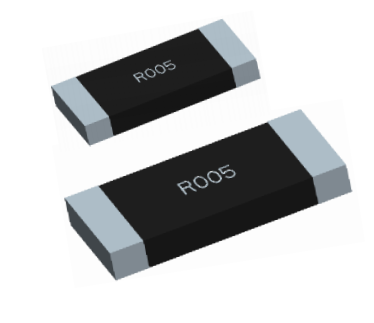

LMR45 Series

Low Resistance Metal Strip Chip Resistors

Description

• Welded construction product

• Resistance range:1~200mR

• Rated power:5~7W

• Low inductance design

• Alloy Material, Shock Resistance

• Operating temperature range:- 65℃~170℃

• AEC-Q200 qualified

Applications

• Current sensing application

• Over current protection

• Servo motor control circuits

• Inverter power

• Electric control system

• Li-battery management system

Part number

LMR

45

F

7P0

【1】 【2】 【3】 【4】

R005

【5】

【1】Series Name: Low resistence Metal strip Chip Resistors

【2】Chip size: 45:4527

【3】Resistance Precision: D:±0.5% ; F:±1% ; G:±2% ; J:±5%

【4】Power Rating:7P0=7W ; 5P0=5W

【5】Resistance Code: R005: 5mΩ ; R050: 50mΩ

Standard Electrical Specifications

Size

4527

Power

Resistance/mΩ

(W)(70℃)

7

5

TCR

±0.5%, ±1%,

±2%, ±5%

(ppm/℃)

1~3

±75

4 ~100

101 ~200

±50

Operating

Material

Temperature

(℃)

Manganin

Kamar

-65℃~170℃

Note: (1) Products of differentsizes are being verified by power rating tests at other ambient temperatures.

Specifications are subject to change without notice

© No: P0R0210133117001Y(Test)

www.prosemitech.com

1 of 5

�LMR45 Series

Low Resistance Metal Strip Chip Resistors

Products & Recommend Pad Dimension

Unit:mm

Type

Resistance

W±0.2

C±0.2

A±0.2

D±0.1

L

a

c

4527

1 ~ 200

11.6

6.9

2.0

1.0

7.0

3.4

8.7

Welded Construction

Silicone coating with laser marking

Ni plated & Sn

Cu terminal

Welding seam

Resistance alloy

Specifications are subject to change without notice

© No: P0R0210133117001Y(Test)

www.prosemitech.com

2 of 5

�LMR45 Series

Low Resistance Metal Strip Chip Resistors

Power Derating Curve

For resistors operated in ambient temperatures 70°C, power rating shall be derated inaccording with

the curve below:

Recommended Solder Curve

Pb – Free assembly

Reflow Condition

Pre heat

- Temperature Min (Ts(min))

150°C

- Temperature Max (Ts(max))

200°C

- Time (Min to Max) (ts)

Average ramp up rate

5°C/second max

(Liquidus Temp (TL) to peak

TS(max) to TL - Ramp-up Rate

Reflow

217°C

- Temperature (tL)

60 – 150 seconds

260°C

Time within 5°C of actual peak Temperature (tp)

20 – 40 seconds

5°C/second max

Ramp-down Rate

© No: P0R0210133117001Y(Test)

5°C/second max

- Temperature (TL) (Liquidus)

Peak Temperature (TP)

Specifications are subject to change without notice

60 – 120 secs

Time 25°C to peak Temperature (TP)

8 minutes Max.

Wave Soldering

260°C, 10 seconds max.

Hand Soldering

350°C, 5 seconds max.

www.prosemitech.com

3 of 5

�LMR45 Series

Low Resistance Metal Strip Chip Resistors

Product Characteristics

Additional Requirements

Limited

Reference

1000 Cycles (-55℃ to +150℃)

±0.5%

JESD22

Method JA-104

100hrs.@T=170℃.Unpowered.

±0.5%

t=24hrs/cycle.Note: Steps 7a & 7b not required.

Unpowered.

±0.5%

Item

Temperature Cycling

High Temperature

Exposure

Moisture Resistance

Biased Humidity

1000hrs 85℃/85%RH。Note: Specified

conditions:10% of operating power.

Condition D Steady State TA=125℃ at rated power.

±0.5%

Thermal Shock

1000X(-55°C to +150°C)

0.5%

Resistance to

Soldering Heat

Short Time Overload

Shock

VIBRATION

MIL-STD-202

Method 106

MIL-STD-202

Method 103

MIL-STD-202

Method 108

MIL-STD-202Met

hod107G

95% Coverage

235℃±5℃,2s±0.5s

Minimum

260℃±5℃,10s±1s

±0.5%

5×Rated power for 5 s

±0.5%

100g , 6ms , axes Z and Y , 10 Shocks per axis

(10 - 2000 HZ) , 20g @0.1ms

0.5%

0.5%

Specifications are subject to change without notice

© No: P0R0210133117001Y(Test)

Method 108

±0.5%

Operational Life

Solderability

MIL-STD-202

J-STD-202

MIL-STD-202

Method 210

MIL-STD-202

Method 201

MIL-STD-202

Method 213

MIL-STD-202Met

hod204

www.prosemitech.com

4 of 5

�LMR45 Series

Low Resistance Metal Strip Chip Resistors

Tapping & Package

Storage Conditions: Temperature:5℃~35℃, Humidity:40%~75%

Embossed Plastic Tape

Type

Pack

4527 Emboss

A

±0.2

7.40

B

±0.2

D0

+0.5-0

11.80

1.50

E

±0.1

1.75

F

±0.05

11.50

P0

±0.1

4.00

P1

±0.1

12.0

P2

±0.1

2.00

W

±0.2

24.00

D1

±0.05

t

±0.15

1.50

2.30

Packaging

Quantity: 3.000pcs

Storage

1. The temperature condition must be controlled at 25±5℃,The R.H. must be controlled at 60±15%

Store in accordance with this requirement, and the validity period is two years after the date of

manufacture。

2. Please avoid the mentioned harsh environment below when storing to ensure product performance

and its’ weldability. Places exposed to sea breeze or other corrosive gas,such as Cl2、H2S、NH3、

SO2 and NO2.

3. When the product is moved and stored, please ensure the correct orientation of the box.Do not drop

or squeeze the box. Otherwise, the electrode or the body of the product may be damaged.

Specifications are subject to change without notice

© No: P0R0210133117001Y(Test)

www.prosemitech.com

5 of 5

�

很抱歉,暂时无法提供与“LMR45F5P0R002”相匹配的价格&库存,您可以联系我们找货

免费人工找货