USB Type-C Power Delivery Sink

Controller

Hynetek Semiconductor Co., Ltd.

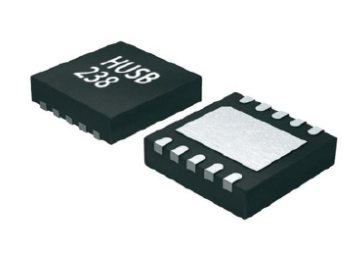

HUSB238

APPLICATIONS

FEATURES

PD sink devices

USB-C cables

Wireless charger

USB-IF certified

TID: 3666

Standalone USB Power Delivery (PD) sink controller

Legacy charging sink

Apple divider 3 detection

GENERAL DESCRIPTION

The HUSB238 is a highly integrated USB Power

Delivery (PD) controller as sink role for up to 100W

power rating.

BC1.2 SDP, CDP and DCP detection

Dead battery function

SOP’ communication function

3V to 25V operation range

30V voltage rating on VIN and GATE pins

25V voltage rating on CC1 and CC2 pins

I2C access for monitoring and advanced settings

Integrated PMOS driver

VBUS over-voltage protection (OVP) and undervoltage protection (UVP)

Over-temperature protection (OTP) with

programmable thresholds

Low power consumption

The HUSB238 is compatible with PD3.0 and Type-C

V1.4, and it can also support Apple Divider 3, BC1.2

SDP, CDP and DCP while the source is attached.

The HUSB238 can be used in electronic devices that

have legacy barrel connectors or USB micro-B

connectors for power such as IoT (Internet of Things)

devices, wireless charger, drones, smart speakers,

power tools, and other rechargeable devices.

The HUSB238 is available in 3mm x 3mm DFN-10L

and 3.9mm x 4mm SOT33-6L package options.

TYPICAL APPLICATION CIRCUIT

VBUS

POWER

SYSTEM

49.9kΩ

USB-C RECEPTACLE

5.1kΩ

HUSB238

10Ω

VIN

GATE

1μF

CC1

CC2

SCL

CC1

CC2

D+

D+

D-

D-

SOC

SDA

VSET

ISET

GND

22.6kΩ

10kΩ

GND

Figure 1. Typical Application Circuit

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Rev. 2.1

www.hynetek.com

�HUSB238

Data Sheet

TABLE OF CONTENTS

Features ........................................................................................................................................................................... 1

Applications ...................................................................................................................................................................... 1

General Description ......................................................................................................................................................... 1

Typical Application Circuit ................................................................................................................................................ 1

Table of Contents ............................................................................................................................................................. 2

Revision History ............................................................................................................................................................... 2

Pin Configuration and Function Descriptions ................................................................................................................... 3

Recommended Operating Conditions .............................................................................................................................. 4

Specifications ................................................................................................................................................................... 4

Absolute Maximum Ratings ............................................................................................................................................. 6

Thermal Resistance ...................................................................................................................................................... 6

ESD Caution ................................................................................................................................................................. 6

Functional Block Diagram ................................................................................................................................................ 7

Theory of Operation ......................................................................................................................................................... 8

Overview ....................................................................................................................................................................... 8

VIN Pin .......................................................................................................................................................................... 8

GATE Pin ...................................................................................................................................................................... 8

CC1 and CC2 Pins........................................................................................................................................................ 8

VSET Pin....................................................................................................................................................................... 8

ISET Pin ........................................................................................................................................................................ 9

RDO Determination....................................................................................................................................................... 9

Operation With I2C Interface ............................................................................................................................................ 9

Legacy Charger Detection ............................................................................................................................................ 9

Dead Battery Function ................................................................................................................................................ 10

SOP’ Function ............................................................................................................................................................. 10

Over-Voltage Protection .............................................................................................................................................. 10

Under-Voltage Protection ............................................................................................................................................ 10

Over-Temperature Protection...................................................................................................................................... 10

Typical Application Circuits.............................................................................................................................................. 11

Package Outline Dimensions ......................................................................................................................................... 12

Ordering Guide ............................................................................................................................................................... 14

Important Notice ............................................................................................................................................................. 15

REVISION HISTORY

Version

Date

Descriptions

Rev. 1.0

Rev. 2.0

Rev. 2.1

12/2020

01/2021

03/2022

Initial version

Added SOT33-6L package information

Add Recommended Operating Conditions

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 2 of 15

�Data Sheet

HUSB238

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

VIN

6

1

VSET

2

CC1

3

5

CC2

ISET

GND

4

VIN

1

10

GATE

D+

2

9

ISET

11

GND

D-

3

8

VSET

CC1

4

7

SCL

CC2

5

6

SDA

HUSB238

(SOT33-6L)

HUSB238

(DFN-10)

Figure 2. Pin Configuration (Top View)

Table 1. Pin Function Descriptions

Pin No.

Pin Name

DFN-10L

SOT33-6L

Type1

Description

Power supply input. Connect this pin to VBUS of USB Type-C connector

and bias this pin via a 1μF ceramic capacitor.

Positive line of USB 2.0 data line for Apple Divider 3 and BC1.2.

Negative line of USB 2.0 data line for Apple Divider 3 and BC1.2.

Configuration line 1 used to negotiate a voltage/current with the attached

adapter.

Configuration line 2 used to negotiate a voltage/current with the attached

adapter.

I2C communication data signal.

I2C communication clock signal.

Connect a resistor to indicate the maximum voltage needed by the

system from the attached power adapter.

Connect a resistor to indicate the maximum current needed by the

system from the attached power adapter.

Open drain gate driver output. Connect this signal to the gate of an

external PMOS through a series resistor. Leave this pin open if not used.

Ground reference. All signals are referred to this pin.

1

1

VIN

P

2

3

4

−

−

3

D+

DCC1

DIO

DIO

AIO

5

4

CC2

AIO

6

7

8

−

−

2

SDA

SCL

VSET

DIO

DIO

AI

9

6

ISET

AI

10

−

GATE

OD

11

5

GND

P

1 Legend:

A = Analog Pin

P = Power Pin

D = Digital Pin

I = Input Pin

O = Output Pin

OD = Open Drain Pin

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 3 of 15

�HUSB238

Data Sheet

RECOMMENDED OPERATING CONDITIONS

Table 2.

Parameter

Rating

VIN Input Voltage Range

Operating Temperature Range (Junction)

Ambient Temperature Range

3.24V to 21V

−40°C to +125°C

-40°C to 85°C

SPECIFICATIONS

VIN = 5V, TA = 25°C, unless otherwise noted.

Table 3.

Parameter

POWER SUPPLY

Supply Voltage

Supply Voltage UVLO Threshold

Supply Current

CC1 AND CC2 PINS

Pull-down Voltage in Dead Battery

Pull-down resistor

Voltage Threshold to Detect a DFP

TX Output Impedance1

Voltage Swing

D+/D- PINS

D- Source Voltage for 0.6V

D+ Source Voltage for 0.6V

Data Detect Voltage

D- Sink Current

D+ Sink Current

D+/D- Comparator Threshold for

2.7V Detection

VSET AND ISET PINS

Source Current

Detect Debounce Time1

Symbol

VIN

VIN_UVLO_RISE

VIN_UVLO_FALL

ISC_OPR

VDBL

VDBH

RD

VTH_DEF

VTH_1P5

VTH_3P0

RTX

Min

Typ

3

Rising edge threshold

Falling edge threshold

VIN = 5V, CC is attached, normal

operation

200μA source current

360μA source current

Max

Unit

25

V

V

V

mA

1.5

2.45

5.6

0.25

0.70

1.31

75

V

V

kΩ

V

V

V

Ω

V

3.1

2.9

3.1

Default current mode

1.5A current mode

3.0A current mode

PD TX mode

0.45

0.85

4.6

0.15

0.61

1.16

33

VDM_SRC

VDP_SRC

VDAT_REF

IDM_SINK

IDP_SINK

VTH_2P7_HI

High threshold for Apple divider 3

0.5

0.5

300

50

50

2.85

0.6

0.6

325

100

100

2.95

0.7

0.7

350

150

150

3.05

V

V

mV

μA

μA

V

VTH_2P7_LO

Low threshold for Apple divider 3

2.25

2.35

2.45

V

IVSET

IISET

tDB_VSET

tDB_ISET

On VSET pin

On ISET pin

For VSET pin

For ISET pin

95

95

100

100

2

2

105

105

μA

μA

ms

ms

5.5

0.4

0.4

V

V

V

V

10

300

mA

Ω

I2C PARAMETERS

Supply Range

Low Level Input Voltage

High Level Input Voltage

Low Level Output Voltage

GATE PIN

Maximum Sink Current1

Pull Low Impedance

1

Test Conditions/Comments

5.1

0.2

0.66

1.23

48

1.125

2.5

Apply for SDA, SCL pins

Apply for SDA, SCL pins

Apply for SDA pin, 2mA load current

1.4

100

Guaranteed by design

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 4 of 15

�Data Sheet

Parameter

PROTECTIONS

Over-Voltage Protection Threshold

OVP Debounce Time1

Under-Voltage Protection Threshold

UVP Debounce Time1

Over-Temperature Protection

Threshold1

HUSB238

Symbol

Test Conditions/Comments

Min

Typ

Max

Unit

VVIN_OV

tDB_OV

VVIN_UV

tDB_UV

Refer to VIN

115

120

50

-2

1

150

125

%

μs

V

ms

ᴼC

Refer to VIN

Rising Threshold

Falling Threshold

OTP Debounce Time1

VIN Discharge Resistor

tDB_OT

RDIS

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

130

100

500

ᴼC

ms

Ω

Page 5 of 15

�HUSB238

Data Sheet

ABSOLUTE MAXIMUM RATINGS

Table 4.

Parameter

Rating

VIN, GATE

CC1, CC2

D+, D−

VSET, ISET, SDA, SCL

Operating Temperature Range (Junction)

Soldering Conditions

Electrostatic Discharge (ESD)

Human Body Mode (HBM)

−0.3V to +30V

−0.3V to +25V

−0.3V to +12V

−0.3V to +6V

−40°C to +125°C

JEDEC J-STD-020

±6000V

Stresses at or above those listed under Absolute Maximum Ratings may cause permanent damage to the product.

This is a stress rating only; functional operation of the product at these or any other conditions above those indicated

in the operational section of this specification is not implied. Operation beyond the maximum operating conditions for

extended periods may affect product reliability.

THERMAL RESISTANCE

Thermal performance is directly linked to printed circuit board (PCB) design and operating environment. Close

attention to PCB thermal design is required.

θJA is the natural convection junction to ambient thermal resistance measured in a one cubic foot sealed enclosure.

θJC is the junction to case thermal resistance.

Table 5. Thermal Resistance

Package Type

DFN-10L

SOT33-6L

θJA

θJC

Unit

75

89

54

27

°C/W

°C/W

ESD CAUTION

Electrostatic Discharge Sensitive Device.

Charged devices and circuit boards can discharge without detection. Although this product features patented

or proprietary protection circuitry, damage may occur on devices subjected to high energy ESD. Therefore,

proper ESD precautions should be taken to avoid performance degradation or loss of functionality.

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 6 of 15

�Data Sheet

HUSB238

FUNCTIONAL BLOCK DIAGRAM

GATE

DRIVER

VIN

RDIS

POR

CIRCUIT

VOLTAGE

REGULATOR

D+

D-

CC1

CC2

OV & UV

PROTECTION

IVSET

VREG

GND

VSET

ISET

APPLE MODE

BC1.2

DETECTION

USB PD

PHYSICAL

LAYER

GATE

PORT

CONTROLLER

USB PD

PROTOCAL

LAYER

IISET

SDA

OTP

I2C ENGINE

SCL

Figure 3. HUSB238 Functional Block Diagram

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 7 of 15

�HUSB238

Data Sheet

THEORY OF OPERATION

OVERVIEW

The HUSB238 is a highly integrated USB Power Delivery (PD) controller as sink role. It’s compatible with PD3.0 and

Type-C V1.4. It can also support Apple Divider 3, BC1.2 SDP, DCP and CDP while source is attached. When

HUSB238 is connected to power source, it applies Rd to both CC lines, trying to establish USB Type-C connection.

After the USB Type-C connection is established, it monitors the CC lines to get source capabilities pack from USB PD

source. If there is valid source capabilities pack before time out, the HUSB238 policy engine requests a power supply

with voltage no greater than the programmed request voltage. If there is no valid source capabilities pack after time

out, the HUSB238 switches to Apple divider 3 or BC1.2 mode trying to determine corresponding charging protocol.

VIN PIN

VIN pin is the power supply input of the HUSB238, which is derived from the output of the PD source. Connect a 1µF

decoupling MLCC between VIN pin and GND pin as closer as possible.

The VIN pin is also connected to an internal MOSFET and 500Ohm discharging resistor, which is used as a bleeder to

help discharge the output capacitor to vSafe5V upon the hard reset, over-voltage fault, over-temperature fault or

detachment of a connected device.

GATE PIN

The GATE pin is open–drain output which allows to drive an external PMOS load switch directly. The GATE pin can be

programmed to turn on after POR or after the explicit contract. The default option is to turn on after POR. Please

contact local Hynetek sales for a device with options other than the default option.

CC1 AND CC2 PINS

CC1 and CC2 are the Configuration Channel pins used for connection and attachment detection, plug orientation

determination and system configuration management across USB Type-C cable. CC1 and CC2 pins can support as

high as 25V voltage, which is used for protection when CC1 or CC2 is shorted to VBUS pin on the connector.

Through the Type-C detection, one of the CC pin is connected to the internal BMC block to achieve PD

communication.

VSET PIN

A fixed 100μA current source is applied on VSET pin. Connect a resister between VSET and GND to indicate the

VSET_VOLTAGE value as shown in Table 6.

Table 6. VSET_VOLTAGE Setting

RVSET (kΩ)

VSET_VOLTAGE (V)

0

6.04

10

14

17.8

Open

5

9

12

15

18

20

The RDO voltage of the HUSB238 is determined by the lower value between VSET_VOLTAGE and

SNK_PDO2_VOLTAGE. SNK_PDO2_VOLTAGE is programmable by internal fuse options and the default value is

20V. The requested voltage value can be changed dynamically with the resistance value change.

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 8 of 15

�Data Sheet

HUSB238

ISET PIN

A fixed 100μA current source is applied on ISET pin. Connect a resister between ISET and GND to indicate the

ISET_CURRENT value as shown in Table 7.

Table 7. ISET_CURRENT Setting

RISET (kΩ)

ISET_CURERNT (A)

0

4.53

7.5

10.5

13.7

16.5

19.6

22.6

Open

1.25

1.5

1.75

2

2.25

2.5

2.75

3

3.25

The RDO current of the HUSB238 is determined by the lower value between ISET_CURRENT and

SNK_PDO2_CURRENT. SNK_PDO2_CURRENT is programmable by internal fuse options and the default value is

3.25A. The requested current value can be changed dynamically with the resistance value change.

RDO DETERMINATION

There are two ways to determine the RDO that the HUSB238 requests from the PD source. Set by the VSET and

ISET pins or set by the internal factory programmed fuse options. The HUSB238 compares the two values and uses

the lower value as its RDO.

For example, if the VSET and ISET is configured as 9V / 3A. The internal factory fuse option is 12V / 2A. Then the

RDO that HUSB238 requests from the PD source is 9V / 2A.

After the RDO is determined, the HUSB238 loops through the PD source PDOs from highest voltage first to find the

first PDO that satisfies the following conditions:

1. SOURCE_PDO_VOLTAGE ≤ RDO_VOLTAGE

2. SOURCE_PDO_CURRENT ≥ RDO_CURRENT

If both the conditions above are satisfied, then HUSB238 sends a request for this source PDO with operating current

set to the RDO current value.

If either one of the condition is not satisfied, the HUSB238 continues to compare with the second highest voltage

source PDO or requests 5V source PDO directly, depending on the internal fuse options. The default fuse option is to

continue to compare with the second highest voltage source PDO. Please contact local Hynetek sales for a device

with options other than the default option.

OPERATION WITH I2C INTERFACE

The HUSB238 is I2C communication capable with system MCU or processor through SDA and SCL pins. The

HUSB238 works as I2C slave role and the I2C address is 0x08.

After POR (Power On Reset), the HUSB238 receives the source capability information from the PD source adapter

and the HUSB238 saves the source capability information in registers. The system MCU can visit the HUSB238

registers through the I2C bus and select a proper PDO to request from external PD source.

The I2C has the highest priority. If using I2C to select a source PDO, it over writes the internal RDO which is created

by VSET, ISET pins and internal factory fuse option, and the HUSB238 requests the I2C selected source PDO once

the I2C commands are written.

LEGACY CHARGER DETECTION

After the power on reset, if the HUSB238 does not establish PD contract with source adapter, the HUSB238 will waits

for 1.5 seconds and then switches to Apple Divider 3 and BC1.2 detections sequentially. For BC1.2 detection, the

HUSB238 detects SDP (Standard Data Port), CDP (Charging Data Port) and DCP (Dedicated Charging Port)

sequentially.

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 9 of 15

�HUSB238

Data Sheet

DEAD BATTERY FUNCTION

The HUSB238 works as PD sink role which requires RD resistor to be presented on the CC pins even in the unpowered state for successful Type-C detection by source adapter.

The dead battery function in the HUSB238 supports default USB, 1.5A and 3.0A source broadcast RP current.

SOP’ FUNCTION

For the USB-C to legacy PC plug applications where high current and high voltage are required, the system needs

current more than 3A in most of the cases. If the SOP’ function is enabled, the HUSB238 is capable to reply SOP’

command, such as Discover Identity, sent by the PD source adapter.

The SOP’ function emulates the E-Marker function in the cable so that the system is capable of obtaining more than

3A charging current from PD source adapter.

OVER-VOLTAGE PROTECTION

The HUSB238 senses the voltage on VIN pin for overvoltage protection. The over-voltage threshold is 1.2 times of

max requested voltage. The OV debounce time is 50μs.

When OV happens, the HUSB238 turns off the external PMOS and enters into discharge mode where the internal

discharge circuit on VIN pin is turned on. The internal 5.1k Rd resistor is also disconnected during discharge mode.

After the discharge timeout, the HUSB238 enters into unattached mode and waits for re-connection with PD source

adapter.

UNDER-VOLTAGE PROTECTION

The HUSB238 senses the voltage on VIN pin for optional under-voltage protection. The under-voltage threshold is the

requested voltage minus 2V. For example, if the requested PDO voltage is 12V, then the UV threshold is 10V. The UV

debounce time is 1ms.

When UV happens, the HUSB238 turns off the external PMOS and enters into discharge mode where the internal

discharge circuit on VIN pin is turned on. The internal 5.1k Rd resistor is also disconnected during discharge mode.

After the discharge timeout, the HUSB238 enters into unattached mode and waits for re-connection with PD source

adapter.

The UVP function of the HUSB238 can be enabled or disabled by internal fuse options. The UVP function is disabled

for default option. Please contact local Hynetek sales for a device with options other than the default option.

OVER-TEMPERATURE PROTECTION

The HUSB238 integrates over-temperature protection function. It monitors the internal junction temperature. When the

junction temperature reaches the over temperature rising threshold, the HUSB238 requests 5V source PDO directly,

regardless of the previous established PDO, to reduce the total system power. When the junction temperature falls

below the over temperature falling threshold, the HUSB238 re-negotiates the previous PDO and tries to recover the

normal charging operation.

The over temperature thresholds are programmable by internal factory fuses. Please contact local Hynetek sales for a

device with options other than the default option.

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 10 of 15

�Data Sheet

HUSB238

TYPICAL APPLICATION CIRCUITS

BATTERY

VBUS

DC-DC Reg

Or Charger

49.9kΩ

+

USB-C RECEPTACLE

5.1kΩ

VIN

GATE

HUSB238

DFN-10

1μF

CC1

CC1

CC2

CC2

D+

D+

D-

D-

SCL

SOC

SDA

VSET

ISET

GND

GND

Figure 4. USB-C Device Application

VBUS

VIN

HUSB238

SOT33-6

1μF

CC1

CC1

CC2

CC2

VSET

ISET

GND

LEGACY CHARGING

CONNECTOR

USB-C CONNECTOR

VIN

1kΩ

GND

GND

Figure 5. USB-C Cable Application

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 11 of 15

�HUSB238

Data Sheet

PACKAGE OUTLINE DIMENSIONS

Figure 6. DFN-10L Package, 3 mm × 3 mm

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 12 of 15

�Data Sheet

HUSB238

Figure 7. SOT33-6L Package, 3.9 mm x 4.0 mm

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 13 of 15

�HUSB238

Data Sheet

ORDERING GUIDE

Model

Package

SOP’

OTP Threshold

RDO Mismatch Action

Package Option

HUSB238_001DD

HUSB238_002DD

HUSB238_002SH

HUSB238_003DD

HUSB238_003SH

HUSB238_004DD

DFN-10L

DFN-10L

SOT33-6L

DFN-10L

SOT33-6L

DFN-10L

YES

NO

NO

YES

YES

NO

90°C / 75°C

150°C / 130°C

150°C / 130°C

90°C / 75°C

90°C / 75°C

150°C / 130°C

Request 5V

Next PDO

Next PDO

Next PDO

Next PDO

Request 5V

Tape & Reel, 4k

Tape & Reel, 4k

Tape & Reel, 7.5k

Tape & Reel, 4k

Tape & Reel, 7.5k

Tape & Reel, 4k

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 14 of 15

�Data Sheet

HUSB238

IMPORTANT NOTICE

Hynetek Semiconductor Co., Ltd. and its subsidiaries (Hynetek) reserve the right to make corrections, enhancements,

improvements and other changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any

product or service per JESD48, latest issue. Buyers should obtain the latest relevant information before placing orders and should

verify that such information is current and complete. All semiconductor products (also referred to herein as “components”) are sold

subject to Hynetek’s terms and conditions of sale supplied at the time of order acknowledgment.

Hynetek warrants performance of its components to the specifications applicable at the time of sale, in accordance with the

warranty in Hynetek’s terms and conditions of sale of semiconductor products. Testing and other quality control techniques are

used to the extent Hynetek deems necessary to support this warranty. Except where mandated by applicable law, testing of all

parameters of each component is not necessarily performed.

Hynetek assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their

products and applications using Hynetek components. To minimize the risks associated with Buyers’ products and applications,

Buyers should provide adequate design and operating safeguards.

Hynetek does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright,

mask work right, or other intellectual property right relating to any combination, machine, or process in which Hynetek components

or services are used. Information published by Hynetek regarding third-party products or services does not constitute a license to

use such products or services or a warranty or endorsement thereof. Use of such information may require a license from a third

party under the patents or other intellectual property of the third party, or a license from Hynetek under the patents or other

intellectual property of Hynetek.

Reproduction of significant portions of Hynetek information in Hynetek data books or data sheets is permissible only if reproduction

is without alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Hynetek is not

responsible or liable for such altered documentation. Information of third parties may be subject to additional restrictions.

Resale of Hynetek components or services with statements different from or beyond the parameters stated by Hynetek for that

component or service voids all express and any implied warranties for the associated Hynetek component or service and is an

unfair and deceptive business practice.

Hynetek is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related

requirements concerning its products, and any use of Hynetek components in its applications, notwithstanding any applicationsrelated information or support that may be provided by Hynetek. Buyer represents and agrees that it has all the necessary

expertise to create and implement safeguards which anticipate dangerous consequences of failures, monitor failures and their

consequences, lessen the likelihood of failures that might cause harm and take appropriate remedial actions. Buyer will fully

indemnify Hynetek and its representatives against any damages arising out of the use of any Hynetek components in safety-critical

applications.

In some cases, Hynetek components may be promoted specifically to facilitate safety-related applications. With such components,

Hynetek’s goal is to help enable customers to design and create their own end-product solutions that meet applicable functional

safety standards and requirements. Nonetheless, such components are subject to these terms.

No Hynetek components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized

officers of the parties have executed a special agreement specifically governing such use.

Only those Hynetek components which Hynetek has specifically designated as military grade or “enhanced plastic” are designed

and intended for use in military/aerospace applications or environments. Buyer acknowledges and agrees that any military or

aerospace use of Hynetek components which have not been so designated is solely at the Buyer's risk, and that Buyer is solely

responsible for compliance with all legal and regulatory requirements in connection with such use.

Hynetek has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any

case of use of non-designated products, Hynetek will not be responsible for any failure to meet ISO/TS16949.

Please refer to below URL for other products and solutions of Hynetek Semiconductor Co., Ltd.

©2021 Hynetek Semiconductor Co., Ltd. All rights reserved.

Trademarks and registered trademarks are the property of their respective owners.

www.hynetek.com

©2021-2022 Hynetek Semiconductor Co., Ltd. All rights reserved.

Page 15 of 15

�