AS7211

Smart Lighting Manager with

Integrated Daylight Sensor, Control

Interfaces and Network Access

General Description

The AS7211 Smart Lighting Manager device is an intelligent, photopic-sensor based

light manager that enables automatic daylight level adaptation and energy

conservation for next generation lighting systems. It is part of the ams “Cognitive

Lighting™” family of products that enable lights to be “aware” and adapt to their

surroundings and provide human lighting needs and energy conservation needs

autonomously.

The AS7211 is equipped with an advanced Cognitive Light Engine (CLE) to optimize

daylight harvesting and drives either dimming ballasts or LED drivers. For local

inputs it uses direct connection to Local Sensor Networks (LSN), like occupancy

sensors, dimmers or bridges. It connects to standard 0-10V dimmers inputs and

drives 0-10V dimming ballasts/drivers for fluorescent lighting or LED drivers for LED

lighting. A UART interface is provided for remote configuration, control and

management of the CLE. This UART interface responds to simple AT commands.

The AS7211 can also directly connect to precision LED drivers from ams, providing a

complete lighting solution that can be easily commissioned and deployed.

Ordering Information appears at end of datasheet.

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

AS7211 – 1

�Key Benefits & Features

The benefits and features of this device are listed below:

Figure 1: Added Value of Using AS7211

Benefits

Features

Very accurate ambient light measurements

possible

Ambient light sensing (photopic response)

optimized for Day-Lighting applications

No life-time drift and very high temperature

stability

Photopic response realized by interference

filters

Evaluation of additional sensors possible

Input signal conditioning not necessary

Output signal conditioning not necessary

Configurable Local Sensor Network (LSN),

supporting either 0-10V or I2C

Accepts 0-10V input signals from dimmers

0-10V output for control of dimmable ballast,

linear fluorescent, LEDs

Integrated 12bit PWM for linear/non-linear

Closed Loop PWM control

dimming

AT Commands: Configuration and control

Simplifies the device set-up

through UART

Network control: UART interface to network

Enables Network controlled lighting

& building management (BLE, Wi-Fi,

ZigBee, BacNet, KNX) systems via AT

commands

Avoidance of AC beat frequency flicker

SYNC pin to synchronize multiple lights

Industrial Temperature range

Temperature range: 0 to 85°C

Low VDD requirement

VDD LV range: 2.7V to 3.6V

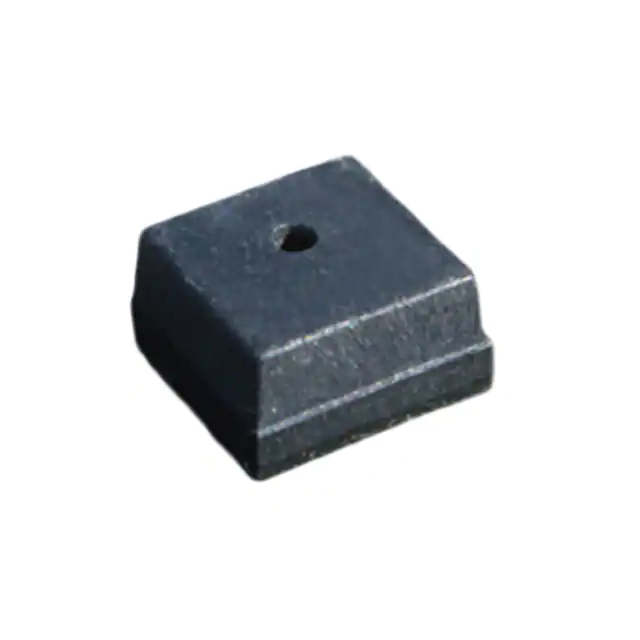

Small package, with built in aperture

20-pin LGA package 4.5 x 4.7 x 2.5mm

Applications

Sense ambient light, dim and maintain brightness of luminaires and lamps in local

loop control, automatic lumen maintenance, flexible network connectivity and simple

control of luminaires and lamps.

LED and florescent luminaires, troffers, high-bays

Track-head and downlights

LED and florescent replacement lamps

AS7211 – 2

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

�Block Diagram

Figure 2: Functional Blocks of AS7211

VDDHV

VDD

Outputs

VDDHV

VDD

VDD

0-10V

Optional Inputs

VDD

0_10V_DIM

OCC

Cognitive Lighting

Engine (CLE)

VDDHV

DAC

PWM_1 / 0_10V_O

PWM

PWM

Generator

PWM_2

Dimming &

Occupancy

PWM_3

VDD

SDA_M

Photopic

Sensors

I2C Master

SYNC / RESN

MODE

SCL_M

Setup

Network Access

VDD

VDD

OSC

16MHz

RX

TX

LED_IND

°C

UART

MISO

SPI

Master

MOSI

SCK

CSN_SD

GND

The AS7211 provides closed loop ambient Daylight sensing and PWM tuning while interfacing to

Local and Network controls.

Pin Assignments

Figure 3: Pin Diagram of AS7211 (top view)

20

16

1

15

5

11

6

10

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

AS7211 – 3

�Figure 4: Pin Description of AS7211 (20 pin LGA)

Pin Number

1

Pin Name

Description

PWM_3

Digital PWM 3

SYNC

SYNC input

RESN

Reset pin, active low

3

SCK

SPI serial clock

4

MOSI

SPI MOSI

5

MISO

SPI MISO

6

CSN_EE

Chip select for the required external serial Flash

memory, active low

7

CSN_SD

Chip select for SD Card interface, active low

8

AUX

Auxiliary mode input pin

9

SCL_M

I2C master clock pin

10

SDA_M

I2C master data pin

11

RX

UART RX pin

12

TX

UART TX pin

13

0_10V_DIM

0-10V input dimming pin

14

VDDHV

High Voltage Supply

15

MODE

Mode selection pin

16

GND

Ground

17

VDD

Low Voltage Supply

18

LED_IND

LED Driver output for Indicator LED, current

sink

PWM_1

Digital PWM 1

0_10V_O

0-10V output pin

PWM_2

Digital PWM 2

2

19

20

AS7211 – 4

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

�Absolute Maximum Ratings

Stresses beyond those listed under “Absolute Maximum Ratings“ may cause

permanent damage to the device. These are stress ratings only. Functional

operation of the device at these or any other conditions beyond those indicated

under “Operating Conditions” is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability. The device is not

designed for high energy UV (ultraviolet) environments, including upward looking

outdoor applications, which could affect long term optical performance.

Figure 5: Absolute Maximum Ratings

Symbol

Parameter

Min

Max

Units

Comments

Supply voltage VDD

-0.3

5

V

pin VDD to GND,

Low Voltage pin

VDDHV_MAX

Supply voltage VDDHV

-0.3

20

V

pin VDDHV to GND,

High Voltage pin

VDD_IO

Input/output pin voltage

-0.3

VDD +

0.3

V

Low Voltage pins to GND

VDDHV_IO

Input/output pin voltage

-0.3

VDDHV

+ 0.3

V

High Voltage pins to GND

Electrical Parameters

VDD_MAX

ISCR

Input current (latch-up

immunity)

± 100

mA

±2000

V

JEDEC JESD78D Nov 2011

(Class II)

Electrostatic Discharge

ESDHBM(1)

Electrostatic discharge

HBM

JS-001-2014

Temperature Ranges and Storage Conditions

Tstrg

Tbody

Storage temperature

-40

85

Package Body

Temperature

Humidity noncondensing

Moisture Sensitive Level

5

°C

260

°C

85

%

3

Norm: IPC/JEDEC J-STD020. The reflow peak

soldering temperature (body

temperature) is specified

according IPC/JEDEC JSTD-020 “Moisture/Reflow

Sensitivity Classification for

Non-hermetic Solid State

Surface Mount Devices”

Represents a 168 hour max.

floor lifetime

Note (1): Except for pins 14 and 19 where ESDHBM = ±1500V

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

AS7211 – 5

�Electrical Characteristics

All limits are guaranteed with VDD = 3.3V, VDDHV = 12V, TAMB = +25ºC. The

parameters with min and max values are guaranteed with production tests or SQC

(Statistical Quality Control) methods.

If VDD and VDDHV are to be the same voltage, they must be sourced by the same

2.97-3.6V supply.

Figure 6: Electrical Characteristics

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

General Operating Conditions

VDD

Low Voltage

operating Supply

2.97

3.3

3.6

V

VDDHV

High Voltage

operating Supply

VDD

12

15

V

-40

25

85

°C

5

mA

TAMB

IVDD

ISTANDBY(1)

Operating

Temperature

Operating Current

Standby Current

12

µA

Internal RC Oscillator

FOSC

tJITTER(2)

Internal RC

oscillator frequency

Jitter

15.7

16

@25°C

16.3

MHz

1.2

ns

0-10V Output (0_10V_O pin)

ROUT_10

Resistive Load

1

kΩ

IS_10

Source Current

10

mA

Sink Current

-10

mA

ISINK_10

CLOAD_10

Capacitive Load

VOUT_10(3)

Output Swing

0

100

pF

10

V

315

kΩ

0-10V Input

RIN_HV

AS7211 – 6

Analog Input

Resistance

VDDHV ≥ 12V

138

200

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

�Temperature Sensor

DTEMP

Absolute accuracy

of the temperature

measurement

-8.5

8.5

°C

1

8

mA

-10

10

%

Indicator LED

IIND

LED Current

IACC

Accuracy of Current

VLED

Voltage range of

connected LED

1, 2, 4 or 8

Vds of current sink

0.2

V

Vin=0V or VDD

-1

1

uA

Digital Inputs and Outputs

IIH, IIL

Logic Input Current

VIH

CMOS Logic High

Input

0.7*

VDD

VDD

V

VIL

CMOS Logic Low

Input

0

0.3*

VDD

V

VOH

CMOS Logic High

Output

I=1mA

VDD0.4

V

VOL

CMOS Logic Low

Output

I=1mA

0.4

V

1

uA

IIh, IIL

Logic Input Current

Vin=0V or VDD

-1

tRISE(2)

Current rise time

C(Pad)=30pF

5

ns

tFALL(2)

Current fall time

C(Pad)=30pF

5

ns

Notes:

(1) 15µA over temperature

(2) Guaranteed, not production tested

(3) For VDDHV>10.5, output max is 10V, else output max tracks VDDHV

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

AS7211 – 7

�Figure 7: AS7211 I2C Master Timing Characteristics

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

100

400

kHz

I2C Interface

fSCLK

SCL Clock

Frequency

tBUF

Bus Free Time

Between a STOP

and START

1.3

µs

tHD:STA

Hold Time

(Repeated) START

0.6

µs

tLOW

LOW Period of SCL

Clock

1.3

µs

tHIGH

HIGH Period of

SCL Clock

0.6

µs

tSU:STA

Setup Time for a

Repeated START

0.6

µs

tHD:DAT

Data Hold Time

0

tSU:DAT

Data Setup Time

100

tR

Rise Time of Both

SDA and SCL

20

300

ns

tF

Fall Time of Both

SDA and SCL

20

300

ns

tSU:STO

Setup Time for

STOP Condition

0.6

CB

Capacitive Load for

Each Bus Line

CI/O

I/O Capacitance

(SDA, SCL)

0.9

µs

ns

µs

CB — total capacitance of

one bus line in pF

400

pF

10

pF

Figure 8: I2C Master Timing Diagram

tR

tF

tLOW

SCL

P

tHIGH

S

tHD:STA

tHD:DAT

S

tSU:DAT

tSU:STA

P

tSU:STO

VIH

SDA

tBUF

Stop

AS7211 – 8

VIL

Start

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

�Figure 9: AS7211 SPI Timing Characteristics

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

16

MHz

SPI Interface

fSCK

Clock frequency

0

tSCK_H

Clock high time

40

ns

tSCK_L

Clock low time

40

ns

tSCK_RISE

SCK rise time

5

ns

tSCK_FALL

SCK fall time

5

ns

tCSN_S

CSN setup time

Time between CSN highlow transition to first SCK

high transition

50

ns

tCSN_H

CSN hold time

Time between last SCK

falling edge and CSN lowhigh transition

100

ns

100

ns

tCSN_DIS

CSN disable time

tDO_S

Data-out setup time

5

ns

tDO_H

Data-out hold time

5

ns

tDI_V

Data-in valid

10

ns

Figure 10: SPI Master Write Timing Diagram

tCSN_DIS

CSN

tSCK_RISE

tCSN_S

tCSN_H

tSCK_FALL

SCK

tDO_S

MOSI

tDO_H

LSB

MSB

HI-Z

HI-Z

MISO

Figure 11: SPI Master Read Timing Diagram

CSN_xx

tSCK_H

tSCK_L

SCK

tDI_V

Dont care

MOSI

MISO

MSB

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

LSB

AS7211 – 9

�Figure 12: Typical Spectral Responsivity

Photopic Response

Normalized Response

Ys(l)

Wave Length [nm]

Figure 13: AS7211 Optical Characteristics

Symbol

Parameter

SOR

Sensor output

Responsivity

Conditions

Min

Typ(1)

Max

Unit

190

200

210

LUX

White LED

CCT = 4000K

Ev = 200 LUX

IRResp

IR Responsivity

DRLUX

Dynamic Range

(1)Typical

IR LED 850nm,

1

Ev = 100 LUX

10

LUX

60000

LUX

values at Int=400.4ms, Gain=1x, TAMB = +25ºC.

AS7211 – 10

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

�Figure 14: AS7211 LGA Package Field of View

Detailed Description

AS7211 Smart Lighting Manager - Overview

The Cognitive Light Engine (CLE) is the “brains” of the Smart Lighting Manager. The

CLE constantly processes information from the Photopic Sensors, Network Access

and Inputs while controlling Outputs. Initial Setup and ongoing parameter storage is

done by reading and writing an external EEPROM via SPI bus.

A Luminaire solution for Daylighting and Spectral Presence requires only the

AS7211. A Luminaire solution with Daylighting, and Lumen Maintenance requires

just the addition of an ams TSL4531 single chip light sensor, connected via I 2C.

Refer to the table in the Figure below.

Overall AS7211 timing generation uses an on chip 16MHz temperature

compensated oscillator for master clock timing.

Figure 15: AS7211 Solution Chart

Device Orientation

(from luminaire light source)

Solution Required

Daylighting

Lumen

Maintenance

Spectral

Presence Detect

AS7211

(into room)

(into luminaire)

(into luminaire)

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

TSL4531

(optional)

(not required)

(not required)

(into room)

AS7211 – 11

�Photopic Sensor

The Photopic sensor, part of the AS7211 Cognitive Light Engine (CLE), is a nextgeneration digital light sensor device which approximates the human eye response.

The sensor contains an integrating analog-to-digital converter (16-bit resolution

ADC), which integrates current from a photodiodes. Upon completion of the

conversion cycle, the result is transferred to the corresponding data registers.

Transfers are double-buffered to ensure integrity of the data is maintained.

The Photopic response is realized by an interference filter, which enables no life-time

drift and very high temperature stability. Note the AS7211 LGA package contains an

internal aperture that provides a Package Field of View (PFOV) of +/- 22°. External

optics can be used as needed to expand or reduce this built in PFOV.

AS7211 Inputs

Figure 16: VDDHV Based Settings for Inputs

VDDHV

Dimming

10.5-15V

Direct input for 0_10V_DIM, dimming input

2.97-10V(1)

External 5:1 resistor divider for 0-10V_DIM, dimming input(2)

Note (1): For VDDHV 12V

3.3V

10V

VDD

3.3V

VDDHV

VDD

10V

0

VDDHV

0

0_10V_DIM

0_10V

Rin=200k typ.

MODE

CLE

ADC

5:1

ADC

CLE

MODE

0_10V_DIM

0-10V Analog Input

AS7211

0-10V Analog Input

AS7211

RMODE

RMODE

The auxiliary sensor input (AUX) can be configured as an analog or digital sensing. It

can be used as a 0-10V analog sensing input, or, as a digital sensing input both of

which are common types of external occupancy sensors. And this sensing can

therefore be used to directly control the luminaire. Refer to AS7211 User Guide as

well as the ams AT Command document for additional usage and setup information.

Synchronization and Reset

Figure 18: Synchronization and Reset Circuit

Opto Coupler

AC Main

SYNC/

RESN

10k

CLE

optional

SYNC and Reset

Push > 100ms

Synchronization and Reset Circuit: This figure shows the basic diagram when using reset and

synchronization function together.

AS7211 provides optional synchronization of the PWMs. This sync signal can be

derived from the AC mains so, for example, all luminaires in a room are

synchronized to prevent beat frequency flicker. If the SYNC pin is left open,

synchronization is automatically disabled.

Refer to the Figure above. When pulled down for more than 100ms the SYNC/RESN

pin will reset the AS7211 Smart Lighting Manager. In this case the push-button

“overrides” the output of the opto-coupler. Therefore a resistor should be placed in

series with the opto-coupler.

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

AS7211 – 13

�AS7211 Outputs

The AS7211 outputs, used to control ballast dimming and/or LED string dimming,

can be configured as either three PWM outputs or two PWMs and one analog

output. The PWMs are 12 bit with max frequency of 5.3 kHz, which is factory set to

888 Hz. Refer to the Figure below.

The three PWM outputs, PWM_1, PWM_2 and PWM_3 all switch with the same duty

cycle, but are not simultaneous for better EMI performance. The PWM_1 output can

be set to either analog (0-VDDHV) or digital (0-VDDHV) dimming. Analog dimming

range is 10-100%. Digital Dimming range is 1-100%. PWM2 and PWM3 track output

1 dimming level, but are always digital (1-100%).

To set the desired device operation MODE use the appropriate RMODE resistor, also

shown in the Figure below.

Figure 19: Outputs

MODE

RMODE

Setting

0

100 Ω

0-10V analog

1

470 Ω

0-10V digital

Outputs

PWM_1/0_10V_O

PWM_2 & PWM_3

Analog 0-VDDHV(1)

Digital PWMs (0-VDD)

Digital PWM

(0-VDDHV) (1)

Digital PWMs (0-VDD)

Note (1): For VDDHV>10.5, output max is 10V, else output max tracks VDDHV.

Indicator LED

An LED, connected to pin LED_IND, is used to indicate programming progress of the

device. During programming of the AS7211 via an external SD card the indicator

LED starts. When programming is finished the indicator LED is off.

Refer to the separate ams document for a complete description of AS7211 Firmware

Update Methodology.

AS7211 – 14

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

�UART and AT Command Interface

The UART block implements the TX and RX signals as defined in the RS-232 / V.24

standard communication protocol.

UART Feature List

Full Duplex Operation (Independent Serial Receive and Transmit Registers)

with FIFO buffer of 8 bytes for each.

Factory set to 115.2k Baud

Supports Serial Frames with 8 Data Bits, 1 Parity Bit and 1 Stop Bit.

Operation

TRANSMISSION

If data is available in the transmit FIFO, it will be moved into the output shift register

and the data will be transmitted at the configured Baud Rate, starting with a Start Bit

(logic zero) and followed by a Stop Bit (logic one).

RECEPTION

At any time, with the receiver being idle, if a falling edge of a start bit is detected on

the input, a byte will be received and stored in the receive FIFO. The following Stop

Bit will be checked to be logic one.

Figure 20: UART Protocol

Data Bits

TX

D0

D1

Start Bit

D2

D3

D4

D5

D6

D7

Parity Bit Stop Bit

Tbit=1/Baude Rate

Always Low

RX

D0

P

Next Start

Even or odd Always High

D0

D1

D2

D3

D4

D5

D6

D7

D0

P

Start Bit detected

After Tbit/2: Sampling of Start Bit

After Tbit: Sampling of Data

Sample Points

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

AS7211 – 15

�AT Command Interface

The network interface on the Smart Lighting Manager supporting the AT Commands

is the UART interface. The Smart Lighting Manager adapts the concept of an AT

command set for lighting control and configuration. The Smart Lighting Manager

uses a text-based serial command interface as popularized by the “AT Command”

model used in early Hayes modems.

For example:

Set the desired daylight LUX level target: ATLUXT = 500 >> OK

The “AT Command Interface”, shown below between the network interface and the

core of the system, provides access to the Smart Lighting Manager’s lighting control

and configuration functions.

Figure 21: AT Command Interface

BLE

Wi-Fi

ZigBee

BacNet

KNX

Network

Bridge

RX

AT Commands

TX

AT

Command

Interface

CLE

AT Command Interface

AS7211

Refer to the separate ams AS7211 AT Command Set document for complete

command set and usage.

AS7211 – 16

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

�I2C Master Interface (Local Sensor Interface)

The I2C Master interface can be used to connect external sensors (such as Daylight,

Occupancy, CO sensors, etc.). Refer to the separate ams Application note for

external sensor usage with the AS7211.

I2C Feature List

Clock is set to 100kHz

7+1-bit addressing mode.

Write formats: Single-Byte-Write, Page-Write

Read formats: Random-Read, Sequential-Read

SDA input delay and SCL spike filtering by integrated RC-components.

I2C Protocol

Figure 22: I2C symbol definition

Symbol

Definition

RW

Note

S

Start condition after stop

R

1 bit

Sr

Repeated start

R

1 bit

SW

Slave address for write

R

Slave address

SR

Slave address for read

R

Slave address

WA

Word address

R

8 bit

A

Acknowledge

W

1 bit

N

No Acknowledge

R

1 bit

Data

Data/write

R

8 bit

Data (n)

Data/read

W

8 bit

P

Stop condition

R

1 bit

WA++

Slave Increment word address

R

during acknowledge

The above I2C symbol definition table describes the symbols used in the following

mode descriptions.

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

AS7211 – 17

�I2C

W RITE ACCESS

Byte Write and Page Write formats are used to write data to the slave.

Figure 23: I2C Byte write

S

SW

A

WA

Data

A

A P

Write WA++

Figure 24: I2C Page write

S

SW

A

WA

Data 1

A

……..

A

Write WA++

Data n

A

Write WA++

A P

Write WA++

The transmission begins with the START condition, which is generated by the

master when the bus is in IDLE state (the bus is free). The device-write address is

followed by the word address. After the word address any number of data bytes can

be sent to the slave. The word address is incremented internally, in order to write

subsequent data bytes on subsequent address locations.

For reading data from the slave device, the master has to change the transfer

direction. This can be done either with a repeated START condition followed by the

device-read address, or simply with a new transmission START followed by the

device-read address, when the bus is in IDLE state. The device-read address is

always followed by the 1st register byte transmitted from the slave. In Read Mode

any number of subsequent register bytes can be read from the slave. The word

address is incremented internally.

I2C READ

ACCESS

Random, Sequential and Current Address Read are used to read data from the

slave.

Figure 25: I2C Random read

S

SW

A

WA

A

S

r

SR

A

read WA++

Data

N P

WA++

Random Read and Sequential Read are combined formats. The repeated START

condition is used to change the direction after the data transfer from the master.

AS7211 – 18

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

�The word address transfer is initiated with a START condition issued by the master

while the bus is idle. The START condition is followed by the device-write address

and the word address.

In order to change the data direction a repeated START condition is issued on the

1st SCL pulse after the acknowledge bit of the word address transfer. After the

reception of the device-read address, the slave becomes the transmitter. In this state

the slave transmits register data located by the previous received word address

vector. The master responds to the data byte with a not-acknowledge, and issues a

STOP condition on the bus.

Figure 26: I2C Sequential read

S

SW

A

WA

A

S

r

SR

A

Data 1

read WA++

A

read WA++

Data n

N P

WA++

I2C sequential read: Shows the format of an I2C sequential read access.

Sequential Read is the extended form of Random Read, as more than one registerdata bytes are transferred subsequently. In difference to the Random Read, for a

sequential read the transferred register-data bytes are responded by an

acknowledgement from the master. The number of data bytes transferred in one

sequence is unlimited (consider the behavior of the word-address counter). To

terminate the transmission the master has to send a not-acknowledge following the

last data byte and generate the STOP condition subsequently.

The AS7211 is compatible to the NXP two wire specifications.

http://www.nxp.com/documents/user_manual/UM10204.pdf

Version 4.0 Feb 2012 for standard mode and fast mode.

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

AS7211 – 19

�Application Information

Schematics

Figure 67: Constant Current LED Daylighting w/Networking & Spectral Sensing

AC

BLE

Wi-Fi

ZigBee

BacNet

KNX

3V

12V

10uF

100nF

0..10V

Dimmer

VDDHV

VDD

RX

TX

Network

Bridge

PWM_1/0_10V_O

AS7211

0_10V_DIM

Occupancy

Sensor

SDA_M

SCL_M

Dimming

Control Output

MODE

MOSI

MISO

SCK

CSN_EE

OCC

Additional

Sensors I2C

AC/DC

LED Driver

EEPROM

3V

LED_IND

GND

Figure 28: Constant Voltage LED Daylighting w/Networking & Spectral Sensing

AC

BLE

Wi-Fi

ZigBee

BacNet

KNX

AC/DC

3V

10uF

100nF

VDDHV

VDD

RX

TX

Network

Bridge

0_10V_DIM

Occupancy

Sensor

SDA_M

SCL_M

MODE

MOSI

MISO

SCK

CSN_EE

OCC

Additional

Sensors I2C

AS3834

LED Driver

PWM_1/0_10V_O

AS7211

0..10V

Dimmer

DC/DC

Boost

GND

EEPROM

3V

LED_IND

Figure 29: Fluorescent Daylighting System w/Networking and Spectral Sensing

BLE

Wi-Fi

ZigBee

BacNet

KNX

Network

Bridge

0..10V

Dimmer

Occupancy

Sensor

Additional

Sensors I2C

AS7211 – 20

100nF

3V

12V

10uF

10uF

RX

TX

VDD

VDDHV

PWM_1/0_10V_O

AS7211

0_10V_DIM

MODE

MOSI

MISO

SCK

CSN_EE

OCC

SDA_M

SCL_M

100nF

GND

EEPROM

3V

LED_IND

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

�PCB Layout

Figure 30: Typical Layout Routing

As shown, to prevent interference trace routing feedthroughs with exposure directly

under the AS7211 should be avoided.

The AS7211 Smart Lighting Integration Kit (SLIK) demo board with schematic and

PCB layout documentation is available from ams for additional design information.

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

AS7211 – 21

�Package Drawings & Markings

Figure 31: Package Drawing

AS7211

Notes:

1.

2.

3.

4.

5.

Unless otherwise specified, all dimensions are in millimeters.

Tolerances: Angular (± .5°), Two Place Decimal (± .015), Three Place Decimal (± .010)

Contact finish is Au.

This package contains no lead (Pb).

This drawing is subject to change without notice.

AS7211 – 22

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

�PCB Pad Layout

Suggested PCB pad layout guidelines for the LGA package are show. Flash Gold is

recommended as a surface finish for the landing pads.

Figure 32: Recommended PCB Pad Layout

Unit: mm

0.30

1.10

0.65

4.60

1

4.40

Notes:

1. Unless otherwise specified, all dimensions are in millimeters.

2. Dimensional tolerances are ±0.05mm unless otherwise noted.

3. This drawing is subject to change without notice.

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

AS7211 – 23

�Mechanical Data

Figure 33: Tape & Reel Information

AS7211 – 24

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

�Soldering, Manufacturing Process Considerations & Storage

Information

Solder Reflow Profile

The module has been tested and has demonstrated an ability to be reflow soldered

to a PCB substrate. The solder reflow profile describes the expected maximum heat

exposure of components during the solder reflow process of product on a PCB.

Temperature is measured on top of component. The components should be limited

to a maximum of three passes through this solder reflow profile.

Figure 34: Recommended Reflow Soldering Profile

Profile Feature

Reference

Average temperature gradient in preheating

Soak Time

Device

2.5°C/s

tSOAK

2 to 3 minutes

Time above 217°C (T1)

t1

Time above 230°C (T2)

t2

Max 50s

Time above Tpeak - 10°C (T3)

t3

Max 10s

Tpeak

260°C

Peak temperature in reflow

Temperature gradient in cooling

ams Preliminary Datasheet, Confidential: [v0-92] 2016–M11–03

Max 60s

Max - 5°C/s

AS7211 – 25

�Manufacturing Process Considerations

The AS7211 package is compatible with standard reflow no-clean and cleaning

processes including aqueous, solvent or ultrasonic techniques. However, as an

open-aperture device, precautions must be taken to avoid particulate or solvent

contamination as a result of any manufacturing processes, including pick and place,

reflow, cleaning, integration assembly and/or testing. Temporary covering of the

aperture is allowed. To avoid degradation of accuracy or performance in the end

product, care should be taken that any temporary covering and associated

sealants/debris are thoroughly removed prior to any optical testing or final

packaging.

Storage Information

Moisture Sensitivity Optical characteristics of the device can be adversely affected

during the soldering process by the release and vaporization of moisture that has

been previously absorbed into the package. To ensure the package contains the

smallest amount of absorbed moisture possible, each device is baked prior to being

dry packed for shipping. Devices are dry packed in a sealed aluminized envelope

called a moisture-barrier bag with silica gel to protect them from ambient moisture

during shipping, handling, and storage before use.

Shelf Life

The calculated shelf life of the device in an unopened moisture barrier bag is 12

months from the date code on the bag when stored under the following conditions:

• Shelf Life: 12 months

• Ambient Temperature: