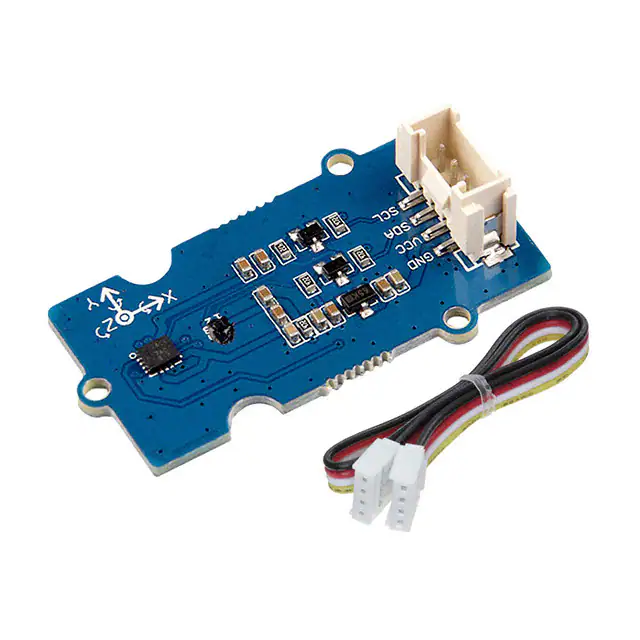

Grove - IMU 9DOF(lcm20600+AK09918)

The Grove - IMU 9DOF (lcm20600+AK09918) is a 9 Degrees of Freedom IMU (Inertial

measurement unit) which combines gyroscope, accelerometer and electronic compass.

We use two chips LCM20600+AK09918 to implement those 3 functions.

The LCM20600 is a 6-axis MotionTracking device that combines a 3-axis gyroscope, 3axis accelerometer. Gyroscope is a device used for measuring or maintaining

orientation and angular velocity, normally, we use it to measure spin and

twist. Accelerometer is a device that measures proper acceleration.

The AK09918 is a 3-axis electronic compass IC with high sensitive Hall sensor

technology. We use an electronic compass to measure the magnetic force, which can

provide us with the direction information.

�

As its name suggests just use this single small module and you can measure 9 Degrees

of Freedom: angular rotation in x/y/z axis, acceleration in x/y/z axis, and magnetic force

in x/y/z axis.

What an amazing module! Just use this module to build your own motion and

orientation system😄

Features

3-Axis Gyroscope with Programmable FSR of ±250 dps, ±500 dps, ±1000 dps, and ±2000

dps

3-Axis Accelerometer with Programmable FSR of ±2g, ±4g, ±8g, and ±16g

3-Axis Electronic Compass with 0.15 μT/LSB (typ.) sensitivity

User-programmable interrupts

16-bit ADC resolution and Programmable Filters for acceleration measurements

16-bit ADC resolution for magnetic measurements

1 KB FIFO buffer enables the applications processor to read the data in bursts(LCM20600)

Embedded temperature sensor

Magnetic sensor overflow monitor function

Built-in oscillator for internal clock source

Specification

Item

Value

Operating voltage

3.3V / 5V

Operating temperature

‐30°C to +85°C

Gyroscope Full‐Scale Range

±250 dps, ±500 dps, ±1000 dps, ±2000 dps

Gyroscope Sensitivity Scale Factor

131 LSB/(dps)@±250 dps

65.5 LSB/(dps)@±500 dps

32.8 LSB/(dps)@±1000 dps

16.4 LSB/(dps)@±2000 dps

Accelerometer Full‐Scale Range

±2g, ±4g, ±8g, ±16g

Accelerometer Sensitivity Scale Factor

16384 LSB/g@±2g

8192 LSB/g@±4g

4096 LSB/g@±8g

2048 LSB/g@±16g

�

Item

Value

Magnetic sensor measurement range

±4912μT (typical)

Magnetic sensor sensitivity

0.15μT (typical)

Interface

I2C

I2C Address

LCM20600

0x69(default)

0x68(optional)

AK09918

0x0C

Applications

Smartphones and Tablets

Wearable Sensors

Hardware Overview

Pin Out

�

Danger

The default I2C address of LCM20600 is 0x69, you can change it to 0x68. The central

pad is connected to the address wire, you can change the I2C address by cutting the

wire and re-welding it. For the safety of you and others, please be careful with knife or

welding gun you may use.

Schemaitc

Power

�

Since the operating voltage range of LCM20600 is 1.71V to 3.45V, and the operating

voltage range of AK09918 is 1.65V to 1.95V, we use a power conversion

chip XC6206P182MR to provide a stable 1.8V for both chips.

Bi-directional level shifter circuit

This is a typical Bi-directional level shifter circuit to connect two different voltage section

of an I2C bus. The I2C bus of two chips use 1.8V, if the I2C bus of the Arduino use 5V or

3.3V, this circuit will be needed. In the schematic above, Q1 and Q2 are N-Channel

MOSFET CJ2102, which act as a bidirectional switch. In order to better understand this

part, you can refer to the AN10441

Platforms Supported

Arduino

Raspberry Pi

BeagleBone

Wio

LinkIt ONE

Caution

The platforms mentioned above as supported is/are an indication of the module's

hardware or theoritical compatibility. We only provide software library or code examples

for Arduino platform in most cases. It is not possible to provide software library / demo

code for all possible MCU platforms. Hence, users have to write their own software

library.

�

Getting Started

Play With Arduino

Hardware

Materials required

Seeeduino V4.2

Base Shield

Grove ‐ IMU 9DOF

Note

1 Please plug the USB cable gently, otherwise you may damage the port. Please use

the USB cable with 4 wires inside, the 2 wires cable can't transfer data. If you are not

sure about the wire you have, you can click here to buy

2 Each Grove module comes with a Grove cable when you buy. In case you lose the

Grove cable, you can click here to buy.

Step 1. Connect the Grove - IMU 9DOF (lcm20600+AK09918) to port I2C of GroveBase Shield.

Step 2. Plug Grove - Base Shield into Seeeduino.

Step 3. Connect Seeeduino to PC via a USB cable.

�

Note

If we don't have Grove Base Shield, We also can directly connect this module to

Seeeduino as below.

Seeeduino

Grove ‐ IMU 9DOF

5V

Red

GND

Black

SDA

White

SCL

Yellow

Software

Note

If this is the first time you work with Arduino, we strongly recommend you to see Getting

Started with Arduinobefore the start.

Step 1. Download the Grove - IMU 9DOF (lcm20600+AK09918) Library from

Github.

Step 2. Refer to How to install library to install library for Arduino.

Step 3. Restart the Arduino IDE. Open the example, you can open it in the following

three ways:

a. Open it directly in the Arduino IDE via the path: File → Examples → Grove

IMU 9DOF ICM20600 AK09918 → compass.

�

b. Open it in your computer by click the compass.ino which you can find in the

folder XXXX\Arduino\libraries\Seeed_ICM20600_AK09918master\examples\compass, XXXX is the location you installed the Arduino

IDE.

c. Or, you can just click the icon

in upper right corner of the code block to copy

the following code into a new sketch in the Arduino IDE.

1#include "AK09918.h"

2#include "ICM20600.h"

3#include

4

5AK09918_err_type_t err;

6int32_t x, y, z;

7AK09918 ak09918;

8ICM20600 icm20600(true);

9int16_t acc_x, acc_y, acc_z;

10int32_t offset_x, offset_y, offset_z;

11double roll, pitch;

12// Find the magnetic declination at your location

13// http://www.magnetic-declination.com/

14double declination_shenzhen = -2.2;

15

16void setup()

17{

18 // join I2C bus (I2Cdev library doesn't do this automatically)

19 Wire.begin();

20

21 err = ak09918.initialize();

22 icm20600.initialize();

23 ak09918.switchMode(AK09918_POWER_DOWN);

24 ak09918.switchMode(AK09918_CONTINUOUS_100HZ);

25 Serial.begin(9600);

26

27 err = ak09918.isDataReady();

28 while (err != AK09918_ERR_OK)

29 {

Serial.println("Waiting Sensor");

30

delay(100);

31

err = ak09918.isDataReady();

32

33 }

34

35 Serial.println("Start figure-8 calibration after 2 seconds.");

36 delay(2000);

37 calibrate(10000, &offset_x, &offset_y, &offset_z);

38 Serial.println("");

39}

40

41void loop()

42{

�

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97}

98

// get acceleration

acc_x = icm20600.getAccelerationX();

acc_y = icm20600.getAccelerationY();

acc_z = icm20600.getAccelerationZ();

Serial.print("A: ");

Serial.print(acc_x);

Serial.print(", ");

Serial.print(acc_y);

Serial.print(", ");

Serial.print(acc_z);

Serial.println(" mg");

Serial.print("G: ");

Serial.print(icm20600.getGyroscopeX());

Serial.print(", ");

Serial.print(icm20600.getGyroscopeY());

Serial.print(", ");

Serial.print(icm20600.getGyroscopeZ());

Serial.println(" dps");

ak09918.getData(&x, &y, &z);

x = x - offset_x;

y = y - offset_y;

z = z - offset_z;

Serial.print("M: ");

Serial.print(x);

Serial.print(", ");

Serial.print(y);

Serial.print(", ");

Serial.print(z);

Serial.println(" uT");

// roll/pitch in radian

roll = atan2((float)acc_y, (float)acc_z);

pitch = atan2(-(float)acc_x, sqrt((float)acc_y*acc_y+(float)acc_z*acc_z));

Serial.print("Roll: ");

Serial.println(roll*57.3);

Serial.print("Pitch: ");

Serial.println(pitch*57.3);

double Xheading = x * cos(pitch) + y * sin(roll) * sin(pitch) + z * cos(roll) * sin(pitch);

double Yheading = y * cos(roll) - z * sin(pitch);

double heading = 180 + 57.3*atan2(Yheading, Xheading) + declination_shenzhen;

Serial.print("Heading: ");

Serial.println(heading);

Serial.println("--------------------------------");

delay(500);

�

99void calibrate(uint32_t timeout, int32_t *offsetx, int32_t *offsety, int32_t*offsetz)

100{

101 int32_t value_x_min = 0;

102 int32_t value_x_max = 0;

103 int32_t value_y_min = 0;

104 int32_t value_y_max = 0;

105 int32_t value_z_min = 0;

106 int32_t value_z_max = 0;

107 uint32_t timeStart = 0;

108

109 ak09918.getData(&x, &y, &z);

110

111 value_x_min = x;

112 value_x_max = x;

113 value_y_min = y;

114 value_y_max = y;

115 value_z_min = z;

116 value_z_max = z;

117 delay(100);

118

119 timeStart = millis();

120

121 while((millis() - timeStart) < timeout)

122 {

123 ak09918.getData(&x, &y, &z);

124

125 /* Update x-Axis max/min value */

126 if(value_x_min > x)

127 {

value_x_min = x;

128

// Serial.print("Update value_x_min: ");

129

// Serial.println(value_x_min);

130

131

132 }

133 else if(value_x_max < x)

134 {

value_x_max = x;

135

// Serial.print("update value_x_max: ");

136

// Serial.println(value_x_max);

137

138 }

139

140 /* Update y-Axis max/min value */

141 if(value_y_min > y)

142 {

value_y_min = y;

143

// Serial.print("Update value_y_min: ");

144

// Serial.println(value_y_min);

145

146

147 }

148 else if(value_y_max < y)

149 {

value_y_max = y;

150

// Serial.print("update value_y_max: ");

151

// Serial.println(value_y_max);

152

153 }

154

�

155 /* Update z-Axis max/min value */

156 if(value_z_min > z)

157 {

value_z_min = z;

158

// Serial.print("Update value_z_min: ");

159

// Serial.println(value_z_min);

160

161

162 }

163 else if(value_z_max < z)

164 {

value_z_max = z;

165

// Serial.print("update value_z_max: ");

166

// Serial.println(value_z_max);

167

168 }

169

170 Serial.print(".");

171 delay(100);

172

173 }

174

175 *offsetx = value_x_min + (value_x_max - value_x_min)/2;

176 *offsety = value_y_min + (value_y_max - value_y_min)/2;

177 *offsetz = value_z_min + (value_z_max - value_z_min)/2;

178}

Note

There are 3 demos in the library:

test_6axis

This example shows how to get gyroscope and acceleration data from ICM20600.

test_magnet

This example shows how to get magnetic data from AK09918.

compass

This example gets magnetic data and acceleration data, to count pitch and roll, and

make a compass application.

Step 4. Upload the demo. If you do not know how to upload the code, please

check How to upload code.

Step 5. Open the Serial Monitor of Arduino IDE by click Tool-> Serial Monitor. Or

tap the Ctrl + Shift + M key at the same time. Set the baud rate to 9600.

�

Success

If every thing goes well, when you open the Serial Monitor, the notice will pop up--Start

figure-8 calibration after 2 seconds. Which means in order to calibrate this module, you

should move it and draw the number 8 trajectory in the air. When the "......." appears,

you can start your calibration.

1Start figure-8 calibration after 2 seconds.

2.......................................................................

3A: -362, -205, 738 mg

4G: -45, 12, -1 dps

5M: -6, -23, -33 uT

6Roll: -15.53

7Pitch: 25.30

8Heading: 23.99

9-------------------------------10A: -269, 583, 61 mg

11G: 102, 377, -2 dps

12M: 18, -21, -18 uT

13Roll: 84.03

14Pitch: 24.65

15Heading: 215.58

16-------------------------------17A: -495, 229, 37 mg

18G: -43, -231, 201 dps

19M: 7, -30, 6 uT

20Roll: 80.83

21Pitch: 64.90

22Heading: 21.76

23--------------------------------

Note

As you can see, the result of compass example includes three parameter: roll, pitch and

Heading. There are the terminology of Euler angles(click to check more information).

Fuction table

Function

Description

ICM20600

initialize()

Initialize the chip LCM20600, by default:

the measurement range of gyroscope is ±2000 dps

the measurement range of accelerometer is ±16g

setGyroScaleRange(gyro_scale_type_t

range)

After the initialization, you can set the gyroscope range to meet your

own needs, the parameter gyro_scale_type_t range list:

RANGE_250_DPS

RANGE_500_DPS

RANGE_1K_DPS

�

Function

Description

RANGE_2K_DPS

e.g.

icm20600.setGyroScaleRange(RANGE_1K_DPS);

this code line will change the gyroscope measurement range to

±1000dps

setAccScaleRange(acc_scale_type_t range) After the initialization, you can set the accelerometer range to meet

your own needs, the parameter acc_scale_type_t range list:

RANGE_2G

RANGE_4G

RANGE_8G

RANGE_16G

e.g.

icm20600.setAccScaleRange(RANGE_8G);

this code line will change the accelerometer measurement range to

±8g

getGyroscope(int16_t* x, int16_t* y,

int16_t* z))

You can use this function to get the gyroscope X/Y/Z 3‐axis data at the

same time, and the unit of the data is dps

getGyroscopeX(void)

getGyroscopeY(void)

getGyroscopeZ(void)

Or, you can get the gyroscope X/Y/Z 3‐axis data separately by using

those three functions, and the unit of the data is dps

getRawGyroscopeX(void)

getRawGyroscopeX(void)

getRawGyroscopeX(void)

Those three functions get the raw data directly from the register of

ICM20600 without convert the data unit to dps

getAcceleration(int16_t* x, int16_t* y,

int16_t* z)

You can use this function to get the X/Y/Z 3‐axis acceleration at the

same time, and the unit of the data is mg

getAccelerationX(void)

getAccelerationY(void)

getAccelerationZ(void)

Or, you can get the X/Y/Z 3‐axis acceleration separately by using those

three functions, and the unit of the data is mg

getRawAccelerationX(void)

getRawAccelerationY(void)

getRawAccelerationZ(void)

Those three functions get the raw data directly from the register of

ICM20600 without convert the data unit to mg

getTemperature(void)

You ca use this function to get the temperature

�

Function

Description

AK09918

getData(int32_t *axis_x, int32_t *axis_y,

int32_t *axis_z)

You can use this function to get the magnetic force of 3‐axis.

Project

This is the introduction Video of this product, simple demos, you can have a try.

Tech Support

Please do not hesitate to submit the issue into our forum.

http://wiki.seeedstudio.com/Grove‐I2C_UV_Sensor‐VEML6070/ 11‐5‐18

�