深圳市长江微电科技有限公司

SZ CJIANG TECHNOLOGY CO.,LTD

Introduction

•Soft saturation.

•High current,low DCR,high efficiency.

•Very low acoustic noise and very low leakage flux noise.

•High reliability.

•100% Lead(Pb)-Free and RoHS compliant.

•Operating temperature -55~+125℃(Including self - temperature rise)

Applications

• Note PC power system,incl. IMVP-6

• DC/DC converter

Dimensions (Unit: mm)

A

C

D

E

B

F

Code

Dimensions(mm)

A

11.9±0.3

B

11.0±0.3

C

2.9±0.2

D

9.0±0.5

E

2.4±0.3

F

4.4±0.5

H

L

G

Recommend Land Pattern

L

10.5ref

H

11.0ref

G

3.7ref

Unit : mm

�深圳市长江微电科技有限公司

SZ CJIANG TECHNOLOGY CO.,LTD

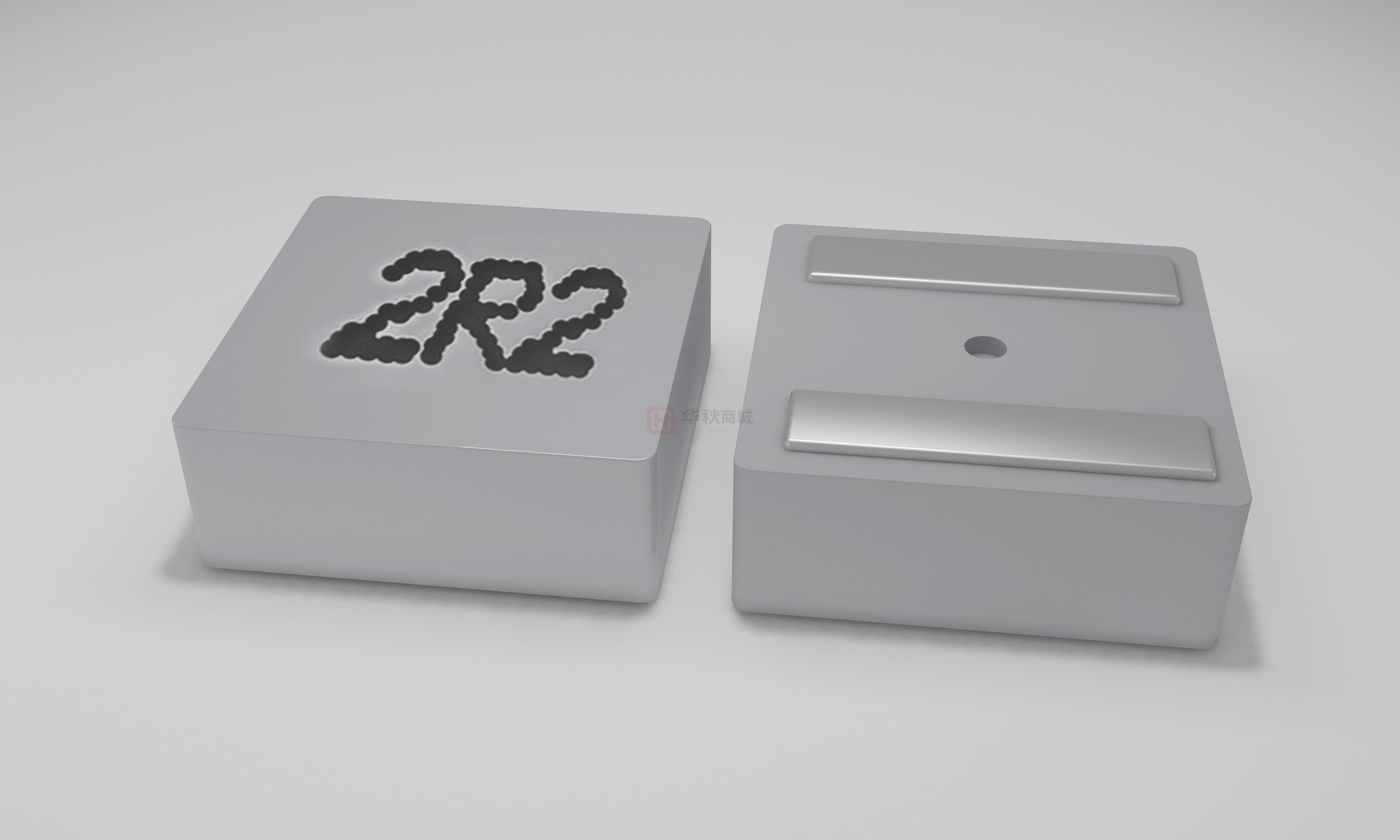

Marking

Note:Using Ink for marking

Marking:

Example

Nominal Value

0.18μH

R18

1.2 μH

1R2

4.5 μH

4R5

Structure and Components

NO

Components

Material

1

CORE

Alloy Powder

2

WIRE

Polyester Wire or equivalent.

3

Clip

100% Pb free solder

4

Ink

Halogen-free ketone

5

paint

Epoxy resin

�深圳市长江微电科技有限公司

SZ CJIANG TECHNOLOGY CO.,LTD

Specification

Part No.

L0 (μH)±20 %

DCR (mΩ)

MAX

Isat (A)

Irms (A)Typ

Max

Typ

20℃

rise

40℃

rise

FEXL1031A-R28M

0.28

1.60

58.0

65.0

25.5

35.0

FEXL1031A-R56M

0.56

2.75

39.0

44.0

23.0

32.0

FEXL1031A-R82M

0.82

4.10

32.0

38.0

18.0

25.0

FEXL1031A-R90M

0.90

4.20

31.0

36.0

17.0

24.0

FEXL1031A-1R0M

1.00

4.95

30.0

35.0

16.0

23.0

FEXL1031A-1R5M

1.50

6.60

25.0

30.0

12.0

18.0

Notes:

1. Test frequency : L : 100KHz /0.1V;

2. All test in 25 °C temperature.

3.Testing Instrument:L:HP4285A,CH11025,CH3302,CH1320,CH1320S LCR METER / Rdc:CH16502, MICRO OHMMETER.

4.Heating Rating Current (Irms) will cause the coil temperature rise of 40℃ approximately (Δt);

5.Saturation Current (Isat ) will cause L0 to drop 30% approximately.

6.The part temperature (ambient + temp rise) should not exceed 125℃ under the worst case operating condition. Circuit design, component,

PCB trace size and thickness airflow and other cooling provisions all could affect the part temperature. Part temperature should be verified in the end application.

7.Special inquiries besides the above common used types can be met on your requirement.

DCR Test

�深圳市长江微电科技有限公司

SZ CJIANG TECHNOLOGY CO.,LTD

Mechanical Reliability

Item

Specification and Requirement

1. No case deformation

or change in visual

Solderability

2. New solder coverage

Test Method

1.Preheat:155℃±5℃ ,60S±2S

2.Tin: lead-free.

3.Temperature:240℃±5℃,flux 3.0S±0.5S.

More than 95%

Mechanical

1. No case deformation

1. Acceleration: 100G

or change in visual

2. Pulse time::6ms

shock

3. 3 times in each positive and negative direction of 3

2. △L/Lo≦±10%

1. No case deformation

Mechanical

or change in visual

vibration

2. △L/Lo≦±10%

mutual perpendicular directions

1. Reflow: 2times

2. Frequency: 10HZ~50HZ~10HZ,20 Min/Cycles

3. Amplitude: 1.52 mm±10%

4. Directions: X,Y,Z

5. Time: 12 cycle / direction

Endurance Reliability

Item

Specification and Requirement

Inductance change:

Thermal Shock

Within ± 10% Without distinct damage

in visual

Test Method

1. First -55℃ for 30 minutes,last 125℃ for 30 minutes

as 1 cycle. Go through

1000 cycles.

2. Max transfer time is 3 minutes.

3. Measured at room temperature after placing for 24±2

hours

Humidity

Resistance

Inductance change:

1.Reflow 2 times,

Within ± 10% Without distinct damage

2.85℃±3℃,85%±3%RH,1000 hours

in visual

3.Measured at room temperature after placing for 24±2

hours

Low

temperature

storage

High

temperature

storage

Inductance change:

1. Temperature:-55 ± 2℃

Within ± 10% Without distinct damage

2. Time:1000 hours

in visual

3. Measured at room temperature after placing for 24±2

hours

Inductance change:

Within ± 10% Without distinct damage

in visual

1. Temperature:+125 ± 2℃

2. Time:1000 hours

3. Measured at room temperature after placing for 24±2

hours

�深圳市长江微电科技有限公司

SZ CJIANG TECHNOLOGY CO.,LTD

Recommended Soldering Technologies

(1)Re-flowing Profile

Preheat condition: 150 ~200℃/60~120sec.

Allowed time above 217℃: 60~90sec.

Peak temp: 260℃

Max time at Peak temp: 10 sec.

Solder paste: Sn/3.0Ag/0.5Cu

Allowed Reflow time: 2x max

(2)Iron Soldering Profile

Iron soldering power: Max. 30W

Pre-heating: 150℃/60sec.

3sec. Max.

350℃

Soldering Tip temperature: 350℃ Max.

Power: max. 30W

Soldering time: 3sec. Max.

Diameter of Soldering

Solder paste: Sn/3.0Ag/0.5Cu

Max.1 times for iron soldering

Soldering Iron

Iron 1.0mm max.

Tc ℃

�深圳市长江微电科技有限公司

SZ CJIANG TECHNOLOGY CO.,LTD

Packaging Information

(1) Tape Packaging Dimensions(Unit:mm)

Tape dimensions (mm)

W

P

P0

P2

D0

D1

T

A0

B0

K0

E

F

24

±0.3

16

±0.1

4

±0.1

2

±0.05

1.5

±0.1

1.5

±0.1

0.35

±0.05

12.4

±0.1

11.5

±0.1

3.3

±0.1

1.75

±0.1

11.5

±0.1

Taping Drawings (UNIT:mm)

�深圳市长江微电科技有限公司

SZ CJIANG TECHNOLOGY CO.,LTD

(2) Reel Dimensions(Unit:mm)

B

N

C

W

A

W

N

B

C

330+2.0

24±0.5

97±0.5

2.2+0.5

13.0±0.2

(3) Packaging Quantity

Standard Quantity

Reel

Inner box

1000 pcs / reel

2Reel / box (2000 pcs)

(4) Peel force of top cover tape

The peel speed shall be about 300mm/minute

The peel force of top cover tape shall be between 0.1 to 1.3 N

Carton box

4 Middle boxes,

(8000 pcs)

A

�深圳市长江微电科技有限公司

SZ CJIANG TECHNOLOGY CO.,LTD

(5) Reel Label

Label on the reel

• Customer's part Number

• Lot Number

• Quantity

• date code

Shipping Label

• Customer's part Number

• Manufacturer's part Number

• Quantity

• date code

(6) Inner Box

(7) Carton

A

B

C

�深圳市长江微电科技有限公司

SZ CJIANG TECHNOLOGY CO.,LTD

Appearance criterion

1、PAD residual powder、inner wire exposed、imprinting

The residual powder on both side of pad is norm and within following criteria are acceptable.

2、Defects

Chip off is generated during molding and manufacturing process.

Chip off acceptance limits subjected to the product size.

Our current Defect limit is based on the IPC-A-610.

Some chip off does not impact the product function, see the IPC standard 1 & 2.

w

T

L

Marking

T

≤10% of the thickness

Each surface can only accept

W

≤10 % of the width

one minor chip off,and more than 3

L

≤10 % of the length

chip off problems are not allowed on

the same product.

Defects usually occur at the corners and edges of the product,There will be

a slight defect black and rough, but not exposed copper, and does not

affect the product performance and reliability.

3、Crack

Production process of cracks appearing in the body is inevitable, some slight crack is caused because the molding,

is not oxidized, crack on the product will not affect product performance.

We have done a reliability test of crack products, even if cracks is more than 0.13mm also will not

affect the electrical properties of the product, crack limits as follows:

Products from a slight crack in the baking process due to thermal expansion, and it is not obvious by visual inspection

(Must not exceed the blue square area).

Cracks on the same side surface are not allowed to exceed 1/2 of the length of the side and the crack width cannot exceed 0.13mm,

and only 1 crack is allowed on the same side.

Bottom cracks are not allowed to exceed 1/2 of the length (or width) of the corresponding body nor the Non-manufacturability swelling,

and the crack width cannot be exceed 0.13mm, and less than 2 cracks are allowed and judged as good products.

Visible cracks and non-manufacturability bulging are not allowed on the front side.

4、oxidation(rust)

the contains iron composite, although the resin has a protective effect of oxidation,but there will be

small amount of product that may occur oxidation, The oxidation area of each surface is allowed to

be about 25% (in the case of non-reliability test),it is recommend that customer use this product in

humidity controlled environment.The basic steps should be to protect the surface oxidation, including

the sealed packages to PCB mount inductors. To avoid the adverse effects caused by oxidation,

Oxidation occurs at the surface only allows the internal oxidation is not allowed, oxidized surface will

not affect the reliability of the product.

Marking

4sides slightly oxidized side:

Acceptable

Marking

Top and bottom slightly oxidized side:

Spray printing effect :

can be accepted if recognizable

Acceptable

Visual inspection: Examination with the naked eye, to distinguish from more technical modes of analysis employing tools or apparatus.

�

很抱歉,暂时无法提供与“FEXL1031A-R82M”相匹配的价格&库存,您可以联系我们找货

免费人工找货