FP6359

High Efficiency 1MHz 3A

Synchronous Step Down DC/DC Converter

Description

Features

The FP6359 is a high efficiency, 1MHz switching

frequency and pulse width modulation (PWM)

synchronous DC-DC step-down converter that

provides wide 2.7V to 6V input voltage range and 3A

continuous load current capability. The 100% duty

cycle feature provides low dropout operation,

extending battery life in portable systems.

The internal synchronous switch increases efficiency

and eliminates the need for external Schottky diode.

At shutdown mode, the input supply current is less

than 1µA.

The current limit protection and on-chip thermal

shutdown features provide protection against any

combination of overload or ambient temperature.

Low RDS(ON) for Internal Switch (Top/Bottom):

95/75mΩ

2.7V-6V Input Voltage Range

3A Output Current

Adjustable Output Voltage Down to 0.6V

1MHz Switching Frequency

Internal Compensation Function

Internal Soft-Start Limits the Inrush Current

100% Dropout Operation

Input Under Voltage Lockout

Power Good Indicator Output

Cycle-by-Cycle Current Limit

Over-Temperature Protection with Auto Recovery

RoHS Compliant and Halogen Free

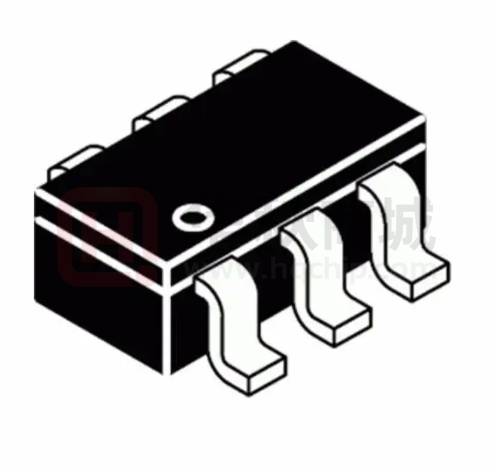

Compact Package: SOT-23-6

Applications

Set Top Box

LCD TV

Tablet

Portable Equipment

Pin Assignments

Ordering Information

S6 Package (SOT-23-6)

FP6359□

Package Type

S6: SOT-23-6

FB PG VIN

6

1

5

4

(Marking)

2

3

EN GND LX

Figure 1. Pin Assignment of FP6359

FP6359- Preliminary 0.1-AUG-2016

SOT-23-6 Marking

Part Number

Product Code

FP6359S6

FU1

1

�FP6359

Typical Application Circuit

OFF ON

EN

VIN

VIN

C1

FP6359

R3

PG

L1

VOUT

LX

PG

R1

C3

C2

(opt.)

FB

GND

R2

Figure 2. Schematic Diagram

VIN=5V, the recommended BOM list is as below.

VOUT

3.3V

2.5V

1.8V

1.5V

1.2V

1.05V

C1

10μF MLCC x2

10μF MLCC x2

10μF MLCC x2

10μF MLCC x2

10μF MLCC x2

10μF MLCC x2

R1

453kΩ

316kΩ

200kΩ

150kΩ

100kΩ

75kΩ

R2

100kΩ

100kΩ

100kΩ

100kΩ

100kΩ

100kΩ

L1

2.2μH

2.2μH

1.8μH

1.5μH

1.5μH

1.2μH

C2

22μF MLCC x2

22μF MLCC x2

22μF MLCC x2

22μF MLCC x2

22μF MLCC x2

22μF MLCC x2

Table 1. Recommended Component Values

FP6359- Preliminary 0.1-AUG-2016

2

�FP6359

Functional Pin Description

Pin Name

Pin No.

Pin Function

EN

1

Enable control pin.

floating.

GND

2

Ground pin.

LX

3

Power switching node. Connect an inductor to the drains of internal high side PMOS and low side

NMOS.

VIN

4

Power supply input pin.

noise influence.

PG

5

Open drain power good output pin.

FB

6

Voltage feedback input pin. Connect FB and VOUT with a resistive voltage divider.

feedback voltage via FB and regulates it at 0.6V.

Pull high to turn the IC on, and pull low to disable the IC. Don’t leave this pin

Placed input capacitors as close as possible from VIN to GND to avoid

This IC senses

Block Diagram

EN

PG

VIN

1MΩ

Power Good

Undervoltage

Lockout

Bias Supply

Enable

Control

Slope Compensation

90%

VREF

FB

COMP

EA

Control Logic

Current Limit

Logic

Control

and

Driver

Logic

1

X

LX

Compensation

Oscillator

OTP

COMP

VREF

GND

Soft

Start

Figure 3. Block Diagram of FP6359

FP6359- Preliminary 0.1-AUG-2016

3

�FP6359

Absolute Maximum Ratings (Note 1)

● VIN to GND --------------------------------------------------------------------------------------------------- -0.3V to +6.5V

● LX to GND ---------------------------------------------------------------------------------------------------- -0.3V to VIN+0.3V

● EN, FB, PG to GND ---------------------------------------------------------------------------------------- -0.3V to VIN

● Junction Temperature Range ---------------------------------------------------------------------------- 150°C

● Lead Temperature (Soldering, 10 sec.) ---------------------------------------------------------------- 260°C

● Storage Temperature Range ----------------------------------------------------------------------------- -65°C to +150℃

●Package Thermal Resistance, (θJA)

SOT-23-6 ------------------------------------------------------------------------------------------ +250ºC/W

●Package Thermal Resistance, (θJC)

SOT-23-6 ------------------------------------------------------------------------------------------ +110°C/W

Note 1:Stresses beyond those listed under “Absolute Maximum Ratings" may cause permanent damage to the device.

Recommended Operating Conditions (Note 2)

● Supply Input Voltage --------------------------------------------------------------------------------------- 2.7V to 6V

● Junction Temperature Range ---------------------------------------------------------------------------- -40°C to +125°C

● Ambient Temperature Range ----------------------------------------------------------------------------- -40°C to +85°C

Note 2:The device is not guaranteed to function outside its operating conditions.

FP6359- Preliminary 0.1-AUG-2016

4

�FP6359

Electrical Characteristics

(VIN=5V, TA=25°C, unless otherwise specified.)

Parameter

Symbol

Input Voltage Range

VIN

Shutdown Current

ISD

Supply Current

IDD

Feedback Reference Voltage

FB Input Current

P-Channel MOSFET On-Resistance

(Note 3)

N-Channel MOSFET On-Resistance

(Note 3)

P-Channel Current Limit (Note 3)

Conditions

Typ

2.7

EN=GND

0.1

Max

Unit

6

V

1

μA

5

VREF

IFB

Min

0.591

VFB=VIN

0.6

-50

mA

0.609

V

50

nA

RDS(ON),P

95

mΩ

RDS(ON),N

75

mΩ

ILIM

4

A

EN Rising Threshold

VENH

1.5

V

EN Falling Threshold

VENL

0.4

V

Input UVLO Threshold

VUVLO

2.7

V

UVLO Hysteresis

VHYS

Oscillation Frequency

FOSC

0.2

0.8

Minimum ON Time

50

Maximum Duty Cycle

Internal Soft Start Time

PG Rising Threshold

PG Sink Current

100

TSS

1.2

MHz

ns

%

1

ms

VPG (H)

VFB Rising

90

%

IPG

VPG=0.1V

1

mA

100

Ω

150

°C

VOUT Discharge Resistance

Thermal Shutdown Temperature

(Note 3)

1

V

TSD

Note 3:Guarantee by design.

FP6359- Preliminary 0.1-AUG-2016

5

�FP6359

Function Description

The FP6359 is a high efficiency, internal

compensation and constant frequency current mode

step-down synchronous DC/DC converter. It has

integrated high-side (95mΩ, typ.) and low-side

(75mΩ, typ.) power switches, and provides 3A

continuous load current. It regulates input voltage

from 2.7V to 6V, and down to an output voltage as

low as 0.6V.

Control Loop

Slope compensated current mode PWM control

provides stable switching and cycle-by-cycle current

limit for superior load, line response, protection of the

internal main switch and synchronous rectifier. The

FP6359 switches at a constant frequency (1MHz) and

regulates the output voltage. During each cycle, the

PWM comparator modulates the power transferred to

the load by changing the inductor peak current based

on the feedback error voltage.

During normal

operation, the main switch is turned on for a certain

time to ramp the inductor current at each rising edge

of the internal oscillator, and switched off when the

peak inductor current is above the error voltage.

When the main switch is off, the synchronous rectifier

will be turned on immediately and stay on until next

cycle starts.

Enable

The FP6359 EN pin provides digital control to turn

on/off the regulator. When the voltage of EN

exceeds the threshold voltage, the regulator will start

the soft start function. If the EN pin voltage is below

the shutdown threshold voltage, the regulator will

turn into the shutdown mode and the shutdown

current will be smaller than 1μA. For auto start-up

operation, connect EN to VIN.

Soft Start

The FP6359 employs internal soft start function to

reduce input inrush current during start up. The

internal soft start time will be 1ms.

Over Current Protection

The FP6359 over current protection function is

implemented by using cycle-by-cycle current limit

architecture. The inductor current is monitored by

measuring the high-side MOSFET series sense

resistor voltage. When the load current increases,

the inductor current will also increase. When the

peak inductor current reaches the current limit

threshold, the output voltage will start to drop.

When the over current condition is removed, the

output voltage will return to the regulated value.

Short Circuit Protection

The FP6359 provides short circuit protection

function to prevent the device damaged from short

condition. When the short condition occurs and

the feedback voltage drops lower than 40% of the

regulation level, the oscillator frequency will be

reduced to prevent the inductor current increasing

beyond the current limit. In the meantime, the

current limit will also be reduced to lower the short

current. Once the short condition is removed, the

frequency and current limit will return to normal.

Over Temperature Protection

The FP6359 incorporates an over temperature

protection circuit to protect itself from overheating.

When the junction temperature exceeds the thermal

shutdown threshold temperature, the regulator will

be shutdown. And the hysteretic of the over

temperature protection is 30°C (typ).

PG Signal Output (PG)

PG pin is an open-drain output and requires a pull

up resistor. PG is actively held low in soft-start,

standby and shutdown. It is released when the

output voltage rises above 90% of nominal

regulation point.

Under Voltage Lockout

When the FP6359 is power on, the internal circuits

will be held inactive until VIN voltage exceeds the

UVLO threshold voltage. And the regulator will be

disabled when VIN is below the UVLO threshold

voltage. The hysteretic of the UVLO comparator is

200mV (typ).

FP6359- Preliminary 0.1-AUG-2016

6

�FP6359

Application Information

Output Voltage Setting

The output voltage VOUT is set by using a resistive

divider from the output to FB. The FB pin regulated

voltage is 0.6V. Thus the output voltage is:

0.

1

A low ESR capacitor is required to keep the noise

minimum.

Ceramic capacitors are better, but

tantalum or low ESR electrolytic capacitors may

also suffice.

Output Capacitor Selection

R1

R2

Table 2 lists recommended values of R1 and R2 for

most used output voltage.

Table 2 Recommended Resistance Values

VOUT

R1

R2

3.3V

453kΩ

100kΩ

2.5V

316kΩ

100kΩ

1.8V

200kΩ

100kΩ

1.5V

150kΩ

100kΩ

1.2V

100kΩ

100kΩ

The output capacitor is used to keep the DC output

voltage and supply the load transient current.

When operating in constant current mode, the

output ripple is determined by four components:

R

L

t

R

L

R

t

R

L ( SL

t

C

L

SR

t

S

t

The following figures show the form of the ripple

contributions.

VRIPPLE(ESR)(t)

Place resistors R1 and R2 close to FB pin to prevent

stray pickup.

Input Capacitor Selection

The use of the input capacitor is filtering the input

voltage ripple and the MOSFETS switching spike

voltage.

Because the input current to the

step-down converter is discontinuous, the input

capacitor is required to supply the current to the

converter to keep the DC input voltage. The

capacitor voltage rating should be 1.25 to 1.5 times

greater than the maximum input voltage. The input

capacitor ripple current RMS value is calculated as:

1

C (RMS

+

VRIPPLE(ESL) (t)

(t)

+

VRIPPLE(C) (t)

(t)

+

VNOISE (t)

(t)

Where D is the duty cycle of the power MOSFET.

This function reaches the maximum value at D=0.5

and the equivalent RMS current is equal to IOUT/2.

The following diagram is the graphical representation

of above equation.

=

VRIPPLE(t)

1.75

3A

1.5

ICIN(RMS) (A)

1.25

(t)

2A

1

0.75

1A

0.5

0.25

0

10

20

30

40

50

60

70

80

90

D (%)

FP6359- Preliminary 0.1-AUG-2016

7

�FP6359

Application Information (Continued)

L ( SR

R

L ( SL

R

L (C

F

SC

L

1

SR

SL

L

F

SC2

That will lower ripple current and result in lower

output ripple voltage.

The Δ L is inductor

peak-to-peak ripple current:

L

L C

1

Where FOSC is the switching frequency, L is the

inductance value, VIN is the input voltage, ESR is the

equivalent series resistance value of the output

capacitor, ESL is the equivalent series inductance

value of the output capacitor and the COUT is the

output capacitor.

Low ESR capacitors are preferred to use. Ceramic,

tantalum or low ESR electrolytic capacitors can be

used depending on the output ripple requirements.

When using the ceramic capacitors, the ESL

component is usually negligible.

It is important to use the proper method to eliminate

high frequency noise when measuring the output

ripple. The figure shows how to locate the probe

across the capacitor when measuring output ripple.

Remove the scope probe plastic jacket in order to

expose the ground at the tip of the probe. It gives a

very short connection from the probe ground to the

capacitor and eliminates noise.

F

1

L=1.0μH

0.8

L=1.5μH

0.6

L=2.2μH

0.4

0.2

0

2.5

3

3.5

5

5.5

6

0.

(MA

F

SC

L

To guarantee sufficient output current, peak inductor

current must be lower than the FP6359 high-side

MOSFET current limit. The peak inductor current

is shown as below:

Ceramic Capacitor

FP6359- Preliminary 0.1-AUG-2016

4.5

VIN (V)

A good compromise value between size and

efficiency is to set the peak-to-peak inductor ripple

current Δ L equal to 30% of the maximum load

current. But setting the peak-to-peak inductor

ripple current Δ L between 20%~50% of the

maximum load current is also acceptable. Then

the inductance can be calculated with the following

equation:

L

A

Load Current

Inductor Selection

The output inductor is used for storing energy and

filtering output ripple current. But the trade-off

condition often happens between maximum energy

storage and the physical size of the inductor. The

first consideration for selecting the output inductor is

to make sure that the inductance is large enough to

keep the converter in the continuous current mode.

4

VOUT =1.2V, FOSC=1MHz

L

GND

1

L

1.2

Probe Ground

VOUT

SC

The following diagram is an example to graphically

represent Δ L equation.

ΔIL (A)

R

(MA

L

2

IPEAK

IOUT(MAX)

∆IL

Time

8

�FP6359

Application Information (Continued)

Feedforward Capacitor Selection

PCB Layout Recommendation

Internal compensation function allows users saving

time in design and saving cost by reducing the

number of external components. The use of a

feedforward capacitor C3 in the feedback network is

recommended to improve transient response or

higher phase margin.

he device’s performance and stability are

dramatically affected by PCB layout.

It is

recommended to follow these general guidelines

shown as below:

1. Place the input capacitors and output capacitors

as close to the device as possible. The traces

which connect to these capacitors should be as

short and wide as possible to minimize parasitic

inductance and resistance.

FB

R2

For optimizing the feedforward capacitor, knowing

the cross frequency is the first thing. The cross

frequency (or the converter bandwidth) can be

determined by using a network analyzer. When

getting the cross frequency with no feedforward

capacitor identified, the value of feedforward

capacitor C3 can be calculated with the following

equation:

C

2

1

FCR

SS

1

R1

1

1

R1 R2

2. Place feedback resistors close to the FB pin.

3. Keep the sensitive signal (FB) away from the

switching signal (LX).

4. Multi-layer PCB design is recommended.

GND

C1

VIN

VIN

4

3

LX

PG

5

2

GND

FB

6

1

EN

R1

C3

C3

R1

FP6359

R3

VOUT

VOUT

L1

C2

GND

R2

Figure 4. Recommended Layout Diagram

Where FCROSS is the cross frequency.

To reduce transient ripple, the feedforward capacitor

value can be increased to push the cross frequency

to higher region.

Although this can improve

transient response, it also decreases phase margin

and causes more ringing. In the other hand, if more

phase margin is desired, the feedforward capacitor

value can be decreased to push the cross frequency

to lower region.

In general, the feedforward

capacitor range is between 10pF to 120pF.

FP6359- Preliminary 0.1-AUG-2016

9

�FP6359

Outline Information

SOT-23-6 Package (Unit: mm)

SYMBOLS

UNIT

DIMENSION IN MILLIMETER

MIN

MAX

A

0.90

1.45

A1

0.00

0.15

A2

0.90

1.30

B

0.30

0.50

D

2.80

3.00

E

2.60

3.00

E1

1.50

1.70

e

0.90

1.00

e1

1.80

2.00

L

0.30

0.60

Note:Followed From JEDEC MO-178-C.

Carrier Dimensions

Life Support Policy

Fitipower’s products are not authorized for use as critical components in life support devices or other medical systems .

FP6359- Preliminary 0.1-AUG-2016

10

�