SMA High Frequency End Launch Connectors PC Mounting Instructions

High frequency end launch performance is dependent upon proper mounting.

The following factors must be controlled for optimum performance:

a. The connector should fit tightly against the circuit board edge, avoid gaps.

b. The center contact pin must lie parallel and flat against the circuit board, avoid gaps.

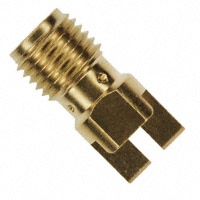

Figure 1

c. The contact pin should be centered on the circuit board signal trace.

d. Use a minimal amount of solder between the contact pin and signal trace. Do not

allow excess solder to build up or flow down the trace.

e. Clean all excess flux and other residue from the launch area, especially between the

trace and ground.

The basic steps required to mount the end launch connector to the circuit board are as

follows:

1. Fixture 140-0000-973 should be used as an aid during manual soldering. The fixture

protects the connector from damage during clamping and also maintains the proper

location of the connector’s insulator and contact. To use the fixture, thread the

coupling nut on the mating end of the connector and hand tighten. This mounting

assembly can now be held in a vice or similar clamping device, as shown in Figure 1.

2. Position connector on the circuit board, making sure the contact pin is aligned with the

center of the signal trace as shown in Figure 2. Make sure that the connector legs and

contact pin are held flush against the top of the circuit board, keeping the axis of the

connector parallel to the plane of the circuit board, as shown in Figure 3.

3. A small amount of Teflon® insulation projects from rear mating plane of the connector,

which acts as a seal when soldering the center conductor pin to the trace. Clamp the

connector tightly against the edge of the board. This action compresses the insulator

seal against the board edge. This effectively creates a barrier between the inner and

outer conductors, preventing the bridging of solder.

4. While ensuring the connector is held in the correct position, solder the ground legs

and/or ground posts to the top and bottom of the board prior to bonding the center pin

to the trace.

5. Once the connector body is properly grounded to the board, the center contact pin

can be bonded to the trace by using a minimal amount of solder as shown in Figure 4.

It is important that solder flows along the length of the exposed pin, creating a good

electrical and mechanical connection. Remove any excess solder that is not required

for a solid joint.

Figure 2

Figure 3

Figure 4

Figure 5

6. Clean all flux and other residues from the trace area between the signal side ground

legs, as any flux present between the signal trace and ground will affect performance.

The completed mounting assembly should look similar to the one shown in Figure 5.

246

Cinch Connectivity Solutions Waseca

299 Johnson Avenue SW, Suite 100

Waseca, MN 56093 USA

+1 507.833.8822

inquiry@cinch.com

cinch.com

© 2017 Cinch Connectors, Inc.

ccsjai 02.17

�SMA Straight Solder Type for Semi-Rigid Cables

The End Launch connector is attached to the circuit board by inserting the

board edge between the legs and soldering the legs and center conductor

to the pads on the board. For optimum high frequency preformance, the

connector to circuit board transtion must be ajdusted for low VSWR. To

compensate for the transition from coax to microstrip, trace widths “A”

and “B” must be adjusted based on circuit board thickness. When properly

adjusted, this technique yields a low VSWR over a wide bandwidth.

The tabluated dimensions “A”, “B”, “C”, “D”, and “E” were determined

experimentally to achieve low VSWR (typically less than 1.5 up to 18 GHz).

The circuit board uses connectors for these tests that are double-sided

FR4 with 1 oz. copper on both sides. The copper was left on the bottom

of the board to create a ground plane for the 50 Ohm microstrip structure.

While not all inclusive, these dimensions are given as reference information

for selected SMA End Launch connectors. Further adjustments may be

necessary depending upon the application. All dimensions are in inches

(millimeters).

Part No.

Base Width

Board Thickness

“A”

“B”

“C”

“D”

“E”

142-0791-801

.375

.062 (1.57)

.073

.073

.250

.440

.200

142-0791-811

.375

.042 (1.07)

.103

.103

.250

.440

.200

142-0791-821

.375

.062 (1.57)

.083

.083

.250

.440

.200

142-1701-821

.375

.062 (1.57)

See Figure 2 below for attachment dimensions

142-1701-831

.375

.059 (1.50)

See Figure 2 below for attachment dimensions

Figure 1

247

Figure 2

Cinch Connectivity Solutions Waseca

299 Johnson Avenue SW, Suite 100

Waseca, MN 56093 USA

+1 507.833.8822

inquiry@cinch.com

cinch.com

© 2017 Cinch Connectors, Inc.

ccsjai 02.17

�Reference dimensions for 50 Ohm grounded coplanar waveguide using

Rogers Corporation RO4003C™ high frequency substrate laminate*

Holes

Part No.

GCPW 50Ω Impedence Reference Dimensions*

Substrate

Conductor

Trace Width

Ground

Thickness

Thickness

“A”

Gaps“B”

142-0761-801

.0080 (0.203)

.0014 (0.036)

.0155 (0.394)

142-0761-811

.0080 (0.203)

.0014 (0.036)

.0155 (0.394)

142-0761-821

.0160 (0.406)

.0014 (0.036)

142-0761-831

.0160 (0.406)

142-0761-841

.0080 (0.203)

142-0761-851

142-0761-861

Mounting and Via

Fig

“C”

“D”

.0100 (0.254)

1

.066 (1.68)

.096 (2.44)

.0100 (0.254)

1

.066 (1.68)

.096 (2.44)

.0285 (0.724)

.0100 (0.254)

1

.084 (2.13)

.113 (2.87)

.0014 (0.036)

.0285 (0.724)

.0100 (0.254)

1

.084 (2.13)

.113 (2.87)

.0014 (0.036)

.0155 (0.394)

.0100 (0.254)

2

.066 (1.68)

.0080 (0.203)

.0014 (0.036)

.0155 (0.394)

.0100 (0.254)

2

.066 (1.68)

.0160 (0.406)

.0014 (0.036)

.0285 (0.724)

.0100 (0.254)

2

.084 (2.13)

142-0761-871

.0160 (0.406)

.0014 (0.036)

.0285 (0.724)

.0100 (0.254)

2

.084 (2.13)

142-0761-881

.0080 (0.203)

.0014 (0.036)

.0155 (0.394)

.0100 (0.254)

1

.066 (1.68)

142-0761-891

.0080 (0.203)

.0014 (0.036)

.0155 (0.394)

.0100 (0.254)

2

.066 (1.68)

142-0771-821

.0160 (0.406)

.0014 (0.036)

.0285 (0.724)

.0100 (0.254)

1

.084 (2.13)

142-0771-831

.0160 (0.406)

.0014 (0.036)

.0285 (0.724)

.0100 (0.254)

2

.084 (2.13)

.096 (2.44)

.113 (2.87)

* These calculated dimensions assume a quasi-static mode of propagation, but dispersion does exist for

coplanar waveguide. The characteristic impedance and effective dielectric constant may increase slightly for

X-band and higher frequencies, unless very small ground to ground gap spacing is used.

It is assumed the conductors have rectangular cross-sections. The etching process used in circuit board

fabrication actually produces trapezoidal shapes. Therefore, the GCPW impedance may increase somewhere

between that of a perfect rectangular conductor and a theoretical zero thickness conductor.

Figure 1

248

Figure 2

Cinch Connectivity Solutions Waseca

299 Johnson Avenue SW, Suite 100

Waseca, MN 56093 USA

+1 507.833.8822

inquiry@cinch.com

cinch.com

© 2017 Cinch Connectors, Inc.

ccsjai 02.17

�

很抱歉,暂时无法提供与“142-0761-841”相匹配的价格&库存,您可以联系我们找货

免费人工找货