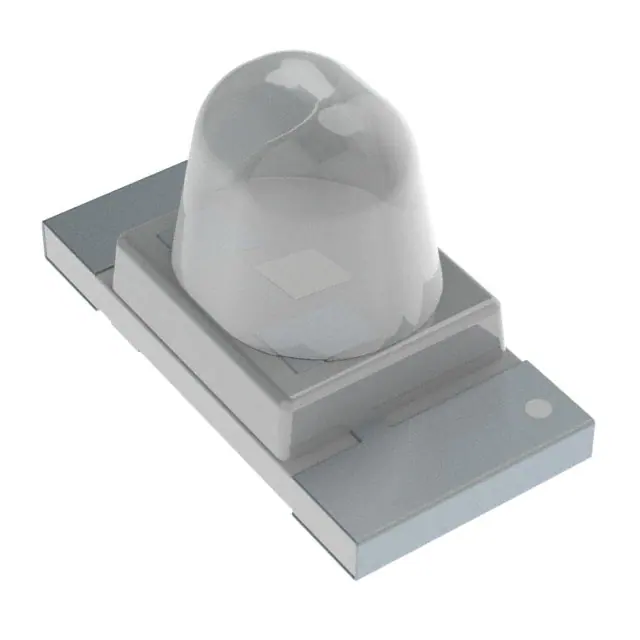

IN-S124BR series

Reverse Mount SMD LED 1204 PCB Type

Featured

•

1204 1.85mm SMD LED

•

High Brightness

•

AlInGaP / InGaN Technology

•

Narrow View Angle

•

High Reliability

•

Clear Lens

Description

The IN-S124BR series is a popular 1204 package with

reverse mount and versatile design capabilities. It is a

PCB type molding style LED which can be used in

various applications.

Recommended Solder Pattern

Applications

•

Consumer Electronics

•

Wearables

•

Automobile After Market

•

Industrial Equipment

Figure 1. IN-S124BR Solder Pattern

Package Dimensions in mm

Inolux Corporation

Proprietary & Confidential

Figure 2. IN-S124BR Package Dimensions

April 10, 2017

Page 1

www.inolux-corp.com

�

IN-S124BR series

Reverse Mount SMD LED 1204 PCB Type

Absolute Maximum Rating at 25oC (Note 1)

Product

Emission

Color

Pd (mW)

IF (mA)

IFP* (mA)

48

20

30

VR (V)

TOP (oC)

TST (oC)

5

-40 C~+85 C

IN-S124BRYG Yellow Green

IN-S124BRY

Yellow

IN-S124BRA

Amber

IN-S124BRR

Red

IN-S124BRB

Blue

IN-S124BRG

Green

IN-S124BRUW

White

78

20

o

o

o

o

-40 C~+100 C

60

Notes

1. Condition for IFP is pulse of 1/10 duty and 0.1msec width

ESD Precaution

ATTENTION: Electrostatic Discharge (ESD) protection

The symbol above denotes that ESD precaution is needed. ESD protection for GaP and AlGaAs based chips is necessary even

though they are relatively safe in the presence of low static-electric discharge. Parts built with AlInGaP, GaN, or/and InGaN based

chips are STATIC SENSITIVE devices. ESD precaution must be taken during design and assembly.

If manual work or processing is needed, please ensure the device is adequately protected from ESD during the process.

Please be advised that normal static precautions should be taken in the handling and assembly of this device to prevent damage or degradation which

may be induced by electrostatic discharge (ESD).

Inolux Corporation

Proprietary & Confidential

April 10, 2017

Page 2

www.inolux-corp.com

�

IN-S124BR series

Reverse Mount SMD LED 1204 PCB Type

Electrical Characteristics T

A

= 25°C (Note 1)

VF(V)

Emission

Color

IF(mA)

IN-S124BRYG

Yellow Green

IN-S124BRY

Product

λ(nm)

Viewing

Angle

I*V(mcd)

typ.

max

λD

λP

△λ

2θ1/2

typ.

20

2.1

2.4

571

573

15

20

715.0

Yellow

20

2.0

2.4

589

591

20

20

1125.0

IN-S124BRA

Amber

20

2.0

2.4

605

609

17

20

1800.0

IN-S124BRR

Red

20

2.0

2.4

624

632

20

20

900.0

IN-S124BRB

Blue

20

3.3

3.9

470

468

40

20

715.0

IN-S124BRG

Green

20

3.3

3.9

525

520

30

20

1440.0

IN-S124BRUW

White

20

3.3

3.9

X=0.29

Y=0.29

-

-

20

715.0

Notes

1. Performance guaranteed only under conditions listed in above tables.

Inolux Corporation

Proprietary & Confidential

April 10, 2017

Page 3

www.inolux-corp.com

�

IN-S124BR series

Reverse Mount SMD LED 1204 PCB Type

Chromaticity Bin (for White only)

x

y

0.2500

0.2500

x

y

0.2900

0.3050

Rank C1

0.2700 0.2700

0.2775 0.2325

Rank D1

0.3100 0.3100

0.3325 0.2875

0.2500

0.2050

x

y

0.2700

0.2775

0.2900

0.2600

x

y

0.3100

0.3325

Rank C2

0.2900 0.2900

0.3050 0.2600

Rank D2

0.3300 0.3300

0.3600 0.3150

0.2700

0.2325

0.3100

0.2875

0.5

0.4

D2

0.3

D1

C2

C1

0.2

0.1

0

0

0.1

0.2

0.3

Inolux Corporation

Proprietary & Confidential

0.4

0.5

0.6

April 10, 2017

Page 4

www.inolux-corp.com

�

IN-S124BR series

Reverse Mount SMD LED 1204 PCB Type

Typical Characteristic Curves – YG, Y, A, R

Inolux Corporation

Proprietary & Confidential

April 10, 2017

Page 5

www.inolux-corp.com

�

IN-S124BR series

Reverse Mount SMD LED 1204 PCB Type

Typical Characteristic Curves – B, G, W

Inolux Corporation

Proprietary & Confidential

April 10, 2017

Page 6

www.inolux-corp.com

�

IN-S124BR series

Reverse Mount SMD LED 1204 PCB Type

Typical Characteristic Curves – Radiation Pattern

Ordering Information

Technolog Test Current

y

IF (mA)

Forward

Luminous Intensity

Voltage

IV (mcd)

VF (V)

(Typ.)

(Typ.)

Product

Emission

Color

IN-S124BRYG

Yellow

Green

AllnGaP

20

715.0

2.1

IN-S124BRYG

IN-S124BRY

Yellow

AllnGaP

20

1125.0

2.0

IN-S124BRY

IN-S124BRA

Amber

AllnGaP

20

1800.0

2.0

IN-S124BRA

IN-S124BRR

Red

AllnGaP

20

900.0

2.0

IN-S124BRR

IN-S124BRB

Blue

InGaN

20

715.0

3.3

IN-S124BRB

IN-S124BRG

Green

InGaN

20

1440.0

3.3

IN-S124BRG

IN-S124BRUW

White

InGaN

20

715.0

3.3

IN-S124BRUW

Inolux Corporation

Proprietary & Confidential

Orderable

Part Number

April 10, 2017

Page 7

www.inolux-corp.com

�

IN-S124BR series

Reverse Mount SMD LED 1204 PCB Type

Label Specifications

Inolux P/N:

I

N

-

S

Material

Inolux

SMD

1

2

Package

S = PCB

Type

4

B

R

Variation

Orientation

124B = 3.2 x 1.6 x

1.85mm

R = Reverse

Mount

X

-

Lens

Color

Customized

Stamp-off

(Blank) = Clear

U = Diffused

R=624nm

A=605nm

Y=589nm

YG=571nm

G=525nm

B=470nm

W=White

Current

(Blank) =

20mA

X

X X X

Lot No.:

Z

Internal

Tracker

2

0

1

7

Year (2017, 2018, …..)

Inolux Corporation

Proprietary & Confidential

01

24

001

Month

Date

Serial

April 10, 2017

Page 8

www.inolux-corp.com

�

IN-S124BR series

Reverse Mount SMD LED 1204 PCB Type

Packaging Information: 2000pcs Per Reel

Tape Dimension

Part No.

IN-S124BR

Dim. A

Dim. B

Dim. C

3.37±0.10 1.78±0.10 2.17±0.10

Q’ty/Reel

2K

Unit: mm

Reel Dimension

Inolux Corporation

Proprietary & Confidential

April 10, 2017

Page 9

www.inolux-corp.com

�

IN-S124BR series

Reverse Mount SMD LED 1204 PCB Type

Packing Dimension

5 boxes per carton are available depending on shipment quantity.

Specification

Material

Quantity

Carrier tape

Per EIA 481-1A specs

Conductive black tape

4000pcs per reel

Reel

Per EIA 481-1A specs

Conductive black

Label

IN standard

Paper

Packing bag

220x240mm

Aluminum laminated bag/ no-zipper

One reel per bag

Carton

IN standard

Paper

Non-specified

Others:

Each immediate box consists of 5 reels. The 5 reels may not necessarily have the same lot number or the same

bin combinations of Iv, λD and Vf. Each reel has a label identifying its specification; the immediate box consists

of a product label as well.

Inolux Corporation

Proprietary & Confidential

April 10, 2017

Page 10

www.inolux-corp.com

�

IN-S124BR series

Reverse Mount SMD LED 1204 PCB Type

Dry Pack

All SMD optical devices are MOISTURE SENSITIVE. Avoid exposure to moisture at all times during

transportation or storage. Every reel is packaged in a moisture protected anti-static bag. Each bag is properly

sealed prior to shipment.

Upon request, a humidity indicator will be included in the moisture protected anti-static bag prior to shipment.

The packaging sequence is as follows:

Reflow Soldering

• Recommended tin glue specifications: melting temperature in the range of 178~192 OC

• The recommended reflow soldering profile is as follows (temperatures indicated are as measured on

the surface of the LED resin):

Lead-free Solder Profile

Inolux Corporation

Proprietary & Confidential

April 10, 2017

Page 11

www.inolux-corp.com

�

IN-S124BR series

Reverse Mount SMD LED 1204 PCB Type

Precautions

•

•

•

•

•

•

Avoid exposure to moisture at all times during transportation or storage.

Anti-Static precaution must be taken when handling GaN, InGaN, and AlInGaP products.

It is suggested to connect the unit with a current limiting resistor of the proper size. Avoid applying a

reverse voltage.

Avoid operation beyond the limits as specified by the absolute maximum ratings.

Avoid direct contact with the surface through which the LED emits light.

If possible, assemble the unit in a clean room or dust-free environment.

Reworking

•

•

•

Rework should be completed within 5 seconds under 260 OC.

The iron tip must not come in contact with the copper foil.

Twin-head type is preferred.

Cleaning

Following are cleaning procedures after soldering:

• An alcohol-based solvent such as isopropyl alcohol (IPA) is recommended.

• Temperature x Time should be 50oC x 30sec. or

很抱歉,暂时无法提供与“IN-S124BRR”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格 香港价格

- 2000+0.817232000+0.10212

- 4000+0.801244000+0.10013

- 6000+0.792366000+0.09902

- 8000+0.780818000+0.09757

- 国内价格 香港价格

- 1+3.254051+0.40663

- 10+2.2076510+0.27587

- 100+1.56620100+0.19572

- 500+1.27512500+0.15934

- 1000+1.179171000+0.14735

- 国内价格

- 1+2.86995

- 100+1.40121

- 128+0.92007

- 353+0.86942

- 4000+0.83566

- 国内价格 香港价格

- 2000+1.097442000+0.13714

- 4000+1.027944000+0.12845

- 6000+0.992246000+0.12399

- 10000+0.9519210000+0.11895

- 14000+0.9279214000+0.11596

- 20000+0.9044820000+0.11303

- 50000+0.8527350000+0.10656

- 100000+0.82052100000+0.10254

- 国内价格 香港价格

- 2000+0.833222000+0.10412

- 6000+0.811016000+0.10135

- 8000+0.805688000+0.10068

- 20000+0.7879120000+0.09846

- 30000+0.7701530000+0.09624

- 国内价格

- 1+3.73680

- 10+2.97000

- 30+2.64600

- 100+2.23560

- 500+2.06280

- 1000+1.95480