200b: x32 Mobile LPDDR4 SDRAM

Features

Mobile LPDDR4 SDRAM

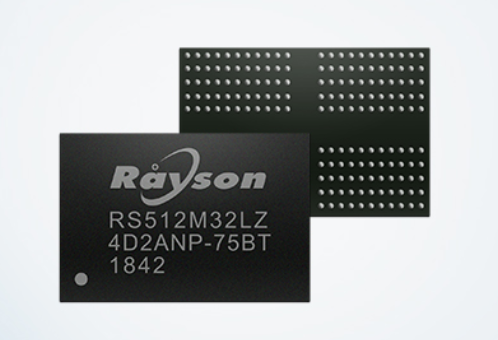

RS256M32LZ4D1ANP, RS512M32LZ4D2ANP, RS1G32LZ4D4ANQ

Features

Options

Marking

• VDD1/VDD2: 1.8V/1.1V

• Array configuration

– 256 Meg x 32 (2 channels x16 I/O)

– 512 Meg x 32 (2 channels x16 I/O)

– 1024 Meg x 32 (2 channels x8 I/O x 2)

• Device configuration

– 256M16 x 2 channel x 1 die

– 256M16 x 2 channel x 2 die

– 512M8 x 2 channel x 4 die

• FBGA “green” package

– 200-ball WFBGA (10mm x 14.5mm x

0.80mm)

– 200-ball VFBGA (10mm x 14.5mm x

0.95mm)

• Speed grade, cycle time

– 625ps @ RL = 28/32 (x16 device)

– 625ps @ RL = 32/36 (x8 device)

– 755ps @ RL= 24/28 (x16 device)

– 755ps @ RL= 28/32 (x8 device)

• Operating temperature range

– –25°C to +85°C

• Revision

• Ultra-low-voltage core and I/O power supplies

– VDD1 = 1.70–1.95V; 1.8V nominal

– VDD2/VDDQ = 1.06–1.17V; 1.10V nominal

• Frequency range

– 1600–10 MHz (data rate range: 3200–20 Mb/s/

pin)

• 16n prefetch DDR architecture

• 2-channel partitioned architecture for low RD/WR

energy and low average latency

• 8 internal banks per channel for concurrent operation

• Single-data-rate CMD/ADR entry

• Bidirectional/differential data strobe per byte lane

• Programmable READ and WRITE latencies (RL/WL)

• Programmable and on-the-fly burst lengths (BL =

16, 32)

• Directed per-bank refresh for concurrent bank operation and ease of command scheduling

• Up to 12.8 GB/s per die (2 channels x 6.4 GB/s)

• On-chip temperature sensor to control self refresh

rate

• Partial-array self refresh (PASR)

• Selectable output drive strength (DS)

• Clock-stop capability

• RoHS-compliant, “green” packaging

• Programmable V SSQ (ODT) termination

A

256M32

512M32

1024M32

D1

D2

D4

NP

NQ

-62

-75

Table 1: Key Timing Parameters

Speed

Grade

-62

-75

Array

configuration

WRITE Latency

READ Latency

Device

Type

Clock Rate

(MHz)

Data Rate

(Mb/s/pin)

Set A

Set B

DBI

Disabled

DBI

Enabled

256Mb x 32

512Mb x 32

x16 device

1600

3200

14

26

28

32

1024Mb x 32

x8 device

1600

3200

14

26

32

36

256Mb x 32

512Mb x 32

x16 device

1333

2667

12

22

24

28

1024Mb x 32

x8 device

1333

2667

12

22

28

32

1

�200b: x32 Mobile LPDDR4 SDRAM

SDRAM Addressing

SDRAM Addressing

The table below shows the addressing for the 8Gb die density. Where applicable, a distinction is made between

per-channel and per-die parameters. All bank, row, and column addresses are shown per-channel.

Table 2: Device Addressing

Configuration

256M32 (8Gb)

512M32 (16Gb)

1

2

4

Device density (per die)

8Gb

8Gb

8Gb

Device density (per channel)

4Gb

8Gb

16Gb

Die per package

Configuration

1024M32 (32Gb)

32Mb x 16 DQ x 8 banks 32Mb x 16 DQ x 8 banks 64Mb x 8 DQ x 8 banks

x 2 channels x 1 rank

x 2 channels x 2 ranks x 2 channels x 2 ranks x 2

Number of channels (per die)

2

2

2

Number of ranks per channel

1

2

2

Number of banks (per channel)

8

8

8

Array prefetch (bits) (per channel)

Number of rows (per bank)

Number of columns (fetch boundaries)

Page size (bytes)

256

256

128

32,768

32,768

65,536

64

64

32

2048

2048

1024

Channel density (bits per channel)

4,294,967,296

8,589,934,592

17,179,869,184

Total density (bits per die)

8,589,934,592

8,589,934,592

8,589,934,592

BA[2:0]

BA[2:0]

BA[2:0]

Row addresses

R[14:0]

R[14:0]

–

Column addresses

Bank address

x16

x8

C[9:0]

C[9:0]

–

Row addresses

–

–

R[15:0]

Column addresses

–

–

C[9:0]

64-bit

64-bit

64-bit

Burst starting address boundary

Notes:

3

1. The lower two column addresses (C0–C1) are assumed to be zero and are not transmitted on the CA bus.

2. Row and column address values on the CA bus that are not used for a particular density are "Don't Care."

3. Refer to Byte Mode section for further information about 1024M32 (32Gb) configuration.

2

�200b: x32 Mobile LPDDR4 SDRAM

Part Number Ordering Information

Part Number Ordering Information

Figure 1: Part Number Chart

3

�200b: x32 Mobile LPDDR4 SDRAM

Part Number Ordering Information

Contents

General Description ....................................................................................................................................... 17

General Notes ............................................................................................................................................ 17

Package Block Diagrams ................................................................................................................................. 18

Ball Assignments and Descriptions ................................................................................................................. 21

Package Dimensions ....................................................................................................................................... 23

MR0, MR[6:3], MR8, MR13 Readout ................................................................................................................. 25

IDD Parameters ............................................................................................................................................... 26

Functional Description ................................................................................................................................... 28

Monolithic Device Addressing ......................................................................................................................... 28

Simplified Bus Interface State Diagram ............................................................................................................ 32

Power-Up and Initialization ............................................................................................................................ 33

Voltage Ramp ............................................................................................................................................. 34

Reset Initialization with Stable Power .......................................................................................................... 36

Power-Off Sequence ....................................................................................................................................... 37

Controlled Power-Off .................................................................................................................................. 37

Uncontrolled Power-Off .............................................................................................................................. 37

Mode Registers ............................................................................................................................................... 38

Mode Register Assignments and Definitions ................................................................................................ 38

Commands and Timing .................................................................................................................................. 64

Truth Tables ................................................................................................................................................... 64

ACTIVATE Command ..................................................................................................................................... 67

Read and Write Access Modes ......................................................................................................................... 68

Preamble and Postamble ................................................................................................................................ 69

Burst READ Operation .................................................................................................................................... 72

Read Timing ............................................................................................................................................... 74

tLZ(DQS), tLZ(DQ), tHZ(DQS), tHZ(DQ) Calculation ..................................................................................... 74

tLZ(DQS) and tHZ(DQS) Calculation for ATE (Automatic Test Equipment) .................................................... 75

tLZ(DQ) and tHZ(DQ) Calculation for ATE (Automatic Test Equipment) ........................................................ 76

Burst WRITE Operation .................................................................................................................................. 78

Write Timing .............................................................................................................................................. 80

tWPRE Calculation for ATE (Automatic Test Equipment) .............................................................................. 81

tWPST Calculation for ATE (Automatic Test Equipment) ............................................................................... 81

MASK WRITE Operation ................................................................................................................................. 82

Mask Write Timing Constraints for BL16 ...................................................................................................... 84

Data Mask and Data Bus Inversion (DBI[DC]) Function ................................................................................... 86

Preamble and Postamble Behavior .................................................................................................................. 90

Preamble, Postamble Behavior in READ-To-READ Operations ...................................................................... 90

READ to READ Operations – Seamless ......................................................................................................... 90

READ to READ Operations – Consecutive .................................................................................................... 91

Write to Write Operations – Seamless .......................................................................................................... 98

Write to Write Operations – Consecutive ..................................................................................................... 101

PRECHARGE Operation ................................................................................................................................. 105

Burst Read Operation Followed by Precharge .............................................................................................. 105

Burst Write Followed by Precharge ............................................................................................................. 106

Auto Precharge .............................................................................................................................................. 107

Burst READ With Auto Precharge ............................................................................................................... 107

Burst WRITE With Auto Precharge .............................................................................................................. 108

RAS Lock Function .................................................................................................................................... 112

Delay time from Write to Read with Auto Precharge .................................................................................... 113

REFRESH Command ..................................................................................................................................... 114

4

�200b: x32 Mobile LPDDR4 SDRAM

Part Number Ordering Information

Refresh Requirement ..................................................................................................................................... 119

SELF REFRESH Operation .............................................................................................................................. 120

Self Refresh Entry and Exit ......................................................................................................................... 120

Power-Down Entry and Exit During Self Refresh ......................................................................................... 121

Command Input Timing After Power Down Exit .......................................................................................... 122

Self Refresh Abort ...................................................................................................................................... 123

MRR, MRW, MPC Command During tXSR, tRFC .......................................................................................... 123

Power-Down Mode ........................................................................................................................................ 126

Power-Down Entry and Exit ....................................................................................................................... 126

Input Clock Stop and Frequency Change ........................................................................................................ 136

Clock Frequency Change – CKE LOW ......................................................................................................... 136

Clock Stop – CKE LOW ............................................................................................................................... 136

Clock Frequency Change – CKE HIGH ........................................................................................................ 136

Clock Stop – CKE HIGH ............................................................................................................................. 137

MODE REGISTER READ Operation ................................................................................................................ 138

MRR after Read and Write Command ......................................................................................................... 139

MRR after Power-Down Exit ....................................................................................................................... 141

MODE REGISTER WRITE ............................................................................................................................... 142

Mode Register Write States ......................................................................................................................... 142

VREF Current Generator (VRCG) ..................................................................................................................... 144

VREF Training ................................................................................................................................................. 146

VREF(CA) Training ........................................................................................................................................ 146

VREF(DQ) Training ....................................................................................................................................... 151

Command Bus Training ................................................................................................................................. 156

Command Bus Training Mode .................................................................................................................... 156

Training Sequence for Single-Rank Systems ................................................................................................ 157

Training Sequence for Multiple-Rank Systems ............................................................................................ 158

Relation between CA Input pin DQ Output pin ........................................................................................... 159

Write Leveling ............................................................................................................................................... 163

Mode Register Write-WR Leveling Mode ..................................................................................................... 163

Write-Leveling Procedure: .......................................................................................................................... 163

Input Clock Frequency Stop and Change .................................................................................................... 164

MULTIPURPOSE Operation ........................................................................................................................... 167

Read DQ Calibration Training ........................................................................................................................ 172

Read DQ Calibration Procedure ................................................................................................................. 172

DQ Read Training Example ........................................................................................................................ 174

MPC of Read DQ Calibration after Power-Down Exit ................................................................................... 175

Write Training ............................................................................................................................................... 176

Internal Interval Timer .............................................................................................................................. 181

DQS Interval Oscillator Matching Error ...................................................................................................... 183

OSC Count Readout Time .......................................................................................................................... 184

Thermal Offset .............................................................................................................................................. 186

Temperature Sensor ...................................................................................................................................... 186

ZQ Calibration ............................................................................................................................................... 187

ZQCAL Reset ............................................................................................................................................. 188

Multichannel Considerations ..................................................................................................................... 189

ZQ External Resistor, Tolerance, and Capacitive Loading ............................................................................. 189

Frequency Set Points ..................................................................................................................................... 190

Frequency set point update Timing ............................................................................................................ 191

Pull-Up and Pull-Down Characteristics and Calibration .................................................................................. 195

On-Die Termination for the Command/Address Bus ....................................................................................... 196

ODT Mode Register and ODT State Table .................................................................................................... 196

5

�200b: x32 Mobile LPDDR4 SDRAM

Part Number Ordering Information

ODT Mode Register and ODT Characteristics ............................................................................................. 197

ODT for CA Update Time ........................................................................................................................... 199

DQ On-Die Termination ................................................................................................................................ 199

Output Driver and Termination Register Temperature and Voltage Sensitivity .............................................. 202

ODT Mode Register ................................................................................................................................... 203

Asynchronous ODT ................................................................................................................................... 203

DQ ODT During Power-Down and Self Refresh Modes ................................................................................ 205

ODT During Write Leveling Mode .............................................................................................................. 205

TRR Mode – Target Row Refresh ..................................................................................................................... 206

TRR Mode Operation ................................................................................................................................. 206

Post-Package Repair ...................................................................................................................................... 208

Failed Row Address Repair ......................................................................................................................... 208

Read Preamble Training ................................................................................................................................. 210

Electrical Specifications ................................................................................................................................. 211

Absolute Maximum Ratings ....................................................................................................................... 211

AC and DC Operating Conditions ................................................................................................................... 211

AC and DC Input Measurement Levels ........................................................................................................... 213

Input Levels for CKE .................................................................................................................................. 213

Differential Input Voltage for CK ................................................................................................................ 213

Peak Voltage Calculation Method ............................................................................................................... 214

Single-Ended Input Voltage for Clock ......................................................................................................... 214

Differential Input Slew Rate Definition for Clock ......................................................................................... 215

Differential Input Cross-Point Voltage ........................................................................................................ 217

Differential Input Voltage for DQS .............................................................................................................. 217

Peak Voltage Calculation Method ............................................................................................................... 218

Single-Ended Input Voltage for DQS ........................................................................................................... 219

Differential Input Slew Rate Definition for DQS .......................................................................................... 220

Differential Input Cross-Point Voltage ........................................................................................................ 221

Input Levels for ODT ................................................................................................................................. 222

AC and DC Output Measurement Levels ......................................................................................................... 222

Single-Ended Output Slew Rate .................................................................................................................. 222

Differential Output Slew Rate ..................................................................................................................... 223

Overshoot and Undershoot Specifications .................................................................................................. 224

Driver Output Timing Reference Load ............................................................................................................ 225

LVSTL I/O System .......................................................................................................................................... 225

Input/Output Capacitance ............................................................................................................................. 227

IDD Specification Parameters and Test Conditions ........................................................................................... 228

IDD Specifications ...................................................................................................................................... 232

AC Timing ..................................................................................................................................................... 234

CA Rx Voltage and Timing .............................................................................................................................. 244

DQ Tx Voltage and Timing ............................................................................................................................. 247

DRAM Data Timing ................................................................................................................................... 247

DQ Rx Voltage and Timing ............................................................................................................................. 248

Clock Specification ........................................................................................................................................ 251

tCK(abs), tCH(abs), and tCL(abs) ................................................................................................................ 252

Clock Period Jitter .......................................................................................................................................... 252

Clock Period Jitter Effects on Core Timing Parameters ................................................................................. 252

Cycle Time Derating for Core Timing Parameters ........................................................................................ 253

Clock Cycle Derating for Core Timing Parameters ....................................................................................... 253

Clock Jitter Effects on Command/Address Timing Parameters ..................................................................... 253

Clock Jitter Effects on READ Timing Parameters .......................................................................................... 253

Clock Jitter Effects on WRITE Timing Parameters ........................................................................................ 254

6

�200b: x32 Mobile LPDDR4 SDRAM

Part Number Ordering Information

Byte Mode ..................................................................................................................................................... 255

Monolithic Device Addressing (Byte Mode) ................................................................................................ 255

Mode Register ........................................................................................................................................... 256

Mode Register Assignments and Definitions ........................................................................................... 256

Command Truth Table ............................................................................................................................... 266

Command Bus Training ............................................................................................................................. 267

Training Mode 1 .................................................................................................................................... 267

Training Sequence of Mode 1 for Single-Rank Systems ............................................................................ 268

Training Sequence of Mode 1 for Multi-Rank Systems ............................................................................. 269

Relation between the CA Input Pin and the DQ Output Pin for Mode 1 .................................................... 270

Timing for CA Training Mode 1 ............................................................................................................... 270

Read DQ Training ...................................................................................................................................... 272

RD DQ Calibration Training Procedure ................................................................................................... 273

DQ Read Training Example .................................................................................................................... 274

On-Die Termination .................................................................................................................................. 274

ODT Control ......................................................................................................................................... 274

AC Timing ................................................................................................................................................. 276

Revision History ............................................................................................................................................ 278

Rev. B– 4/16 ............................................................................................................................................... 278

Rev. A – 7/15 .............................................................................................................................................. 278

7

�200b: x32 Mobile LPDDR4 SDRAM

Part Number Ordering Information

List of Figures

Figure 1: Part Number Chart ............................................................................................................................ 3

Figure 2: Single-Die, Dual-Channel Package Block Diagram ............................................................................ 18

Figure 3: Dual-Die, Dual-Channel Package Block Diagram .............................................................................. 19

Figure 4: Quad-Die, Dual-Channel Package Block Diagram ............................................................................. 20

Figure 5: 200-Ball Dual-Channel Discrete FBGA ............................................................................................. 21

Figure 6: 200-Ball WFBGA – 10mm x 14.5mm (Package Code: NP) ................................................................... 23

Figure 7: 200-Ball VFBGA – 10mm x 14.5mm (Package Code: NQ) .................................................................... 24

Figure 8: Simplified State Diagram ................................................................................................................. 32

Figure 9: Simplified State Diagram ................................................................................................................. 33

Figure 10: Voltage Ramp and Initialization Sequence ...................................................................................... 35

Figure 11: ACTIVATE Command .................................................................................................................... 68

Figure 12: tFAW Timing .................................................................................................................................. 68

Figure 13: DQS Read Preamble and Postamble – Toggling Preamble and 0.5nCK Postamble ............................. 69

Figure 14: DQS Read Preamble and Postamble – Static Preamble and 1.5nCK Postamble .................................. 69

Figure 15: DQS Write Preamble and Postamble – 0.5nCK Postamble ................................................................ 70

Figure 16: DQS Write Preamble and Postamble – 1.5nCK Postamble ................................................................ 71

Figure 17: Burst Read Timing ......................................................................................................................... 72

Figure 18: Burst Read Followed by Burst Write or Burst Mask Write .................................................................. 73

Figure 19: Seamless Burst Read ...................................................................................................................... 73

Figure 20: Read Timing .................................................................................................................................. 74

Figure 21: tLZ(DQS) Method for Calculating Transitions and Endpoint ............................................................ 75

Figure 22: tHZ(DQS) Method for Calculating Transitions and Endpoint ........................................................... 75

Figure 23: tLZ(DQ) Method for Calculating Transitions and Endpoint .............................................................. 76

Figure 24: tHZ(DQ) Method for Calculating Transitions and Endpoint ............................................................. 77

Figure 25: Burst WRITE Operation ................................................................................................................. 78

Figure 26: Burst Write Followed by Burst Read ................................................................................................ 79

Figure 27: Write Timing ................................................................................................................................. 80

Figure 28: Method for Calculating tWPRE Transitions and Endpoints ............................................................... 81

Figure 29: Method for Calculating tWPST Transitions and Endpoints ............................................................... 81

Figure 30: Mask Write Command - Same Bank ............................................................................................... 82

Figure 31: Masked Write Command - Different Bank ...................................................................................... 83

Figure 32: MASKED WRITE Command with Write DBI Enabled; DM Enabled .................................................. 88

Figure 33: WRITE Command with Write DBI Enabled; DM Disabled ................................................................ 89

Figure 34: READ Operations: tCCD = Min, Preamble = Toggle, 1.5nCK Postamble ............................................. 90

Figure 35: Seamless READ: tCCD = Min +1, Preamble = Toggle, 1.5nCK Postamble ........................................... 91

Figure 36: Consecutive READ: tCCD = Min +1, Preamble = Toggle, 0.5nCK Postamble ....................................... 91

Figure 37: Consecutive READ: tCCD = Min +1, Preamble = Static, 1.5nCK Postamble ........................................ 92

Figure 38: Consecutive READ: tCCD = Min +1, Preamble = Static, 0.5nCK Postamble ........................................ 92

Figure 39: Consecutive READ: tCCD = Min + 2, Preamble = Toggle, 1.5nCK Postamble ...................................... 93

Figure 40: Consecutive READ: tCCD = Min + 2, Preamble = Toggle, 0.5nCK Postamble ...................................... 94

Figure 41: Consecutive READ: tCCD = Min + 2, Preamble = Static, 1.5nCK Postamble ....................................... 94

Figure 42: Consecutive READ: tCCD = Min + 2, Preamble = Static, 0.5nCK Postamble ....................................... 95

Figure 43: Consecutive READ: tCCD = Min + 3, Preamble = Toggle, 1.5nCK Postamble ...................................... 96

Figure 44: Consecutive READ: tCCD = Min + 3, Preamble = Toggle, 0.5nCK Postamble ...................................... 96

Figure 45: Consecutive READ: tCCD = Min + 3, Preamble = Static, 1.5nCK Postamble ....................................... 97

Figure 46: Consecutive READ: tCCD = Min + 3, Preamble = Static, 0.5nCK Postamble ....................................... 97

Figure 47: Seamless Write: tCCD = Min, 0.5nCK Postamble .............................................................................. 98

Figure 48: Seamless Write: tCCD = Min, 1.5nCK Postamble, 533MHz < Clock Frequency ≤ 800MHz, ODT Worst

Timing Case ............................................................................................................................................... 99

Figure 49: Seamless Write: tCCD = Min, 1.5nCK Postamble ............................................................................. 100

8

�200b: x32 Mobile LPDDR4 SDRAM

Part Number Ordering Information

Figure 50: Consecutive Write: tCCD = Min + 1, 0.5nCK Postamble ................................................................... 101

Figure 51: Consecutive Write: tCCD = Min + 1, 1.5nCK Postamble ................................................................... 101

Figure 52: Consecutive Write: tCCD = Min + 2, 0.5nCK Postamble ................................................................... 102

Figure 53: Consecutive Write: tCCD = Min + 2, 1.5nCK Postamble ................................................................... 102

Figure 54: Consecutive Write: tCCD = Min + 3, 0.5nCK Postamble ................................................................... 103

Figure 55: Consecutive Write: tCCD = Min + 3, 1.5nCK Postamble ................................................................... 104

Figure 56: Consecutive Write: tCCD = Min + 4, 1.5nCK Postamble ................................................................... 104

Figure 57: Burst Read Followed by Precharge – BL16, Toggling Preamble, 0.5nCK Postamble ........................... 106

Figure 58: Burst Read Followed by Precharge – BL32, 2tCK, 0.5nCK Postamble ................................................ 106

Figure 59: Burst WRITE Followed by PRECHARGE – BL16, 2nCK Preamble, 0.5nCK Postamble ........................ 107

Figure 60: Burst READ With Auto Precharge – BL16, Non-Toggling Preamble, 0.5nCK Postamble ..................... 108

Figure 61: Burst READ With Auto Precharge – BL32, Toggling Preamble, 1.5nCK Postamble ............................. 108

Figure 62: Burst WRITE With Auto Precharge – BL16, 2 nCK Preamble, 0.5nCK Postamble ................................ 109

Figure 63: Command Input Timing with RAS Lock ......................................................................................... 113

Figure 64: Delay Time from Write to Read with Auto Precharge ...................................................................... 113

Figure 65: All-Bank REFRESH Operation ....................................................................................................... 116

Figure 66: Per Bank REFRESH Operation ....................................................................................................... 117

Figure 67: Postponing REFRESH Commands (Example) ................................................................................. 119

Figure 68: Pulling In REFRESH Commands (Example) ................................................................................... 119

Figure 69: Self Refresh Entry/Exit Timing ...................................................................................................... 121

Figure 70: Self Refresh Entry/Exit Timing with Power-Down Entry/Exit .......................................................... 122

Figure 71: Command Input Timings after Power-Down Exit during Self Refresh .............................................. 123

Figure 72: MRR, MRW, and MPC Commands Issuing Timing During tXSR ....................................................... 124

Figure 73: MRR, MRW, and MPC Commands Issuing Timing During tRFC ...................................................... 125

Figure 74: Basic Power-Down Entry and Exit Timing ...................................................................................... 127

Figure 75: Read and Read with Auto Precharge to Power-Down Entry ............................................................. 128

Figure 76: Write and Mask Write to Power-Down Entry .................................................................................. 129

Figure 77: Write with Auto Precharge and Mask Write with Auto Precharge to Power-Down Entry .................... 130

Figure 78: Refresh Entry to Power-Down Entry .............................................................................................. 131

Figure 79: Activate Command to Power-Down Entry ...................................................................................... 131

Figure 80: Precharge Command to Power-Down Entry ................................................................................... 132

Figure 81: Mode Register Read to Power-Down Entry ..................................................................................... 133

Figure 82: Mode Register Write to Power-Down Entry .................................................................................... 134

Figure 83: Multi Purpose Command for Start ZQ Calibration to Power-Down Entry ......................................... 135

Figure 84: MODE REGISTER READ Operation ............................................................................................... 139

Figure 85: READ to MRR Timing ................................................................................................................... 140

Figure 86: Write to MRR Timing .................................................................................................................... 141

Figure 87: MRR Following Power-Down ......................................................................................................... 142

Figure 88: MODE REGISTER WRITE Timing .................................................................................................. 142

Figure 89: VRCG Enable Timing .................................................................................................................... 145

Figure 90: VRCG Disable Timing ................................................................................................................... 145

Figure 91: V REF Operating Range (VREF,max, V REF,min) ....................................................................................... 146

Figure 92: V REF Set-Point Tolerance and Step Size .......................................................................................... 147

Figure 93: tVref for Short, Middle and Long Timing Diagram ........................................................................... 148

Figure 94: V REF(CA) Single-Step Increment ...................................................................................................... 148

Figure 95: V REF(CA) Single-Step Decrement ..................................................................................................... 149

Figure 96: V REF(CA) Full Step from V REF,min to V REF,max ...................................................................................... 149

Figure 97: V REF(CA) Full Step from V REF,max to V REF,min ...................................................................................... 149

Figure 98: V REF Operating Range (VREF,max, V REF,min) ....................................................................................... 151

Figure 99: V REF Set Tolerance and Step Size .................................................................................................... 152

Figure 100: V REF(DQ) Transition Time for Short, Middle, or Long Changes ........................................................ 153

Figure 101: V REF(DQ) Single-Step Size Increment ............................................................................................. 153

9

�200b: x32 Mobile LPDDR4 SDRAM

Part Number Ordering Information

Figure 102:

Figure 103:

Figure 104:

Figure 105:

Figure 106:

Figure 107:

Figure 108:

Figure 109:

Figure 110:

Figure 111:

Figure 112:

Figure 113:

Figure 114:

Figure 115:

Figure 116:

Figure 117:

Figure 118:

Figure 119:

Figure 120:

Figure 121:

Figure 122:

Figure 123:

Figure 124:

Figure 125:

Figure 126:

Figure 127:

Figure 128:

Figure 129:

Figure 130:

Figure 131:

Figure 132:

Figure 133:

Figure 134:

Figure 135:

Figure 136:

Figure 137:

Figure 138:

Figure 139:

Figure 140:

Figure 141:

Figure 142:

Figure 143:

Figure 144:

Figure 145:

Figure 146:

Figure 147:

Figure 148:

Figure 149:

Figure 150:

Figure 151:

Figure 152:

Figure 153:

V REF(DQ) Single-Step Size Decrement ............................................................................................ 154

V REF(DQ) Full Step from V REF,min to V REF,max ................................................................................... 154

V REF(DQ) Full Step from V REF,max to V REF,min ................................................................................... 154

Command Bus Training Mode Entry – CA Training Pattern I/O With V REF(CA) Value Update ............ 159

Consecutive V REF(CA) Value Update .............................................................................................. 160

Command Bus Training Mode Exit With Valid Command ............................................................. 161

Command Bus Training Mode Exit With Power-Down Entry ......................................................... 162

Write-Leveling Timing – tDQSL (MAX) ......................................................................................... 164

Write Leveling Timing – tDQSL (MIN) .......................................................................................... 164

Clock Stop and Timing During Write Leveling .............................................................................. 165

DQS_t/DQS_c to CK_t/CK_t Timings at the Pins Referenced from the Internal Latch ..................... 166

WR-FIFO – tWPRE = 2nCK, tWPST = 0.5nCK ................................................................................. 168

RD-FIFO – tWPRE = 2nCK, tWPST = 0.5nCK, tRPRE = Toggling, tRPST = 1.5nCK .............................. 169

RD-FIFO – tRPRE = Toggling, tRPST = 1.5nCK ............................................................................... 170

DQ Read Training Timing: Read to Read DQ Calibration ............................................................... 173

DQ Read Training Timing: Read DQ Calibration to Read DQ Calibration/Read .............................. 173

MPC Read DQ Calibration Following Power-Down State ............................................................... 175

WRITE to MPC [WRITE FIFO] Operation Timing .......................................................................... 177

MPC [WRITE FIFO] to MPC [READ FIFO] Timing ......................................................................... 178

MPC [READ FIFO] to Read Timing ............................................................................................... 179

MPC [WRITE FIFO] with DQ ODT Timing .................................................................................... 180

Power Down Exit to MPC [WRITE FIFO] Timing ........................................................................... 181

Interval Oscillator Offset – OSCoffset ............................................................................................. 183

In case of DQS Interval Oscillator is stopped by MPC Command ................................................... 184

In case of DQS Interval Oscillator is stopped by DQS interval timer ............................................... 185

Temperature Sensor Timing ........................................................................................................ 187

ZQCal Timing ............................................................................................................................. 188

Frequency Set Point Switching Timing ......................................................................................... 192

Training for Two Frequency Set Points ......................................................................................... 194

Example of Switching Between Two Trained Frequency Set Points ................................................ 194

Example of Switching to a Third Trained Frequency Set Point ....................................................... 195

ODT for CA ................................................................................................................................. 196

ODT for CA Setting Update Timing in 4-Clock Cycle Command .................................................... 199

Functional Representation of DQ ODT ........................................................................................ 200

Asynchronous ODTon/ODToff Timing ......................................................................................... 204

Target Row Refresh Mode ............................................................................................................ 207

Post-Package Repair Timing ........................................................................................................ 209

Read Preamble Training .............................................................................................................. 210

AC Input Timing Definition ......................................................................................................... 213

CK Differential Input Voltage ....................................................................................................... 213

Definition of Differential Clock Peak Voltage ................................................................................ 214

Clock Single-Ended Input Voltage ................................................................................................ 215

Differential Input Slew Rate Definition for CK_t, CK_c .................................................................. 216

V ix Definition (Clock) .................................................................................................................. 217

DQS Differential Input Voltage .................................................................................................... 218

Definition of Differential DQS Peak Voltage .................................................................................. 219

DQS Single-Ended Input Voltage ................................................................................................. 219

Differential Input Slew Rate Definition for DQS_t, DQS_c ............................................................. 220

V ix Definition (DQS) .................................................................................................................... 221

Single-Ended Output Slew Rate Definition ................................................................................... 223

Differential Output Slew Rate Definition ...................................................................................... 224

Overshoot and Undershoot Definition ......................................................................................... 225

10

�200b: x32 Mobile LPDDR4 SDRAM

Part Number Ordering Information

Figure 154:

Figure 155:

Figure 156:

Figure 157:

Figure 158:

Figure 159:

Figure 160:

Figure 161:

Figure 162:

Figure 163:

Figure 164:

Figure 165:

Figure 166:

Figure 167:

Figure 168:

Figure 169:

Figure 170:

Figure 171:

Figure 172:

Figure 173:

Driver Output Timing Reference Load ......................................................................................... 225

LVSTL I/O Cell ............................................................................................................................ 226

Pull-Up Calibration ..................................................................................................................... 227

tCMDCKE Timing ....................................................................................................................... 238

tESCKE Timing ........................................................................................................................... 241

CA Receiver (Rx) Mask ................................................................................................................ 244

Across Pin V REF CA Voltage Variation ............................................................................................ 244

CA Timings at the DRAM Pins ..................................................................................................... 245

CA tcIPW and SRIN_cIVW Definition (for Each Input Pulse) .......................................................... 245

CA V IHL_AC Definition (for Each Input Pulse) ................................................................................ 245

Read Data Timing Definitions – tQH and tDQSQ Across DQ Signals per DQS Group ....................... 247

DQ Receiver (Rx) Mask ................................................................................................................ 248

Across Pin V REF DQ Voltage Variation ........................................................................................... 248

DQ-to-DQS tDQS2DQ and tDQDQ .............................................................................................. 249

DQ tDIPW and SRIN_dIVW Definition for Each Input Pulse .......................................................... 250

DQ V IHL(AC) Definition (for Each Input Pulse) ............................................................................... 250

Entering CBT Mode and CA Training Pattern (Input and Output) .................................................. 270

Exiting CBT Mode with Valid Command ...................................................................................... 271

Exiting CBT Mode with Power Down Entry ................................................................................... 272

DQ Read Training Timing ............................................................................................................ 274

11

�200b: x32 Mobile LPDDR4 SDRAM

Part Number Ordering Information

List of Tables

Table 1: Key Timing Parameters ....................................................................................................................... 1

Table 2: Device Addressing .............................................................................................................................. 2

Table 3: Ball/Pad Descriptions ....................................................................................................................... 22

Table 4: Mode Register Contents .................................................................................................................... 25

Table 5: IDD Parameters – Single-Die .............................................................................................................. 26

Table 6: IDD6 Full-Array Self Refresh Current ................................................................................................... 27

Table 7: Monolithic Device Addressing – 2 Channels per Die ........................................................................... 29

Table 8: Monolithic Device Addressing – 1 Channel per Die ............................................................................. 30

Table 9: Mode Register Default Settings .......................................................................................................... 34

Table 10: Voltage Ramp Conditions ................................................................................................................ 34

Table 11: Initialization Timing Parameters ...................................................................................................... 36

Table 12: Reset Timing Parameter .................................................................................................................. 37

Table 13: Power Supply Conditions ................................................................................................................ 37

Table 14: Power-Off Timing ............................................................................................................................ 38

Table 15: Mode Register Assignments ............................................................................................................. 38

Table 16: MR0 Device Feature 0 (MA[7:0] = 00h) .............................................................................................. 39

Table 17: MR0 Op-Code Bit Definitions .......................................................................................................... 39

Table 18: MR1 Device Feature 1 (MA[7:0] = 01h) .............................................................................................. 40

Table 19: MR1 Op-Code Bit Definitions .......................................................................................................... 40

Table 20: Burst Sequence ............................................................................................................................... 42

Table 21: MR2 Device Feature 2 (MA[7:0] = 02h) .............................................................................................. 43

Table 22: MR2 Op-Code Bit Definitions .......................................................................................................... 43

Table 23: Frequency Ranges for RL, WL, nWR and nRTP Settings ..................................................................... 45

Table 24: MR3 I/O Configuration 1 (MA[7:0] = 03h) ......................................................................................... 45

Table 25: MR3 Op-Code Bit Definitions .......................................................................................................... 46

Table 26: MR4 Device Temperature (MA[7:0] = 04h) ........................................................................................ 47

Table 27: MR4 Op-Code Bit Definitions .......................................................................................................... 47

Table 28: MR5 Basic Configuration 1 (MA[7:0] = 05h) ...................................................................................... 48

Table 29: MR5 Op-Code Bit Definitions .......................................................................................................... 48

Table 30: MR6 Basic Configuration 2 (MA[7:0] = 06h) ...................................................................................... 48

Table 31: MR6 Op-Code Bit Definitions .......................................................................................................... 48

Table 32: MR7 Basic Configuration 3 (MA[7:0] = 07h) ...................................................................................... 48

Table 33: MR7 Op-Code Bit Definitions .......................................................................................................... 48

Table 34: MR8 Basic Configuration 4 (MA[7:0] = 08h) ...................................................................................... 49

Table 35: MR8 Op-Code Bit Definitions .......................................................................................................... 49

Table 36: MR9 Test Mode (MA[7:0] = 09h) ....................................................................................................... 49

Table 37: MR9 Op-Code Definitions ............................................................................................................... 49

Table 38: MR10 Calibration (MA[7:0] = 0Ah) ................................................................................................... 49

Table 39: MR10 Op-Code Bit Definitions ........................................................................................................ 50

Table 40: MR11 ODT Control (MA[7:0] = 0Bh) ................................................................................................. 50

Table 41: MR11 Op-Code Bit Definitions ........................................................................................................ 50

Table 42: MR12 Register Information (MA[7:0] = 0Ch) ..................................................................................... 51

Table 43: MR12 Op-Code Bit Definitions ........................................................................................................ 51

Table 44: MR13 Register Control (MA[7:0] = 0Dh) ............................................................................................ 51

Table 45: MR13 Op-Code Bit Definition .......................................................................................................... 52

Table 46: Mode Register 14 (MA[7:0] = 0Eh) .................................................................................................... 53

Table 47: MR14 Op-Code Bit Definition .......................................................................................................... 53

Table 48: V REF Setting for Range[0] and Range[1] ............................................................................................. 54

Table 49: MR15 Register Information (MA[7:0] = 0Fh) ..................................................................................... 55

Table 50: MR15 Op-code Bit Definition .......................................................................................................... 55

12

�200b: x32 Mobile LPDDR4 SDRAM

Part Number Ordering Information

Table 51: MR15 Invert Register Pin Mapping ................................................................................................... 55

Table 52: MR16 PASR Bank Mask (MA[7:0] = 010h) .......................................................................................... 55

Table 53: MR16 Op-Code Bit Definitions ........................................................................................................ 55

Table 54: MR17 PASR Segment Mask (MA[7:0] = 11h) ...................................................................................... 56

Table 55: MR17 PASR Segment Mask Definitions ............................................................................................ 56

Table 56: MR17 PASR Segment Mask .............................................................................................................. 56

Table 57: MR18 Register Information (MA[7:0]=12h) ....................................................................................... 57

Table 58: MR18 LSB DQS Oscillator Count ...................................................................................................... 57

Table 59: MR19 Register Information (MA[7:0] = 13h) ..................................................................................... 57

Table 60: MR19 DQS Oscillator Count ............................................................................................................ 57

Table 61: MR20 Register Information (MA[7:0] = 14h) ..................................................................................... 58

Table 62: MR20 Register Information ............................................................................................................. 58

Table 63: MR20 Invert Register Pin Mapping ................................................................................................... 58

Table 64: MR21 Register Information (MA[7:0] = 15h) ..................................................................................... 58

Table 65: MR22 Register Information (MA[7:0] = 16h) ..................................................................................... 58

Table 66: MR22 Register Information ............................................................................................................. 59

Table 67: MR23 Register Information (MA[7:0] = 17h) ..................................................................................... 60

Table 68: MR23 Register Information ............................................................................................................. 60

Table 69: MR24 Register Information (MA[7:0] = 18h) ..................................................................................... 60

Table 70: MR24 Register Information ............................................................................................................. 61

Table 71: MR25 Register Information (MA[7:0] = 19h) ..................................................................................... 61

Table 72: MR25 Register Information ............................................................................................................. 61

Table 73: MR26:31 Register Information (MA[7:0] = 1Ah–1Fh) ......................................................................... 62

Table 74: MR32 Register Information (MA[7:0] = 20h) ..................................................................................... 62

Table 75: MR32 Register Information ............................................................................................................. 62

Table 76: DQ Read Calibration Bit Order and Inversion Example – MR32 = 1Ch, MR40 = 59h, MR15 = MR20 =

55h ............................................................................................................................................................ 62

Table 77: MR33:39 Register Information (MA[7:0] = 21h–27h) .......................................................................... 63

Table 78: MR40 Register Information (MA[7:0] = 28h) ..................................................................................... 63

Table 79: MR40 Register Information ............................................................................................................. 63

Table 80: MR41:47 Register Information (MA[7:0] = 29h–2Fh) .......................................................................... 64

Table 81: MR48:63 Register Information (MA[7:0] = 30h–3Fh) .......................................................................... 64

Table 82: Command Truth Table .................................................................................................................... 64

Table 83: Reference Voltage for tLZ(DQS), tHZ(DQS) Timing Measurements ..................................................... 76

Table 84: Reference Voltage for tLZ(DQ), tHZ(DQ) Timing Measurements ........................................................ 77

Table 85: Method for Calculating tWPRE Transitions and Endpoints ................................................................ 81

Table 86: Reference Voltage for tWPST Timing Measurements ......................................................................... 82

Table 87: Same Bank (ODT disabled) .............................................................................................................. 84

Table 88: Different Bank (ODT disabled) ........................................................................................................ 84

Table 89: Same Bank (ODT enabled) .............................................................................................................. 85

Table 90: Different Bank (ODT enabled) ......................................................................................................... 85

Table 91: Function Behavior of DMI Signal During WRITE, MASKED WRITE, and READ Operations ................. 86

Table 92: Precharge Bank Selection ............................................................................................................... 105

Table 93: Timing Between Commands (PRECHARGE and AUTO PRECHARGE): DQ ODT is Disable ................. 109

Table 94: Timing Between Commands (PRECHARGE and AUTO PRECHARGE): DQ ODT is Enable ................. 112

Table 95: Bank and Refresh Counter Increment Behavior ............................................................................... 114

Table 96: REFRESH Command Timing Constraints ........................................................................................ 116

Table 97: Legacy REFRESH Command Timing Constraints ............................................................................. 118

Table 98: Modified REFRESH Command Timing Constraints ......................................................................... 118

Table 99: Refresh Requirement Parameters .................................................................................................... 119

Table 100: MRR ............................................................................................................................................ 138

Table 101: Truth Table for MRR and MRW ..................................................................................................... 143

13

�200b: x32 Mobile LPDDR4 SDRAM

Part Number Ordering Information

Table 102:

Table 103:

Table 104:

Table 105:

Table 106:

Table 107:

Table 108:

Table 109:

Table 110:

Table 111:

Table 112:

Table 113:

Table 114:

Table 115:

Table 116:

Table 117:

Table 118:

Table 119:

Table 120:

Table 121:

Table 122:

Table 123:

Table 124:

Table 125:

Table 126:

Table 127:

Table 128:

Table 129:

Table 130:

Table 131:

Table 132:

Table 133:

Table 134:

Table 135:

Table 136:

Table 137:

Table 138:

Table 139:

Table 140:

Table 141:

Table 142:

Table 143:

Table 144:

Table 145:

Table 146:

Table 147:

Table 148:

Table 149:

Table 150:

Table 151:

Table 152:

Table 153:

MRR/MRW Timing Constraints: DQ ODT is Disable ...................................................................... 143

MRR/MRW Timing Constraints: DQ ODT is Enable ....................................................................... 144

VRCG Enable/Disable Timing ....................................................................................................... 145

Internal V REF(CA) Specifications ..................................................................................................... 150

Internal V REF(DQ) Specifications .................................................................................................... 155

Mapping MR12 Op Code and DQ Numbers ................................................................................... 157

Mapping CA Input pin DQ Output pin .......................................................................................... 159

Write Leveling Timing Parameters ................................................................................................. 165

Write Leveling Setup and Hold Timing .......................................................................................... 165

MPC Command Definition ........................................................................................................... 167

MPC Commands .......................................................................................................................... 168

Timing Constraints for Training Commands .................................................................................. 170

Invert Mask Assignments .............................................................................................................. 172

DQ Read Calibration Bit Ordering and Inversion Example .............................................................. 174

MR Setting vs. DMI Status ............................................................................................................. 175

MPC [WRITE FIFO] AC Timing ..................................................................................................... 181

DQS Oscillator Matching Error Specification ................................................................................. 183

AC Timing .................................................................................................................................... 185

Temperature Sensor ..................................................................................................................... 187

ZQ Calibration Parameters ........................................................................................................... 188

Mode Register Function with Two Physical Registers ...................................................................... 190

Relation Between MR Setting and DRAM Operation ...................................................................... 191

Frequency Set Point AC Timing ..................................................................................................... 192

tFC Value Mapping ....................................................................................................................... 192

tFC Value Mapping ....................................................................................................................... 193

Pull-Down Driver Characteristics – ZQ Calibration ........................................................................ 195

Pull-Up Characteristics – ZQ Calibration ....................................................................................... 195

Valid Calibration Points ................................................................................................................ 195

Command Bus ODT State ............................................................................................................. 197

ODT DC Electrical Characteristics – up to 3200 Mbps .................................................................... 197

ODT DC Electrical Characteristics – Beyond 3200 Mbps ................................................................. 198

ODT DC Electrical Characteristics – up to 3200 Mbps .................................................................... 200

ODT DC Electrical Characteristics – Beyond 3200 Mbps ................................................................. 201

Output Driver and Termination Register Sensitivity Definition ....................................................... 202

Output Driver and Termination Register Temperature and Voltage Sensitivity ................................. 202

ODTLON and ODTLOFF Latency Values .......................................................................................... 204

Termination State in Write Leveling Mode ..................................................................................... 205

Post-Package Repair Timing Parameters ........................................................................................ 209