21

17

13

9

5

1

5

1

5

1

5

1

5

/WP

(IO2)

22

18

14

10

6

2

6

2

6

2

6

2

6

/HOLD

(IO3)

23

19

15

11

7

3

7

3

7

3

7

3

Byte1

August 2019

Rev 1.4

Byte2

7

Byte3

31 / 75

Byte3

�Instructions Description

BY25Q40AL

Fast Read Quad I/O with “8/16/32/64-Byte Wrap Around” in Standard SPI mode

The Fast Read Quad I/O instruction can also be used to access a specific portion within a page by

issuing a “Set Burst with Wrap” (77h) instruction prior to EBh. The “Set Burst with Wrap” (77h)

instruction can either enable or disable the “Wrap Around” feature for the following EBh

instructions. When “Wrap Around” is enabled, the data being accessed can be limited to an 8, 16,

32 or 64-byte section of a 256-byte page. The output data starts at the initial address specified in

the instruction, once it reaches the ending boundary of the 8/16/32/64- byte section, the output will

wrap around to the beginning boundary automatically until /CS is pulled high to terminate the

instruction.

The Burst with Wrap feature allows applications that use cache to quickly fetch a critical address

and then fill the cache afterwards within a fixed length (8/16/32/64-byte) of data without issuing

multiple read instructions.

The “Set Burst with Wrap” instruction allows three “Wrap Bits”, W6-4 to be set. The W4 bit is used

to enable or disable the “Wrap Around” operation while W6-5 are used to specify the length of the

wrap around section within a page. Refer to section 7.2.7 for detail descriptions.

August 2019

Rev 1.4

32 / 75

�Instructions Description

7.2.7

BY25Q40AL

Set Burst with Wrap (77h)

The Set Burst with Wrap (77h) instruction is used in conjunction with “Fast Read Quad I/O (EBh)”,

“instructions to access a fixed length of 8/16/32/64-byte section within a 256-byte page. Certain

applications can benefit from this feature and improve the overall system code execution

performance.

Similar to a Quad I/O instruction, the Set Burst with Wrap instruction is initiated by driving the /CS

pin low and then shifting the instruction code “77h” followed by 24 dummy bits and 8 “Wrap Bits”,

W7-0. The instruction sequence is shown in Figure 7.2.8. Wrap bit W7 and the lower nibble W3-0

are not used.

W4 = 0

W4 =1 (DEFAULT)

W6, W5

Wrap Around

Wrap Length

Wrap Around

Wrap Length

0 0

Yes

8-byte

No

N/A

0 1

1 0

1 1

Yes

Yes

Yes

16-byte

32-byte

64-byte

No

No

No

N/A

N/A

N/A

Once W6-4 is set by a Set Burst with Wrap instruction, all the following “Fast Read Quad I/O

(EBh)”, instructions will use the W6-4 setting to access the 8/16/32/64-byte section within any

page. To exit the “Wrap Around” function and return to normal read operation, another Set Burst

with Wrap instruction should be issued to set W4 = 1. The default value of W4 upon power on or

after a software reset is 1.

Figure 7.2.8. Set Burst with Wrap Instruction

/CS

SCLK

Mode 3

Mode 0

0

1

2

3

4

5

6

8

9

don’t

care

X

X

Instruction

SI

(IO0)

7

77H

10

11

don’t

care

X

X

12

13

14

15

don’t

Wrap Bit

care

X

w4

X

X

SO

(IO1)

X

X

X

X

X

X

w5

X

/WP

(IO2)

X

X

X

X

X

X

w6

X

/HOLD

(IO3)

X

X

X

X

X

X

X

X

August 2019

Rev 1.4

Mode 3

Mode 0

33 / 75

�Instructions Description

BY25Q40AL

7.3 ID and Power Instructions

7.3.1

Deep Power-down (B9h)

Although the standby current during normal operation is relatively low, standby current can be

further reduced with the Power-down instruction. The lower power consumption makes the

Power-down instruction especially useful for battery powered applications (See ICC1 and ICC2 in

DC Characteristics.)The instruction is initiated by driving the /CS pin low and shifting the

instruction code “B9h” as shown in Figure 7.3.1

The /CS pin must be driven high after the eighth bit has been latched. If this is not done the

Power-down instruction will not be executed. After /CS is driven high, the power- down state will

entered within the time duration of tDP (See AC Characteristics). While in the power-down state

only the Release Power-down / Device ID (ABh) instruction, which restores the device to normal

operation, will be recognized. All other instructions are ignored. This includes the Read Status

Register instruction, which is always available during normal operation. Ignoring all but one

instruction makes the Power Down state a useful condition for securing maximum write protection.

The device always powers-up in the normal operation with the standby current of ICC1

Figure 7.3.1. Deep Power-down Instruction

/CS

SCLK

Mode 3

Mode 0

0

1

2

3

4

5

6

7

tDP

Mode 3

Mode 0

Instruction

SI

B9H

Stand-by current

August 2019

Rev 1.4

Power-down current

34 / 75

�Instructions Description