Datasheet SHT3xA-DIS

Automotive Grade Humidity and Temperature Sensor

Automotive grade, AEC-Q100 qualified

Fully calibrated, linearized, and temperature

compensated digital output

Wide supply voltage range, from 2.4 V to 5.5 V

I2C Interface with communication speeds up to

1 MHz and two user selectable addresses

Typical accuracy of 1.5 %RH and 0.2 °C for

SHT35A

Very fast start-up and measurement time

Product Summary

SHT3xA-DIS is the next generation of Sensirion’s

automotive grade temperature and humidity sensors. It

builds on a new CMOSens® sensor chip that is at the

heart of Sensirion’s new humidity and temperature

platform. The SHT3xA-DIS has increased intelligence,

reliability and improved accuracy specifications

compared to its predecessor. Its functionality includes

enhanced signal processing, two distinctive and user

selectable I2C addresses and communication speeds of

up to 1 MHz. The DFN package has a footprint of 2.5 x

2.5 mm2 while keeping a height of 0.9 mm. This allows

for integration of the SHT3xA-DIS into a great variety of

applications. Additionally, the wide supply voltage range

of 2.4 V to 5.5 V guarantees compatibility with a wide

range of applications. Its design and test coverage is

specifically optimized for the high quality standards of the

automotive industry.

Benefits of Sensirion’s CMOSens® Technology

9

High reliability and long-term stability

Industry-proven technology with a track record of

more than 15 years

Designed for mass production

High process capability

High signal-to-noise ratio

Further Information ............................................ 19

nRESET

RH Sensor T Sensor

ADC

ADC

Sensor Performance.............................................2

2

Specifications .......................................................6

3

Pin Assignment ....................................................8

4

Operation and Communication .............................9

5

Packaging...........................................................15

6

Shipping Package ..............................................17

7

Quality ................................................................18

Power on

Reset

VSS

Calibration

Memory

Content

1

VDD

Data processing

& Linearization

Digital Interface

ADDR

SDA SCL

RESET

Alert Logic

Alert

Figure 1 Functional block diagram of the SHT3xA-DIS. The

sensor signals for humidity and temperature are factory

calibrated, linearized and compensated for temperature

and supply voltage dependencies.

8

Ordering Information...........................................18

www.sensirion.com

December 2019 - Version 7

1/21

�Datasheet SHT3xA-DIS

1

Sensor Performance

Humidity Sensor Specification

Parameter

SHT30A Accuracy tolerance1

SHT31A Accuracy tolerance1

SHT35A Accuracy tolerance1

Repeatability2

Resolution

Hysteresis

Specified range3

Response time5

Long-term drift

Condition

Value

Units

Typ.

Max.

Typ.

Max.

Typ.

Max.

Low, typ.

Medium, typ.

High, typ.

Typ.

at 25°C

extended4

63%

Typ.7

3

Figure 2

2

Figure 3

±1.5

Figure 4

0.21

0.15

0.08

0.01

0.8

0 to 100

86

2

s

80%RH). After returning into the normal

temperature and humidity range the sensor will slowly come back to calibration state by itself. Prolonged exposure to

extreme conditions may accelerate ageing. To ensure stable operation of the humidity sensor, the conditions described in

the document “SHTxx Assembly of SMD Packages”, section “Storage and Handling Instructions” regarding exposure to

volatile organic compounds have to be met. Please note as well that this does apply not only to transportation and

manufacturing, but also to operation of the SHT3xA-DIS.

2

2.1

Specifications

Electrical Specifications

Parameter

Supply voltage

Power-up/down level

Slew rate change of the

supply voltage

Symbol

Condition

VDD

VPOR

VDD,slew

idle state

(single shot mode)

T= 25°C

idle state

(single shot mode)

T= 125°C

Supply current

IDD

Heater power

Max.

2.4

2.1

3.3

2.3

5.5

2.4

-

-

20

-

0.2

2.0

Units Comments

V

V

Voltage changes on the

VDD line between

VDD,min and VDD,max

V/ms should be slower than

the maximum slew rate;

faster slew rates may

lead to reset;

A

-

-

6.0

Current when sensor is

not performing a

measurement during

single shot mode

Current when sensor is

not performing a

A measurement during

periodic data acquisition

mode

Current consumption

A while sensor is

measuring

Current consumption

(operation with one

measurement per

A

second at lowest

repeatability, single shot

mode)

-

45

-

Measuring

-

600

1500

1.7

-

-

1.5x VDD

-

mA

See also section 3.5

4.5

-

33

mW

Depending on the

supply voltage

IOH

PHeater

Typ.

idle state

(periodic data

acquisition mode)

Average

Alert Output driving

strength

Min.

Heater running

-

Table 3 Electrical specifications, typical values are valid for T=25°C, min. & max. values for T=-40°C … 125°C.

www.sensirion.com

December 2019 - Version 7

6/21

�Datasheet SHT3xA-DIS

2.2

Timing Specification for the Sensor System

Parameter

Symbol

Conditions

Min.

Typ.

Max.

Power-up time

tPU

After hard reset,

VDD ≥ VPOR

-

0.5

1

Soft reset time

tSR

After soft reset.

-

0.5

1

tRESETN

tMEAS,l

tMEAS,m

Low repeatability

Medium repeatability

1

-

2.5

4.5

4

6

tMEAS,h

High repeatability

-

12.5

15

Duration of reset pulse

Measurement duration

Units Comments

Time between VDD reaching

ms VPOR and sensor entering idle

state

Time between ACK of soft

ms reset command and sensor

entering idle state

µs See section 3.6

ms The three repeatability modes

ms differ with respect to

measurement duration, noise

ms level and energy consumption.

Table 4 System timing specification, valid from -40 °C to 125 °C and 2.4 V to 5.5 V.

2.3

Absolute Minimum and Maximum Ratings

Stress levels beyond those listed in Table 5 may cause permanent damage to the device or affect the reliability of the

sensor. These are stress ratings only and functional operation of the device at these conditions is not guaranteed. Ratings

are only tested each at a time.

Parameter

Rating

Supply voltage VDD

-0.3 to 6

Max Voltage on pins (pin 1 (SDA); pin 2 (ADDR); pin 3 (ALERT); pin 4 (SCL); pin 6

-0.3 to VDD+0.3

(nRESET))

Input current on any pin

±100

Operating temperature range

-40 to 125

Storage temperature range

-40 to 150

9

ESD HBM (human body model)

4

ESD CDM (charge device model)10

750

Table 5 Minimum and maximum ratings; voltages may only be applied for short time periods.

9

Units

V

V

mA

°C

°C

kV

V

According to ANSI/ESDA/JEDEC JS-001-2014; AEC-Q100-002.

According to ANSI/ESD S5.3.1-2009; AEC-Q100-011.

10

www.sensirion.com

December 2019 - Version 7

7/21

�Datasheet SHT3xA-DIS

3

Communication frequencies up to 1 Mhz are supported

following the specifications given in Table 20.

Pin Assignment

The SHT3xA-DIS comes in a tiny 8-pin DFN package –

see Table 6.

Name

Comments

1

SDA

2

ADDR

3

ALERT

4

5

SCL

VDD

6

nRESET

7

R

8

VSS

Serial data; input / output

Address pin; input; connect to either

logic high or low, do not leave floating

Indicates alarm condition; output; must

be left floating if unused

Serial clock; input / output

Supply voltage; input

Reset pin active low; input; if not used it

is recommended to be left floating; can

be connected to VDD with a series

resistor of R ≥2 kΩ

No electrical function; to be connected

to VSS

Ground

1

8

2

7

3

6

4

5

VDD

nRESET(6)

VDD(5)

ALERT(3)

SCL(4)

ADDR(2)

SDA(1)

die

VSS(8) pad

100nF

Pin

Both SCL and SDA lines are open-drain I/Os with diodes

to VDD and VSS. They should be connected to external

pull-up resistors (please refer to Figure 11). A device on

the I2C bus must only drive a line to ground. The external

pull-up resistors (e.g. Rp=10 kΩ) are required to pull the

signal high. For dimensioning resistor sizes please take

bus capacity and communication frequency into account

(see for example Section 7.1 of NXPs I2C Manual for

more details11). It should be noted that pull-up resistors

may be included in I/O circuits of microcontrollers. It is

recommended to wire the sensor according to the

application circuit as shown in Figure 11.

RP

RP

R(7)

Figure 11 Typical application circuit. Please note that the

positioning of the pins does not reflect the position on the

real sensor. This is shown in Table 6.

Table 6 SHT3xA-DIS pin assignment (transparent top view).

Dashed lines are only visible if viewed from below. The die

pad is internally connected to VSS.

3.3

Die Pad (center pad)

The electrical specifications of the SHT3xA-DIS are

shown in Table 3. The power supply pins must be

decoupled with a 100 nF capacitor that shall be placed

as close to the sensor as possible – see Figure 11 for a

typical application circuit.

The die pad or center pad is visible from below and

located in the center of the package. It is electrically

connected to VSS. Hence electrical considerations do

not impose constraints on the wiring of the die pad.

However, due to mechanical reasons it is recommended

to solder the center pad to the PCB. For more

information on design-in, please refer to the document

“SHTxx STSxx Design Guide”.

3.2

3.4

3.1

Power Pins (VDD, VSS)

Serial Clock and Serial Data (SCL, SDA)

SCL is used to synchronize the communication between

microcontroller and the sensor. The clock frequency can

be freely chosen between 0 to 1000 kHz. Commands

with clock stretching according to I2C Standard11 are

supported.

The SDA pin is used to transfer data to and from the

sensor. Communication with frequencies up to 400 kHz

must meet the I2C Fast Mode11 standard.

11

ADDR Pin

Through the appropriate wiring of the ADDR pin the I2C

address can be selected (see Table 7 for the respective

addresses). The ADDR pin can either be connected to

logic high or logic low. The address of the sensor can be

changed dynamically during operation by switching the

level on the ADDR pin. The only constraint is that the

level has to stay constant starting from the I2C start

condition until the communication is finished. This allows

to connect more than two SHT3xA-DIS onto the same

http://www.nxp.com/documents/user_manual/UM10204.pdf

www.sensirion.com

December 2019 - Version 7

8/21

�Datasheet SHT3xA-DIS

bus. The dynamical switching requires individual ADDR

lines to the sensors.

Please note that the I2C address is represented through

the 7 MSBs of the I2C read or write header. The LSB

switches between read or write header. The wiring for

the default address is shown in Table 7 and Figure 11.

The ADDR pin must not be left floating. Please note that

only the 7 MSBs of the I2C Read/Write header constitute

the I2C Address.

SHT3xA-DIS

I2C Address in Hex.

representation

I2C address A

0x44 (default)

I2C address B

0x45

Condition

ADDR (pin 2)

connected to logic

low

ADDR (pin 2)

connected to logic

high

Table 7 I2C device addresses.

3.5

ALERT Pin

The alert pin may be used to connect to the interrupt pin

of a microcontroller. The output of the pin depends on

the value of the RH/T reading relative to programmable

limits. Its function is explained in a separate application

note. If not used, this pin must be left floating. The pin

switches high, when alert conditions are met. The

maximum driving loads are listed in Table 3. Be aware

that self-heating might occur, depending on the amount

of current that flows. Self-heating can be prevented if the

Alert Pin is only used to switch a transistor.

3.6

nRESET Pin

The nReset pin may be used to generate a reset of the

sensor. A minimum pulse duration of 1 µs is required to

reliably trigger a reset of the sensor. Its function is

explained in more detail in section 4. If not used it is

recommended to leave the pin floating or to connect it to

VDD with a series resistor of R ≥2 kΩ. However, the

nRESET pin is internally connected to VDD with a pull

up resistor of R = 50 kΩ (typ.).

4

Operation and Communication

The SHT3xA-DIS supports I2C fast mode (and

frequencies up to 1000 kHz). Clock stretching can be

enabled and disabled through the appropriate user

command. For detailed information on the I2C protocol,

refer to NXP I2C-bus specification12.

After sending a command to the sensor a minimal

waiting time of 1ms is needed before another

command can be received by the sensor

12

All SHT3xA-DIS commands and data are mapped to a

16-bit address space. Additionally, data and commands

are protected with a CRC checksum. This increases

communication reliability. The 16 bits commands to the

sensor already include a 3 bit CRC checksum. Data sent

from and received by the sensor is always succeeded by

an 8 bit CRC.

In write direction it is mandatory to transmit the

checksum, since the SHT3xA-DIS only accepts data if it

is followed by the correct checksum. In read direction it

is left to the master to read and process the checksum.

4.1

Power-Up and Communication Start

The sensor starts powering-up after reaching the powerup threshold voltage VPOR specified in Table 3. After

reaching this threshold voltage the sensor needs the

time tPU to enter idle state. Once the idle state is entered

it is ready to receive commands from the master

(microcontroller).

Each transmission sequence begins with a START

condition (S) and ends with a STOP condition (P) as

described in the I2C-bus specification. Whenever the

sensor is powered up, but not performing a

measurement or communicating, it automatically enters

idle state for energy saving. This idle state cannot be

controlled by the user.

4.2

Starting a Measurement

A measurement communication sequence consists of a

START condition, the I2C write header (7-bit I2C device

address plus 0 as the write bit) and a 16-bit

measurement command. The proper reception of each

byte is indicated by the sensor. It pulls the SDA pin low

(ACK bit) after the falling edge of the 8th SCL clock to

indicate the reception. A complete measurement cycle is

depicted in Table 8.

With the acknowledgement of the measurement

command, the SHT3xA-DIS starts measuring humidity

and temperature.

4.3

Measurement Commands for Single Shot

Data Acquisition Mode

In this mode one issued measurement command

triggers the acquisition of one data pair. Each data pair

consists of one 16 bit temperature and one 16 bit

humidity value (in this order). During transmission each

data value is always followed by a CRC checksum, see

section 4.4.

In single shot mode different measurement commands

can be selected. The 16 bit commands are shown in

Table 8. They differ with respect to repeatability (low,

http://www.nxp.com/documents/user_manual/UM10204.pdf

www.sensirion.com

December 2019 - Version 7

9/21

�Datasheet SHT3xA-DIS

medium and high) and clock stretching (enabled or

disabled).

The repeatability setting influences the measurement

duration and thus the overall energy consumption of the

sensor. This is explained in section 2.

Condition

Repeatability

Clock

stretching

Hex. code

MSB

LSB

High

06

Medium

enabled

0x2C

0D

Low

10

High

00

Medium

disabled

0x24

0B

Low

16

e.g. 0x2C06: high repeatability measurement with clock

stretching enabled

The sensor will send the temperature value first and then

the relative humidity value. After having received the

checksum for the humidity value a NACK and stop

condition has to be sent (see Table 8).

The I2C master can abort the read transfer with a NACK

condition after any data byte if it is not interested in

subsequent data, e.g. the CRC byte or the second

measurement result, in order to save time.

In case the user needs humidity and temperature data

but does not want to process CRC data, it is

recommended to read the two temperature bytes of data

with the CRC byte (without processing the CRC data);

after having read the two humidity bytes, the read

transfer can be aborted with a with a NACK.

No Clock Stretching

When a command without clock stretching has been

issued, the sensor responds to a read header with a not

acknowledge (NACK), if no data is present.

Clock Stretching

When a command with clock stretching has been issued,

the sensor responds to a read header with an ACK and

subsequently pulls down the SCL line. The SCL line is

pulled down until the measurement is complete. As soon

as the measurement is complete, the sensor releases

the SCL line and sends the measurement results.

4.5

Measurement Commands for Periodic

Data Acquisition Mode

In this mode one issued measurement command yields

a stream of data pairs. Each data pair consists of one 16

bit temperature and one 16 bit humidity value (in this

order).

Table 8 Measurement commands in single shot mode. The

first “SCL free” block indicates a minimal waiting time of 1ms.

(Clear blocks are controlled by the microcontroller, grey

blocks by the sensor).

4.4

Readout of Measurement Results for

Single Shot Mode

After the sensor has completed the measurement, the

master can read the measurement results (pair of RH&

T) by sending a START condition followed by an I2C

read header. The sensor will acknowledge the reception

of the read header and send two bytes of data

(temperature) followed by one byte CRC checksum and

another two bytes of data (relative humidity) followed by

one byte CRC checksum. Each byte must be

acknowledged by the microcontroller with an ACK

condition for the sensor to continue sending data. If the

sensor does not receive an ACK from the master after

any byte of data, it will not continue sending data.

www.sensirion.com

In periodic mode different measurement commands can

be selected. The corresponding 16 bit commands are

shown in Table 9. They differ with respect to repeatability

(low, medium and high) and data acquisition frequency

(0.5, 1, 2, 4 & 10 measurements per second, mps). Clock

stretching cannot be selected in this mode.

The data acquisition frequency and the repeatability

setting influences the measurement duration and the

current consumption of the sensor. This is explained in

section 2 of this datasheet.

If a measurement command is issued, while the sensor

is busy with a measurement (measurement durations

see Table 4), it is recommended to issue a break

command first (see section 4.8). Upon reception of the

break command the sensor will abort the ongoing

measurement and enter the single shot mode.

December 2019 - Version 7

10/21

�Datasheet SHT3xA-DIS

Hex. code

MSB

LSB

High

32

Medium

0.5

0x20

24

Low

2F

High

30

Medium

1

0x21

26

Low

2D

High

36

Medium

2

0x22

20

Low

2B

High

34

Medium

4

0x23

22

Low

29

High

37

Medium

10

0x27

21

Low

2A

e.g. 0x2130: 1 high repeatability mps - measurement per

second

4

5

6

I2C Address

7

8

9

W

I2C write header

1

2

3

4

5

6

7

Command MSB

8

9

The ART feature can also be evaluated using the

Evaluation Kit EK-H5 from Sensirion.

Command

Hex Code

Periodic Measurement with

ART

0x2B32

2

3

4

5

6

I2C Address

7

8

9

W

I2C write header

1

2

3

4

5

6

7

Command MSB

8

9

10 11 12 13 14 15 16 17 18

Command LSB

ACK

1

S

16-bit command

Table 11 Command for a periodic data acquisition with

the ART feature (Clear blocks are controlled by the

microcontroller, grey blocks by the sensor).

10 11 12 13 14 15 16 17 18

Command LSB

16-bit command

Table 9 Measurement commands for periodic data acquisition

mode (Clear blocks are controlled by the microcontroller, grey

blocks by the sensor). N.B.: At the highest mps setting selfheating of the sensor might occur.

4.6

The ART (accelerated response time) feature can be

activated by issuing the command in Table 11. After

issuing the ART command the sensor will start acquiring

data with a frequency of 4Hz.

The ART command is structurally similar to any other

command in Table 9. Hence section 4.5 applies for

starting a measurement, section 4.6 for reading out data

and section 4.8 for stopping the periodic data acquisition.

ACK

3

ACK

S

2

ACK

1

ART Command

ACK

mps

4.7

ACK

Condition

Repeatability

Readout of Measurement Results for

Periodic Mode

Transmission of the measurement data can be initiated

through the fetch data command shown in Table 10. If

no measurement data is present the I2C read header is

responded with a NACK (Bit 9 in Table 10) and the

communication stops. After the read out command fetch

data has been issued, the data memory is cleared, i.e.

no measurement data is present.

Command

Hex code

Fetch Data

0x E0 00

4.8

Break command / Stop Periodic Data

Acquisition Mode

The periodic data acquisition mode can be stopped using

the break command shown in Table 12. It is

recommended to stop the periodic data acquisition prior

to sending another command (except Fetch Data

command) using the break command. Upon reception of

the break command the sensor will abort the ongoing

measurement and enter the single shot mode. This takes

1ms.

Command

Hex Code

Break

0x3093

Table 12 Break command (Clear blocks are controlled by

the microcontroller, grey blocks by the sensor).

4.9

Reset

A system reset of the SHT3xA-DIS can be generated

externally by issuing a command (soft reset) or by

sending a pulse to the dedicated reset pin (nReset pin).

Additionally, a system reset is generated internally

during power-up. During the reset procedure the sensor

will not process commands.

Table 10 Fetch Data command (Clear blocks are controlled

by the microcontroller, grey blocks by the sensor).

www.sensirion.com

In order to achieve a full reset of the sensor without

removing the power supply, it is recommended to use the

nRESET pin of the SHT3xA-DIS.

December 2019 - Version 7

11/21

�Datasheet SHT3xA-DIS

Interface Reset

Code

0x00

0x06

1

2

3

4

5

6

7

8

S General Call Address

General Call 1st byte

The SHT3xA-DIS provides a soft reset mechanism that

forces the system into a well-defined state without

removing the power supply. When the system is in idle

state the soft reset command can be sent to the

SHT3xA-DIS. This triggers the sensor to reset its system

controller and reloads calibration data from the memory.

In order to start the soft reset procedure the command

as shown in Table 13 should be sent.

It is worth noting that the sensor reloads calibration data

prior to every measurement by default.

Command

Hex Code

Soft Reset

0x30A2

0x0006

9

1

2

3

4

5

6

7

Reset Command

8

9

ACK

Soft Reset / Re-Initialization

Command

Address byte

Second byte

Reset command using the

general call address

ACK

If communication with the device is lost, the following

signal sequence will reset the serial interface: While

leaving SDA high, toggle SCL nine or more times. This

must be followed by a Transmission Start sequence

preceding the next command. This sequence resets the

interface only. The status register preserves its content.

General Call 2nd byte

Table 14 Reset through the general call address (Clear

blocks are controlled by the microcontroller, grey blocks by

the sensor).

Reset through the nReset Pin

Pulling the nReset pin low (see Table 6) generates a

reset similar to a hard reset. The nReset pin is internally

connected to VDD through a pull-up resistor and hence

active low. The nReset pin has to be pulled low for a

minimum of 1 µs to generate a reset of the sensor.

Hard Reset

Table 13 Soft reset command (Clear blocks are controlled

by the microcontroller, grey blocks by the sensor).

A hard reset is achieved by switching the supply voltage

to the VDD Pin off and then on again. In order to prevent

powering the sensor over the ESD diodes, the voltage to

pins 1 (SDA), 4 (SCL) and 2 (ADDR) also needs to be

removed.

4.10 Heater

Reset through General Call

Additionally, a reset of the sensor can also be generated

using the “general call” mode according to I2C-bus

specification12. This generates a reset which is

functionally identical to using the nReset pin. It is

important to understand that a reset generated in this

way is not device specific. All devices on the same I2C

bus that support the general call mode will perform a

reset. Additionally, this command only works when the

sensor is able to process I2C commands. The

appropriate command consists of two bytes and is

shown in Table 14.

The SHT3xA is equipped with an internal heater, which

is meant for plausibility checking only. The temperature

increase achieved by the heater depends on various

parameters and lies in the range of a few degrees

centigrade. It can be switched on and off by command,

see table below. The status is listed in the status register.

After a reset the heater is disabled (default condition).

Command

Heater Enable

Heater Disabled

Hex Code

MSB

LSB

0x30

6D

66

Table 15 Heater command (Clear blocks are controlled by

the microcontroller, grey blocks by the sensor).

4.11 Status Register

The status register contains information on the

operational status of the heater, the alert mode and on

the execution status of the last command and the last

write sequence. The command to read out the status

www.sensirion.com

December 2019 - Version 7

12/21

�Datasheet SHT3xA-DIS

register is shown in Table 16 whereas a description of

the content can be found in Table 17.

Command

Hex code

Read Out of status register

0xF32D

All flags (Bit 15, 11, 10, 4) in the status register can be

cleared (set to zero) by sending the command shown in

Table 18.

Command

Hex Code

Clear status register

0x 30 41

Table 18 Command to clear the status register (Clear

blocks are controlled by the microcontroller, grey blocks by

the sensor).

Table 16 Command to read out the status register (Clear

blocks are controlled by the microcontroller, grey blocks by

the sensor).

Bit

Field description

15

Alert pending status

'0': no pending alerts

'1': at least one pending alert

Reserved

Heater status

‘0’ : Heater OFF

‘1’ : Heater ON

Reserved

RH tracking alert

‘0’ : no alert

‘1’ . alert

T tracking alert

‘0’ : no alert

‘1’ . alert

14

13

12

11

10

9:5

4

Reserved

System reset detected

Default

value

‘1’

‘0’

‘0’

‘0’

‘0

‘0’

‘xxxxx’

‘1’

'0': no reset detected since last ‘clear

status register’ command

3:2

1

0

'1': reset detected (hard reset, soft reset

command or supply fail)

Reserved

Command status

'0': last command executed successfully

'1': last command not processed. It was

either invalid, failed the integrated

command checksum

Write data checksum status

'0': checksum of last write transfer was

correct

'1': checksum of last write transfer failed

Table 17 Description of the status register.

Clear Status Register

www.sensirion.com

‘00’

‘0’

4.12 Checksum Calculation

The 8-bit CRC checksum transmitted after each data

word is generated by a CRC algorithm. Its properties are

displayed in Table 19. The CRC covers the contents of

the two previously transmitted data bytes. To calculate

the checksum only these two previously transmitted data

bytes are used.

Property

Value

Name

Width

Protected data

Polynomial

Initialization

Reflect input

Reflect output

Final XOR

Examples

CRC-8

8 bit

read and/or write data

0x31 (x8 + x5 + x4 + 1)

0xFF

False

False

0x00

CRC (0xBEEF) = 0x92

Table 19 I2C CRC properties.

4.13 Conversion of Signal Output

Measurement data is always transferred as 16-bit values

(unsigned integer). These values are already linearized

and compensated for temperature and supply voltage

effects. Converting those raw values into a physical

scale can be achieved using the following formulas.

Relative humidity conversion formula (result in %RH):

RH 100

‘0’

S RH

2 16 1

Temperature conversion formula (result in °C & °F):

ST

2 1

S

T F 49 315 16 T

2 1

T C 45 175

16

SRH and ST denote the raw sensor output for humidity

and temperature, respectively. The formulas work only

December 2019 - Version 7

13/21

�Datasheet SHT3xA-DIS

correctly when SRH and ST are used in decimal

representation.

4.14 Communication Timing

Parameter

Symbol

SCL clock frequency

Hold time (repeated) START

condition

LOW period of the SCL

clock

HIGH period of the SCL

clock

fSCL

Min.

Typ.

Max.

Units

0

-

1000

kHz

0.24

-

-

µs

tLOW

0.5

-

-

µs

tHIGH

0.26

-

-

µs

-

250

300

300

0.9

ns

ns

ns

ns

ns

µs

tHD;STA

Conditions

After this period, the first

clock pulse is generated

SDA hold time

tHD;DAT

SDA set-up time

SCL/SDA rise time

SCL/SDA fall time

SDA valid time

Set-up time for a repeated

START condition

Set-up time for STOP

condition

Capacitive load on bus line

Low level input voltage

High level input voltage

Low level output voltage

tSU;DAT

tR

tF

tVD;DAT

0

0

50

-

tSU;STA

0.26

-

-

µs

tSU;STO

0.26

-

-

µs

CB

VIL

VIH

VOL

0

0.7xVDD

-

-

400

0.3xVDD

1xVDD

0.66

pF

V

V

V

3 mA sink current

Comments

Transmitting data

Receiving data

Table 20 Timing specifications for I2C communication, valid for T=-40°C … 125°C and VDD = VDDmin… VDDmax. The nomenclature

above is according to the I2C Specification (UM10204, Rev. 6, April 4, 2014).

1/fSCL

tHIGH

tR

tLOW

tF

70%

SCL

tSU;DAT

30%

tHD;DAT

DATA IN

70%

SDA

30%

tVD;DAT

tF

DATA OUT

tR

70%

SDA

30%

Figure 12 Timing diagram for digital input/output pads. SDA directions are seen from the sensor. Bold SDA lines are

controlled by the sensor, plain SDA lines are controlled by the micro-controller. Note that SDA valid read time is triggered

by falling edge of preceding toggle.

www.sensirion.com

December 2019 - Version 7

14/21

�Datasheet SHT3xA-DIS

5

Packaging

SHT3xA-DIS sensors are provided in an open-cavity

DFN package. DFN stands for dual flat no leads. The

humidity sensor opening is centered on the top side of

the package.

The sensor chip is made of silicon and is mounted to a

lead frame. The latter is made of Cu plated with

Ni/Pd/Au. Chip and lead frame are overmolded by an

epoxy-based mold compound leaving the central die pad

and I/O pins exposed for mechanical and electrical

connection. Please note that the side walls of the sensor

are diced and therefore these diced lead frame surfaces

are not covered with the respective plating.

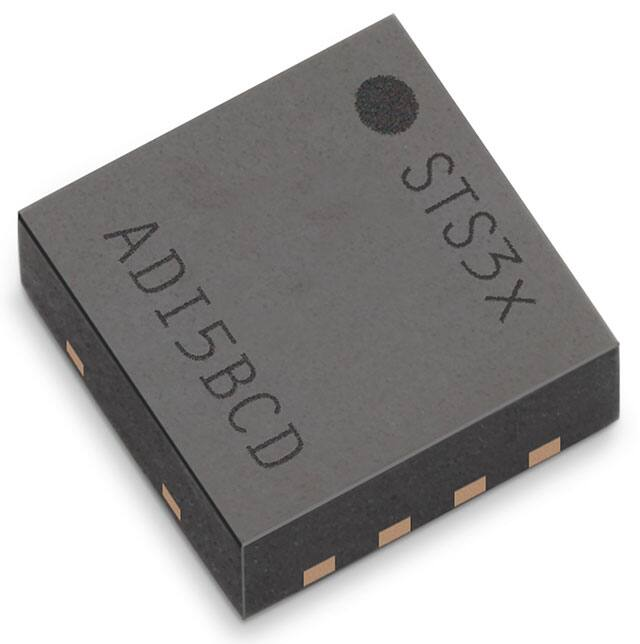

The bottom line consists of 7 letters, with the initial A

indicating the automotive version. The two digits XY

(=DI) describe the output mode. The fourth letter (A)

represents the manufacturing year (4 = 2014, 5 = 2015,

etc). The last three digits (BCD) represent an

alphanumeric tracking code. That code can be decoded

by Sensirion only and allows for tracking on batch level

through production, calibration and testing – and will be

provided upon justified request.

If viewed from below pin 1 is indicated by triangular

shaped cut in the otherwise rectangular die pad. The

dimensions of the triangular cut are shown in Figure 14

through the labels T1 & T2.

The package (except for the humidity sensor opening)

follows JEDEC publication 95, design registration 4.20,

small scale plastic quad and dual inline, square and

rectangular, No-LEAD packages (with optional thermal

enhancements) small scale (QFN/SON), Issue D.01,

September 2009.

SHT 3 x

SHT3xA-DIS has a Moisture Sensitivity Level (MSL) of

1, according to IPC/JEDEC J-STD-020. At the same

time, it is recommended to further process the sensors

within 1 year after date of delivery.

5.1

A XYABCD

Traceability

All SHT3xA-DIS sensors are laser marked for easy

identification and traceability. The marking on the sensor

top side consists of a pin-1 indicator and two lines of text.

Figure 13 Top view of the SHT3xA-DIS illustrating the laser

marking.

The top line consists of the pin-1 indicator which is

located in the top left corner and the product name. The

small letter x stands for the accuracy class.

www.sensirion.com

December 2019 - Version 7

15/21

�Datasheet SHT3xA-DIS

5.2

Package Outline

Figure 14 Dimensional drawing of SHT3xA-DIS sensor package

Parameter

Package height

Leadframe height

Pad width

Package width

Center pad length

Package length

Center pad width

Pad pitch

Pad length

Symbol

Min

Nom.

Max

Units Comments

A

A3

b

D

D2

E

E2

e

L

S

0.8

0.2

2.4

1

2.4

1.7

0.25

-

0.9

0.2

0.25

2.5

1.1

2.5

1.8

0.5

0.35

-

1

0.3

2.6

1.2

2.6

1.9

0.45

1.5

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

T1xT2

-

0.3x45°

-

mm

Max cavity

Center pad marking

Only as guidance. This value includes all tolerances,

including displacement tolerances. Typically the opening

will be smaller.

indicates the position of pin 1

Table 21 Package outline.

5.3

Land Pattern

Figure 15 shows the land pattern. The land pattern is

understood to be the open metal areas on the PCB, onto

which the DFN pads are soldered.

The solder mask is understood to be the insulating layer

on top of the PCB covering the copper traces. It is

recommended to design the solder pads as a NonSolder Mask Defined (NSMD) type. For NSMD pads, the

solder mask opening should provide a 60 μm to 75 μm

design clearance between any copper pad and solder

mask. As the pad pitch is only 0.5 mm we recommend to

have one solder mask opening for all 4 I/O pads on one

side.

www.sensirion.com

For solder paste printing it is recommended to use a

laser-cut, stainless steel stencil with electro-polished

trapezoidal walls and with 0.1 or 0.125 mm stencil

thickness. The length of the stencil apertures for the I/O

pads should be the same as the PCB pads. However,

the position of the stencil apertures should have an offset

of 0.1 mm away from the center of the package. The die

pad aperture should cover about 70 – 90 % of the die

pad area –thus it should have a size of about 0.9 mm x

1.6 mm.

For information on the soldering process and further

recommendation on the assembly process please

consult

the

Application

Note

HT_AN_SHTxx_Assembly_of_SMD_Packages , which

can be found on the Sensirion webpage.

December 2019 - Version 7

16/21

�Datasheet SHT3xA-DIS

Recommended Land Pattern

Recommended Stencil Aperture

2.55

0.5

1.6

0.25

0.5

0.5

1.7

0.5

0.25

0.5

0.5

2.35

0.2

1

0.3

0.55

0.9

0.55

Figure 15 Recommended metal land pattern (left) and stencil apertures (right) for the SHT3xA-DIS. The dashed lines represent the

outer dimension of the DFN package. The PCB pads (left) and stencil apertures (right) are indicated through the shaded areas.

6

Shipping Package

Ø1.5 +.1 /-0.0

4.00

2.00 ±.05 SEE Note 2

Ø1.00 MIN

1.75 ±.1

4.00 SEE Note 1

0.30 ±.05

A

5.50 ±.05

SEE NOTE 2

R 0.2 MAX.

B0

B

12.0 +0.3/-0.1

A

R 0.25 TYP.

K0

A0

SECTION A - A

A0 = 2.75

B0 = 2.75

K0 = 1.20

TOLERANCES - UNLESS

NOTED 1PL ±.2 2PL ±.10

NOTES:

1. 10 SPROCKET HOLE PITCH CUMULATIVE TOLERANCE ±0.2

2. POCKET POSITION RELATIVE TO SPROCKET HOLE MEASURED

AS TRUE POSITION OF POCKET, NOT POCKET HOLE

3. A0 AND B0 ARE CALCULATED ON A PLANE AT A DISTANCE "R"

ABOVE THE BOTTOM OF THE POCKET

DETAIL B

Figure 16 Technical drawing of the packaging tape with sensor orientation in tape. Header tape is to the right and trailer tape to the

left on this drawing. Dimensions are given in millimeters.

www.sensirion.com

December 2019 - Version 7

17/21

�Datasheet SHT3xA-DIS

7

Quality

Qualification of the SHT3xA-DIS is performed based on

the AEC Q 100 qualification test method.

7.1

Material Contents

The device is fully RoHS and WEEE compliant, e.g. free

of Pb, Cd, and Hg.

8

Ordering Information

The SHT3xA-DIS can be ordered in tape and reel

packaging with different sizes, see Table 22. The reels

are sealed into antistatic ESD bags. The document

“SHT3x shipping package” that shows the details about

the shipping package is available upon request.

Name

SHT30A-DIS-B2.5kS

SHT30A-DIS-B10kS

SHT31A-DIS-B2.5kS

SHT31A-DIS-B10kS

SHT35A-DIS-B2.5kS

SHT35A-DIS-B10kS

Quantity

2500

10000

2500

10000

2500

10000

Order Number

3.000.364

1-101249-01

3.000.282

1-101255-01

3.000.365

1-101620-01

Table 22 SHT3xA-DIS ordering options.

www.sensirion.com

December 2019 - Version 7

18/21

�Datasheet SHT3xA-DIS

9

Further Information

For more in-depth information on the SHT3xA-DIS and its application please consult the document in Table 23.

Parameter values specified in the datasheet overrule possibly conflicting statements given in references cited in

this datasheet.

Document Name

Description

Source

SHT3x Shipping Package

Information on Tape, Reel and shipping bags

(technical drawing and dimensions)

Available upon request

Available for download at the Sensirion

humidity sensors download center:

SHTxx STSxx Assembly of SMD

Packages

Assembly Guide (Soldering Instructions)

SHTxx STSxx Design Guide

Design guidelines for designing SHTxx humidity

sensors into applications

SHTxx Handling Instructions

Available for download at the Sensirion

Guidelines for proper handling of SHTxx humidity

humidity sensors download center:

sensors

www.sensirion.com/humidity-download

Sensirion Humidity Sensor

Specification Statement

Definition of sensor specifications.

www.sensirion.com/humidity-download

Available for download at the Sensirion

humidity sensors download center:

www.sensirion.com/humidity-download

Available for download at the Sensirion

humidity sensors download center:

www.sensirion.com/humidity-download

Table 23 Documents containing further information relevant for SHT3xA-DIS.

www.sensirion.com

December 2019 - Version 7

19/21

�Datasheet SHT3xA-DIS

Revision History

Date

Version

Page(s)

Changes

May 2015

1

All

Initial release

17. July 2015

2

5

Updated information on absolute minimum and maximum ratings

November 2015

3

All

Updated temperature specifications; correction of typos; minor refinement of

sensor parameters

January 2017

4

All

SHT35A specifications included, general makeover, minor refinement of sensor

parameters

March 2017

5

16

Pad length updated, Table 21

Land pattern drawing in Figure 15 simplified (no parameter changed)

October 2018

6

2

Improved repeatability Table 1

2

Updated T-resolution and -repeatability Table 2

6

Updated Table 3

7

Section 2.3: Introduced “Ratings are only tested each at a time.”

9

Introduced note on minimal waiting time in section 4

9

Updated Table 7

10

Updated caption Table 8

10

10

11

14

19

All

December 2019

www.sensirion.com

7

Removed “The stop condition is optional.” In section 4

Changed formulation in section 4.5 “Upon reception of the break command the

sensor will abort the ongoing measurement and enter the single shot mode.”

Changed formulation in section 4.8 to “Upon reception of the break command

the sensor will abort the ongoing measurement and enter the single shot

mode. This takes 1ms.”

Updated Table 20

Introduced “Parameter values specified in the datasheet overrule possibly

conflicting statements given in references cited in this datasheet.“ in section 9.

Typo & wording corrections etc.

1

Updated general introductory information

18

Updated available reel sizes in Table 22

December 2019 - Version 7

20/21

�Datasheet SHT3xA-DIS

Important Notices

Warning, Personal Injury

Do not use this product as safety or emergency stop devices

or in any other application where failure of the product could

result in personal injury. Do not use this product for

applications other than its intended and authorized use.

Before installing, handling, using or servicing this product,

please consult the data sheet and application notes. Failure

to comply with these instructions could result in death or

serious injury.

If the Buyer shall purchase or use SENSIRION products for any

unintended or unauthorized application, Buyer shall defend,

indemnify and hold harmless SENSIRION and its officers,

employees, subsidiaries, affiliates and distributors against all

claims, costs, damages and expenses, and reasonable attorney

fees arising out of, directly or indirectly, any claim of personal

injury or death associated with such unintended or unauthorized

use, even if SENSIRION shall be allegedly negligent with respect

to the design or the manufacture of the product.

ESD Precautions

The inherent design of this component causes it to be sensitive

to electrostatic discharge (ESD). To prevent ESD-induced

damage and/or degradation, take customary and statutory ESD

precautions when handling this product.

See application note “ESD, Latchup and EMC” for more

information.

Warranty

SENSIRION warrants solely to the original purchaser of this

product for a period of 12 months (one year) from the date of

delivery that this product shall be of the quality, material and

workmanship defined in SENSIRION’s published specifications

of the product. Within such period, if proven to be defective,

SENSIRION shall repair and/or replace this product, in

SENSIRION’s discretion, free of charge to the Buyer, provided

that:

notice in writing describing the defects shall be given to

SENSIRION within fourteen (14) days after their

appearance;

such defects shall be found, to SENSIRION’s reasonable

satisfaction, to have arisen from SENSIRION’s faulty

design, material, or workmanship;

the defective product shall be returned to SENSIRION’s

factory at the Buyer’s expense; and

the warranty period for any repaired or replaced product

shall be limited to the unexpired portion of the original

period.

This warranty does not apply to any equipment which has not

been installed and used within the specifications recommended

by SENSIRION for the intended and proper use of the

equipment. EXCEPT FOR THE WARRANTIES EXPRESSLY

SET FORTH HEREIN, SENSIRION MAKES NO WARRANTIES,

EITHER EXPRESS OR IMPLIED, WITH RESPECT TO THE

PRODUCT. ANY AND ALL WARRANTIES, INCLUDING

WITHOUT

LIMITATION,

WARRANTIES

OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSLY EXCLUDED AND DECLINED.

SENSIRION is only liable for defects of this product arising under

the conditions of operation provided for in the data sheet and

proper use of the goods. SENSIRION explicitly disclaims all

warranties, express or implied, for any period during which the

goods are operated or stored not in accordance with the technical

specifications.

SENSIRION does not assume any liability arising out of any

application or use of any product or circuit and specifically

disclaims any and all liability, including without limitation

consequential or incidental damages. All operating parameters,

including without limitation recommended parameters, must be

validated for each customer’s applications by customer’s

technical experts. Recommended parameters can and do vary in

different applications.

SENSIRION reserves the right, without further notice, (i) to

change the product specifications and/or the information in this

document and (ii) to improve reliability, functions and design of

this product.

Copyright © 2019, by SENSIRION.

CMOSens® is a trademark of Sensirion

All rights reserved

Headquarters and Subsidiaries

SENSIRION AG

Laubisruetistr. 50

CH-8712 Staefa ZH

Switzerland

Sensirion Inc. USA

phone: +1 312 690 5858

info-us@sensirion.com

www.sensirion.com

Sensirion Korea Co. Ltd.

phone: +82 31 337 7700~3

info-kr@sensirion.com

www.sensirion.co.kr

phone: +41 44 306 40 00

fax:

+41 44 306 40 30

info@sensirion.com

www.sensirion.com

Sensirion Japan Co. Ltd.

phone: +81 3 3444 4940

info-jp@sensirion.com

www.sensirion.co.jp

Sensirion China Co. Ltd.

phone: +86 755 8252 1501

info-cn@sensirion.com

www.sensirion.com.cn/

Sensirion Taiwan Co. Ltd.

phone: +41 44 306 40 00

To find your local representative, please visit www.sensirion.com/contact

info@sensirion.com

www.sensirion.com

December 2019 - Version 7

21/21

�