A-CT81-3KV-08e-2E4-222M-2T3 数据手册

CZX/JL107A0

NO:TH-22595

汽车用承认申请书

APPLICATION FOR APPROVAL

产品符合欧盟 RoHS 环保要求

CUSTOMER:

华秋

PART NAME:

汽车用瓷介电容器

CODE N0.:

A-CT81-3KV-**e-2*4-****-2T3

DRAUGHT BY:

胡桂云

CHECKED BY:

秦建国

APPROVERED BY:

刘祥峰

DATE:

Sep. 30,2022

APPROVAL

厂商

沂南同皓电子元件有限公司

中国·山东沂南县城花山路

电话(TEL):

传真:(FAX):

邮编:(P.C.):

网址:(WEB SITE)

电邮(E-Mail):

FIELD

Mfr.

YINAN DON'S ELECTRONIC COMPONENT CO.,LTD

HUASHAN ROAD,YINAN COUNTY,SHANDONG,CHINA

0086-539-3255539 3330887

0086-539-3221669

276300

http://www.sdtfly.com

tf_lxj@126.com

沂南同皓电子元件有限公司

YINAN

DON’S

ELECTRONIC

COMPONENT CO▪, LTD▪

�变

更

清

单

REVISION LIST

序号

变更内容

变更标记

NO.

DATE

CHANGE CONTENT

REMARK

1

2022-09-30

首次提供 First provides

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

日

期

�□承认书内容目录

序号

(NO)

规格书内容

Specification Content

所在页码

Page

1

规格书封面 Specification Cover

1

2

变更清单 Revision List

2

3

承认书内容目录 Specification Content

3

4

用途 Application

4

5

规格型号 Specification type

4

6

标记 Marking

4

7

引线形式 Lead Shape

5

8

结构 Structure

6

9

主要原材料 Main Material

6

10

测试条件 Test Condition

6

11

容量-温度变化曲线 Cap.─Temp. Curve

7

12

焊接曲线及参数 Welding curves and parameters

7

13

型号命名方法 Part Code Designation

8

14

包装 packing

9

15

规格及试验方法 Specification and Test Method

10-13

瓷 介 电 容 器 使 用 注 意 事 项 Ceramic capacitor use matters

needing attention

14-16

备注

Remark

�瓷介电容器

Ceramic Capacitors

□用途 Application

1.用作 PHEV/EV 交流线路滤波器以及初级-次级耦合蓄电池充电器的 Y 等级电容器。Used as PHEV / EV AC line filter and

a Class Y capacitor of the primary secondary coupled battery charger.

2.用作 PHEV/EV 和 HEV 直流-直流变换器用滤波电容器。Used as filter capacitor for PHEV / EV and HEV DC-DC converter.

3.符合 AEC-Q200 标准

Comply with AEC-Q200 standard.

□规格及尺寸(Specification and dimension)

品

CODE

编码

CODE

名

NO.

Dmax(mm)

Tmax(mm)

F(mm)

d(mm)

A-CT81-3KV-10e-2B4-102K-2T3

10.0

5.0

7.5

0.55

A-CT81-3KV-08e-2E4-222M-2T3

8.5

5.0

7.5

0.55

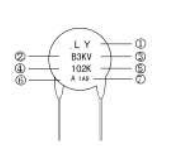

□标记 (Marking)

示例(Example)

项 目( Item )

①.LY

LY:公司代号;LY:Manufacturer's Code;

②B

温度特性

Temperature Characteristic

③3KV

额定电压

Rated Voltage

④102

标称容量

Rated Capacitance

⑤K

容量偏差

Tolerance of Capacitance

⑥A

汽车专用标记(Special mark for automobile)

⑦1A9

生产日期

Production Date

说明:生产日期第一位表示制作年度,标示方法参照年度对照表;第二位表示制作月份,第三位表示具体制作日期,标示方

法参照 34 进制对比表;例如:生产日期 1A9 表示:1:2021 年 A:10 月,9:9 日

(Production date first said the annual, marking methods according to annual comparison table; second said

production month, third said the specific production date marking method of comparison, table 34 hexadecimal;

Example:Production date 1A9 show: 1:2021year A: october

9: the 9 day ):

年度对比表:

年

度

年代码

年

度

2021

2022

2023

2024

2025

2026

2027

1

2

3

4

5

6

7

2028

2029

2030

2031

2032

8

9

0

1

2

以此类推

年代码

34 进制对比表:

34 进制

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

H

10 进制

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

34 进制

J

K

L

M

N

P

Q

R

S

T

V

W

X

Y

Z

10 进制

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

�□编带资料

●e 式(引线间距 F =7.5mm ,孔间距 P0=15.0mm ,产品间距 P=15.0mm)

Type e(lead spacing F=7.5mm ,Hole spacing P0=15.0mm,Product spacing P=15.0mm)

)

项目 Item

代号 Code

e type, Dimensions(mm)

引线线径 Lead diameter

d

0.55±0.055

产品间距 Pitch of component

P

15.0±1.0

传送孔间距 Pitch of sprocket hole

P0

15.0±0.3

传送孔位置偏差

Position of sprocket hole

P1

3.75±0.7

P2

7.5±1.3

引线间距 Lead spacing

F

7.5±1.0

产品倾倒 Deviation across tape

Δh

纸带宽度 Carrier tape width

W

18.0±0.5

胶带宽度 Hold-down tape width

W0

6.0min

传送孔位置偏差 Position of sprocket hole

W1

9.0±0.5

胶带偏差 Hold-down tape distortion

W2

1.5±1.5

引线弯处到传送孔中心

Lead distance between reference

And kink lead

H0

16.0-0.5/+2.0

传送孔孔径 Diameter of sprocket hole

D0

4.0±0.2

不良切断位置 Portion to cut

L

11.0+0/-1.0

包封料垂延 Coating extension on lead

e

t1

纸带厚度 thickness of tape

引线弹性弯曲 Lead flexible blend

t2

ΔS

0±2.0max

不过弯中央 No over the center of crim

0.5±0.3

1.5max

0±2.0

�□结构(Structure)

包封层(Coating) :

环氧树脂(Epoxy Resin)

介 质(Dielectric):

陶

瓷 (Ceramic)

电 极(Electrode :

银

(Silver)

焊 料(Solder)

锡(Alloy Tin)

:

引 线(Lead Wire) :

镀锡引出线(Lead)

□主要材料(Main Material)

序号

材料名称

制造商名称

规格

1

介质

Ceramic core

沂南同皓电子元件有限公司

YINAN DON’S ELECTRONIC COMPENENT CO.,LTD

CT81 DC

2

电极

Silver paste

广东羚光新材料股份有限公司

GUANGDONG LINGGUANG NEW MATERIAL CO., LTD.

SP-YD58

SP-YD60

3

无卤包封料

HALOGEN FREE EXPOXY POWDER

COATING

西安贝克电子材料有限公司

XI'AN BETTER ELECTRONIC MATERIALS CO., LTD.

天津凯华电子材料科技有限公司

TIANJIN KAIHUA ELECTRICS MATERIALS INC

4

镀锡线

Tin-plated copper weld

Steel wire

5

无铅焊料

Unleaded solder

马鞍山鑫冠电子材料有限公司

MA’ANSHAN XIN CROWN ELECTRONIC MATERIAL LIMITED COMPANY

芜湖云新电子科技有限公司

WUHU YUNXIN ELECTRONIC SCIENCE AND TECHNOLOGY CO.,LTD

南京达迈科技实业有限公司

Nanjing Damai Science & Technology Industry Co.,Ltd

天津百瑞杰焊接材料有限公司

TIANJIN BAIRUIJIE WELDING MATERIAL CO.,LTD

□测试条件(Test Condition)

温度(Temp.): 常规测试(Routine test)

:15~35℃,

有疑义时测试(Test in case of disagreement)

:20±2℃

相对湿度(R.H.):45~75%

电压(Vol.): 1.0±0.2Vrms

频率(Freq.): 1±0.2KHz

XCP-231

EF-150

0.50-0.60

97%Sn 2.5%Ag

0.5%Cu

�□容量─温度变化曲线 Cap.─Temp. Curve

2B4

2E4

□焊接曲线及参数(Welding curves and parameters)

手工焊

Hand-soldering

400±10℃

3-5s

波峰焊

Wave-soldering

260±5℃

3-5s

�□命名方法 Part Code Designation

A-CT81 - 3KV -10 e - 2B4 -102 K -2

①

②

③

④

⑤

⑥

⑦

①引线分类 Lead Wire classification

代码

Code

A

种类

Class

汽车专用标记

Special mark for automobile

②种类 Class

代码

Code

CT81

③额定电压 Rated Voltage

3KV

3000V.DC

最大外径

Max Diameter

of Body

08

8.5mm

10

10.0mm

代码

Code

额定电压

Rated Vol.

代码

Code

最大外径

Max Diameter

of Body

⑤引线形式 Lead Shape

代码

Code

e

⑥温度特性 Temperature Characteristic

代码

Code

容量变化

Cap. Change

2B4

-10~+10%

2E4

-56~+22%

静电容量

Capacitance

102

1000pF

222

2200pF

代码

Code

⑧容量允差 Tolerance

④主体外径 Body Diameter

代码

Code

⑩

代码

Code

Ⅱ类高压 Class Ⅱ High-Voltage

额定电压

Rated Vol.

⑨

⑦标称容量 Rated Capacitance

种类

Class

代码

Code

⑧

T3

形式

Shape

前后弯 Vertical crimp

代码

Code

容量允差

Tolerance

K

±10%

M

±20%

⑨引线间距 Lead spacing

代码

Code

间距

spacing

1

5.0mm

2

7.5mm

3

10.0mm

⑩包装方式

代 码

Code

T3

package Shape

形式

Shape

P0=15.0mm P=15.0mm

静电容量

Capacitance

�□编带包装(Taping Package packing)

1、包装数量(packing quantity)

:

引线间距

Lead spacing

F=7.5mm

P=P0=15.0mm

包装盒分类

Kinds of plastic box

成型方式

Molding mode

1#

e

包装数量

Quantity per bag

800~1000

备注

Remark

包装盒尺寸:

Size of plastic box

#

1 :336×240×45mm

#

2 :336×290×48mm

2、外包装方式(over-wrap packing shape)

:

800/1000 pcs in a inner box

Ten boxes in a carton

3、包装标识(packing marking)

:

最小包装标识(Minimum package label)

外包装箱标识(Taping Package Carton logo)

内包装箱(internal packing boxes)

(A1:360×200×140mm、A2:198×177×138mm)

外包装箱(over-wrap boxes)

(B1:460×380×220mm、B2:425×380×170mm)

装箱数量应为最小包装的整数倍。

(The packing quantity should be integral multiple of minimal

packaging. )

�□规格及试验方法 Specification and Test Method

项 目

规

格

ITEM

SPECIFICATION

1.存储温度范围

Storage Temp. Range

2.使用温度范围

Operating Temp. Range

3.外观尺寸

Appearance and

Dimension

试 验 方 法 及 条 件

TEST METHOD AND CONDITION

-55℃~+125℃

-40℃~+125℃

外观用目视法观测

尺寸用游标卡尺测量

Appearance be watched on sight

Dimension be measured by caliper

6.损耗因数

Dissipation Factor

外观无可见损伤

尺寸在规格内

Appearance has

no marked defect.

Dimensions shall be

within specified

tolerance.

应清晰可见

Should be discerned

easily.

在规格范围内

Within specified

tolerance

B: 2.5%max

E:2.5%max

7.绝缘电阻

Insulation Resistance

大于 10,000MΩ

10,000MΩmin

500±50V.DC 的电压充电一分钟。

The insulation Resistance shall be measured

within 60±5 sec of charging.

8.耐电压

Dielectric

Strength

端子间

Between

Lead Wires

无不良

No failure.

端子间施加 200%的额定电压一分钟。

(充放电电流≤50mA)

Apply a DC voltage of 200% of the rated voltage for 1 min.

(Charge/discharge current≤50mA )

端子与

外壳间

Body

Insulation

无不良

No failure.

如图,将电容器的引线连在一起,主体外紧包一层金属箔,边沿距

引线 3-4mm,

在电容器引线和金属箔间施加 200%的额定电压一分钟。

(充放电电流≤50mA)

The terminals of the capacitor shall

be connected together, A metal foil

shall be closely wrapped around the

body of the capacitor to the distance

of about 3-4 mm from each terminal,

A voltage of 200% of the rated is

applied between the capacitor lead

wires and the metal balls for 1 min.

(Charge/discharge current≤50mA )

B:-10~+10%

E:-56~+22%

静电容量测试须依下列顺序进行。

预处理: 在 85±2℃下放置 1 小时后取出,

在室内条件下放置 24±2 小时。

The capacitance shall be measured at each step as following.

Pre-treatment: Capacitor shall be stored at 85±2℃ for 1

hour, then placed at room condition for 24±2hours before

initial measurements.

4.标识

Mark

5.静电容量

Capacitance

9.容量温度特性

Temperature

Characteristic

用目视法观测

Be watched on sight

温度 Temp. 20±2℃

电压 Vol. 1.0±0.2Vrms

频率 Freq. 1±0.1KHz

同上

Same condition as capacitance

步骤(Step)

温度(Temp.)

with 500±50V.DC

①

②

③

④

⑤

20±2℃ -25±2℃ 20±2℃ 85±2℃ 20±2℃

�项 目

ITEM

规 格

SPECIFICATION

10.可焊性

Solder

ability of

lead wires

导线上沾锡面积大于 90%。

Lead wire shall be soldered

with uniformly coated on the

axial direction over 90% of the

circumferential direction .

11.端子强度

Strength of

Lead Wires

(c 式不做此

项 Type c

none)

抗拉强度

Pull

12.耐焊接热

Soldering

Effect

外观

Appearance

无显著异常

No marked

defect

容量变化

Capacitance

Change

B:±10%max

E:±20%max

损耗因数

D.F.

绝缘电阻

I.R.

抗电强度

Dielectric

Strength

外观

Appearance

B: 5.0%max

E: 5.0%max

1000MΩ min

容量变化

Capacitance

Change

B:±10%max

E:±20%max

损耗因数

D.F.

B: 2.5%max

E: 2.5%max

外观

Appearance

无显著异常

No marked

defect

B:±10%max

E: ±20%max

13.耐振性

Vibration

Resistance

14.湿热循环

Humidity

Cycling

弯曲强度

Bending

容量变化

Capacitance

Change

损耗因数 D.F.

绝缘电阻 I.R.

抗电强度

Dielectric

Strength

导线不断裂

电容器不破损

Lead wire

shall not cut

off and

capacitor

shall not be

damaged

按第八条。

Per Item 8.

无显著异常

No marked

defect

B: 5.0%max

E: 5.0%max

2500MΩ min

按第八条。

Per Item 8.

试 验 方 法 及 条 件

TEST METHOD AND CONDITION

将电容器置于蒸气中老化 8 小时±15 分钟。进行蒸气老化后,导线须浸

入助焊剂后再浸入 245±5℃的熔锡内,松香浓度 25%wt,距离主体

1.5~2.0mm,时间 2±0.5 秒。

The capacitor was aged in steam for 8 hours±15 minutes, After

steam aging,The lead wires of the capacitor shall be dipped into

a alcohol solution of 25% wt rosin and then into molten

solder of 245±5℃ for 2±0.5 sec. In both case the depth of

dipping is up to about 1.5 to 2.0 mm from the root of the lead

wires.

把制品固定,在端子引出方向施加负荷 10N 保持 10±1

秒。

Fix the body of the capacitor and apply a tensile

weight gradually to each lead wire in the radial

direction of capacitor up to 10N,and keep it for

10±1sec.

在端子间施加 5N 负荷并弯曲 90°,回复原后反向弯曲 90°,每次弯曲

时间为 2 至 3 秒,连续 3 次。

Each lead wire shall be subjected to 5N weight and then a

90°bend, at the point of egress, in one direction return to

original position, and then a 90°bend in the opposite direction

at the rate of one bend in 2-3 s for 3times.

将端子浸入温度为 260±5 ℃的熔锡内,外保留 1.5-2.0mm 距离主体边

缘,并保持 10±1 秒。

试验前:电容器应放置在 125±2℃的温度下 1 小时,

然后在常温下恢复 24±2 小时后测试。

试验后: 室内条件下恢复 24±2 小时。

The lead wires shall be immersed

into the melted solder of 260±5 ℃

up to about 1.5 to 2.0 mm from the main

body for 10±1 sec.

Pre-treatment: The capacitor shall be

placed at. 125±2℃ for 1 hour, then

placed at room condition for 24 ±2

hours before initial measurement.

Post-treatment: Capacitor shall be

stored for 24±2 hours at room condition.

把电容器焊接到测试架(玻璃纤维环氧树脂板)上,并用树脂(粘合剂)

涂敷至元件主体部分。将电容器应牢固地焊接到支撑引线上,并以

10Hz 至 2000Hz 的频率范围进行振荡,总振幅为 1.5mm,并且按照大约 20

分钟的振荡变化速率由 10Hz 至 2000Hz,然后返回至 10Hz 频率。分别沿

3 个互相垂直的方向实施该振荡 12 次(共 36 次).最大加速度为 5g.

The capacitor is welded to the test frame (glass fiber epoxy resin

plate) and coated to the main part of the element with resin

(adhesive).The capacitor shall be firmly welded to the support

lead and oscillated in the frequency range of 10Hz to 2000Hz, with

a total amplitude of 1.5mm, and changed from 10Hz to 2000Hz at

an oscillation rate of about 20 minutes, and then returned to 10Hz.

The oscillation is carried out 12 times (36 times in total) along

three mutually perpendicular directions. The maximum

acceleration is 5g.

电容器在温度 40±2℃, 湿度 95±3%RH 下放置 8 小时,

室温下放置 16 小时,循环 10 次。

试验后:在室内条件下恢复 1 至 2 小时。

Set the capacitor for 8 hours at 40±2℃ in 95±3% RH, then

placed at room condition for 16 hours, circulating for 10 times.

Post-treatment: The capacitor shall be stored for 1 to 2 hours

at room condition.

�项

目

ITEM

15.机械冲击

Mechanical

Shock

规

格

SPECIFICATION

外观

Appearance

容量变化

Capacitance

Change

损耗因数

D.F.

绝缘电阻

I.R.

16.温度循环

Temp

Cycling

17.寿命试验

Life Test

试 验 方 法 及 条 件

TEST METHOD AND CONDITION

无显著异常

No marked

defect

把电容器焊接到测试架(玻璃纤维环氧树脂板)上,

并用树脂(粘合剂)涂敷至元件主体部分。

沿三个相互垂直方向的轴在每个方向上来回

B:±10%max (从轴到样品及从样品到轴)

。

E: ±20%max 实施三个周期的冲击(共 18 次冲击)

试验脉冲为半正弦波,持续时间为 6ms,峰值为 100g 且速度变化为 4.7m/s.

The capacitor is welded to the test frame (glass fiber epoxy resin plate)

B: 2.5%max

and coated to the main part of the element with resin (adhesive).

E: 2.5%max

Back and forth in each direction along three mutually perpendicular axes

(from the shaft to the sample and from the sample to the shaft) three

10000MΩ min

cycles of impact (18 impacts in total).

The test pulse is a half sine wave with a duration of 6 ms, a peak value

of 100 g and a speed change of 4.7 m/s.

外观

Appearance

无显著异常

No marked

defect

容量变化

Capacitance

Change

B:±10%max

E: ±20%max

损耗因数

D.F.

B: 5.0%max

E: 5.0%max

绝缘电阻

I.R.

1000MΩ min

抗电强度

Dielectric

Strength

按第八条。

Per Item 8

外观

Appearance

无显著异常

No marked

defect

容量变化

Capacitance

Change

B:±20%max

E: ±20%max

损耗因数

D.F.

B: 5.0%max

E: 5.0%max

绝缘电阻

I.R.

4000MΩ min

抗电强度

Dielectric

Strength

按第八条。

Per Item 8

将电容器放入高低温箱,按下列步骤循环 1000 次。转换时间不超 1 分钟。

试验前:在 125±2℃温度下放置 1 小时,在常温下恢复 24±2 小时后测试。

试验后: 在室内条件下恢复 24±2 小时测试。

The capacitor shall be introduced into the test chamber, and shall be

exposed to the temperature conditions as shown in table at 1000 cycles.

The conversion time shall not exceed 1 minute.

pretreatment: The capacitor shall be placed at 125±2℃ for 1 hour,

then placed at room condition for 24±2hours before initial measurement.

Post-treatment: Capacitor shall be stored for 24 ± 2 hours at room

conditions.

步骤(STEP)

1

2

温度(TEMP.)

-55-3/+0℃

125+3/+0℃

时间(TIME)

30-3/+0min.

30-3/+0min.

施加 150%的额定电压并在 125±2℃下放置 1000 小时。(充放电电流限于 50mA

以下)

试验前:电容器应放置在 125±2℃的温度下 1 小时,

然后在常温下恢复 24±2 小 时后测试。

试验后: 在室内条件下恢复 24±2 小时。

Apply a DC voltage of 150% of the rated voltage for 1000 hours at 125

±2℃ .

(Charge/discharge current≤ 50mA).

pre-treatment: The capacitor shall be placed at 125±2℃ for 1 hour,

then placed at room condition for 24 ± 2 hours before initial

measurement.

Post-treatment: Capacitor

shall be stored for 24 ± 2 hours

at room condition.

�项

目

ITEM

18.偏高湿度

Biased

Humidity

规

格

SPECIFICATION

外观

Appearance

无显著异常

No marked

Defect

容量变化

Capacitance

Change

损耗因数

D.F.

B:±10%max

E: ±20%max

绝缘电阻

I.R.

B: 5.0%max

E: 5.0%max

1500MΩ min

试 验 方 法 及 条 件

TEST METHOD AND CONDITION

电容器在温度85±2℃, 湿度85±2%RH下,施加额定电压和DC1.3+0.2/-0V(添

加100kΩ电阻器),放置1000±12小时。

(充放电电流≤50mA)

试验前:电容器应放置在 125±2℃的温度下 1 小时,

然后在常温下恢复 24±2 小时后测试。

试验后: 在室内条件下恢复 24±2 小时。

Apply the rated voltageand 1.3to1.5volts(Add 100kΩresistor) ,Set the

capacitor for 1000±12 hours at 85±2℃in 85±2% RH.

(discharge current≤50mA)

pre-treatment: The capacitor shall be placed at 125±2℃ for 1 hour,

then placed at room condition for 24±2 hours before initial

measurement.

Post-treatment: The capacitor shall be stored for 24±2 hours at room

condition.

抗电强度

Dielectric

Strength

按第八条。

Per Item 8

19.溶剂抵抗

Resistance

to solvents

外观

Appearance

无显著异常

No marked

Defect

将电容器放在下面 4 种溶剂中放置 3 分钟, 后擦拭 10 次;擦拭后,立即按上

述方法再重复 2 回,共计 3 次.然后用清水进行清洗,室温下空气干燥。

溶剂 1:20℃~30℃;按下述配方构成混合溶剂:1 份体积的分析纯异丙醇,3

份体积的 80%体积的煤油和 20%体积的乙苯构成的混合液。

溶剂 2:20℃~30℃; 水洗清洗剂。

溶剂 3:20℃~30℃;90%柠檬稀和 10%表面活性剂组成的混合液;

溶剂 4:在 63℃~70℃,按下述配方构成混合溶剂:42 份体积去离子水,1 份

体积丙二醇甲醚,1 份体积的乙醇胺。

Place the capacitor in the following four solvents for 3 minutes, and

then wipe it for 10 times; After wiping,Immediately repeat the above

method twice, three times in total, then clean with water and dry in

air at room temperature.

Solvent 1: 20℃~30℃; The mixed solvent is composed of 1 part by volume

of analytical pure isopropanol, 3 parts by volume of a mixed liquid

composed of 80% by volume of kerosene and 20% by volume of ethylbenzene.

Solvent 2: 20℃~30℃; Water washing detergent.

Solvent 3: 20℃~30℃; A mixture of 90% diluted lemon and 10% surfactant;

Solvent 4: at 63℃~70℃, the mixed solvent is composed of 42 parts by

volume of deionized water, 1 part by volume of propylene glycol methyl

ether and 1 part by volume of ethanolamine.

20.高温存储

High

temperature

storage

外观

Appearance

无显著异常

No marked

Defect

容量变化

Capacitance

Change

B:±10%max

E: ±20%max

损耗因数

D.F.

B: 5.0%max

E: 5.0%max

将电容器放在 125℃±2℃的温度条件下放置 1000±12 小时.

试验前:电容器应放置在 125±2℃的温度下 1 小时,

然后在常温下恢复 24±2 小时后测试。

试验后: 在室内条件下恢复 24±2 小时。

Place the capacitor at 125°C±2°C for 1000±12 hours.

pre-treatment: The capacitor shall be placed at 125±2℃ for 1 hour,

then placed at room condition for 24±2 hours before initial

measurement.

Post-treatment: The capacitor shall be stored for 24±2 hours at room

condition.

绝缘电阻

I.R.

4000MΩ min

�□瓷介电容器使用注意事项 Ceramic capacitor use matters needing attention :

1. 工作电压 Operating voltage:

在交流电路或纹波电流电路中使用直流额定电压电容器时,请务必确保外加电压的Vp-p值或包含直流偏置电压的Vo-p值

保持在额定电压范围内.

若向电路施加电压,开始或停止时可能会因谐振或切换产生暂时的不规则电压.请务必使用额定电压范围大于此不规则电

压的电容器.

Be sure to maintain the Vp-p value of the applied voltage or the Vo-p which contains DC bias within the

rated voltage range.

When the voltage is started to apply to the circuit or it is stopped applying, the irregular voltage may be

generated for a transit period because of resonance or switching. Be sure to use a capacitor within rated voltage

containing this irregular voltage.

直流电压

DC voltage

直流+交流电压

DC+AC voltage

交流电压

AC voltage

冲击电压(1)

Pulse voltage(1)

冲击电压(2)

Pulse voltage(2)

2. 工作温度和自身发热 Operating temperature and self-generated heat:

电容器的表面温度应保持在其额定工作温度范围的上限以下.务必考虑到电容器自身发出的热量.电容器在高频电流、冲

击电流等中使用时可能会因介电损耗自身发热.所施加之正弦波电压的频率应低于200kHz.外加电压应使自身发热等负荷在

25℃周围温度条件下不超过20℃范围.测量时应使用ø0.1mm小热容量的 (K) 的热电偶,而且电容器不应受到其它组件的散热

或周围温度波动影响.

过热可能会导致电容器特性及可靠性下降.(切勿在冷却风扇运转时进行测量,否则无法确保测量数据的精确性.)

Keep the surface temperature of a capacitor below the upper limit of its rated operating temperature range.

Be sure to take into account the heat generated by the capacitor itself. When the capacitor is used in a

high-frequency current, pulse current or the like, it may have the self-generated heat due to dielectric-loss.

The frequency of the applied sine wave voltage shall be lower than 200kHz.Applied voltage should be the load

such as self-generated heat is within 20℃ on the condition of atmosphere temperature 25℃. When measuring, use

a thermocouple of small thermal capacity-K ofφ0.1mm and be in the condition where capacitor is not affected

by radiant heat of other components and wind of surroundings.

Excessive heat my lead to deterioration of the capacitor’s characteristics and reliability.( Do not measure

when the cooling fan is running, otherwise unable to ensure the accuracy of the measurement data .)

3. 耐电压的测试条件Test condition for withstanding voltage:

3.1 测试设备Test equipment:

交流耐电压的测试设备应具有能够产生类似于50/60Hz正弦波的功能,如果施加变形的正弦波或超过规定电压值的超载

电压,则可能会导致故障.

Test equipment for AC withstanding voltage shall be used with the performance of the wave similar to

50/60 Hz sine waves.

If the distorted sine wave or over load exceeding the specified voltage value is applied, the defective may

be caused.

�3.2 电压外加方法Voltage applied method:

施加耐电压时,电容器的引线或端子应与耐电压测试设备的输出端连接牢固,然后再将电压从近零增加到测试电压.

如果测试电压不从近零逐渐提高而是直接施加在电容器上,则施加时应包含过零点*.测试结束时,测试电压应降到近零,然后

再将电容器引线或端子从耐电压测试设备的输出端取下.

如果测试电压不从近零逐渐提高而是直接施加在

电容器上,则可能会出现浪涌电压,从而导致故障.

*过零点是指电压正弦通过0V的位置. 参见右图:

When the withstanding voltage is applied, capacitor’s lead or

terminal shall be firmly connected to the output of the withstanding

voltage test equipment, and then the voltage shall be raised from near

zero to the test voltage.

If the test voltage without the raise from near zero voltage would be applied directly to capacitor,

test voltage should be applied with the *zero cross. At the end of the test time, the test voltage shall be

reduced to near zero, and then capacitor's lead or terminal shall be taken off the output of the withstanding

voltage test equipment.

If the test voltage without the raise from near zero voltage would be applied directly to capacitor,

the surge voltage may arise, and therefore, the defective may be caused.

ZERO CROSS is the point where voltage sine wave pass 0V.- See the right figure.

4. 失效安全性Fail-Safe:

如果电容器破损,会导致短路电路故障.务必在本产品上适当提供例如保险丝等自动防故障功能,以免导致电击、火灾、或

冒烟等.

When capacitor would be broken, failure may result in a short circuit. Be sure to provide an appropriate

fail-safe function like a fuse on your product if failure would follow an electric shock, fire or fume.

5. 储存环境Storage condition:

电容器的绝缘涂层不具有良好密封作用.因此,请勿将电容器存放在腐蚀性气体中,尤其是存在氯气、硫气、酸、碱、盐等

的场所.同时应防潮.在对本产品进行清洗、覆膜或封膜前,请先在指定设备上测试经清洗、覆膜或封膜的产品的性能,以确定

上述过程不会影响产品质量.电容器应存放在下列条件的场所:

环境温度:-25℃——+50℃;相对湿度:40℃时不大于90%;气压:40——106KPA

请在24个月内使用电容器.

使用本品时如忽略上述警告事项,则在严重情况下可能导致短路,并引起冒烟或局部离散.

The insulating coating of capacitors does not form a perfect seal; therefore, do not use or store capacitors

in a corrosive atmosphere, especially where chloride gas, sulfide gas, acid, alkali, salt or the like are present.

And avoid exposure to moisture. Before cleaning, bonding, or molding this product, verify that these processes

do not affect product quality by testing the performance of a cleaned, bonded or molded product in the intended

equipment. Capacitors should be stored in the following conditions:

The environment temperature : -25℃~+50℃;

Relative humidity : 40 ℃ is not greater than 90%

Air pressure : 40~106KPA

Use capacitors within 24 months.

Failure to follow the above cautions may result, worst case, in a short circuit and cause fuming or partial

dispersion when the product is used.

�6. 焊接、安装与使用Soldering 、mounting and use:

6.1 振荡与冲击Vibration and impact

使用时请勿使电容器或引线受到过度冲击或振荡.

When using do not make the capacitor or lead by excessive impact or vibration.

6.2 焊接Soldering

将该产品焊接在PCB/PWB上时,不应超出电容器的耐焊接热规格,本产品过热会使内部接点锡焊料熔化,导致温度骤变,从

而造成陶瓷组件产生裂纹.

当使用烙铁焊接电容器时,应遵循以下条件:

烙铁头温度: 最高400℃;烙铁功率: 最大50W;焊接时间: 最多3.5秒

When soldering this product to a PCB/PWB, do not exceed the solder heat resistance specification of the

capacitor. Subjecting this product to excessive heating could melt the internal junction solder, Lead to

temperature shock , Resulting in the ceramic element to produce crack.

When soldering capacitor with a soldering iron, it should be performed in following conditions:

Temperature of iron-tip: 400 degrees C. max.

Soldering iron wattage: 50W max.

Soldering time: 3.5 sec. max.

7. 清洗(超声波清洗)Cleaning (ultrasonic cleaning):

进行超声波清洗时,应遵守下列条件:

洗涤槽容量: 20瓦特输出功率/每升或以下;洗涤时间: 最多5分钟;

不得直接振荡PCB/PWB.过度的超声波洗涤会导致引线的超载损坏.

To perform ultrasonic cleaning, observe the following conditions.

Rinse bath capacity: Output of 20 watts per liter or less. Rinsing time: 5 minutes

max.

Do not vibrate the PCB/PWB directly.Excessive ultrasonic cleaning may lead to fatigue destruction of the lead

wires.

□运输Transport:

电容器在运输途中,要注意避免阳光直射,雨、雪、雾、水浸透等.

In transit, Capacitors should be avoided direct sunlight, rain, snow, fog, water soaked and

so on.

�