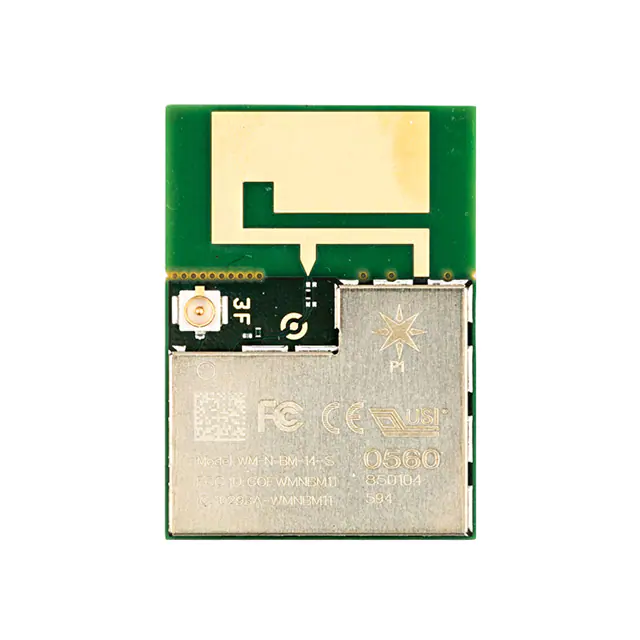

P1 Datasheet (v009)

void setup() {

Particle.publish("my‐event","The internet just got smarter!");

}

Functional description

Overview

The P1 is Particle's tiny Wi-Fi module that contains both the Broadcom Wi-Fi chip and a

reprogrammable STM32F205RGY6 32-bit ARM Cortex-M3 microcontroller. The P1 comes

preloaded with Particle firmware libraries, just like our dev kits, and it's designed to simplify your

transition from prototype to production. The P1 is the PØ's big brother; it's a bit bigger and a tad

more expensive, but it includes some extra flash and an antenna and u.FL connector on board.

Particle provides free access to Particle Cloud for prototyping. Paid tiers of Particle Cloud start when

you create a product with more than 25 devices.

�Features

Particle P1 Wi-Fi module

o Broadcom BCM43362 Wi-Fi chip

o 802.11b/g/n Wi-Fi

o STM32F205RGY6 120Mhz ARM Cortex M3

o 1MB flash, 128KB RAM

o 1MB external SPI flash (MX25L8006E)

o Integrated PCB antenna

o Integrated u.FL connector for external antenna

o Integrated RF switch

25 Mixed-signal GPIO and advanced peripherals

Open source design

Real-time operating system (FreeRTOS)

Soft AP setup

FCC, CE and IC certified

Interfaces

Block Diagram

Power

Power to the P1 is supplied via 3 different inputs: VBAT_WL (pin 2 & 3), VDDIO_3V3_WL (pin 5),

VDD_3V3 (pin 26 & 27). Optionally +3.3V may be supplied to VBAT_MICRO (pin 38) for data

retention in low power sleep modes. Each of these inputs also requires a 0.1uF and 10uF ceramic

decoupling capacitor, located as close as possible to the pin (see Fig 1). The voltage should be

regulated between 3.0VDC and 3.6VDC. (Please refer to Absolute Maximum Ratings for more info).

�Typical average current consumption is 80mA with 5V @ input of the recommended SMPS power

supply with Wi-Fi on. Deep sleep quiescent current is typically 80uA (Please refer to Recommended

Operating Conditions for more info). When powering the P1 make sure the power supply can handle

600mA continuous. If a lesser power supply is provided, peak currents drawn from the P1 when

transmitting and receiving will result in voltage sag at the input which may cause a system brown out

or intermittent operation.

Warning: When powering the P1 from long wires, care should be taken to protect against damaging

voltage transients if using the same regulator as is used on the Photon. From the Richtek

datasheet:

When a ceramic capacitor is used at the input and the power is supplied by a wall adapter through long wires, a load

step at the output can induce ringing at the input, VIN. At best, this ringing can couple to the output and be mistaken

as loop instability. At worst, a sudden inrush of current through the long wires can potentially cause a voltage spike at

VIN large enough to damage the part.

To avoid these voltage spikes, keep input wiring as short as possible. If long wires are unavoidable,

it is advisable to add a 5.1V zener diode or similar transient suppression device from VIN to GND.

Another technique is adding more capacitance to the input using an electrolytic capacitor. Please

refer to AN-88 by Linear for a good discussion on this topic.

Fig. 1 Recommended power connections with decoupling capacitors.

�RF

The RF section of the P1 includes an on-board PCB trace antenna and a u.FL connector which

allows the user to connect an external antenna. These two antenna outputs are selectable via a user

API, made possible by an integrated RF switch.

The default selected antenna will be the PCB antenna.

The area surrounding the PCB antenna on the carrier PCB should be free of ground planes and

signal traces for maximum Wi-Fi performance.

FCC Approved Antennas

Antenna Type

Manufacturer

MFG. Part #

Gain

Dipole antenna

LumenRadio

104-1001

2.15dBi

PCB Antenna

Included

-

-

Peripherals and GPIO

The P1 module has ton of capability in a super small footprint, with analog, digital and

communication interfaces.

Note: P1 pin names will be preserved as they are named in the USI datasheet, however for the

scope of this datasheet we will also refer to them as their Photon and code equivalents, i.e. D7

instead of MICRO_JTAG_TMS and A2 instead of MICRO_GPIO_13. This will help to simplify

descriptions, while providing a quick reference for code that can be written for the P1 such as int

value = analogRead(A2);

Peripheral Type

Qty

Input(I) / Output(O)

FT[1] / 3V3[2]

Digital

24

I/O

FT/3V3

Analog (ADC)

13

I

3V3

Analog (DAC)

2

O

3V3

SPI

2

I/O

3V3

I2S

1

I/O

3V3

I2C

1

I/O

FT

CAN

1

I/O

3V3[4]

�Peripheral Type

Qty

Input(I) / Output(O)

FT[1] / 3V3[2]

USB

1

I/O

3V3

PWM

12[3]

O

3V3

Notes:

[1]

FT = 5.0V tolerant pins. All pins except A3 and DAC are 5V tolerant (when not in analog mode). If

used as a 5V input the pull-up/pull-down resistor must be disabled.

[2]

3V3 = 3.3V max pins.

[3]

PWM is available on D0, D1, D2, D3, A4, A5, WKP, RX, TX, P1S0, P1S1, P1S6 with a caveat:

PWM timer peripheral is duplicated on two pins (A5/D2) and (A4/D3) for 10 total independent PWM

outputs. For example: PWM may be used on A5 while D2 is used as a GPIO, or D2 as a PWM while

A5 is used as an analog input. However A5 and D2 cannot be used as independently controlled

PWM outputs at the same time. P1S6 requires System Feature Wi-Fi Powersave Clock to be

disabled. See System Features in Firmware Reference.

[4]

Technically these pins are 5.0V tolerant, but since you wouldn't operate them with a 5.0V

transceiver it's proper to classify them as 3.3V.

RGB LED, SETUP and RESET button

When using the P1 module, it is very important to remember that your device must have an RGB

LED to show the user the connectivity status. Also required is a SETUP and RESET button to enter

various Device Modes. By default the RGB LED outputs are configured for a Common Anode type of

LED. These components should be wired according to the P1 Reference Design - User I/O. RGB pins

may be accessed in code as: RGBR, RGBG and RGBB.

JTAG and SWD

Pin D3 through D7 are JTAG interface pins. These can be used to reprogram your P1 bootloader or

user firmware image with standard JTAG tools such as the ST-Link v2, J-Link, R-Link, OLIMEX

ARM-USB-TINI-H, and also the FTDI-based Particle JTAG Programmer. If you are short on available

pins, you may also use SWD mode which requires less connections.

�Photon Pin

JTAG

SWD

STM32F205RGY6 Pin

P1 Pin #

P1 Pin Name

Default Internal[1]

D7

JTAG_TMS

SWD/SWDIO

PA13

54

MICRO_JTAG_TMS

~40k pull-up

D6

JTAG_TCK

CLK/SWCLK

PA14

55

MICRO_JTAG_TCK

~40k pull-down

D5

JTAG_TDI

PA15

53

MICRO_JTAG_TDI

~40k pull-up

D4

JTAG_TDO

PB3

52

MICRO_JTAG_TDO

Floating

D3

JTAG_TRST

PB4

51

MICRO_JTAG_TRSTN

3V3

Power

Power

GND

Ground

Ground

RST

Reset

Reset

~40k pull-up

Notes: [1] Default state after reset for a short period of time before these pins are restored to GPIO (if

JTAG debugging is not required, i.e. USE_SWD_JTAG=y is not specified on the command line.)

A standard 20-pin 0.1" shrouded male JTAG interface connector should be wired as follows:

(click to stop squinting)

�External Coexistence Interface

The P1 supports coexistence with Bluetooth and other external radios via three pins available on the

P1 module.

When two radios occupying the same frequency band are used in the same system, such as Wi-Fi

and Bluetooth, a coexistence interface can be used to coordinate transmit activity, to ensure optimal

performance by arbitrating conflicts between the two radios.

P1 Pin Name

P1 Pin #

I/O

Description

BTCX_RF_ACTIVE

57

I

Coexistence signal: Bluetooth is active

BTCX_STATUS

56

I

Coexistence signal: Bluetooth priority status and TX/RX direction

BTCX_TXCONF

58

O

Output giving Bluetooth permission to TX

When these pins are programmed to be used as a Bluetooth coexistence interface, they're set as

high impedance on power up and reset.

Memory Map

STM32F205RGY6 Flash Layout Overview

Bootloader (16 KB)

DCT1 (16 KB), stores Wi-Fi credentials, keys, mfg info, system flags, etc..

DCT2 (16 KB), swap area for DCT1

EEPROM emulation bank 1 (16 KB)

EEPROM emulation bank 2 (64 KB)

System firmware (512 KB) [256 KB Wi-Fi/comms + 256 KB hal/platform/services]

Factory backup, OTA backup and user application (384 KB) [3 x 128 KB]

DCT Layout

The DCT area of flash memory has been mapped to a separate DFU media device so that we can

incrementally update the application data. This allows one item (say, server public key) to be

updated without erasing the other items.

DCT layout in release/stable found here in firmware.

https://github.com/spark/firmware/blob/release/stable/platform/MCU/STM32F2xx/SPARK_Firmware_Driver/inc/dct.h

�Region

Offset

Size

system flags

0

32

version

32

2

device private key

34

1216

device public key

1250

384

ip config

1634

120

feature flags

1754

4

country code

1758

4

claim code

1762

63

claimed

1825

1

ssid prefix

1826

26

device code

1852

6

version string

1858

32

dns resolve

1890

128

reserved1

2018

64

server public key

2082

768

padding

2850

2

flash modules

2852

100

product store

2952

24

antenna selection

2976

1

cloud transport

2977

1

alt device public key

2978

128

alt device private key

3106

192

alt server public key

3298

192

alt server address

3490

128

device id

3618

12

radio flags

3630

1

mode button mirror

3631

32

led mirror

3663

96

led theme

3759

64

reserved2

3823

435

�Note: Writing 0xFF to offset 34 (DEFAULT) or 3106 (ALTERNATE) will cause the device to regenerate a new private key on the next boot. Alternate keys are currently unsupported on the P1 but

are used on the Electron as UDP/ECC keys. You should not need to use this feature unless your

keys are corrupted.

// Regenerate Default Keys

echo ‐e "\xFF" > fillbyte && dfu‐util ‐d 2b04:d00a ‐a 1 ‐s 34 ‐D fillbyte

// Regenerate Alternate Keys

echo ‐e "\xFF" > fillbyte && dfu‐util ‐d 2b04:d00a ‐a 1 ‐s 3106 ‐D fillbyte

Memory Map (Common)

Region

Start Address

End Address

Size

Bootloader

0x8000000

0x8004000

16 KB

DCT1

0x8004000

0x8008000

16 KB

DCT2

0x8008000

0x800C000

16 KB

EEPROM1

0x800C000

0x8010000

16 KB

EEPROM2

0x8010000

0x8020000

64 KB

Memory Map (Modular Firmware - default)

Region

Start Address

End Address

Size

System Part 1

0x8020000

0x8060000

256 KB

System Part 2

0x8060000

0x80A0000

256 KB

User Part

0x80A0000

0x80C0000

128 KB

OTA Backup

0x80C0000

0x80E0000

128 KB

Factory Backup

0x80E0000

0x8100000

128 KB

Memory Map (Monolithic Firmware - optional)

Region

Start Address

End Address

Size

Firmware

0x8020000

0x8080000

384 KB

Factory Reset

0x8080000

0x80E0000

384 KB

Unused (factory reset modular)

0x80E0000

0x8100000

128 KB

�Pin and button definition

Pin markings

Pin description

Pin

Description

RST

Active-low reset input. On-board circuitry contains a 1k ohm pull-up resistor between RST and 3V3, and 0.1uF capacitor

between RST and GND.

VBAT

Supply to the internal RTC, backup registers and SRAM when 3V3 not present (1.65 to 3.6VDC).

3V3

This pin represents the regulated +3.3V DC power to the P1 module. In reality, +3.3V must be supplied to 3 different inputs:

VBAT_WL (pin 2 & 3), VDDIO_3V3_WL (pin 5), VDD_3V3 (pin 26 & 27). Optionally +3.3V may be supplied to

VBAT_MICRO (pin 38) for data retention in low power sleep modes. Each of these inputs also requires a 0.1uF and 10uF

ceramic decoupling capacitor, located as close as possible to the pin.

TX

Primarily used as UART TX, but can also be used as a digital GPIO or PWM[1].

RX

Primarily used as UART RX, but can also be used as a digital GPIO or PWM[1].

WKP

Active-high wakeup pin, wakes the module from sleep/standby modes. When not used as a WAKEUP, this pin can also be

used as a digital GPIO, ADC input or PWM[1]. Can be referred to as A7 when used as an ADC.

DAC

12-bit Digital-to-Analog (D/A) output (0-4095), referred to as DAC or DAC1 in software. Can also be used as a digital GPIO

or ADC. Can be referred to as A6 when used as an ADC. A3 is a second DAC output used as DAC2 in software.

A0~A7

12-bit Analog-to-Digital (A/D) inputs (0-4095), and also digital GPIOs. A6 and A7 are code convenience mappings, which

means pins are not actually labeled as such but you may use code like analogRead(A7). A6 maps to the DAC pin and A7

maps to the WKP pin. A4,A5,A7 may also be used as a PWM[1] output.

D0~D7

Digital only GPIO pins. D0~D3 may also be used as a PWM[1] output.

�Pin

Description

P1S0

12-bit Analog-to-Digital (A/D) inputs (0-4095), and also can be used as a digital GPIO or PWM[1].

P1S1

12-bit Analog-to-Digital (A/D) inputs (0-4095), and also can be used as a digital GPIO or PWM[1].

P1S2

12-bit Analog-to-Digital (A/D) inputs (0-4095), and also can be used as a digital GPIO.

P1S3

12-bit Analog-to-Digital (A/D) inputs (0-4095), and also can be used as a digital GPIO.

P1S4

Primarily used as a digital GPIO.

P1S5

12-bit Analog-to-Digital (A/D) inputs (0-4095), and also can be used as a digital GPIO.

P1S6

Can be used as a digital GPIO or PWM[1] output. Must disable Wi-Fi Powersave Clock first, see System Features in Firmware

Reference.

Notes: [1] PWM is available on D0, D1, D2, D3, A4, A5, WKP, RX, TX, P1S0, P1S1, P1S6 with a

caveat: PWM timer peripheral is duplicated on two pins (A5/D2) and (A4/D3) for 10 total independent

PWM outputs. For example: PWM may be used on A5 while D2 is used as a GPIO, or D2 as a PWM

while A5 is used as an analog input. However A5 and D2 cannot be used as independently

controlled PWM outputs at the same time. P1S6 requires System Feature Wi-Fi Powersave Clock to

be disabled. See System Features in Firmware Reference.

Pinout diagram

�

You can download a high resolution pinout diagram in a PDF version here.

https://docs.particle.io/assets/images/p1-pinout.pdf

Notes: [1] Connected to MCO1 by default, outputs 32kHz clock for WICED powersave mode. See

System Features in the Firmware Reference to disable the Wi-Fi Powersave Clock and allow usage

of this pin.

[2]

MICRO_SPI1_SS is only for reference as a P1 module pin name. It is technically speaking the

STM32 pin PA4 which is the SS pin in an hardware SPI driven sense, however in the Particle API

SPI SS is only user controlled as a GPIO. The hardware SS pin is not implemented. The default SS

pin for the Particle SPI API is A2 (STM32 pin PC2), but any GPIO can be used for this function with

SPI.begin(pin).

�Complete P1 Module Pin Listing

Type /

STM32F205RGY6

Port

P1 Pin

#

P1 Pin Name

1

GND

PWR

Ground

2~3

VBAT_WL

PWR

+3.3V

4

GND

PWR

Ground

5

VDDIO_3V3_WL

PWR

+3.3V

6

GND

PWR

Ground

7

WL_REG_ON

PWR

BCM43362 Debugging Pin

8~12

NC

13

GND

14

NC

15

GND

16

WL_JTAG_TDI

DEBUG

BCM43362 Debugging Pin

17

WL_JTAG_TCK

DEBUG

BCM43362 Debugging Pin

18

WL_JTAG_TRSTN

DEBUG

BCM43362 Debugging Pin

19

WL_JTAG_TMS

DEBUG

BCM43362 Debugging Pin

20

WL_JTAG_TDO

DEBUG

BCM43362 Debugging Pin

21

MICRO_SPI1_MISO

PA6

A4 (SPI MISO)

22

MICRO_SPI1_SCK

PA5

A3 (SPI SCK)

23

MICRO_SPI1_MOSI

PA7

A5 (SPI MOSI)

24

MICRO_SPI1_SS

PA4

DAC

25

GND

PWR

Ground

26~27

VDD_3V3

PWR

+3.3V

28

GND

PWR

Ground

29

MICRO_UART2_RTS

PA1

RGBR (RGB LED RED)

30

MICRO_UART2_CTS

PA0

WKP

31

MICRO_UART2_RXD

PA3

RGBB (RGB LED BLUE)

32

MICRO_UART2_TXD

PA2

RGBG (RGB LED GREEN)

33

TESTMODE

PA8

P1S6 (Connected to MCO1 by default, outputs 32kHz clock for WICED

powersave mode. See System Features in the Firmware Reference to

disable the Wi-Fi Powersave Clock and allow usage of this pin.)

34

MICRO_RST_N

NC

PWR

NC

PWR

I

Description

NC

Ground

NC

Ground

/RESET (Active low MCU reset)

�Type /

STM32F205RGY6

Port

P1 Pin

#

P1 Pin Name

35

MICRO_I2C1_SCL

PB6

D1 (I2C SCL)

36

MICRO_I2C1_SDA

PB7

D0 (I2C SDA)

37

GND

PWR

Ground

38

VBAT_MICRO

PWR

Supply to the internal RTC, backup registers and SRAM when 3V3 not

present (1.65 to 3.6VDC)

39

GND

PWR

Ground

40

MICRO_GPIO_1

PB0

P1S0

41

MICRO_GPIO_2

PB1

P1S1

42

MICRO_GPIO_3

PC0

P1S2

43

MICRO_GPIO_5

PC3

A1

44

MICRO_GPIO_6

PC4

P1S3

45

MICRO_GPIO_7

PB5

D2 (I2S SD)

46

MICRO_GPIO_8

PC7

/SETUP (I2S MCK)

47

MICRO_GPIO_9

PC13

P1S4

48

MICRO_GPIO_12

PC1

P1S5

49

MICRO_GPIO_13

PC2

A2 (DEFAULT SPI SS)

50

MICRO_GPIO_14

PC5

A0

51

MICRO_JTAG_TRSTN

PB4

D3

52

MICRO_JTAG_TDO

PB3

D4 (I2S SCK)

53

MICRO_JTAG_TDI

PA15

D5 (I2S WS)

54

MICRO_JTAG_TMS

PA13

D7

55

MICRO_JTAG_TCK

PA14

D6

56

BTCX_STATUS

I

Coexistence signal: Bluetooth status and TX/RX direction

57

BTCX_RF_ACTIVE

I

Coexistence signal: Bluetooth is active

58

BTCX_TXCONF

O

Output giving Bluetooth permission to TX

59

GND

60

WL_SLEEP_CLK

61

MICRO_UART1_RTS

PA12

OTG_FS_DP (USB D+)

62

MICRO_UART1_CTS

PA11

OTG_FS_DM (USB D--)

63

MICRO_UART1_RXD

PA10

RX

64

MICRO_UART1_TXD

PA9

TX

PWR

DEBUG

Description

Ground

BCM43362 Debugging Pin

�Type /

STM32F205RGY6

Port

P1 Pin

#

P1 Pin Name

65~73

GND

PWR

74

PAD1

NC

NC

75

PAD2

NC

NC

Description

Ground

Technical specification

Absolute maximum ratings

Parameter

Symbol

Supply Input Voltage

V3V3-MAX

Storage Temperature

Tstg

ESD Susceptibility HBM (Human Body Mode)

VESD

Min

Typ

-40

Max

Unit

+3.6

V

+85

°C

2

kV

Recommended operating conditions

Parameter

Symbol

Min

Typ

Max

Unit

Supply Input Voltage

V3V3[1]

+3.0

+3.3

+3.6

V

Supply Input Current (VBAT_WL)

IVBAT_WL

310

mA

Supply Input Current (VDDIO_3V3_WL)

IVDDIO_3V3_WL

50

mA

Supply Input Current (VDD_3V3)

IVDD_3V3

120

mA

Supply Input Voltage

VVBAT_MICRO

+3.6

V

Supply Input Current (VBAT_MICRO)

IVBAT_MICRO

19

uA

Operating Current (Wi-Fi on)

I3V3 avg[1]

100

mA

Operating Current (Wi-Fi on)

I3V3 pk[1]

430[2]

mA

Operating Current (Wi-Fi on, w/powersave)

I3V3 avg[1]

18

100[3]

mA

Operating Current (Wi-Fi off)

I3V3 avg[1]

30

40

mA

Sleep Current (5V @ VIN)

IQs

1

2

mA

Deep Sleep Current (5V @ VIN)

IQds

80

100

uA

Operating Temperature

Top

+60

°C

95

%

Humidity Range Non condensing, relative humidity

+1.65

80

235[2]

-20

�Notes:

[1]

V3V3 and I3V3 represents the the combined 4 inputs that require +3.3V: VBAT_WL, VDDIO_3V3_WL,

VDD_3V3 and VBAT_MICRO.

[2]

These numbers represent the extreme range of short peak current bursts when transmitting and

receiving in 802.11b/g/n modes at different power levels. Average TX current consumption in will be

80-100mA.

[3]

These are very short average current bursts when transmitting and receiving. On average if

minimizing frequency of TX/RX events, current consumption in powersave mode will be 18mA

Wi-Fi Specifications

Feature

Description

WLAN Standards

IEEE 802 11b/g/n

Antenna Port

Single Antenna

Frequency Band

2.412GHz -- 2.462GHz (United States of America and Canada)

2.412GHz -- 2.472GHz (EU)

Sub Channels

1 -- 11 (United States of America and Canada)

1 -- 13 (EU)

Modulation

DSSS, CCK, OFDM, BPSK, QPSK, 16QAM, 64QAM

P1 module Wi-Fi output power

RF Average Output Power, 802.11b CCK Mode

RF Average Output Power, 802.11g OFDM Mode

RF Average Output Power, 802.11n OFDM Mode

Typ.

Tol.

Unit

1M

Avail. upon request

+/- 1.5

dBm

11M

-

+/- 1.5

dBm

6M

-

+/- 1.5

dBm

54M

-

+/- 1.5

dBm

MCS0

-

+/- 1.5

dBm

MCS7

-

+/- 1.5

dBm

I/O Characteristics

These specifications are based on the STM32F205RGY6 datasheet, with reference to Photon pin

nomenclature.

�Parameter

Symbol

Standard I/O input low level voltage

VIL

I/O FT[1] input low level voltage

Conditions

Min

Typ

Max

Unit

-0.3

0.28*(V3V32)+0.8

V

VIL

-0.3

0.32*(V3V32)+0.75

V

Standard I/O input high level voltage

VIH

0.41*(V3V32)+1.3

V3V3+0.3

V

I/O FT[1] input high level voltage

VIH

V3V3 > 2V

0.42*(V3V3-2)+1

5.5

V

VIH

V3V3 ≤ 2V

0.42*(V3V3-2)+1

5.2

V

Standard I/O Schmitt trigger voltage

hysteresis[2]

Vhys

200

mV

I/O FT Schmitt trigger voltage hysteresis[2]

Vhys

5% V3V3[3]

mV

Input/Output current max

Iio

±25

mA

Input/Output current total

Iio total

±120

mA

Input leakage current[4]

Ilkg

GND ≤ Vio ≤ V3V3

GPIOs

±1

µA

Input leakage current[4]

Ilkg

RPU

Vio = 5V, I/O

FT

3

µA

Weak pull-up equivalent resistor[5]

RPU

Vio = GND

30

40

50

kΩ

Weak pull-down equivalent resistor[5]

RPD

Vio = V3V3

30

40

50

kΩ

I/O pin capacitance

CIO

DAC output voltage (buffers enabled by

default)

VDAC

0.2

DAC output resistive load (buffers enabled by

default)

RDAC

5

DAC output capacitive load (buffers enabled

by default)

CDAC

5

pF

V3V3-0.2

V

kΩ

50

pF

Notes:

[1]

FT = Five-volt tolerant. In order to sustain a voltage higher than V3V3+0.3 the internal pull-up/pull-

down resistors must be disabled.

[2]

Hysteresis voltage between Schmitt trigger switching levels. Based on characterization, not tested

in production.

[3]

With a minimum of 100mV.

[4]

Leakage could be higher than max. if negative current is injected on adjacent pins.

�[5]

Pull-up and pull-down resistors are designed with a true resistance in series with switchable

PMOS/NMOS. This PMOS/NMOS contribution to the series resistance is minimum (~10% order).

Mechanical specifications

Overall dimensions

P1 module dimensions are: 0.787"(28mm) (W) x 1.102"(20mm) (L) x 0.0787"(2.0mm) (H) +/0.0039"(0.1mm) (includes metal shielding)

Actual size (so tiny!)

�P1 Module Dimensions

These are the physical dimensions of the P1 module itself, including all pins:

P1 Module Recommended PCB land pattern

The P1 can be mounted directly on a carrier PCB with following PCB land pattern:

A P1 part for EAGLE can be found in the Particle EAGLE library https://github.com/spark/hardwarelibraries#pcb-footprints-land-pattern

�P1 Reference Design Schematic

Schematic - USB

Schematic - Power

Schematic - User I/O

�Schematic - P1 Wi-Fi Module

P1 Reference Design Layout

P1 Reference Design Top Layer (GTL)

To be added.

P1 Reference Design Bottom Layer (GBL)

To be added.

Recommended solder reflow profile

�Phase

Temperatures and Rates

A-B.

Ambient~150°C, Heating rate: < 3°C/s

B-C.

150~200°C, soak time: 60~120 s

C-D.

200~245°C, Heating rate: < 3°C/s

D.

D-E.

Peak temp.: 235~245°C, Time above 220°C: 40~90 s

245~220°C, Cooling rate: < 1°C/s

Ordering information

P1 modules are available from store.particle.io as cut tape in quantities of 10 each.

Qualification and approvals

RoHS

CE

FCC ID: COFWMNBM11

IC: 10293A-WMNBM11

�Product handling

Tape and Reel Info

Moisture sensitivity levels

The Moisture Sensitivity Level (MSL) relates to the packaging and handling precautions required.

The P1 module is rated level 3. In general, this precaution applies for Photons without headers.

When reflowing a P1 directly onto an application PCB, increased moisture levels prior to reflow can

damage sensitive electronics on the P1. A bake process to reduce moisture may be required.

For more information regarding moisture sensitivity levels, labeling, storage and drying see the MSL

standard see IPC/JEDEC J-STD-020 (can be downloaded from www.jedec.org).

ESD Precautions

The P1 module contains highly sensitive electronic circuitry and is an Electrostatic Sensitive Device

(ESD). Handling a P1 module without proper ESD protection may destroy or damage it permanently.

Proper ESD handling and packaging procedures must be applied throughout the processing,

handling and operation of any application that incorporates P1 modules. ESD precautions should be

implemented on the application board where the P1 module is mounted. Failure to observe these

precautions can result in severe damage to the P1 module!

�Default settings

The P1 module comes pre-programmed with a bootloader and a user application called Tinker. This

application works with an iOS and Android app also named Tinker that allows you to very easily

toggle digital pins, take analog and digital readings and drive variable PWM outputs.

The bootloader allows you to easily update the user application via several different methods, USB,

OTA, Serial Y-Modem, and also internally via the Factory Reset procedure. All of these methods

have multiple tools associated with them as well.

You may use the online Web IDE Particle Build to code, compile and flash a user application OTA

(Over The Air). Particle Dev is a local tool that uses the Cloud to compile and flash OTA as well.

There is also a package Spark DFU‐UTIL for Particle Dev that allows for Cloud compiling and local

flashing via DFU over USB. This requires dfu‐util to be installed on your system. 'dfu-util' can also be

used with Particle CLI for Cloud compiling and local flashing via the command line. Finally the lowest

level of development is available via the GNU GCC tool chain for ARM, which offers local compile and

flash via dfu-util. This gives the user complete control of all source code and flashing methods. This

is an extensive list, however not exhaustive.

Glossary

Radio Frequency

SMT

Surface Mount Technology (often associated with SMD which is a surface mount device).

AP

Access Point

USB

Universal Serial Bus

Quiescent current

Current consumed in the deepest sleep state

FT

Five-tolerant; Refers to a pin being tolerant to 5V.

3V3

+3.3V; The regulated +3.3V supply rail. Also used to note a pin is only 3.3V tolerant.

�RTC

Real Time Clock

OTA

Over The Air; describing how firmware is transferred to the device.

FCC IC CE Warnings and End Product Labeling

Requirements

Federal Communication Commission Interference Statement This equipment has been tested

and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one of the following measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

-Consult the dealer or an experienced radio/TV technician for help.

FCC Caution: Any changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate this equipment. This device complies with Part

15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause

undesired operation.

FCC Radiation Exposure Statement: This equipment complies with FCC radiation exposure limits

set forth for an uncontrolled environment. This transmitter module must not be co-located or

operating in conjunction with any other antenna or transmitter. This End equipment should be

�installed and operated with a minimum distance of 20 centimeters between the radiator and your

body.

IMPORTANT NOTE: In the event that these conditions can not be met (for example certain laptop

configurations or co-location with another transmitter), then the FCC authorization is no longer

considered valid and the FCC ID can not be used on the final product. In these circumstances, the

OEM integrator will be responsible for re-evaluating the end product (including the transmitter) and

obtaining a separate FCC authorization.

End Product Labeling The final end product must be labeled in a visible area with the following:

Contains FCC ID: 2AEMI-PHOTON

Manual Information to the End User The OEM integrator has to be aware not to provide

information to the end user regarding how to install or remove this RF module in the user’s manual

of the end product which integrates this module.

Canada Statement This device complies with Industry Canada’s licence-exempt RSSs. Operation is

subject to the following two conditions:

1. This device may not cause interference; and

2. This device must accept any interference, including interference that may cause undesired

operation of the device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio

exempts de licence.

L’exploitation est autorisée aux deux conditions suivantes:

1. l’appareil ne doit pas produire de brouillage;

2. l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d’en compromettre le fonctionnement.

Caution Exposure: This device meets the exemption from the routine evaluation limits in section

2.5 of RSS102 and users can obtain Canadian information on RF exposure and compliance. Le

dispositif répond à l'exemption des limites d'évaluation de routine dans la section 2.5 de RSS102 et

les utilisateurs peuvent obtenir des renseignements canadiens sur l'exposition aux RF et le respect.

�The final end product must be labelled in a visible area with the following: The Industry

Canada certification label of a module shall be clearly visible at all times when installed in the host

device, otherwise the host device must be labelled to display the Industry Canada certification

number of the module, preceded by the words “Contains transmitter module”, or the word

“Contains”, or similar wording expressing the same meaning, as follows:

Contains transmitter module IC: 20127-PHOTON

This End equipment should be installed and operated with a minimum distance of 20 centimeters

between the radiator and your body. Cet équipement devrait être installé et actionné avec une

distance minimum de 20 centimètres entre le radiateur et votre corps.

The end user manual shall include all required regulatory information/warning as shown in this

manual.

Revision history

Revision

Date

Author

Comments

v001

4-May-2015

BW

Initial release

v002

31-May-2015

BW

Update assets

v003

1-June-2015

BW

Updated VBAT_MICRO info

v004

24-July-2015

BW

Added FCC IC CE Warnings and End Product Labeling Requirements,

Updated power output, added approved antennas, Corrected DAC2 as A3,

Corrected A0 as pin 50, Corrected External Coexistence Interface pin

numbers, Added RGB LED, SETUP and RESET button section.

v005

11-April-2016

BW

Added: full STM32 part number, Memory map, DAC limits, SWD pin

locations, max source/sink current, known errata URL and tape-and-reel

dimensions. Updated: BT COEX info, pinout diagrams (fixed RESET pin

number error), operating conditions, pin descriptions (P1S0~P1S5 pins), landpattern image signal keepout note.

v006

14-July-2016

BW

Updated P1 pin listing: TESTMODE pin 33 (PA8), connected to MCO1 by

default, outputs 32kHz clock for WICED powersave mode - currently

unsupported for user control.

v007

20-September2016

BW

Updated P1 pin listing: TESTMODE pin 33 (PA8), can use now as P1S6 if

enabled. Updated Pinmap and added P1S6. Updated Pin Description and

Peripherals and GPIO.

v008

25-July-2017

BW

Added note to clarify MICRO_SPI1SS label, renamed SPI1/SPI3_ to match

Particle API instead of STM32 pin names to avoid confusion (now SPI and

SPI1), updated the Pin Description section and added high resolution pinout

PDF, updated PWM notes, JTAG_TDO pin number (54 -> 52), block diagram

and DCT layout, added warning to power section

v009

30-August-2017

BW

Added part number for 1MB external SPI flash (MX25L8006E)

https://docs.particle.io/datasheets/p1-datasheet/ 11-1-17

�