DSO Nano V3 User’s Manual

Contents

I Product Intro………………………………………………………………………………………..…….2

II General Safety Rules ……………………………………………………………………………….. 2

III Major Functions ………………………………………………………………………………………..2

IV Operation Precautions …………………………………………………………………………………..3

V General Inspection………………………………………………………………………………………. 3

VI Functional Inspections.............................................................................................................................. 3

VII Battery Recharging Instruction……………………………………………………………………….3

VIII Firmware Upgrades………………………………………………………………………….3

IX Product Familiarization………………………………………………………………………………. 5

1. Interface and Buttons………………………………………………………………………………5

2. Screen………………………………………………………………………………………………5

X Measurement Operation Instruction………………………………………………………………….6

1. Parameter Area Intro…………………………………………………………………………………6

2. Measurement Area Intro………………………………………………………………………6

3. Specific Parameters Intro………………………………………………………………………6

XI Application Examples……………………………………………………………………………….11

1. Example One: Measure Simple Signal……………………………………………………………11

2. Example Two: Measure with Cursor………………………………………………………………12

3. Example Three: Save Waveform Image……………………………………………………………13

4. Example Four: Acquire Single Signal………………………………………………………………14

5. Example Five: Compare Waveform Signals………………………………………………………15

�I Product Intro

DSO Nano pocket size oscilloscope is a compatible 32bit digital storage oscilloscope. Based on ARM

!"

Cortex -M3, it’s equipped with 320*240 color display, USB port and recharging function. It’s compact, simple

to operate; meets the basic demands of school lab, electric furniture repairmen and electric engineering.

II General Safety Rules

To ensure your safety & avoid any damages to the product/connected devices, please read the following

safety rules carefully. To avoid any possible dangers, please use this product according to the rules.

Use appropriate power cord. Please use dedicated power cord which is certified in the country/region.

Connect/disconnect properly. Do not plug/unplug when the probe(s)/test lead(s) is connected to the

power source. Before you plug/unplug the current probes, please disconnect the power to the circuit-under-test.

Observe all terminal ratings. To avoid fire/electric shock, please don’t measure signal with DC100V or

above, or the device might be destroyed. Please read the manual carefully to know the detailed info of related

ratings before connection.

Please do not operate in humid environment.

Please do not operate in inflammable/explosive environment.

Please keep the surface of the product clean and dry.

III Major Functions

Display

2.8” color TFT LCD

display resolution

320×240

Display Colors

65K

Virtual Broadband

0-200kHz

Max. Sampling Rate

1Msps 12 bit

Sampling Storage Depth

4096 points

Transverse Sensitivity

1uS/Div~2S/Div(1-2-5 stepping)

Vertical Sensitivity

10mv/Div~10V/Div(x1 probe)

0.5V/Div~10V/Div(x10 probe)

Input Resistance

>500KΩ

Max. Input Voltage

80Vpp(x1 probe)

Coupling Mode

DC

Triggering Mode

Auto,Normal,Single,None

Fre,Duty,Vp-p,Vrms,Vavg,Vmax,Vmin

Vertical Precise Measurement Cursor

Horizontal Precise Measurement Cursor

Auto Measurement

Rising/Falling Edge Trigger

Triggering Cursor

Triggering Sensitivity Cursor

Hold/Run

Inbuilt Test Signal

10Hz~1MHz(1-2-5 stepping)

Waveform Storage

2Mbyte

PC Connection Interface

Connection through USB

Recharging Method

Recharging through USB interface

Dimensions

105mm×53mm×8mm

2

�IV

Operation Precautions

▌Temperature:

Working condition:+0℃ to +500℃

Non-working condition:-20℃ to +60℃:

▌Humidity:

Working condition:High temperature:40°C - 50°C,0%-60%RH

Working condition:Low temperature:0°C - 40°C,10%-90%RH

Non-working condition:High temperature:40°C- 60°C,5%-60%RH

Non-working condition:Low temperature:0°C - 40°C,5%-90%RH

V General Inspection

When you get a new DSO Nano, it’s suggested to inspect the product by the following steps:

1.Inspect for damage caused by shipping.

If the carton/plastic protection pad is seriously damaged, please keep the package until the product and

accessories pass the inspection electrically and mechanically.

2.Inspect the product

Please contact the company if the following problems occur: 1) product surface is damaged, 2) product

doesn’t work properly, 3) product does not pass performance test.

If the damage is resulted from shipping, please keep the package and contact the transportation department/

RIGOL distributor who is in charge of this service, for repair or exchange.

VI

Functional Inspection

Make a quick functional inspection to ensure the product is working soundly. Please perform following steps:

1. Turn on the power supply, access homepage of the oscilloscope.

2. Connect the oscilloscope with standard signals (e.g. square wave 20KHz,Vpp=5V), set the switch on

probe tip as 1X, plug oscilloscope probe to the jack.

Check whether the measured signal value is the same as the standard value; it can be calibrated if the

margin is small.

VII

Battery Recharging Instruction

When the battery sign shows as “

be power on or off while recharging.

VIII

”, or when the display is dim, please recharge in time. The product can

Firmware Upgrade

To upgrade firmware, please perform following steps:

1. Open web to access www.minidso.com, download the latest applicable firmware to your PC.

2. Simultaneously press “▼” of DSO Nano and turn on power supply, enter DFU firmware upgrade mode.

3. Use USB to connect DSO Nano to your PC, a removable disk named DFU V3_26_D will appear on

your PC. Copy the hex firmware to the root directory of your disk. After the extension of the firmware

changes from “hex” to “rdy”, restart DSO Nano, thus firmware is upgraded. Here we upgrade firmware to the

latest Version 201V4_22.

3

�1. Copy file from PC to virtual USB disk

2. After extension changes from “hex”to

“rdy”,it is upgraded.

4

�IX

Product Familiarization

1. Interface & Buttons

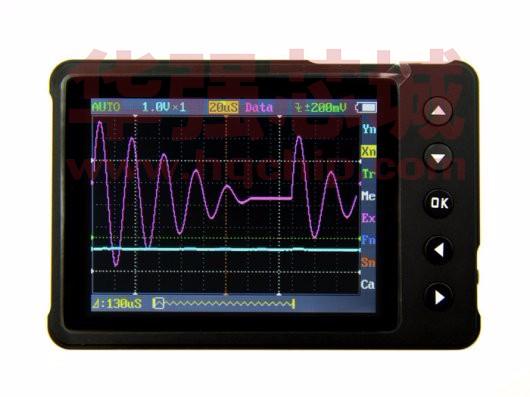

2. Screen

The screen display is depicted as below:

A

B

C

D

E

F

G

H

Parameter Area

Measurement

Area

Parameter

Area

Display the position of

current waveform

The table below shows the intro of button functions

5

�Button

Function

A

Run/Hold

Choose to save current file

▲

Upward selection

▼

Downward selection

◄

(left/decrease)change setting parameters

►

(right/increase)change setting parameters

OK

Menu

Choose to save current parameter setting

NOTE:There are corresponding colors for items in Parameter Area and Measurement Area.

X

Measurement Operation Instruction

1. Parameter Area Intro

Menu

Item

Function(Operate: Press ◄or ►)

A

AUTO/NORM/SINGL/NONE

Automation/Normal/Single

B

10mV-10V(1-2-5 stepping)

y-axis voltage per grid

C

×1/×10

multiple

D

1uS—2S(1-2-5 stepping)

x-axis voltage per grid

E

-Inp/Data/-Data/Inp+D/D-Inp/Inp-D/Off

Operation of 2 waveforms (Inp is

current

waveform;

D/Data

is

previously saved waveform);Off is

hide Inp and D/Data waveform

F

Triggering

Method:

Falling

edge

trigger, Rising edge trigger.

G

H

Horizontal triggering range

±80mV—±7.8V

Power supply by battery/ by USB

/

2. Measurement Area Intro

Item

Function Intro

Yn

Y-axis Function Setting

Xn

X-axis Function Setting

Tr

Triggering Function Setting

Me

Measurement Function Setting

Ex

Waveform Operation Function Setting

Fn

Save and Load Function Setting

Sn

Output Waveform Parameters Setting

Ca

Calibration Setting

3. Specific Parameter Intro

Choose the items in parameter area through “▲” or “▼”. Press “OK” to access parameter setting menu, use

“▲” or “▼” to choose the parameter item, and then use

“◄” and “►” to change the parameter value of the place

where the cursor blinks.

(1)Annotation of Yn parameters

6

�Y Ranges

Y-axis voltage per grid

ProbeAtt

Multiple

FitRange

Auto adjustment

Y Offset

Waveform adjusts up & down within the window

CursorV1

Cursor V1:top limit of visible trigger level

CursorV2

CursorV2:bottom limit of visible trigger level

CursorTp

Hide/ Display Measurement Cursor

(2)Annotations of Xn Parameters

7

�TimeBase

X-axis voltage per grid

Fit Base

Auto adjustment

ViewPosi

Horizontal movement to view waveform

SmplDpth

Internal storage depth(1k~6k)

CursorT1

Time measurement cursorT1

CursorT2

Time measurement cursorT2

CursorTp

Hide/Display Measurement Cursor

(3)Annotations of Tr parameters

Choices of Triggering Mode

SyncMode

AUTO/NORM/SINGL/NONE

Automation/Normal/Singular

TrigMode

Rising edge/falling edge triggering mode

Auto Fit

Auto adjustment

Threshol

Horizontal Triggering Position Level

Sensitiv

Horizontal Triggering Range

CursorTp

Hide/Display Horizontal Triggering Position Level

(4)Annotations of Me Parameters

8

�Freq

Signal Frequency

Duty

Duty factor

Vrms

Voltage Effective Value

Vavg

Average Value of Voltage

Vp-p

Peak-to-Peak Voltage

Vmax

Maximum Voltage

Vmin

Minimum Voltage

(5)Annotations of Ex Parameters

Ext Refn

2 waveforms operation (Inp is current waveform; D/Data is

previously saved waveform)

-Inp/Data/-Data/Inp+D/D-Inp/Inp-D/Off

Ext Posi

Display current waveform

9

�(6)Annotations of Fn Parameters

Save Bmp

Save bmp file (waveform image) to the built-in U disk

Save Dat

Save dat file to the built-in U disk

Save Buf

Save buf file (sampling buffering data) to built-in U disk

Save Csv

Save csv file (export sampling buffering data)to built-in U disk

Load Dat

load Dat

Load Buf

load Buf

(7)Annotations of Sn Parameters

Out Freq

Signal output frequency

Out Duty

Signal output dutyfactor

10

�(8)Annotations of Ca Parameters

Oscilloscope Calibration:Press A

Cal Zero

Calibration without voltage

CalRange

Calibration with voltage

Restore

XI

Master Reset

Application Examples

1. Example One: Measure Simple Signal

Observe one unknown signal in a circuit, quickly measure & display the signal’s frequency & peak-to-peak value.

Please operate according to following steps:

ØConnect the channel probe to the detection point of the circuit.

ØSet the Channel mode as AUTO, adjust the (Horizontal) time calibration and (Vertical) voltage calibration,

make sure the signal displays clearly.

ØAdjust Threshol horizontal triggering position to make signal display stable.

ØUse “▲” or “▼” to choose Me items in Measurement Area, then press “M”, use “◄” or “►”to choose the signal

11

�parameters that need analysis, e.g. Freq(frequency), Duty(dutyfactor), Vpp(peak-to-peak voltage)etc., the

measured value will be displayed at the lower right corner of the screen, as shown in the image below:

2. Example Two: Measure with Cursor

Measured value

A cursor can be used to measure the time and voltage of the waveform very quickly.

(1)Measure the cycle of signal source

Please operate according to the following steps:

ØUse “▲” or “▼”to choose Xn items in Measurement Area.

ØPress “OK”

ØUse “▲” or “▼” to choose CursorT1

ØUse“◄” or “►” to adjust the position of CursorT1 to the crest.

ØUse “▲” or “▼” to choose CursorT2

ØUse“◄” or “►” to adjust the position of CursorT2 to the next crest.

And get:△V=1.00mS i.e. the cycle of signal source. As shown in the image below:

T1

12

T2

�(2)Measure peak-to-peak voltage of the signal source.

Please operate according to following steps:

ØUse “▲” or “▼” to choose Yn items in Measurement Area

ØPress “OK”

ØUse “▲” or “▼” to choose CursorV1

ØUse “◄” or “►” to adjust the position of CursorV1 to the crest

ØUse“▲” or “▼”to choose CursorV2

ØUse “◄” or “►” to adjust the position of CursorV2 to the valley

And get:△V=2.08V. i.e. the peak-to-peak voltage of signal source, as shown in the image below:

V1

V2

3. Example Three: Save waveform image

Sometimes waveform images need to be archived or analyzed on PC platform.

Please operate according to following steps:

ØUse “▲” or “▼” to choose the Fn items in Measurement Area, press “OK”, use“▲” or “▼” o choose Save

Bmp, and then use “◄” or “►” to choose the file name on the lower right corner of the screen ,e.g.Save000.BMP,

as shown in the image; and then press“Ø||” to save it to the built-in U disk.

ØJust copy the image to your PC, and you can analyze the waveform image.

13

�4. Example Four: Acquire Single Signal

It’s the superiority and feature of digital oscilloscope to easily aquire non-periodic signals like impulsion and

peak. To aquire a single signal, you need a priori knowledge of it to set trigger level & trigger edge. E.g. if

impulsion is a TTL PWL logic signal, trig level should be set as 2V, trig edge as rising edge trig. If the signal is

not stable, it’s suggested to observe in a normal triggering mode to define trig level & trig edge.

Operation steps are as follows:

ØConnect the channel probe to the detection point of the circuit.

ØSet the triggering: set F as

(rising edge trigger) Triggering setting: DC Coupling.

ØAdjust horizontal time level and vertical scale to proper range.

ØAdjust proper triggering threshold.

ØUse “ ▲ ” or “ ▼ ”to choose Tr items in Measurement Area, press “M”; use “ ▲ ” or “ ▼ ”to choose SyncMode,

and then use “◄” or “►” to choose signal triggering mode, wait for the signal that match the triggering condition

to show up. If there is one signal reaching the preset threshold, it will be sampled and displayed on the screen. As

shown in the picture.

14

�5. Example Five: Compare waveform signals

Please operate according to following steps:

ØInput standard signal waveform to the channel, chose Data in EX, and then choose Save001.DAT to save

the waveform, as shown in the image below.

ØInput unknown to-be-measured signal to the channel, choose Fn → Load Dat → Load001.DAT, and then the

to-be-compared waveforms are shown on the screen simultaneously, as shown in the image.

15

�