A motorized development platform

�To our valued customers

I want to express my thanks to you for being interested in our products and for having confidence in

MikroElektronika.

The primary aim of our company is to design and produce high quality electronic products and to

constantly improve the performance thereof in order to better suit your needs.

We hope you’ll have great fun with the Buggy, and that it’ll be a great learning experience as well.

Nebojsa Matic,

Owner and General Manager

of MikroElektronika

���Table of contents

Introduction

6

Motors

20

Package contains

7

Power supply

21

It has the look and the features

8

mikroBUS™ sockets

22

Assembling

10

click™ boards

23

Choose your driver

17

Firmware

24

clicker 2 & mikromedia pinout

18

Android app

24

clicker 2 – a click™ board two-seater

19

Schematic

25

Lights

20

What’s Next?

26

5

�A motorized development platform

Introduction

For years we have been honing our expertise in designing

powerful and easy to use hardware development tools. Our

reputation was forged, in part, on our range of mikromedia

boards and the ever-growing line of click™ boards. This time,

we’ve put all that experience to use, and put it on wheels —

the Buggy is a four-wheel robotics workstation that takes

advantage of all the innovations we came up with in

recent years: it employs a clicker 2 / mikromedia pinout that

makes it compatible with a wide range of microcontroller

architectures. Then we added mikroBUS™ sockets giving

you the choice of over 100 click™ boards to enhance the

four-wheeler and make it your own with various sensors and

communication boards. We also published a free Android App

for remotely controlling the Buggy and we made the code

available to you. Finally, we took great care to provide you with

the relevant documentation to make it easy to start working

on your Buggy projects right away. Hence this manual. Enjoy.

Open source

Android App to

jump-start your

development

42 mm

1 653.54 mils

61 mm

2 401.57 mils

139 mm

5 472.44 mils

Package dimensions:

L 277mm, W 232mm, H 56mm

Three additional

click™ board sockets,

additional outputs,

mounting holes

Four-wheel

clicker 2 or

mikromedia

workstation

Package weight:

~800-850g

Power supply

3.7V, 2000mAh LiPo battery

6

108.5 mm

4 271.65 mils

84 mm

3 307.08 mils

�Package contains

hoizontal bar

2 x side panels

LiPo

battery

4 x removable wheels

the main panel

with circuitry,

motors, lights

3 x mikroBUS™ plates

Mini USB cable

The kit contains 1) the main panel with circuitry, motors, lights, and the mikromedia connector; 2) a pair of battery holder tabs; 3) two side panels and a horizontal

bar; 4) three mikroBUS™ plates; and 5) four wheels.

7

�A motorized development platform

It has the looks...

Multiple slots �for

soldering t� he top bar

Top bar with mounting

�holes for antennas

Two mikroBUS™ socket

�plates on the front

Front signal light

Front (main

beam) headlight

Removable �wheels

8

�... and the features

Analog input screw

t� erminals (shared with

�mikroBUS™ sockets 2 & 3)

Power screw �terminal

(5 and 3.3V)

Rear and stop light

Rear signal light

ON/OFF switch

Mini USB connector for

�charging the battery

Rear mikroBUS™

�socket plate

9

�A motorized development platform

Assembly

With basic soldering skills you’ll assemble the Buggy in no time. Check out

the “package contains” section on page 7 to make sure you have everything

prepared. Then proceed with step 1 and all the way through.

10

�STEP 1 - Remove wheels from one side

STEP 2 - Connect the battery

STEP 3 - Insert the battery

The Buggy’s main board is packed in the box with

wheels attached. Remove both wheels from the

left side of the board, by pulling on them.

Pull the battery wire under the rail and attach it

to the battery connector.

Push the whole battery under the rail. Be careful not

to pinch the wire. The battery should fit squarely

between Buggy’s four motors.

STEP 4 - Insert battery holder tabs

STEP 5 - Solder battery holder tabs

STEP 6 - Reattach the wheels

Look for the two smallest pieces of PCB in the

box. Those are the supporting tabs that keep the

battery in place. Pick either one and place it in the

sockets on either side of the board, so that the

curved side is facing outwards

Hold the battery-holder tab and flip the

main board so that the battery is now facing

downwards. Solder the tab. Repeat step 4 and 5

for the second battery-holder tab.

The axle and the socket on the wheel are not

completely round, so be careful to correctly align

them before pushing the wheel towards the axle.

11

�A motorized development platform

STEP 7 - Insert mikroBUS™ socket plates

STEP 8 - Solder mikroBUS™ socket plates

STEP 9 - Set side panels in place

The Buggy comes with three additional

mikroBUS™ socket plates. Pick either one and slip

it inside one of the three slits on the main board,

marked mikroBUS 1, mikroBUS 2, and mikroBUS 3.

While holding the mikroBUS™ socket plate inside

the slit with your finger, flip the Buggy. Solder

the plates, making sure to cover each of the eight

contact points. Repeat steps 7 and 8 for the

remaining two plates.

Next, position the two side panels. You won’t be

soldering them yet, but pay attention to place the

panels in the correct direction: the lower part faces

forward, where the white and yellow LEDs are.

STEP 10 - Attach top bar

STEP 11 - Solder top bar

STEP 12 - Solder side panels

The top bar connects the two side panels and

keeps the Buggy rigid, while also providing slots for

soldering additional electronics. Notice that each

side panel has four different slots for placing the

top bar. You can use whichever one suits you best.

Solder the top bar to each side panel. You can

always unsolder it later if you’d like to to change

its position.

With the top bar soldered, flip the Buggy. Solder

the two side panels to the main board; there are

two contact points for each panel, one in each

corner of the main board. Now flip the Buggy back

on its wheels. You’re done assembling!

12

�www.mikroe.com/buggy

��A motorized development platform

www.mikroe.com/buggy

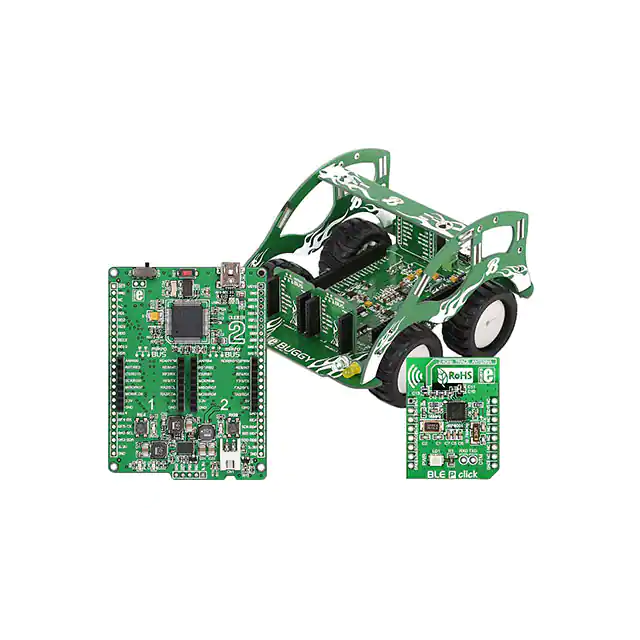

��Choose your driver

Now that you’ve assembled the Buggy, the only remaining thing is to put a microcontroller in the driver’s seat. You have two types of choices: (1) clicker 2 is a

compact development platform with a MCU and two mikroBUS™ sockets (2) mikromedia is a multimedia development system with a 320x240 TFT touchscreen and

a rich set of onboard modules. Both of these boards are available for different microcontroller architectures.

clicker 2

mikromedia

click™

board

If you want to remotely

control your Buggy, you’ll

also need a communications

click™ board with a wireless

transceiver module (Wi-Fi or

Bluetooth work well).

17

�A motorized development platform

Not connected

Reference Ground

Not connected

Left side motors control

Pin functions

Right side motors control

mikroBUS 1 PWM pin

mikroBUS 2 PWM pin

mikroBUS 3 PWM pin

Brake lights

Right signal lights

Low intensity lights

mikroBUS 3 CS pin

mikroBUS 3 RST pin

main beam headlights

Not connected

RX

TX

SCL

I2C Lines

SDA

3.3V power supply

Reference Ground

UART Lines

18

NC

GND

NC

NC

PWM-A

PWM-B

PWM-C

PWM-D

PWM1

PWM2

PWM3

BRAKE

TURN-R

H.LAMPS

CS3

RST3

M.BEAM

NC

NC

NC

UART

UART

I2C

I2C

3.3V

GND

5V

GND

AN1

AN2

AN3

BAT-VSENSE

CS2

RST2

TURN-L

INT1

INT2

INT3

BAT-STAT

VBUS

NC

NC

NC

NC

NC

RST1

CS1

SPI

SPI

SPI

3.3V

GND

System power supply

Reference Ground

mikroBUS 1 AN pin

mikroBUS 2 AN pin

mikroBUS 3 AN pin

battery sensing pin

mikroBUS 2 CS pin

mikroBUS 2 RST pin

left signal light

mikroBUS 1 INT pin

mikroBUS 2 INT pin

mikroBUS 3 INT pin

battery charging status

USB power supply

Not connected

mikroBUS 1 RST pin

mikroBUS 1 CS pin

SCK

SPI Lines

MISO

MOSI

3.3V power supply

Reference Ground

Pin functions

clicker 2 & mikromedia pinout

The Buggy carries a standard clicker 2/mikromedia

pinout with a pair of 1x26

connection pads. However,

to make the Buggy easier

to program, some of the

pins have descriptive labels

that point out their functions in relations to the motors, lights and so on.

�clicker 2 – a click™ board two-seater

Available for several MCU architectures, clicker 2 is a compact development kit with two mikroBUS™ sockets for click™ board connectivity. You can use it to quickly

build your own gadgets with unique functionalities and features. It’s an ideal Buggy driver because it lets you leverage the huge potential of click™ boards, our

constantly expanding range of over 100 add-on boards.

19

�A motorized development platform

Lights

Motors

VCC-5V

D3

PMEG3010ER

Just like a real car, the Buggy has a set

of front and rear lights for signaling and

for lighting the way. These lights are

routed in a way that makes them easier

to program should you develop your own

firmware for the Buggy. They’re grouped

in three sets based on function: (1)

The pair of white LEDs on the front are

headlights, with two modes of brightness;

(2) The red LED brake lights on the rear

also have two brightness levels; and (3)

the two pair of yellow LED signal lights

are grouped by left and right side.

Highlighted above are the five pins that

control the lights. TURN L and TURN R

regulate the signal lights. H.LAMPS turns

on the headlights and rear lights at low

intensity. Activate both the M.BEAM and

VCC

TURN_L

BRAKE

TURN_R

HEADLAMPS

MAIN BEAM

HDR2

FL

VCC

LDY

RL

LDR

2

2

1

VCC

LDW

VCC

PWM-C and

PWM-D

pins control

the right

side motors

PWM-A

and PWM-B

pins control

the left

side motors

0

REAR LEFT LIGHTS

VCC

VCC

FR

LDY

VCC

LDR

VCC

RR

LDY

2

2

1

1

0

0

VCC

REAR RIGHT LIGHTS

FRONT RIGHT LIGHTS

LED schematics

20

U6

1

0

FRONT LEFT LIGHTS

VCC

U7

H.LAMPS at the same time for brighter

headlights. For brighter rear lights (stop

lights), activate the BRAKE and H.LAMPS

at the same time.

VCC

LDW

HDR1

Pins for controling Buggy’s light

VCC

LDY

The Buggy has a differential motor drive. The four DC motors

are split by left and right axis (controlled by DRV833RTY motor

drivers, U6 and U7, one for each side). Steering takes place when

you vary the relative rate of rotation between the left and right

side. This type of steering is simpler to manipulate if you’ll be

writing your own firmware for the Buggy. Also, when one pair

of wheels is put in reverse while the other is in normal gear, the

Buggy will start to spin, which wouldn’t be possible otherwise.

To prevent the motors from drawing too much current from the

battery (and in doing so prevent the other components from

functioning properly) a few resistors are placed to limit current

draw. Each motor can draw a maximum of 400 mA, for a total of

1.6 A for all four motors.

�Power supply

Battery charger

Screw teminals

ON/OFF switch

The Buggy runs on a 3.7V 2000mA battery.

Once you install the battery, there’s no need to

take it out; charge it through the Buggy’s USB

port. A miniature single-cell, fully integrated LiIon, Li-Polymer charge management controller.

MCP73832 enables that. A red power indication

LED will signalize when the battery is charging.

Once charged, it’ll turn off.

The Buggy’s expandability is not limited to

mikroBUS™ sockets and click™ boards. You can

attach a variety of sensors and antennas to its

top bar. A pair of screw terminals will allow you

to connect those additional components to the

main power supply. Both 3.3V and 5V outputs

are available. There’s an additional pair of screw

terminals that are analog inputs.

The ON/OFF switch on the rear of the Buggy,

between the USB port and the left rear lights,

controls the main power supply. A clicker 2 board

also has its own ON/OFF switch, which should

be kept in the ON position in order for the main

power supply switch to work. A green LED will

indicate the presence of a power supply. When

removing the clicker 2, keep both switches OFF.

21

�A motorized development platform

VCC-3.3V

mikroBUS sockets

AN-MB

RST-MB

CS-MB

SPI-SCK

SPI-MISO

SPI-MOSI

22

AN-MB

CS-MB

I2C-SDA

I2C-SCL

INT-MB

PWM-MB

14

13

12

11

10

AN-MB

CS-MB

I2C-SDA

I2C-SCL

INT-MB

PWM-MB

15

14

13

12

11

10

9

2

3

4

5

6

7

8

SPI-SCK

SPI-MOSI

SPI-MISO

UART-TX

UART-RX

16

PWM-MB

INT-MB

UART-RX

UART-TX

I2C-SCL

I2C-SDA

PWM

INT

RX

TX

SCL

SDA

5V

GND

VCC-5V

VmBUS HEADER

(H1/H2/H3)

VCC-5V

Vertical mikroBUS™ socket schematic

VmBUS HEADER

(H1/H2/H3)

3

4

5

6

7

SPI-MOSI

SPI-MISO

UART-TX

UART-RX

8

2

Learn more about the mikroBUS™ standard at www.mikroe.com/mikrobus

1

Front mikroBUS™ plates

15

16

VCC-3.3V

PWM-MB

INT-MB

UART-RX

UART-TX

I2C-SCL

I2C-SDA

PWM

INT

RX

TX

SCL

SDA

5V

GND

1

AN

RST

CS

SCK

MISO

MOSI

3.3V

GND

9

AN-MB

RST-MB

CS-MB

SPI-SCK

SPI-MISO

SPI-MOSI

RST-MB

The Buggy comes with three mikroBUS™ sockets, two in the front, one in

the rear. If you connect a clicker 2 board to the Buggy you’ll get two more

sockets for a total o five mikroBUS™ sockets.

There are more than a 100 click™ boards available. Each click™ board comes

with a single module, and these vary from sensors to displays, audio to motor

control, communication to fiber optics, even speech recognition.

VCC-3.3V

VCC-5V

SPI-SCK

mikroBUS is a specially designed pinout standard with SPI, I2C, Analog,

UART, Interrupt, PWM, Reset and Power supply pins. It has two 1x8 headers,

each with VCC and GND power supply pads.

™

VCC-3.3V

AN

RST

CS

SCK

MISO

MOSI

3.3V

GND

RST-MB

™

Enhancing the Buggy with various sensors and communication modules

is easy — you just plug a MikroElektronika click™ board into one of the 3+2

available mikroBUS™ sockets and you’re good to go.

VCC-5V

Rear mikroBUS™ plate

�click™ boards are plug-and-play!

For a few years now, MikroElektronika has been expanding

their range of click™ boards. Almost each month several

new click™ boards are released, carrying all types of

sensors and communication modules. There are over a

100 click™ boards to choose from. You’ll be able to expand

your Buggy with additional functionality with literally

zero hardware configuration. Just plug and play.

For the complete list of available click™ boards, please visit:

www.mikroe.com/click

BLE P click™

BlueTooth click™

GPS click™

WiFi PLUS click™

GSM click™

microSD click™

MPU 9DOF click™

nRF C click™

Proximity click™

BUZZ click™

23

�A motorized development platform

Firmware

Android application

If your clicker 2 board came with the Buggy as

part of a kit, then you’re all set — the firmware

compatible with the Android app shown on the

right is already installed.

If you’ve purchased only the Buggy by itself, no

problem. Clicker 2 and mikromedia boards have a

USB-HID bootloader which makes it easy to install

the firmware. All you have to do is download the

mikroBootloader application for your clicker 2 or

mikromedia board, along with the firmware, all

available from www.mikroe.com/buggy.

A free open-source Android App for driving the

Buggy is available from mikroe.com/buggy. The App

talks to the Buggy through a wireless transceiver

click™ board (Bluetooth or Wi-Fi). It’s a great starting

point to develop your own original applications for

the Buggy, just open the project in your Android

SDK of choice (for example Android Studio, shown

here). But first, spend some time driving the Buggy

around from your smartphone or tablet, just for fun.

Edit the code for the Buggy App and make it

your own — shown here is Android Studio, a

popular Android platform IDE

mikrobootloader application

Then turn off the Buggy, detach the clicker 2

board, plug it to your computer via USB, and follow

the simple 4-step procedure in mikroBootloader.

If you’re making your own custom firmware for the

Buggy in mikroC™, mikroBasic™ or mikroPascal™,

you’ll also upload it with the mikroBootloader.

24

Install the app on your smartphone or tablet

and take your Buggy to the road

�Schematic

L2

1.5uH

U2

Vbat

VIN

10 PWM-MB2

VCC-5V

H1

16PIN HOLDER

H2

16PIN HOLDER

UART-TX

UART-RX

11 INT-MB3

10 PWM-MB3

8

SPI-MISO 5

12 I2C-SCL

7

SPI-MOSI 4

13 I2C-SDA

6

2

15 AN-MB3

3

1

RST-MB2

SPI-SCK

16

7

UART-RX

8

6

SPI-MOSI 4

14 CS-MB3

2

1

3

PWR-EN

BAT-VSENSE

R4

100K

C1

R54

100K

VCC-3.3V

J1A

M2

DMP2305U

R51

100K

VCC-5V

9

100pF

11 INT-MB2

VCC-3.3V

C141

12 I2C-SCL

C140

15 AN-MB2

100nF 10nF

13 I2C-SDA

C79

1uF

14 CS-MB2

C72

22uF

16

C68

22uF

9

C67

22uF

10 PWM-MB1

C66

10pF

1

R49

100K

CN5

R45

10K

C70

SPI-MISO 5

R11

15K

R43

1K

C71

100nF

14 CS-MB1

TPS63060

VIN

12 I2C-SCL

C69

22uF

13 I2C-SDA

D1

PMEG3010ER

100K

VCC-5V

R41

100K

UART-TX

R46

R10

8K2

USB-VBUS

10

9

8

7

6

11 INT-MB1

R7

10K

2

R9

100K

USB MINIB

E8

10uF

16

VCC-IN

E7

10uF

L1

L2

VIN

VOUT

EN PGND FB

PS

GND

PG

VAUX

3

VBUS

DD+

ID

GND

1

2

3

4

5

VIN

PWR-EN

RST-MB1

FP1

1

2

3

4

5

15 AN-MB1

Vusb_IN

SPI-SCK

CN4

1uF

SW1

JS202011AQN

VCC-IN

VCC-IN

3.3V VOLTAGE REGULATOR

R62

3K9

C3

100nF

R2

5K6

C80

2.2uF

H3

16PIN HOLDER

R5

470

PMEG3010ER

C4

100nF

R6

12K

VCC-IN

VCC-5V

VCC-5V

8

E4

10uF

7

Charging Current approx. 250mA

C5

22uF

6

E2

10uF

MCP73832

Q8

BC846

VCC-3.3V

R1

82K

UART-RX

VCC-5V

4

SPI-MISO 5

VCC-IN

5

STAT PROG

VSS

VBAT VDD

UART-TX

E1

10uF

R56

10K

BAT-STAT

U11

SPI-MOSI 4

1

2

3

POWER

3

R59

2K2

VCC-3.3V

LD1

D2

2

R61

10K

GND

1

R60

10K

VCC-3.3V

U1

MCP1826

RST-MB3

E10 10uF

Q2

BC846

VCC-5V

Vbat

SPI-SCK

VCC-IN

9

6

R58

10K

Q1

BC846

SHDN

VIN

GND

VOUT

ADJ

LD2

1

2

3

4

5

R57

2K2

CHARGE

VCC-3.3V

CN1

Vbat

C27

22uF

VCC- 3.3V

Vbat

AN-MB3

C28

100nF

R3

10K

AN-MB2

R2

Q6

PDTC114EU

2

R1

Q5

PDTC114EU

3

H9

MOTOR_HLD_PADS

3

2

16

15

14

13

5

6

7

8

R39

0.5

GND

Vbat

VINT

GND

VM

VCP

12

11

10

9

C33

10nF

C34

2.2uF

UART-RX

UART-TX

I2C-SCL

I2C-SDA

RX

TX

SCL

SDA

VCC-3.3V

VCC- IN

HDR2

1

R1

LIGHTS HOLDER

R33

1K

R2

Q4

PDTC114EU

AN

TURN_R

2

1

0

1

R1

R2

INT

HEADLAMPS

Q3

PDTC114EU

1

VCC-3.3V

BRAKE

REAR

RIGHT

R1

R8

1K

Q9

PDTC114EU

SCK

SDI

SDO

RR

LIGHTS HOLDER

R30

2K2

R2

RST-MB1

CS-MB1

SPI-SCK

SPI-MISO

SPI-MOSI

LEFT

0

1

3

R38

0.5

AISEN

AOUT2

BOUT2

BISEN

AOUT1

nSLEEP

AIN1

AIN2

1

2

3

4

BOUT1

nFAULT

BIN1

BIN2

1

4

1

4

4

1

U7

DRV8833RTY

1

H11

MOTOR_HLD_PADS

M

MOTOR

REAR

LEFT

(RL)

2

2

3

M

4

MOTOR

FRONT

LEFT

(FL)

2

3

PWM

PWM-A

PWM-B

VCC- 3.3V

RL

1

2

PWM-A

PWM-B

PWM-C

PWM-D

PWM-MB1

PWM-MB2

PWM-MB3

BRAKE

TURN_R

HEADLAMPS

CS-MB3

RST-MB3

MAIN BEAM

2

2

C32

100nF

R37

10K

TURN_L

AN-MB1

AN-MB2

AN-MB3

BAT-VSENSE

CS-MB2

RST-MB2

TURN_L

INT-MB1

INT-MB2

INT-MB3

BAT-STAT

USB-VBUS

FRONT

RIGHT

LIGHTS HOLDER

R32

1K

R2

2

C31

22uF

Vbat

FR

1

R1

R2

HDR1

2

16

15

14

13

5

6

7

8

2

2

0

1

D3

PMEG3010ER

VCC- 3.3V

LEFT

LIGHTS HOLDER

R31

2K2

3

C30

2.2uF

R1

3

MAIN BEAM 1

VCC-5V

Vbat

FL

1

0

VCC- 5V

3

2

2

12

11

10

9

Q7

PDTC114EU

3

R36

0.5

GND

VINT

GND

VM

VCP

VCC-3.3V

R34

220

C29

10nF

3

R35

0.5

H5

MOTOR_HLD_PADS

AISEN

AOUT2

BOUT2

BISEN

CN2

Vbat

3

1

2

3

4

AOUT1

nSLEEP

AIN1

AIN2

U6

DRV8833RTY

BOUT1

nFAULT

BIN1

BIN2

4

1

4

1

1

4

M

2

MOTOR

FRONT

RIGHT

(FR)

2

3

H4

MOTOR_HLD_PADS

3

4

M

1

MOTOR

REAR

RIGHT

(RR)

2

3

CN3

PWM-D

PWM-C

Vbat

25

�A motorized development platform

What’s Next?

You have now completed the journey through each and every feature of the Buggy.You got to know its features, supported microcontrollers and other

expandability options. Now you are ready to start building your own robotic vehichle. We are suggesting several steps which are probably the best way to

begin. We invite you to join our community. You will find very useful projects and tutorials and can get help from a large ecosystem of users. Welcome!

1

2

3

You still don’t have an appropriate compiler? Locate

the compiler that suits you best on our website

(see link below).

If you want to find answers to your questions on many

interesting topics we invite you to visit our forum at

www.mikroe.com/forum and browse through

more than 150 thousand posts. You are likely to

find just the right information. On the other hand,

if you want to download free projects and libraries,

or share your own code, please visit the Libstock™

website. With user profiles, you can get to know

other programmers, and subscribe to receive

notifications on their code.

We all know how important it is to be able to rely on

someone in moments when we are stuck with our

projects, facing a deadline, or when we just want

to ask a simple, basic question that’s pulling us

back for a while. We do understand how important

this is to people; our Support Department is one

of the pillars upon which our company is based.

MikroElektronika offers Free Tech Support to

the end of product lifetime, so if something goes

wrong, we are ready and willing to help!

Compilers

Choose between mikroC™, mikroBasic™ and

mikroPascal™, and download a fully functional

demo version, so you can begin building your

applications.

www.mikroe.com/compilers

26

Community

www.libstock.com

Support

www.mikroe.com/support

�DISCLAIMER

All the products owned by MikroElektronika are protected by copyright law and international copyright treaty. Therefore, this manual is to be treated as any

other copyright material. No part of this manual, including product and software described herein, may be reproduced, stored in a retrieval system, translated or

transmitted in any form or by any means, without the prior written permission of MikroElektronika. The manual PDF edition can be printed for private or local use,

but not for distribution. Any modification of this manual is prohibited.

MikroElektronika provides this manual ‘as is’ without warranty of any kind, either expressed or implied, including, but not limited to, the implied warranties or

conditions of merchantability or fitness for a particular purpose.

MikroElektronika shall assume no responsibility or liability for any errors, omissions and inaccuracies that may appear in this manual. In no event shall MikroElektronika,

its directors, officers, employees or distributors be liable for any indirect, specific, incidental or consequential damages (including damages for loss of business profits

and business information, business interruption or any other pecuniary loss) arising out of the use of this manual or product, even if MikroElektronika has been advised

of the possibility of such damages. MikroElektronika reserves the right to change information contained in this manual at any time without prior notice, if necessary.

HIGH RISK ACTIVITIES

The products of MikroElektronika are not fault – tolerant nor designed, manufactured or intended for use or resale as on – line control equipment in

hazardous environments requiring fail – safe performance, such as in the operation of nuclear facilities, aircraft navigation or communication systems, air

traffic control, direct life support machines or weapons systems in which the failure of Software could lead directly to death, personal injury or severe

physical or environmental damage (‘High Risk Activities’). MikroElektronika and its suppliers specifically disclaim any expressed or implied warranty of

fitness for High Risk Activities.

TRADEMARKS

The MikroElektronika name and logo, mikroC™, mikroBasic™, mikroPascal™, Visual TFT™, Visual GLCD™, mikroProg™, Ready™, MINI™, mikroBUS™, EasyPIC™, EasyAVR™,

Easy8051™, click™ boards and mikromedia™ are trademarks of MikroElektronika. All other trademarks mentioned herein are property of their respective companies.

All other product and corporate names appearing in this manual may or may not be registered trademarks or copyrights of their respective companies, and are only

used for identification or explanation and to the owners’ benefit, with no intent to infringe.

Copyright © 2015 MikroElektronika. All Rights Reserved.

27

�If you want to learn more about our products, please visit our website at www.mikroe.com

If you are experiencing some problems with any of our products or just need additional

information, please place your ticket at www.mikroe.com/support

If you have any questions, comments or business proposals,

do not hesitate to contact us at office@mikroe.com

BUGGY manual

ver. 1.02

0 100000 027523

�