SLG59M1713V

An Ultra-small, 4 mΩ, 2 A

Integrated Power Switch with Multiple Protection Features

General Description

Pin Configuration

Operating from a 2.5 V to 5.5 V power supply and fully

specified over the -40 °C to 85 °C temperature range, the

SLG59M1713V is a high-performance 4 mΩ, 2 A

single-channel nFET integrated power switch with adjustable

inrush current control which is achieved by adjusting the VOUT

slew rate with an external capacitor. Using a proprietary

MOSFET design, the SLG59M1713V achieves a stable 4 mΩ

RDSON across a wide input/supply voltage range.

Incorporating two-stage current protection as well as thermal

protection, the SLG59M1713V is designed for all 0.8 V to 5.5V

power rail applications. Using Silego’s proprietary CuFET™

technology for high-current operation, the SLG59M1713V is

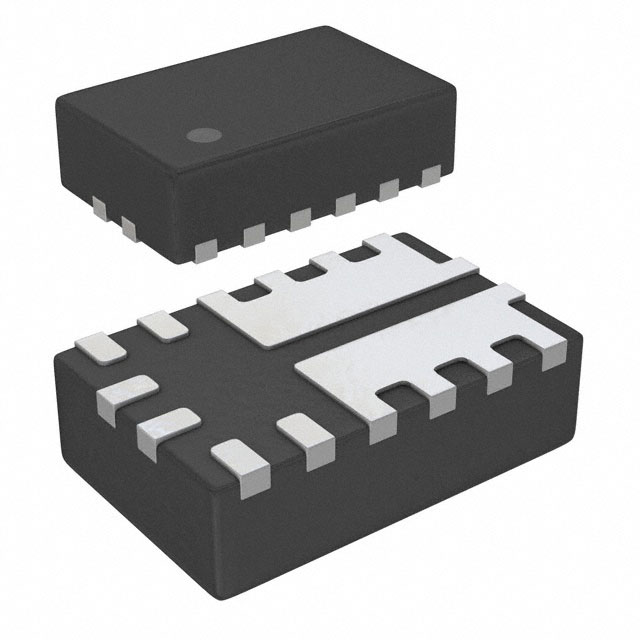

packaged in a space-efficient, low thermal resistance,

RoHS-compliant 1.6 mm x 2.5 mm STQFN package

ON

1

NC

2

VIN

3

VIN

4

VIN

5

VIN

6

16

15

SLG59M1713V

VDD

GND

7

VIN

14

CAP

13

NC

8

12

VOUT

11

VOUT

10

VOUT

9

VOUT

VOUT

16-pin FC-STQFN

(Top View)

Features

•

•

•

•

•

•

Low Typical RDSON nFET: 4 mΩ

Maximum Continuous Switch Current: Up to 2 A

Supply Voltage: 2.5 V ≤ VDD ≤ 5.5 V

Wide Input Voltage Range: 0.8 V ≤ VIN ≤ VDD

Capacitor-adjustable Start-up and Inrush Current Control

Two-stage Overcurrent Protection:

• Fixed threshold, 4 A Active Current Limit

• Fixed 0.5 A Short-circuit Current Limit

• Internal VOUT Discharge

• Operating Temperature: -40 °C to 85 °C

• Low θJA, 16-pin 1.6 mm x 2.5 mm STQFN Packaging

• Pb-Free / Halogen-Free / RoHS compliant

Applications

• Notebook Power Rail Switching

• Tablet Power Rail Switching

• Smartphone Power Rail Switching

Block Diagram

2 A @ 4 mΩ

VOUT

VIN

CIN

+2.5 to 5.5 V

CLOAD

VDD

Charge

Pump

Linear Ramp

Control

CAP

CSLEW

4 nF

Over Current and

Over Temperature

Protection

SW Closed

ON

CMOS Input

SW Open

GND

Silego Technology, Inc.

000-0059M1713-100

Rev 1.00

Revised February 23, 2017

�SLG59M1713V

Pin Description

Pin #

Pin Name

Type

Pin Description

1

VDD

Power

With an internal 1.9 V UVLO threshold, VDD supplies the power for the operation of the

power switch and internal control circuitry where its range is 2.5 V ≤ VDD ≤ 5.5 V. Bypass

the VDD pin to GND with a 0.1 μF (or larger) capacitor

2

NC

NC

3-7

VIN

MOSFET

Drain terminal of Power MOSFET (Pins 3-7 fused together). Connect a 10 μF (or larger)

low ESR capacitor from this pin to GND. Capacitors used at VIN should be rated at 10 V

or higher.

8-12

VOUT

MOSFET

Source terminal of Power MOSFET (Pins 8-12 fused together) Connect a low ESR

capacitor (up to 500 μF) from this pin to GND. Capacitors used at VOUT should be rated

at 10 V or higher.

13

NC

NC

14

CAP

Input

A low-ESR, stable dielectric, ceramic surface-mount capacitor connected from CAP pin to

GND sets the VOUT slew rate and overall turn-on time of the SLG59M1713V. For best

performance, the range for CSLEW values are 2 nF ≤ CSLEW ≤ 22 nF. Capacitors used at

the CAP pin should be rated at 10 V or higher.

15

GND

GND

Ground

Input

A low-to-high transition on this pin closes the power switch. ON is an asserted-HIGH,

level-sensitive CMOS input with VIL < 0.3 V and VIH > 0.85 V. Connect this pin to the output

of a general-purpose output (GPO) from a microcontroller or other application processor.

While there is an internal pull down circuit to ground (~4 MΩ), do not allow this pin to be

open-circuited.

16

ON

No Connect

No Connect

Ordering Information

Part Number

Type

Production Flow

SLG59M1713V

STQFN 16L

Industrial, -40 °C to 85 °C

SLG59M1713VTR

STQFN 16L (Tape and Reel)

Industrial, -40 °C to 85 °C

000-0059M1713-100

Page 2 of 18

�SLG59M1713V

Absolute Maximum Ratings

Parameter

VDD

VIN to GND

VOUT to GND

ON, CAP to

GND

TS

Description

Conditions

Min.

Typ.

Max.

Unit

--

--

6

V

Power Switch Input Voltage to

GND

-0.3

--

6

V

Power Switch Output Voltage to

GND

-0.3

--

VIN

V

ON and CAP Pin Voltages to GND

-0.3

--

6

V

Power Supply Pin to GND

-65

--

150

°C

ESDHBM

ESD Protection

Human Body Model

2000

--

--

V

ESDCDM

ESD Protection

Charged Device Model

500

--

--

V

MSL

θJA

WDIS

IDSMAX

Storage Temperature

Moisture Sensitivity Level

Package Thermal Resistance,

Junction-to-Ambient

1

1.6 x 2.5 mm 16L STQFN; Determined using 1 in2, 1.2 oz. copper pads under each

VIN and VOUT on FR4 pcb material

--

35

--

°C/W

Package Power Dissipation

--

--

1.2

W

Max Continuous Switch Current

--

--

2

A

--

--

3

A

MOSFET IDSPK Peak Current from Drain to Source

Maximum pulsed switch current, pulse

width < 1 ms, 1% duty cycle

Note: Stresses greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress rating

only and functional operation of the device at these or any other conditions above those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect reliability.

Electrical Characteristics

TA = -40 °C to 85 °C (unless otherwise stated)

Parameter

VDD

VDD(UVLO)

IDD

RDSON

Description

Conditions

Power Supply Voltage

Min.

Typ.

Max.

Unit

2.5

--

5.5

V

VDD Undervoltage Lockout

Threshold

VDD ↑

1.6

1.9

2.2

V

VDD ↓

1.5

1.8

2.2

V

Power Supply Current when OFF

VDD = VIN = 5.5 V; ON = 0

--

1

2

μA

Power Supply Current,

ON (Steady State)

VDD = VIN = ON = 5.5 V; No Load

--

120

170

μA

VDD = VIN = 5 V;

TA 25°C MOSFET @100 mA

--

4

5.5

mΩ

5

6.8

mΩ

ON Resistance

VDD = VIN = 5 V;

TA 85°C MOSFET @100 mA

MOSFET

IDS

Current from VIN to VOUT

Continuous

--

--

2

A

IFET_OFF

MOSFET OFF Leakage Current

VDD = VIN = 5.5 V;

VOUT = 0 V; ON = 0 V

--

--

2

μA

0.8

--

VDD

V

VIN

ILIMIT

Drain Voltage

Active Current Limit, IACL

VOUT > 0.3 V

3

4

5

A

Short-circuit Current Limit, ISCL

VOUT < 0.3 V

--

0.5

--

A

000-0059M1713-100

Page 3 of 18

�SLG59M1713V

Electrical Characteristics (continued)

TA = -40 °C to 85 °C (unless otherwise stated)

Parameter

TON_Delay

VOUT(SR)

TTotal_ON

TOFF_Delay

CLOAD

Description

Conditions

ON pin Delay Time

50% ON to VOUT Ramp Start

VDD = VIN = 5 V; CSLEW = 4 nF;

RLOAD = 20 Ω, CLOAD = 10 μF

VOUT Slew Rate

Total Turn-on Time

Min.

Typ.

Max.

Unit

--

200

--

μs

10% VOUT to 90% VOUT ↑

Set by External CSLEW1

V/ms

Example: CSLEW = 4 nF;

VDD = VIN = 5 V; RLOAD = 20 Ω,

CLOAD = 10 μF

2.5

V/ms

50% ON to 90% VOUT ↑

Set by External CSLEW1

ms

Example: CSLEW = 4 nF;

VDD = VIN = 5 V; RLOAD = 20 Ω,

CLOAD = 10 μF

1.4

1.7

2

ms

2.9

3.5

OFF Delay Time

50% ON to VOUT Fall Start;

VDD = VIN = 5 V;

RLOAD = 20 Ω, no CLOAD

--

8

15

μs

Output Load Capacitance

CLOAD connected from VOUT to

GND

--

--

500

μF

RDISCHRG

Output Discharge Resistance

180

220

260

Ω

ON_VIH

High Input Voltage on ON pin

0.85

--

VDD

V

ON_VIL

Low Input Voltage on ON pin

-0.3

0

0.3

V

ION(LKG)

ON Pin Leakage Current

--

1.5

--

μA

Thermal shutoff turn-on temperature

--

125

--

°C

THERMOFF Thermal shutoff turn-off temperature

--

100

--

°C

THERMON

ON = ON_VIH or ON = GND

Notes:

1. Refer to typical Timing Parameter vs. CSLEW performance charts for additional information when available.

TON_Delay, Slew Rate, and TTotal_ON Timing Details

ON

50% ON

50% ON

TOFF_Delay

90% VOUT

VOUT

90% VOUT

TON_Delay

10% VOUT

10% VOUT

VOUT(SR) (V/ms)

TFALL

TTotal_ON

000-0059M1713-100

Page 4 of 18

�SLG59M1713V

Typical Performance Characteristics

RDSON vs. VDD and Temperature

RDSON vs. VIN and VDD

000-0059M1713-100

Page 5 of 18

�SLG59M1713V

VOUT Slew Rate vs. Temperature, VDD, VIN, and CSLEW

TTotal_ON vs. CSLEW, VIN, VDD, and Temperature

000-0059M1713-100

Page 6 of 18

�SLG59M1713V

Timing Diagram - Basic Operation including Active Current Limit Protection

HIGH

VDD

1.9 V

LOW

Time

VIN

ON

TTotal_ON

TRISE

HIGH

VOUT

90%

TON_Delay

0.25 V

IACL

10%

Abnormal Step Load

Current Event

IACL

Active Current Limit

Operation

IDS

ISCL

ISCL

FAULT

TFAULTLOW

ACL Threshold Triggered

000-0059M1713-100

TFAULTHIGH

Nominal Steady State

Operation Resumes

Page 7 of 18

�SLG59M1713V

Timing Diagram - Active Current Limit & Thermal Protection Operation

HIGH

VDD

1.9 V

LOW

Time

VIN

Nominal Steady State

Operation Resumes

ON

TTotal_ON

TRISE

VOUT

Active Current Limit

Operation

Thermal Protection

Operation

90%

TON_Delay

10%

IACL

Abnormal Step Load

Current Event

IACL

IDS

ISCL

ISCL

FAULT

TFAULTLOW

Die temp > THERMON

000-0059M1713-100

TFAULTHIGH

Die temp < THERMOFF

Page 8 of 18

�SLG59M1713V

SLG59M1713V Power-Up/Power-Down Sequence Considerations

To ensure glitch-free power-up under all conditions, apply VDD first, followed by VIN after VDD exceeds 1.9 V. Then allow VIN to

reach 90% of its max value before toggling the ON pin from Low-to-High. Likewise, power-down in reverse order.

If VDD and VIN need to be powered up simultaneously, glitching can be minimized by having a suitable load capacitor. A 10 μF

CLOAD will prevent glitches for rise times of VDD and VIN less than 2 ms.

If the ON pin is toggled HIGH before VDD and VIN have reached their steady-state values, the IPS timing parameters may differ

from datasheet specifications.

The slew rate of output VOUT follows a linear ramp set by a capacitor connected to the CAP pin. A larger capacitor value at the

CAP pin produces a slower ramp, reducing inrush current from capacitive loads.

SLG59M1713V Current Limiting Operation

The SLG59M1713V has two types of current limiting triggered by the output VOUT voltage.

1. Standard Current Limiting Mode (with Thermal Shutdown Protection)

When the VOUT voltage > 300 mV, the output current is initially limited to the Active Current Limit (IACL) specification listed in the

Electrical Characteristics table. The ACL monitor’s response time is very fast and is triggered within a few microseconds to sudden

(transient) changes in load current. When a load current overload is detected, the ACL monitor increases the FET resistance to

keep the current from exceeding the power switch’s IACL threshold. During active current-limit operation, VOUT is also reduced

by IACL x RDSONACL. This observed behavior is illustrated in the timing diagrams on Pages 7 and 8.

However, if a load-current overload condition persists where the die temperature rises because of the increased FET resistance,

the power switch’s internal Thermal Shutdown Protection circuit can be activated. If the die temperature exceeds the listed

THERMON specification, the FET is shut OFF completely, thereby allowing the die to cool. When the die cools to the listed

THERMOFF temperature threshold, the FET is allowed to turn back on. This process may repeat as long as the output current

overload condition persists.

2. Short Circuit Current Limiting Mode (with Thermal Shutdown Protection)

When the VOUT voltage < 300 mV (which is the case with a hard short, such as a solder bridge on the power rail), the power

switch’s internal Short-circuit Current Limit (SCL) monitor limits the FET current to approximately 500 mA (the ISCL threshold).

While the internal Thermal Shutdown Protection circuit remains enabled and since the ISCL threshold is much lower than the IACL

threshold, thermal shutdown protection may become activated only at higher ambient temperatures.

SLG59M1713V Start-up Inrush Current Considerations with Capacitive Loads

In distributed power applications, the SLG59M1713V is generally implemented on the outboard or downstream side of switching

regulator dc/dc converters with internal overcurrent protection. As an adjustable output voltage slew-rate, integrated power switch,

it is important to understand the start-up operation of the SLG59M1713V with capacitive loads. An equivalent circuit of the

SLG59M1713V’s slew-rate control loop with capacitors at its VIN and VOUT pins is shown in Figure 1:

000-0059M1713-100

Page 9 of 18

�SLG59M1713V

SLG59M1713V Start-up Inrush Current Considerations with Capacitive Loads (continued)

CSLEW

Figure 1. SLG59M1713V’s Equivalent Slew-rate Control Loop Circuit.

For a desired VOUT slew-rate (VOUT(SR)), a corresponding CSLEW value is selected. At the VOUT pin and with ON = LOW, the

internal FET is OFF, VOUT is initially at 0V, and there is no stored charge on CLOAD. When a low-to-high transition is applied to

the IC’s ON pin, an internal current source (I1) is enabled which, in turn, charges the external slew-rate capacitor, CSLEW. The

SLG59M1713V’s internal micropower op amp sets the circuit’s VOUT(SR) based on the slew rate of the nodal voltage at its

non-inverting pin (the voltage at the CAP pin).

As a function of VOUT(SR) and CLOAD, a 1st-order expression for the circuit’s FET current (and inrush current) when a low-to-high

transition on the ON pin is applied becomes:

Start-up Current IDS or IINRUSH = VOUT(SR) x CLOAD

From the expression above and for a given VOUT(SR), CLOAD determines the magnitude of the inrush current; that is, for large

values of CLOAD, large inrush currents can result. If the inrush currents are large enough to trigger the overcurrent protection of

an upstream dc/dc converter, the system can be shut down.

In applications where the desired VOUT(SR) is fast and CLOAD is very large (>200 µF), there is a secondary effect on the observed

VOUT(SR) attributed to the SLG59M1713V’s internal short-circuit current limit monitor (its SCL monitor). If the resultant inrush

current is larger than the IC’s ISCL threshold, the SCL current monitor limits the inrush current and the current to charge CLOAD

until the ISCL OFF threshold is crossed (~0.3V). During the time the SCL monitor’s been activated, the inrush current profile may

exhibit an observable reduction in VOUT(SR) as shown in Figure 2 where CSLEW was set to 4nF and 470 µF was chosen for CLOAD.

000-0059M1713-100

Page 10 of 18

�SLG59M1713V

SLG59M1713V Start-up Inrush Current Considerations with Capacitive Loads (continued)

Figure 2. A SLG59M1713V with CSLEW set to 4nF and 470µF for CLOAD. CLOAD-to-CSLEW

ratio is greater than 33,600. Note that the internal SCL monitor’s been triggered and VOUT(SR) is reduced until VOUT reaches ~0.3V.

A closer analysis of the IC’s internal slew-control large-scale yields the following:

ISCL

I1

= MSR x

CLOAD

CSLEW

where

ISCL = IC’s short-circuit current limit threshold, typically 0.5A;

MSR = An internal slew-rate multiplier from the IC’s CAP pin to the VOUT pin;

I1 = An internal current source to charge the external capacitor (CSLEW).

Rearranging the equation to isolate both CLOAD and CSLEW yields the following:

CLOAD

ISCL

= I xM

CSLEW

1

SR

For the SLG59M1713V device, the right-hand side of the expression is approximately 33,600 after taking into account part-to-part

variations because of process, voltage, and temperature.

Referring to the configuration of Figure 2’s scope capture, the CLOAD-to-CSLEW ratio is 117,500 (470µF/4nF) where it is evident

that the SCL monitor circuit is charging CLOAD shortly after a low-to-high ON transition. If it is desired to avoid a reduction in

VOUT(SR), the choices are decreasing CLOAD and/or increasing CSLEW so that the ratio is always less than 33,600 including taking

into account external capacitor tolerances for initial accuracy and temperature.

As shown in Figure 3, it was chosen to reduce VOUT(SR) by increasing CSLEW to 15nF while keeping CLOAD at 470µF. With this

configuration, the ratio of CLOAD to CSLEW is about 31,333 (smaller than 33,600). Upon a low-to-high transition on the ON pin,

the VOUT increases smoothly with no evidence of SCL monitor’s interaction.

000-0059M1713-100

Page 11 of 18

�SLG59M1713V

SLG59M1713V Start-up Inrush Current Considerations with Capacitive Loads (continued)

Figure 3. A SLG59M1713V with CSLEW set to 15nF and 470µF retained for CLOAD.

CLOAD-to-CSLEW ratio is smaller than 33,600. Note smooth VOUT transition.

Power Dissipation

The junction temperature of the SLG59M1713V depends on different factors such as board layout, ambient temperature, and

other environmental factors. The primary contributor to the increase in the junction temperature of the SLG59M1713V is the power

dissipation of its power MOSFET. Its power dissipation and the junction temperature in nominal operating mode can be calculated

using the following equations:

PD = RDSON x IDS2

where:

PD = Power dissipation, in Watts (W)

RDSON = Power MOSFET ON resistance, in Ohms (Ω)

IDS = Output current, in Amps (A)

and

TJ = PD x θJA + TA

where:

TJ = Junction temperature, in Celsius degrees (°C)

θJA = Package thermal resistance, in Celsius degrees per Watt (°C/W)

TA = Ambient temperature, in Celsius degrees (°C)

000-0059M1713-100

Page 12 of 18

�SLG59M1713V

Power Dissipation (continued)

During active current-limit operation, the SLG59M1713V’s power dissipation can be calculated by taking into account the voltage

drop across the power switch (VIN-VOUT) and the magnitude of the output current in active current-limit operation (IACL):

PD = (VIN-VOUT) x IACL or

PD = (VIN – (RLOAD x IACL)) x IACL

where:

PD = Power dissipation, in Watts (W)

VIN = Input Voltage, in Volts (V)

RLOAD = Load Resistance, in Ohms (Ω)

IACL = Output limited current, in Amps (A)

VOUT = RLOAD x IACL

For more information on Silego GreenFET3 integrated power switch features, please visit our Application Notes page at our

website and see App Note “AN-1068 GreenFET3 Integrated Power Switch Basics”.

000-0059M1713-100

Page 13 of 18

�SLG59M1713V

Package Top Marking System Definition

Pin 1 Identifier

PPPPP

WWNNN

ARR

Part Code

Date Code + LOT Code

Assembly + Rev. Code

PPPPP - Part ID Field

WW - Date Code Field1

NNN - Lot Traceability Code Field1

A - Assembly Site Code Field 2

RR - Part Revision Code Field2

Note 1: Each character in code field can be alphanumeric A-Z and 0-9

Note 2: Character in code field can be alphabetic A-Z

000-0059M1713-100

Page 14 of 18

�SLG59M1713V

Package Drawing and Dimensions

16 Lead STQFN Package 1.6 mm x 2.5 mm (Fused Lead)

000-0059M1713-100

Page 15 of 18

�SLG59M1713V

SLG59M1713V 16-pin STQFN PCB Landing Pattern

000-0059M1713-100

Page 16 of 18

�SLG59M1713V

Tape and Reel Specifications

Max Units

Leader (min)

Nominal

Reel &

Package # of

Package Size

Hub Size

Length

Type

Pins

per Reel per Box

Pockets

[mm]

[mm]

[mm]

STQFN

16L

1.6x2.5mm

0.4P FCA

Green

1.6x2.5x

0.55mm

16

3000

3000

178/60

100

400

Trailer (min)

Pockets

Length

[mm]

Tape

Width

[mm]

100

400

8

Part

Pitch

[mm]

4

Carrier Tape Drawing and Dimensions

Package

Type

STQFN 16L

1.6x2.5mm

0.4P FCA

Green

D0

Pocket BTM Pocket BTM

Length

Width

Pocket

Depth

Index Hole

Pitch

Pocket

Pitch

Index Hole

Diameter

Index Hole Index Hole

to Tape

to Pocket Tape Width

Edge

Center

A0

B0

K0

P0

P1

D0

E

F

W

1.8

2.8

0.7

4

4

1.55

1.75

3.5

8

P0

Y

E

W

F

Section Y-Y

Y

P1

A0

B0

CL

K0

Refer to EIA-481 specification

Recommended Reflow Soldering Profile

Please see IPC/JEDEC J-STD-020: latest revision for reflow profile based on package volume of 2.2 mm3 (nominal). More

information can be found at www.jedec.org.

000-0059M1713-100

Page 17 of 18

�SLG59M1713V

Revision History

Date

Version

2/23/2017

1.00

000-0059M1713-100

Change

Production Release

Page 18 of 18

�