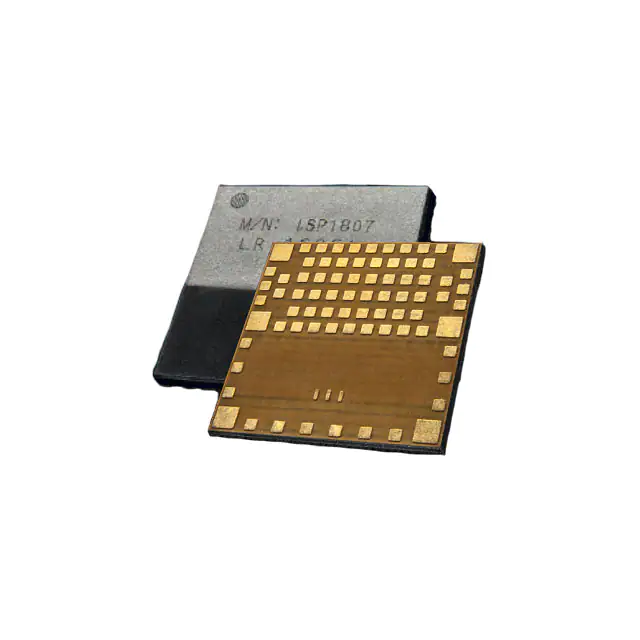

ISP1807

Data Sheet

Built-in Antenna Low Energy Module

BT 5 Long Range, Zigbee, Thread, ANT+

This ultra-small LGA module, 8 x 8 x 1 mm, is based on the

nRF52840 Chip. Its powerful Cortex™ M4 CPU, flash and RAM

memory combined with an optimized antenna offers the

perfect solution for Bluetooth connectivity. The solution is

best in class for RF performance and low power

consumption. Long range and multiple digital and analogue

interfaces give optimum flexibility for sensor integration.

Key Features

Applications

▪ 2.4GHz Ultra Low Power RF Transceiver

▪ Full Bluetooth 5 – long range stack

ANT/ANT+ stack

2.4 GHz proprietary stack

▪ Advanced Wearables: watches, fitness

devices, wireless payment wearables,

connected health, augmented reality

applications …

▪ BT Mesh, Zigbee, Thread stacks available

▪ Smart Home sensors and controllers

▪ NFC-A Tag for OOB pairing

▪ Industrial IoT sensors and controllers

▪ Fully integrated RF matching and Antenna

▪ Advanced remote controls

▪ Integrated 32 MHz& 32kHZ Clock

▪ Remote &Gaming controllers

▪ DC/DC converter with loading circuit

▪ Beacons

▪ Based on Nordic Semiconductor nRF52

▪ 32-bit ARM Cortex M4F CPU

▪ ARM CryptoCell 310

Certifications

▪ 1 MB Flash / 256 kB SRAM

▪ Configurable 46 GPIOs including 8 ADC

▪ Bluetooth SIG certified

▪ Many interfaces USB, SPI, UART, PDM, I2C

▪ CE certified

▪ Power supply 1.7 to 3.6V, USB supply 5V

▪ FCC, IC certified

▪ Very small size 8.0 x 8.0 x 1.0 mm

▪ TELEC, KCC certified

▪ Temperature -40 to +85 °C

▪ RoHS and Reach compliant

▪ Pin to Pin compatible with ISP1507

▪ Conflict Mineral Declaration

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed

to any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 1/25

�ISP1807

Data Sheet

Revision History

Revision

Date

Ref

Change Description

R0

23/11/2017

cr pg

Preliminary release

R1

12/12/2017

cr pg

Engineering samples release

R2

20/04/2018

cr pg

Section 5.2 – FW tool correction and update

Section 6.5 – Extension name change

R3

22/08/2018

cr pg

Section 3 – Typo error correction

R4

12/12/2018

cr pg

Section 2.9 – Schematic updated

R5

18/02/2019

cr pg

Definitive release

R6

14/03/2019

cr pg

Correction VCC / VCCH

No High-Power Mode availability

R7

06/06/2019

mm pg

Change to MSL3

R8

08/11/2019

mm pg

Section 4.1 – Mechanical dimension precision

Section 8 – Certification list update

R9

17/04/2020

cb pg

Section 4.2 – Assembly guideline precisions

Section 8 – Certification list update

R10

03/05/2021

Vn pg

Section 8 – Certification list update

R11

29/04/2022

pd pg

Document layout update

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 2/25

�ISP1807

Data Sheet

Contents

1.

Block Diagram ............................................................................................................................................ 4

2.

2.1.

2.2.

2.3.

2.4.

2.5.

2.6.

2.7.

2.8.

2.9.

Specifications ............................................................................................................................................. 5

Important Notice................................................................................................................................. 5

Absolute Maximum Ratings ............................................................................................................... 5

Operating Conditions ......................................................................................................................... 5

Power Consumption........................................................................................................................... 6

Clock Sources .................................................................................................................................... 6

Radio Specifications .......................................................................................................................... 6

Range Measurement ......................................................................................................................... 7

Antenna Performance ........................................................................................................................ 7

Electrical Schematic........................................................................................................................... 9

3.

Pin Description ......................................................................................................................................... 10

4.

4.1.

4.2.

4.3.

Mechanical Outlines ................................................................................................................................ 13

Mechanical Dimensions ................................................................................................................... 13

SMT Assembly Guidelines............................................................................................................... 15

Antenna Keep-Out Zone .................................................................................................................. 15

5.

5.1.

5.2.

5.3.

Product Development Tools .................................................................................................................. 16

Hardware .......................................................................................................................................... 16

Firmware .......................................................................................................................................... 16

Development Tools .......................................................................................................................... 17

6.

6.1.

6.2.

6.3.

6.4.

6.5.

Packaging & Ordering information ....................................................................................................... 18

Marking ............................................................................................................................................ 18

Prototype Packaging ........................................................................................................................ 18

Jedec Trays...................................................................................................................................... 18

Tape and Reel ................................................................................................................................. 19

Ordering Information ........................................................................................................................ 20

7.

7.1.

7.2.

7.3.

Storage & Soldering information .......................................................................................................... 21

Storage and Handling ...................................................................................................................... 21

Moisture Sensitivity .......................................................................................................................... 21

Soldering information ....................................................................................................................... 22

8.

8.1.

8.2.

8.3.

8.4.

8.5.

8.6.

8.7.

Quality & User information ..................................................................................................................... 23

Certifications .................................................................................................................................... 23

USA – User information ................................................................................................................... 23

Canada – User information .............................................................................................................. 24

RF Exposure Information ................................................................................................................. 24

Informations concernant l'exposition aux fréquences radio (RF).................................................... 24

Discontinuity ..................................................................................................................................... 24

Disclaimer ........................................................................................................................................ 25

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 3/25

�ISP1807

Data Sheet

1.

Block Diagram

This module is based on nRF52840 Nordic Semiconductor 2.4GHz wireless System on Chip (SoC)

integrating a 2.4 GHz transceiver, an ARM ®Cortex® -M4 32-bit processor with 64 MHz FPU,

a 1 MB flash memory, a 256 kB RAM and analog and digital peripherals.

It can support BLE, ANT/ANT+ and a range of proprietary 2.4 GHz protocols, such as Gazell from Nordic

Semiconductor.

Fully qualified BLE stacks for nRF52840 are implemented in the S140 SoftDevices which can be freely

downloaded. ISP1807 can then be used in Bluetooth Central, Peripheral, Observer or Broadcaster role

with up to 20 connections and for both ends of other proprietary protocols. nRF52840 platform also

provides extensive software support for ANT, ZIGBEE and THREAD applications.

Ultra-low power consumption and advanced power management enables battery lifetimes up to several

years on a coin cell battery. Even though its very small size 8 x 8 x 1.0 mm, the module integrates

decoupling capacitors, 32 MHz and 32.768 kHz crystals, load capacitors, DC-DC converter, RF matching

circuit and antenna in addition to the wireless SoC.

Only the addition of a suitable DC power source is necessary for BLE / ANT / ZIGBEE / THREAD

connectivity. Sensor applications require the further addition of appropriate sensors. The antenna was

designed to be optimized with several standard ground plane sizes. The NFC tag antenna can be

connected externally.

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 4/25

�ISP1807

Data Sheet

2.

Specifications

2.1. Important Notice

The electrical specifications of the module are directly related to the Nordic Semiconductor specifications

for the nRF52840 chipset. Bellow information is only a summary of the main parameters. For more detailed

information, especially about current consumption, please refer to the up-to-date specification of the

chipset available on Nordic Semi website.

2.2. Absolute Maximum Ratings

Parameter

Min

Main Supply Voltage respect to ground – VCC_nRF

Max

Unit

-0.3

3.9

V

USB Supply Voltage respect to ground – VBUS

-0.3

5.8

V

IO Pin Voltage

-0.3

3.9

V

RF Input Level

10

dBm

NFC Antenna pin current

80

mA

+125

°C

Moisture Sensitivity Level

5

-

ESD Human Body Model

4000

V

ESD Charged Device Model

750

V

10000

cycles

Storage Temperature

Typ

-40

Flash Endurance

ATTENTION

CONSERVE PRECAUTIONFOR HANDLING

ELECTROSTATIC SENSITIVE DEVICES

Human Body Model Class 3A

2.3. Operating Conditions

Parameter

Min

Typ

Max

Unit

VCC_nRF Supply Voltage, independent of DCDC enable

1.7

3.0

3.6

V

VBUS Supply Voltage

4.35

5.0

5.5

V

Extended Industrial Operating Temperature Range

-40

+25

+85

°C

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 5/25

�ISP1807

Data Sheet

2.4. Power Consumption

Parameter

Min

Typ

Max

Unit

Peak Current, Transmitter +8 dBm, VCC 3V + DCDC

16.4

mA

Peak Current, Transmitter 0 dBm, VCC 3V + DCDC

6.4

mA

Peak Current, Receiver 1 Mbps, VCC 3V + DCDC

6.26

mA

System OFF, no RAM retention

0.4

µA

System ON, no RAM retention, wake on RTC

1.5

µA

Additional RAM retention current per 4 KB block

30

N

nA

Typ

Max

Unit

Internal High Frequency Clock for RF Stability:

32 MHz Crystal Frequency Tolerance (1)

+/- 40

ppm

Internal Low Frequency Clock for BLE Synchronization:

32.768 kHz Crystal Frequency Tolerance (1)

+/- 40

ppm

Internal Low Frequency Clock for BLE Synchronization:

RC Oscillator (2)

+/- 250

ppm

RF Frequency Tolerance for BLE Operation

+/- 40

ppm

Max

Unit

2480

Mhz

+8.5

dBm

2.5. Clock Sources

Parameter

(1)

(2)

Min

including initial tolerance, drift, aging, and frequency pulling

Frequency tolerance after calibration

2.6. Radio Specifications

Parameter

Min

Frequency Range

2402

Typ

Maximum Output Power

+8

Rx Sensitivity Level, BLE1 Mbps

-95

dBm

Rx Sensitivity Level, BLE Long Range 125 kbps

-103

dBm

Antenna Gain

0.6

dBi

EIRP

Data Rate

www.insightsip.com

-19.4

8.6

dBm

125

2000

kbps

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 6/25

�ISP1807

Data Sheet

2.7. Range Measurement

Range measurement between ISP1807-LR test board (configured as Central) and ISP1807-LR test

board (configured as Peripheral).

Parameter

Min

Typ

Max

Unit

Range Open field @1m height (0 dBm, 1 Mbps)

150

m

Range Open field @1m height (0 dBm, 125 Kbps)

175

m

Range Open field @1m height (8 dBm, 1 Mbps)

230

m

Range Open field @1m height (8 dBm, 125 Kbps)

450

m

2.8. Antenna Performance

Typical Antenna Return Loss

Module mounted on a

USB dongle ground plane

Radiation Pattern in 3 planes

Module mounted on a USB

dongle ground plane

Gain measurement

in dBi in the BLE band

from 2.4 to 2.5 GHz.

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 7/25

�ISP1807

Data Sheet

Ground Plane Effect Simulation

USB dongle

ground plane

(size: 18 x 30 mm²)

Cell phone config 1

ground plane

(size: 40 x 100 mm²)

Cell phone config 2 with

side ground plane

(size: 40 x 100 mm²)

www.insightsip.com

Cell phone config 1 with

side ground plane

(size: 40 x 100 mm²)

Cell phone config 3 with

side ground plane

(size: 40 x 100 mm²)

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 8/25

�ISP1807

Data Sheet

2.9. Electrical Schematic

Electrical schematic showing

ISP1807 module connections

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 9/25

�ISP1807

Data Sheet

3.

Pin Description

The module uses an LGA format with a double row of pads on a 0.65 mm pitch. The pad layout follows

the QFN Jedec standard for 2 row LGA parts. The NC pads are to be connected to isolated metal pads on

the application PCB for mechanical stability and reliability (drop test).

Pin

Name

Pin function

Description

1

2

Ground

Digital I/O

NFC Input

Digital I/O

14

15

16

17

18

19

20

VSS

P0_09

NFC1

P0_12

TRACEDATA1

P0_10

NFC2

P0_14

P0_26

VSS

D+

P0_16

DP0_21

VBUS

P0_18

RESET

VSS

P0_20

VSS

P0_22

VSS

P0_24

OUT_ANT

21

22

VSS

OUT_MOD

Ground

Antenna I/O

23

24

25

26

27

28

29

30

31

32

33

VSS

VSS

VSS

VCC_nRF

P0_17

SWDIO

P0_13

SWDCLK

VSS

P0_08

P0_07

TRACECLK

Ground

Ground

Ground

Power

Digital I/O

Digital I/O

Digital I/O

Digital Input

Ground

Digital I/O

Digital I/O

Should be connected to ground plane on application PCB

General purpose I/O pin

NFC antenna connection

General purpose I/O pin

Trace port output

General purpose I/O pin

NFC antenna connection

General purpose I/O pin

General purpose I/O pin

Should be connected to ground plane on application PCB

USB D+

General purpose I/O pin

USB DGeneral purpose I/O pin

5V input for USB 3.3V regulator

General purpose I/O pin

Configurable as system RESET pin

Should be connected to ground plane on application PCB

General purpose I/O pin

Should be connected to ground plane on application PCB

General purpose I/O pin

Should be connected to ground plane on application PCB

General purpose I/O pin

This pin is connected to the internal antenna

It should be connected to Pin 22 OUT_MOD for normal operation

Should be connected to ground plane on application PCB

This pin is the RF I/O pin of the BLE module

It should be connected to Pin 20 OUT_ANT for normal operation

Should be connected to ground plane on application PCB

Should be connected to ground plane on application PCB

Should be connected to ground plane on application PCB

Power supply (1.7 – 3.6V)

General purpose I/O pin

Serial Wire Debug I/O for debug and programming

General purpose I/O pin

Serial Wire Debug clock input for debug and programming

Should be connected to ground plane on application PCB

General purpose I/O pin

General purpose I/O pin

Trace port clock output

3

4

5

6

7

8

9

10

11

12

13

Digital I/O

NFC Input

Digital I/O

Digital I/O

Ground

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Power

Digital I/O

Ground

Digital I/O

Ground

Digital I/O

Ground

Digital I/O

Antenna I/O

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 10/25

�ISP1807

Data Sheet

Pin

Name

Pin function

Description

34

35

P0_06

P0_04

AIN2

P0_05

AIN3

P0_15

P0_03

AIN1

P0_27

P0_02

AIN0

P0_25

P0_31

AIN7

P0_11

TRACEDATA2

P0_30

AIN6

P0_19

P0_29

AIN5

P0_23

P0_28

AIN4

P1_02

P1_06

P1_15

P1_14

P1_13

P1_05

P1_08

P1_09

TRACEDATA3

P1_00

TRACEDATA0

P1_03

P1_12

P1_10

P1_11

P1_07

P1_04

P1_01

NC

Digital I/O

Digital I/O

Analog Input

Digital I/O

Analog Input

Digital I/O

Digital I/O

Analog Input

Digital I/O

Digital I/O

Analog Input

Digital I/O

Digital I/O

Analog Input

Digital I/O

General purpose I/O pin

General purpose I/O pin

SAADC/COMP/LPCOMP input

General purpose I/O pin

SAADC/COMP/LPCOMP input

General purpose I/O pin

General purpose I/O pin

SAADC/COMP/LPCOMP input

General purpose I/O pin

General purpose I/O pin

SAADC/COMP/LPCOMP input

General purpose I/O pin

General purpose I/O pin

SAADC/COMP/LPCOMP input

General purpose I/O pin

Trace port output

General purpose I/O pin

SAADC/COMP/LPCOMP input

General purpose I/O pin

General purpose I/O pin

SAADC/COMP/LPCOMP input

General purpose I/O pin

General purpose I/O pin

SAADC/COMP/LPCOMP input

General purpose I/O pin

General purpose I/O pin

General purpose I/O pin

General purpose I/O pin

General purpose I/O pin

General purpose I/O pin

General purpose I/O pin

General purpose I/O pin

Trace port output

General purpose I/O pin

Trace port output

General purpose I/O pin

General purpose I/O pin

General purpose I/O pin

General purpose I/O pin

General purpose I/O pin

General purpose I/O pin

General purpose I/O pin

Isolated pad on application PCB for mechanical stability

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

to 78

Digital I/O

Analog Input

Digital I/O

Digital I/O

Analog Input

Digital I/O

Digital I/O

Analog Input

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Digital I/O

Not Connected

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 11/25

�ISP1807

Data Sheet

ISP1807

pad placement and pin assignment

for the LGA QFN package

TOP VIEW

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 12/25

�ISP1807

Data Sheet

4.

Mechanical Outlines

4.1. Mechanical Dimensions

Package dimensions

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 13/25

�ISP1807

Data Sheet

Dimensional drawing for 62-Pad LGA Package

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 14/25

�ISP1807

Data Sheet

4.2. SMT Assembly Guidelines

For PCB Land Patterns and Solder Mask layout, Insight SiP recommends using the same dimensions as

module pads, ie 0.4 x 0.4 mm for standard pads and 0.8 x 0.8 mm for corner pads.

For implementations in which most or all of the inner pads are used Insight SiP recommends the use of

capped vias placed in the centre of each pad.

For standard PCB types (no micro vias - all vias are top to bottom): we use nominal 0.4mm catch pads

with 0.2mm vias. The vias should be plugged and capped to avoid solder wicking.

For HDI PCB types having micro vias on a layer by layer basis: we use 0.25mm catch pads and 0.1mm

copper filled laser vias. Ideally the via is centered in the pad.

For reduced pinout implementations we recommend using external pads only. The use of a small number

of internal pads can be accommodated by placing normal vias in the centre of the device. In this case only

the required pads should be Solder Mask opened and the vias tented with solder mask to prevent short

circuits.

In general, we recommend NSMD solder mask with 50µm SM extension.

4.3. Antenna Keep-Out Zone

For optimal antenna performance, it is recommended to respect a metal exclusion zone to the edge of the

board: no metal, no traces and no components on any application PCB layer except mechanical LGA

pads.

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 15/25

�ISP1807

Data Sheet

5.

Product Development Tools

5.1. Hardware

In order to assist clients in developing their Bluetooth Smart solutions based on the ISP1807, Insight SIP

offers a Development Kit containing:

One Interface Board

J-Link Lite CortexM-9 JTAG/SWD Emulator

One Test Board

A Development Dongle

5 ISP1807 module samples

Cables, power supply and coin battery holder

Using this development kit, product developers can use a working solution as starting point to develop

their own products. Time to market is saved by avoiding starting from a blank sheet of paper. In addition,

there may be some applications that use the hardware as is.

Please refer to the documentation for more information:

http://www.insightsip.com/fichiers_insightsip/pdf/ble/ISP1807/isp_ble_DS1807_DK.pdf

5.2. Firmware

ISP1807supports Bluetooth Low Energy protocol stacks. It also provides extensive software support for

ANT, ZIGBEE and THREAD applications as well as 2.4 GHz protocol stacks, including Gazell. All are

available as downloads at www.nordicsemi.com.

The S140 SoftDevice is a Bluetooth low energy (BLE) Central and Peripheral protocol stack solution.

The S140 SoftDevice supports up to twenty connections with an additional observer and a broadcaster

role all running concurrently.

The S140 SoftDevice integrates a Bluetooth low energy Controller and Host, and provides a full and

flexible API for building Bluetooth low energy nRF52 System on Chip (SoC) solutions:

- Bluetooth 5.0 compliant low energy single-mode protocol stack suitable for Bluetooth low energy

products.

- Concurrent central, observer, peripheral, and broadcaster roles with up to 20 concurrent connections

along with one Observer and one Broadcaster.

- Link layer supporting LE 1M PHY and LE 2M PHY.

- LL Privacy.

- LE Data Packet Length Extension.

- LE Secure Connections pairing model

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 16/25

�ISP1807

Data Sheet

5.3. Development Tools

The following development tools and software are recommended for using and testing ISP1807 module:

Nordic Semiconductor nRFgo Studio:

Downloadable after registering at www.nordicsemi.com.

Nordic Semiconductor Master Control Panel:

Downloadable after registering at www.nordicsemi.com.

Keil MDK-ARM Lite:

Downloadable from https://www.keil.com/demo/eval/arm.htm.

Segger J-Link Lite:

Downloadable from http://www.segger.com/jlink-software.html.

nRF52 Software Development Kit (SDK):

nRF52 SDK can be downloaded after registering at www.nordicsemi.com. It contains example of source

codes applications (C language):

- Precompiled HEX files

- Source code

- Keil ARM project files

- IAR project files

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 17/25

�ISP1807

Data Sheet

6.

Packaging & Ordering information

6.1. Marking

M /N :

I

S P 1 8 0 7

T T

Y Y W W R

ISP1807

YY

Part Number

2 letters Module Type (see

section 6.5)

2 digits year number

WW

2 digits week number

R

1 letter Hardware revision

TT

6.2. Prototype Packaging

For engineering samples and prototype quantities

up to 99 units, deliveries are provided in thermoformed

trays or cut tapes.

They are delivered in sealed pack with desiccant

pack and humidity sensors. Please see section 7.2

for more information on moisture sensitivity.

Please order with “ST” code packaging suffix.

6.3. Jedec Trays

For pre-production volumes, ISP1807 are available in Jedec trays. They are delivered in sealed pack with

desiccant pack and humidity sensors. These Jedec trays are also suitable for further baking. Please see

section 7.2 for more information on moisture sensitivity. Please order with “JT” code packaging suffix.

Refer to tray sizes below. Complete information on Jedec trays is available on request.

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 18/25

�ISP1807

Data Sheet

Top view position of

modules within the tray.

6.4. Tape and Reel

ISP1807 are also available in Tape & Reel. They are delivered in sealed pack with desiccant pack and

humidity sensors. Reels are proposed in standard quantities of 500 units (180mm / 7” reel) or 2000 units

(330mm / 13” reel) only. Please order with “RS” code packaging suffix for 500-unit reels and “R2” for

2000-unit reels.

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 19/25

�ISP1807

Data Sheet

Top view position of modules within the reel.

6.5. Ordering Information

I S P 1 8 0 7

- T

▼

▼

▼

T - Z Z

▼

▼ ▼

▼

▼ ▼

▼

▼ ▼

I S P 1 8 0 7

Part Number

- L R

Long range version

- E B

Evaluation Board(1)

- T B

Test board (1)

- S T

Standard Tray or Cut Tape

-

Jedec Tray Packaging

J T

- R S

Reel of 500 units

- R 2

Reel of 2000 units

(1) Please see section 5.1 and refer to the following documentation for more information on development

kit and test board:

http://www.insightsip.com/fichiers_insightsip/pdf/ble/ISP1807/isp_ble_DS1807_DK.pdf

http://www.insightsip.com/fichiers_insightsip/pdf/ble/ISP1807/isp_ble_ANXXXXX.pdf

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 20/25

�ISP1807

Data Sheet

7.

Storage & Soldering information

7.1. Storage and Handling

Keep this product away from other high frequency devices which may interfere with operation such as

other transmitters and devices generating high frequencies.

Do not expose the module to the following conditions:

- Corrosive gasses such as Cl2, H2S, NH3, SO2, or NOX

- Extreme humidity or salty air

- Prolonged exposure to direct Sunlight

- Temperatures beyond those specified for storage

Do not apply mechanical stress

Do not drop or shock the module

Avoid static electricity, ESD and high voltage as these may damage the module

ATTENTION

CONSERVE PRECAUTIONFOR HANDLING

ELECTROSTATIC SENSITIVE DEVICES

7.2. Moisture Sensitivity

All plastic packages absorb moisture. During typical solder reflow operations when SMDs are mounted

onto a PCB, the entire PCB and device population are exposed to a rapid change in ambient temperature.

Any absorbed moisture is quickly turned into superheated steam. This sudden change in vapor pressure

can cause the package to swell. If the pressure exerted exceeds the flexural strength of the plastic mold

compound, then it is possible to crack the package. Even if the package does not crack, interfacial

delamination can occur.

Since the device package is sensitive to moisture absorption, it is recommended to bake the product before

assembly. The baking process for dry packing is 24 hours at 125°C.

ISP1807 has been tested MSL-3 according to standards. After baking, modules can be exposed to ambient

room conditions (approximately 30 °C/60%RH) during 168 hours before assembly on the PCB.

CAUTION

MOISTURE

SENSITIVE DEVICES

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 21/25

�ISP1807

Data Sheet

7.3. Soldering information

Recommendation for RoHS reflow process is according to Jedec J–STD-020 and 033 standard profiles.

Preheat/Soak

Temperature Min (Tsmin)

Temperature Max (Tsmax)

Time (ts) from (Tsmin to Tsmax)

Ramp-up rate (TL to Tp)

Liquidous temperature (TL)

Time (tL) maintained above TL

www.insightsip.com

150 °C

200 °C

60-120 sec

3 °C/sec max

217 °C

60-150 sec

Peak package body temperature (T p)

Classification Temperature (Tc)

Time (tp) maintained above TC-5 °C

Ramp-down rate (Tp to TL)

Time 25 °C to peak temperature

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

260°C

(+0/-5°C)

260 °C

30 sec

6 °C/sec max

8 mn max

Document reference

isp_ble_DS1807_R11.docx

Page 22/25

�ISP1807

Data Sheet

8.

Quality & User information

8.1. Certifications

All below certificates can be downloaded on the website:

Bluetooth SIG Declaration ID n° D046560

CE Certified, DoC Insight SiP Ref TR201105

TELEC Certified, n° 020-200037

KCC Certification n° R-C-iNs-ISP1807

FCC Certification n° 2AAQS-ISP1807

IC Certification n° 11306A-ISP1807

RoHS3 and Reach compliant, Ref TR200301 and TR191101

Conflict Mineral Declaration available, Ref TR180701

To support customers in their application certification, Insight SiP can provide test reports on request.

8.2. EC – CE Certification

This device can be operated in at least one Member State without infringing applicable requirements on

the use of radio spectrum.

8.3. USA – User information

This intends to inform how to specify the FCC ID of our module “ISP1807” on the product. Based on the

Public Notice from FCC, the host device should have a label which indicates that it contains our module.

The label should use below example wording or any similar wording that expresses the same meaning:

“Contains FCC ID: 2AAQS-ISP1807”

The label of the host device should also include the below FCC Statement. When it is not possible, this

information should be included in the User Manual of the host device:

“This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions.

(1) This device may not cause harmful interference

(2) This device must accept any interference received, including interference that may cause

undesired operation.

Caution: Any Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.”

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 23/25

�ISP1807

Data Sheet

8.4. Canada – User information

This intends to inform how to specify the IC ID of our module “ISP1807” on the product. According to

Canadian standards “RSS-210” and “RSS-Gen”, the host device should have a label which indicates that

it contains our module. The label should use below example wording or any similar wording that expresses

the same meaning:

“Contains IC: 11306A-ISP1807”

The label of the host device should also include the below IC Statement. When it is not possible, this

information should be included in the User Manual of the host device:

“This device complies with Industry Canada license-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this device may not cause interference, and (2) this

device must accept any interference, including interference that may cause undesired

operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio

exempts de licence. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil

ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d'en compromettre le

fonctionnement.”

8.5. RF Exposure Information

This equipment complies with FCC/IC radiation exposure limits set forth for an uncontrolled environment

and meets the FCC radio frequency (RF)Exposure Guidelines in Supplement C toOET65 and RSS-102 of

the IC radio frequency (RF) Exposure rules. This equipment has very low levels of RF energy that it

deemed to comply without maximum permissive exposure evaluation (MPE).

8.6. Informations concernant l'exposition aux fréquences radio (RF)

La puissance de sortie émise par l’appareil de sans-fil est inférieure à la limite d'exposition aux fréquences

radio d'Industry Canada (IC). Ce module a également été évalué et démontré conforme aux limites

d'exposition aux RF d'IC dans des conditions d'exposition à des appareils mobiles et/ou portables.

8.7. Discontinuity

Normally a product will continue to be manufactured as long as all of the following are true:

- The manufacturing method is still available.

- There are no replacement products.

- There is demand for it in the market.

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 24/25

�ISP1807

Data Sheet

In case of obsolescence, Insight SiP will follow Jedec Standard JSD-48. A Product Discontinuation Notice

(PDN) will be sent to all distributors and made available on our website. After this, the procedure goes as

follows:

- Last Order Date will be 6 months after the PDN was published.

- Last Shipment Date will be 6 months after Last Order Date, i.e. 12 months after PDN.

8.8. Disclaimer

Insight SiP’s products are designed and manufactured for general consumer applications, so testing and

use of the product shall be conducted at customer’s own risk and responsibility. Please conduct validation

and verification and sufficient reliability evaluation of the products in actual condition of mounting and

operating environment before commercial shipment of the equipment. Please also pay attention (i) to apply

soldering method that don’t deteriorate reliability, (ii) to minimize any mechanical vibration, shock,

exposure to any static electricity, (iii) not to overstress the product during and after the soldering process.

The products are not designed for use in any application which requires especially high reliability where

malfunction of these products can reasonably be expected to result in personal injury or damage to the

third party's life, body or property, including and not limited to (i) aircraft equipment, (ii) aerospace

equipment, (iii) undersea equipment, (iv) power plant control equipment, (v) medical equipment,

(vi) transportation equipment, (vii) traffic signal equipment, (viii) disaster prevention / crime prevention

equipment.

The only warranty that Insight SiP provides regarding the products is its conformance to specifications

provided in datasheets. Insight SiP hereby disclaims all other warranties regarding the products, express

or implied, including without limitation any warranty of fitness for a particular purpose, that they are defectfree, or against infringement of intellectual property rights. Insight SiP customers agree to indemnify and

defend Insight SiP against all claims, damages, costs and expenses that may be incurred, including without

any limitation, attorney fees and costs, due to the use of products.

www.insightsip.com

The information contained in this document is the

property of Insight SiP and should not be disclosed to

any third party without written permission.

Specification subject to change without notice.

Document reference

isp_ble_DS1807_R11.docx

Page 25/25

�