深圳市华灿天禄电子有限公司

物料承认书

SPECIFICATION FOR APPROVAL

客户名称:

Customer:

产品名称:

Description:

规格型号:

Modelno:

PH系列

物料编号:

Cust P/N:

出厂签章

校 对Issuer

审 核Engineer

李攀进

批 准Approver

罗观彬

承认签章 CUSTOMER

校 对Issuer

审 核Engineer

批 准Approver

地址:深圳市宝安区40区安乐科技创新园B栋726

TEL:0755-27204342 FAX:0755-29785862

Http://www.HCTLDZ.com

E-mail: jinpan.hu@hctldz.com

确认合格后烦请回签一份给我司存档,谢谢!

Pls. sign acknowledge and re-turn document to us after confirming, thank you !

�产 品 承 认 书 目 录

1、封面---------------------------------1-1

2、目录---------------------------------2-2

3、技术规范-----------------------------3-9

4、产品图纸-----------------------------10-14

�1、 SCOPE

适用范围

The contents of specifications for PHB series connector strip, including product performance,

test methods and inspection requirements

本规格书内容适用于 PHB 系列条形连接器,包含了产品的性能、试验方法和检验要求

2、 APPLICABLE STANDARDS

适用的标准

2.1

GB/T2421

Testing method for Environmental of Electrical Connectors Class 1:

General Principles

2.2

2.3

2.4

GB/T2421

电工电子产品环境试验 第一部分 总则

GB/T2423

Testing method for Environmental of Electrical Connectors

GB/T2423

电工电子产品环境试验方法

GB/T2424

Testing method for Environmental of Electrical Connectors

GB/T2424

电工电子产品环境试验导则

GB/T5095

Testing Procedure/method for components of electric equipment

电子设备用机电元件基本试验规程及测量方法

3、 USE CONDITION

使用条件

3.1

Ambient temperature Range:-25℃~+85℃

环境温度:-25℃~+85℃

3.2

Applicable Wire Sizes:AWG#22~#28

适用线规:AWG#22~#28

3.3

Applicable PC board thickness:1.6mm

适用 PC 板厚度:1.6mm

4、 Appearance and Dimension

外观及尺寸

4.1

Appearance:Product surface without defect、dirt、crack、and mechanical damang,

Contact without rust,plating not oxided and not peeled.

产品表面不应有对制品有害的缺陷、污垢、裂痕及机械损伤;接触件无锈蚀、镀层

氧化、脱落等现象.

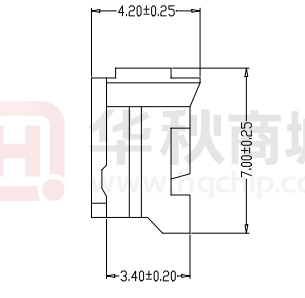

4.2

Dimension:According to drawings

外形尺寸:依照附图

4.3

Exchangable:Exchangable with same specification products.

互换性:相同规格应能互换

�5、Material

材 料

P/N

零件名称

Type

类 型

Material

材 料

Finish

表面处理

Terminal

端 子

Contact

插 簧

Phosphor bronze

锡青磷铜 厚 0.20mm

Tin Plating:3~5μm

镀锡:3~5μm

Housing

孔 座

Plastic

塑 壳

Nylon66

Plastic

塑 壳

Nylon66/LCP U L94V-0

Wafer

针 座

Contact

插 针

6、Electrical Performance

电 气 性 能

N0.

Ltem

序号

项 目

U L94V-0

Brass

黄铜 厚□0.50mm

Expiain

说 明

Color: White

颜色:白色

RoHS

Co lor: Beige

颜色:米色

Tin Plating:2.5~5μm

镀锡:2.5~5μm

Test mode

试验方法

Requirement

技术要求

6.1

Current Rated

额定电流

3A

6.2

Voltage Rated

额定电压

250V AC

6.3

ContactResistance

接触电阻

A maximum vol tage of 20mV and a maximum

current of 100mA are applied to the Mate connector

组合状态下的连接器,两端施以最大测试电压 20

mV 以及最大测试电流 100 mA

Does not include wire resistance

不包含电线阻抗

6.4

withstandvoltage

耐电压

Apply 8 00V AC(rms)for 1 minute a nd the leakage

current s hall not e xceed 0.5m A to the adjac ent

terminal and ground of the Mate connectors

组合状态下的连接器,相邻两导体末端各施以电

压 800V AC(有效值)时间 1 分钟,且漏电流必须小

于 0.5mA(毫安培)

Apply 500V DC(rms)for 1 minute between adjacent

contacts to measure the insulation resistance

6.5

InsulationResistance

绝缘电阻

相邻两接触导体,1 分钟时间内施予 500V D C 电

压,测量期间的绝缘阻抗值

AC

DC

DC

Initial value Less than

20mΩ

初始值≤20 mΩ

No breakdownor flashover

无击穿或者产生火花

More than 1000 MΩ

≥1000MΩ

�7、Mechanical Performance:

机 械 性 能

N0.

Ltem

序号

项 目

7.1

Terminal crimping

wire strength

端子压接导线强度

Test mode

试验方法

Terminal crimping wires , axia l

per m inute t o 2 5 ± 3m m rate of

the pullout force

端子所压接电线,以每分钟

25±3mm 速率之轴向拔出力

7.2

7.3

7.4

7.5

Fixed terminals

and hole seat

端子与孔座固定力

Singlecontact

insertion force

单接触插入力

Single contact

withdrawal force

单接触拔出力

Pin Retention

force

PIN 针固定力

Requirement

技术要求

AWG#22 wire

AWG#22 导线

More than 50N

≥50N

AWG#24 wire

AWG#24 导线

More than 30N

≥30N

AWG#26 wire

AWG#26 导线

More than 20N

≥20N

AWG#28 wire

AWG#28 导线

More than 13N

≥13N

The terminal and the hole seat, at a rate per minute

to 25 ± 3mm along the wire direction are pulled out

from the hole in the seat capacity

端子与孔座配合,以每分钟 25±3mm 的速率沿导

线方向将端子从孔座中拔出的力

The Housi ng together wi th t he terminal en ds with

Wafer matched, at a rate p er m inute to 25 ± 3mm,

inserting force test

孔座连同端子与针座两端互配,以每分钟 25±3mm

的速率,作插入力测试

The Housi ng together wi th t he terminal en ds with

Wafer matched, at a rate per minute to 25 ± 3mm, as

the pull-out test

孔座连同端子与针座两端互配,以每分钟 25±3mm

的速率,作拔出力测试

Exerts a force on the pin end, at a rate per minute 25

± 3mm, until the needle exit seat pull-out force

7.6

More than 15N

≥15N

Less than 6N

≤6N

More than 0.5N

≥0.5N

Per contact

单一接触点

More than 15N

在针脚前端施加力,以每分钟 25±3mm 的速率,

≥15N

直到针退出针座的拔出力

Mate connectors up 3 0 cycles at a Maximun rate of

10cycles per minute prior toenvironmental test

Durability

耐久性

Per contact

单一接触点

组合状态下的连接器且未经环境测试,每分钟内

进行 10 次嵌入与拔出,连续 30 次嵌入与拔出往

返测试

Contact Resistance

≤30 mΩ

接触电阻≤30 mΩ

�N0.

序号

Test mode

试验方法

Ltem

项 目

Connector combination sta te of t he we lding circ uit

board as test samples, the request in accordance with

the fol lowing spe cifications, resist ance to vibration

test, w hether to produce dis continuous c urrent

determined du ring th e experim ent

(off)

phenomenon, after th e ex periment measuring

contact resistance

7.7

Vibration

振动

组合状态下的连接器焊接电路板上作为试验样

品,依照如下规格要求,进行耐振动试验,试验

过程中确定是否产生不连续电流(断电)现象,

试验过后测量接触电阻值

Frequency(频率):10-55-10 Hz/minute

Amplitude(振幅):1.5mm p-p

Direction(方向):

1、Axis of up and down 上下轴向(Y 轴)

2、Axis of right the left 左右轴向(X 轴)

3、Axis of front and back 前后轴向(Z 轴)

Period(周期):2 hous for each direction

每一个轴向持续 2 小时

8、Endurance Characteristics:

环 境 性 能

N0.

Ltem

序号

项 目

Test mode

试验方法

Connector combination c ondition is placed in t he

oven, the request in acc ordance with the following

specifications, high temperature aging test, after the

test and measurement of contact resistance

8.1

Thermal Aging

高温老化试验

组合状态下的连接器放置于加热烤箱中,依照如

下规格要求,进行高温老化试验,试验后并测量

接触电阻值

Temperature:85± 2 ℃

Period:96 hours continuously

温度:85± 2 ℃

周期:持续 96 小时

Requirement

技术要求

Appearance:No damage

外观:无损伤

Contact Resistance

≤30 mΩ

接触电阻≤30 mΩ

current Discontinuity:

1 micro second Max

电流中断:1μsec Max

Requirement

技术要求

Appearance:No damage

外观:无损伤

Contact Resistance

≤30 mΩ

接触电阻≤30 mΩ

�N0.

序号

8.2

Ltem

项 目

Temperature

温升

Test mode

试验方法

Mate c onnector m easure the temperature rise of

contact when the maximum rated current is passed

30℃ Ma x

组合状态下的连接器,通过最大容许电流测量导

体温度上升值

Connector combination un der the condition of

constant t emperature and humidity plac e spac e, i n

accordance w ith the requir ements of t he foll owing

specifications, consta nt te mperature a nd hum idity

test, aft er t he experiment m easuring c ontact

resistance, insulation res istance a nd withsta nd

voltage test

8.3

Humidity

恒定潮湿

Requirement

技术要求

组合状态下的连接器放置恒定温度的湿气空间,

依照如下规格要求,进行恒温恒湿试验,试验过

后测量接触电阻、绝缘电阻以及耐电压测试

Temperature: 40 ± 2 ℃

Relative humidity:90-95%RH

Period:96 hours continuously

Appearance:No damage

外观:无损伤

Contact Resistance:

≤30mΩ

接触电阻:≤30 mΩ

Insulation Resistance:

≥500MΩ

绝缘电阻:≥500MΩ

No breakdown or flashover

无击穿或者产生火花

温度:40±2℃

相对湿度:90-95%

周期:持续 96 小时

The combined state of connectors as test samples, in

accordance w ith the requir ements of t he foll owing

specifications, therm al sho ck t est, after the test

measuring c ontact resis tance, i nsulation resistance,

and resistance to voltage

8.4

Temperature cycling

温度循环

组合状态下的连接器作为试验样品,依照如下规

格要求,进行冷热冲击试验,试验后测量接触电

阻、绝缘电阻、以及耐电压测试

One cycle consists of:

-55±3℃,30min,Room temp.10-15 min

85±3℃,30min,Room temp.10-15 min

Total cycle:5 cycle

-55±3℃,30 分钟,放置转换时间 10-15 分钟

85±3℃,30 分钟,放置转换时间 10-15 分钟

循环次数:5 次

Same as paragraph 8.3

同 8.3 章节

�N0.

序号

Ltem

项 目

Test mode

试验方法

The combined state of connector as test samples, salt

spray test a ccording to the following specifications,

test samples will be clean again with the water to dry

naturally, measurement of contact resistance

组合状态下的连接器作为试验样品,依照如下规

格要求进行盐水喷雾试验,试验后将样品用清水

冲干净自然凉干,测量接触电阻值

8.5

Salt spray

盐雾

Temperature:35±3℃

Solution:5±1%

Period:

Stamping after tin plated for 8 hours

Stamping before tin plated for 48 hours

温度:35±3℃

浓度:5±1%

周期:

先电镀后冲压 8 小时

先冲压后电镀 48 小时

In accordance with the following specifications were

placed tin soldering test

放置锡炉中依照如下规格进行焊锡试验

8.6

Solder ability

可焊性

Solder Temperature:245±5℃

Immersion period:3±0.5S

焊锡温度:245±5℃

沉浸周期:3±0.5S

Requirement

技术要求

Appearance:No damage

外观:无损伤

Contact Resistance:

≤30mΩ

接触电阻:≤30 mΩ

Area of Soldering:≥90%

焊锡面积:≥90%

anual soldering tin process

Soldering time:3±0.5S

Soldering pot:305±5℃

手工烙铁焊锡工艺

焊接时间:3±0.5S

焊接温度:305±5℃

8.7

Resistance to

soldering heat

耐焊接热

Mode of operation:

操作方式:

Position DIP type needle solder, conductor or a fixed

piece at the end of the 1.5mm distance

DIP 型针座焊锡位置,距离导体或固定片末端

1.5mm

Wave soldering tin soldering process

Soldering time:5±0.5S

Soldering pot:230±5℃

波峰焊焊锡工艺

焊接时间:5±0.5S

焊接温度:230±5℃

Appearance:No damage

外观:无损伤

�9、Packaging Transportation Storage

包装、运输、贮存

9.1

Packaging

包装

(1)

Terminal packaging for the dish material packaging, rubber shell packaging for plastic

bags, packaging bags or plastic box seat for packaging, loading (paste) into the certificate,

indicate the product name, specifications, quantity production date and other

information

端子内包装为盘装带料包装、胶壳内包装为塑料袋,针座包装为袋装或吸塑盒包装,装

(贴)入合格证,注明产品名称、规格型号、数量生产日期等信息

(2)

Exterior package is carton, facing the packing list, the packing list marked with product

name, specificcation model, quantity, date of dispatch.

外包装为纸箱,贴装箱单、装箱单上注明产品名称、规格型号、数量、出货日期

(3)

The product in the box must not rock

产品在箱内不晃动

9.2

Transportation

运输

Any vehicle can be adopted for the transportation,but moisture-proof and no mechanical

damage,transport temperature to.-20℃~+50℃

允许用任何方式运输,但需避免雨雪直淋和阳光照射,不能有碰撞和挤压等机械损伤,

运输环境温度为-20℃~+50℃

9.3

Storage

贮存

(1)

The connector of packing finished should be in the ambient temperature between-10℃

to+40℃, Relative humidity≤80%. To store in storehouse does not have acidic, alkaline

air and other corrosive gas in the ambient air.

包装完毕的连接器应在环境温度为-20℃~+40℃,相对湿度≤80%,周围空气中没有酸性,

碱性及其它腐蚀性气体的库房中贮存

(2)

Re-qualification test shall be conducted immediately while the storing duration exceed 6

months

贮存期为 6 个月,超期 6 个月需从新检查

�����������