产 品 承 认 书

SPECIFICATION

客

户 Customer Name:

产品名称 Product Name: 铝电解电容器 Aluminum Electrolytic Capacitor

型

号

Type:

CD297

规 格 Specification:

200V 1000μF

30*35mm

物料编码 Material code:

144EC0016

日

2023-7-12

期

Date:

供应商签署栏

制作

审核

批准

审核

批准

公司印章

客户确认栏

承认

结论:

□合格

□不合格

□其它:

烦请确认后回传,以方便交货确认;未回签表示默认合格,订货

合同按此样品执行交货。

�电容器外形图、产品明细

Capacitors with shape size made request and the product details

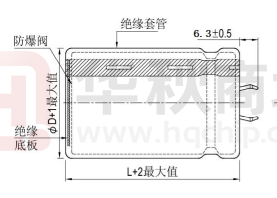

电容器外形图 Capacitor figure shape:

※ 表 1(TABLE 1)

No.

1

物料编码

Material code

144EC0016

型 号

Type

CD297

规格

Specification

200V1000uF

额定电压 浪涌电压

额定容量范围

Rated

Surge

(%)Tolerance on Rated

Voltage

Voltage

Capacitance

(Vdc)

(Vdc)

-20%~+20%

200V

230V

工作温度范围

OperatingTemp.

Range(℃)

损 耗

tanδ

(120Hz)

(Max)

漏电流

Leakage

Current

(uA)(5min.)

最大纹波电流

Max Ripple

Current (A)at

105℃120Hz

耐久性

Endurance

at 105℃

(Hours)

-25-+105

15

1340

1.84

5000

体积

Dimensions mm

D±1

L+2

F±1

30

35

10

�产品特性 PRODUCT CHARACTERISTICS

1 产品特性 PRODUCT CHARACTERISTICS

1.1 电气特性 ELECTRICAL CHARACTERISTICS

序号

项目

测试方法

性能

No.

Item

Test method

Performance

1.1.1

额定工作电压

10V.DC~450V.DC

Rated voltage

1.1.2

电容量

Capacitance

测试频率:120Hz(±20%)

容量范围:

测试电路:串联等效

56μF ~56000μF

测试电压:0.5Vrms 以下+1.5~ 2.0VDC

容量偏差:-20%~+20%

Measuring frequency: 120Hz±20%

Range of Capacitance:

Measuring circuit:

56μF ~56000μF

Series equivalent circuit

Measuring voltage:

Capacitance tolerance:

-20%~+20%

0.5Vrms or less +1.5 to 2.0 VDC

1.1.3

损失角正切值

Dissipation Factor

测试条件与 1.1.2 电容量测试相同

DF 见表 1

Testing condition are the same as1.1.2 for

DF: See Table 1.

capacitance

1.1.4

漏电流

Leakage current

在电容器两端施加额定工作电压,并串联 1000

16~450V:

±100Ω电阻,在施加电压 5 分钟后,测量漏电 I = 3 CV or 1.5mA,

流。

取较小值(5 分钟后)

capacitor and its protective resistor which shall be

16~450V:

I = 3 CV or 1.5mA,

1000±100Ω. The leakage current shall then be

I:漏电流(μA)

measured after an electrification period of 5 min..

C:容量(μF)

测试电路如下图:

The rated voltage shall be applied across the

Measurement circuit

Whichever is smaller(after5 min)

V:额定工作电压(V)

I:Leakage current(μA)

C:Capacitance(μF)

V:Rated voltage (V)

Rs: Protective resistor(1000±100Ω)

DC ammeter

DC voltmeter

S1: Switch

S2: Protective switch for an ammeter

�产品特性 PRODUCT CHARACTERISTICS

1.1.5

阶段

温度特性

1

Temperature

2

Characteristic

3

4

温度

20±2℃

+0

-25, -40 -3℃

20±2℃

+3

105 -0℃

时间

热平衡状态

2h

热平衡状态

2h

阶段 1:测量容量和阻抗(|z| 20℃ 120Hz±

20%)

1.1.6

耐浪涌电压

阶段 2:电容器恒温贮存 2 小时,在热平衡状态

测阻抗(|z|-25,-40℃ 120Hz±20%)

阶段 4:电容器恒温贮存 2 小时,在热平衡状态

测电容量

Step 1:Capacitance and impedance shall be

measured. (|z| 20℃ 120Hz±20%)

Step 2:After the capacitor being stored for 2 hours,

impedance shall be measured at thermal

stability. (|z|-25,-40℃ 120Hz±20%)

Step 4:After the capacitor being stored for 105℃2

hours, capacitance shall be measured. The

measurement shall be made at thermal stability

施加表 1 所列浪涌电压,充电 30±5 秒,放电

Surge Test

5.5±0.5 分钟作为一个周期,共进行 1000 次。

测试温度:15℃-35℃

然后在标准大气条件下放置达到热稳定,测试各

参数

Application of DC surge Voltage stated at table-1,

1000

times of charging for 30 ± 5 sec.,

discharging with a period of 5.5±0.5 min..

Test temperature: 15℃-35℃

阶段 2:

阻抗值与阶段 1 阻抗值相比,不大

于表 2 要求。

阶段 4:

容量变化应在初值的±20%范围内

Step 2:

Impedance value ratio to the value at

step 1 shall be not more than the

value given table-2

Step 4:

Variation of capacitance Within

±20% of the initial value.

容量变化:在初始值的±20%以内。

损耗角正切值不大于 200%的表 1 规

定值。

漏电流:达到 1.1.4 要求

Capacitance change:

Within ± 20% of the initial value

Dissipation factor:

Not more than 200% of the

specified value in Table-1.

Leakage current:

To satisfy No.1.1.4

And the capacitor shall be stored under standard

atmospheric conditions to obtain thermal stability,

after which measurements shall be made.

Test circuit

Note: This requirement is applicable only to instantaneous over voltage which may

be applied to terminals of capacitor, therefore, not applicable to such

over voltages as often applied.

�产品特性 PRODUCT CHARACTERISTICS

1.2 机械特性 MECHANICAL PERFORMANCE

序号

项目

测试方法

特性

No.

Item

Test method

Performance

1.2.1

端子强度

端子抗拉强度:

Terminal

沿电容器端子引线方向施加拉力(如下表),10±1 秒。 或短路,无可见机械损伤

测量电容器应无接触不良、开路

When the capacitor is measured,

Strength

引出端拉力 N

20

there shall be no intermittent

contacts,or open or short-circuiting.

Tensile strength of termination:

There shall be no such mechanical

A static load(stated in the table below) shall be applied damage.

to the terminal in the axial direction and acting in a

direction away from the body for 10±1 sec..

1.2.2

振动试验

Resistance to

Vibration

1.2.3

可焊性

Solderability

测量电容器应无接触不良开路或

依据 GB-T 5993-2003

在 3 个互相垂直的方向分别施加 2 小时振动,共 6 小 短路,无可见机械损伤。

时

When the capacitor is measured

频率:10-55Hz

there shall be no intermittent

振幅:1.5mm.

contacts, or open or short circuiting

振速:1 分钟内振速 10~55~10Hz

There shall be no such mechanical

To comply with GB-T 5993-2003

damage.

Direction and duration of vibration:

3 orthogonal directions mutually each for 2h , Total 6h.

Vibration Frequency Range :10-55Hz

Peak to peak amplitude: 1.5mm

Sweep rate :10to55to10Hz in about 1 min.

依据 GB-T 5993-2003进行试验

焊锡温度:235±5℃

浸入时间:2±0.5 秒

To comply with GB-T 5993-2003

Temperature of solder: 235±5℃

Dipping time: 2±0.5sec.

This specification shall be met after the capacitors are

stored under standard atmospheric conditions for 6

months.

浸入焊锡的引线表面积约 90%以

上应附着新锡

At least 90% of circumferential

surface of the dipping portion of

termination shall be covered with

new solder.

�产品特性 PRODUCT CHARACTERISTICS

1.3 耐久性测试 ENDURANCE PERFORMANCE

序号

项目

测试方法

No.

Item

耐焊耐热

Resistance to

soldering heat

Test method

1.3.1

1.3.2

耐湿性

Resistance to damp

heat

1.3.3

高温负荷试验

Load Life Test

特性

Performance

容量变化:在初始值±10%范围内

焊槽法:

损失角正切值:不大于规定值

焊锡温度:260±5℃

漏电流:满足 1.1.4 要求

浸入时间:10±1 秒

外观:无异状

电路板 :1.6mm

Variation of capacitance:

Solder bath method

Within ±10% of the initial value

Solder bath temperature : 260±5℃

Dissipation factor:

Immersion time : 10±1sec.

Not more than the specified value

Printed wiring board: 1.6mm

Leakage current:

To satisfy No.1.1.4

Appearance:

No remarkable abnormality.

容量变化:在初始值±10%范围内

依据GB-T 5993-2003进行试验

损失角正切值:不大于规定值

试验温度:40±2℃

漏电流:满足 1.1.4 要求

试验时间:240±8h

外观:无异状

相对湿度:90~95%

试验后,电容器在标准大气条件下 1~2 小时, Variation of capacitance:

然后测试参数

Within ±10% of the initial value.

To comply with GB-T 5993-2003

Dissipation factor:

Test temperature : 40±2℃

Not more than the specified value

Test time

: 240±8h

Leakage current: To satisfy No.1.1.4

Relative humidity: 90~95%

Appearance:

After completion of test, the capacitor shall be

No remarkable abnormality.

subjected to standard atmospheric conditions for

1 to 2 hours, after which measurements shall be

made.

试验温度:105±2℃,施加额定电压和额定

纹波电流

Application of the rated voltage and the rated

ripple current, Test temperature:105±2℃

+8

试验时间:5000 -0 h

+8

Test time:

5000 -0 h

容量变化:在初始值±20%范围内

损耗角正切值:不超过规定值的 200%

漏电流:不大于规定值

外观:无异状

Variation of capacitance:

Within ±20% of the initial value.

Dissipation factor:

Not more than 200% of the specified

value

Leakage current:

Not more than the specified value

Appearance:

No remarkable abnormality.

�产品特性 PRODUCT CHARACTERISTICS

1.3.4

高温贮存试验

容量变化:初始值±20%范围内。

在105±2℃环境下无负荷贮存 1000 -0 h,加额定 损耗角正切值:不超过规定值的 200%

漏电流:不超过规定值的 200%

工作电压处理30分钟,至少恢复 16 小时后。

外观:无异状

The capacitors are then stored with no voltage

Variation of capacitance:

Within±20%ofthevaluebeforetest.

applied at a temperature of 105 ± 2 ℃ for

Dissipation factor:

+8

Not more than 200% of the specified value

1000 -0 h ,to be applied for 30 minutes and

Leakage current:

then resumed 16 hours.

Not more than 200% of the specified value

Appearance:

No remarkable abnormality.

规格

电容器上应加1A-10A逆向直流电,防爆壳正常

Specifications

动作,无金属片飞散、起火、爆炸。

规格

反向电流

The capacitor is shall be connected in inverse

Size

Inverse

Current

polarity,and appliced DC current at 1A-10A

≦22Φ

1A

constant,The pressure relief device shall open in

>22Φ

10A

such a way as to avoid any danger of fire or

explosion of capacitor elements (Terminal and

mental foil etc.) or cover.

+8

Shelf Life Test

1.3.5

防爆试验

Safety Vent Test

※ 表 2(TABLE 2)

Rated voltage (v)

10

16

25

35

50

63

80

100

160-250

350-450

|z|-25℃/|z|20℃

4

4

3

3

2

2

2

2

4

8

|z|-40℃/|z|20℃

15

15

10

8

6

6

5

5

-

-

※ 纹波电流频率因子 RIPPLE CURRENT FREQUENCY COEFFICIENT

Frequency(Hz)

50/60

100/120

500

1K

10K up

16-100V

0.92

1.00

1.13

1.19

1.20

160-250V

0.81

1.00

1.32

1.45

1.50

315-450V

0.88

1.00

1.20

1.25

1.40

�电解电容器结构及套管标志

Electrolytic capacitor structure and casing mark

1、电解电容器结构 Electrolytic capacitor structure

No.

组件 PART

材料 MATERIALS

1

焊针 Terminal

镀锡的铜层铁线 Tinned copper-ply wire

2

引出条 Foil Leads

铝 99.9 % Aluminum 99.9 %

3

盖板 Cover board

电木、橡胶 bakelite、rubber

4

套管 Casing

5

外壳 Aluminum shell

铝 99.5% Aluminum 99.5%

6

阳极箔 Al-foil(+)

化成铝 99.99% Formed aluminum 99.99%

7

阴极箔 Al-foil(-)

腐蚀铝 98.7% Etched aluminum 98.7%

8

电解纸 Electrolytic paper

马尼拉麻浆、西班牙草浆 Manila hemp pulp, Spanish

PET

黑色

PET

black

straw

2、产品套管标志 Casing marks of products:

KNSCHA

KNSCHA

序号 No.

1

2

3

4

项目

标称电压

标称容量

负极标志

商标

Item

mesh

Rated

voltage

Rated

capacitance

Cathode

line

Trade

mark

5

6

型号

使用极限温度 Maximum

Type

operating temperature

�电解电容器储存条件及保存周期

The provision of capacitor storage condition and period

一、储存条件 STORAGE CONDITION:

1.电解电容器应在包装完好(塑料袋、纸箱)状态下进行存放,严禁暴晒

和雨淋。The capacitor should be packed with plastic and carton perfectly,

and it should be forbidden to barely under the sunshine and rain.

2.存放电解电容器库房温、湿度条件:温度 0-40℃,相对湿度低于 85%,并通风良好。

The warehouse condition required: temperature:0℃—40℃,relative humidity :less

85%, and air the warehouse easily。

3.库房周围环境应无酸性、碱性及其它有害气体。The warehouse should be none acid

and alkaline gas around。

二、保存周期 STORAGE PERIOD:

1、在上述储存条件下,电解电容器保存周期为一年。The period is about one year,

under the conditions mentioned above。

2、制造单位成品在仓库中保存周期为一年,当保存周期超过半年,成品出库前必须按

抽样标准检验,并符合要求。when the period is exceed for half a year, the capacitor

should be test again to assure the quality。

3、使用单位电容器保存周期如超过一年,在投入使用前,对中高压产品(Wv≥100V)

或低压大容量产品(C≥1000UF)应进行恢复性老练(缓、慢升压至额定工作电压并保持

4~6 小时)后,才能投入使用。If the storage period of the capacitors exceed one year,

concerning the mid & high voltage or low voltage high capacitance products. We must

add rated working voltage slowly to the capacitors and maintain 4-6hours before

use it。

4 、 对 引 线 式 电 解 电 容 器 引 线 可 焊 性 有 效 期 为 一 年 。 for terminal electronic

capacitors, the period of the terminal soldering characters is 1 year.

�电容器包装说明 Packing information

一、散件包装:

1. 产品用纸盒封装,根据产品体积不同,每盒数量不等,盒内放有合格证

Packing with paper Box, the content of each paper Box is according to the volume

of the capacitors.Inside the box marked on the product quality。

2. 数盒为一包装箱,外有箱贴,标明产品规格、型号、数量、生产日期、生产批号等

A small paper Box Number of a package, label outside, marked with specification,

type, number, date of production, production batch number etc。

3.

包装箱外有 ROHS 标识 Outer packing boxes with

ROHS

logo

二、包装规格说明 PACKING SPECIFICATION

内盒 Inside the box

内盒尺寸

Inside Box Dimensions

外箱 Outside the box

外箱尺寸

Outside Box Dimensions

产品尺寸

Case Size

长L

高H

宽W

长L

高H

宽W

ΦD×L

305

65

233

488

290

325

30*35

包装数量

Packing Quantity

内盒

Inside

63

外箱

Outside

630

�铝电解电容器使用注意事项

IMPORTANT INFORMATION ON THE APPLICATION OF ALUMINUM ELECTROLYTIC CAPACITORS

其它说明 OTHER REMARKS

1 铝电解电容器使用注意事项 IMPORTANT INFORMATION ON THE APPLICATION

OF ALUMINUM ELECTROLYTIC CAPACITORS

(1)直流铝电解电容器应按正确的极性使用 DC aluminum electrolytic capacitors are normally polarized

当直流铝电解电容器按反极性接入电路时,电容器会导致电子线路短路,由此产生的电流会引致电容器

损坏。若电路中有可能在负引线施加正电压,请选无极性产品。

When reverse voltage is applied on DC aluminum electrolytic capacitor ,the circuit will be short

out and the capacitor will be damaged due to abnormal current flows through the capacitor.Please

use non- polar types of capacitors when the positive voltage is applied on the cathode

terminal.

(2)在额定工作电压以下使用 Use capacitor within rated voltage

当电容器上所施加电压高于额定工作电压时,电容器的漏电流将上升,其电气特性将在短时内劣化直至损

坏。请注意电压峰值勿超出额定工作电压。

When capacitor is used at higher voltage than the rated voltage, leakage current increased,

characteristics drastically deteriorated and damaged in a short period may occur as a result.

Please take extra caution that the peak voltage should not exceed the rated voltage.

(3)作快速充放电使用 Sudden charge and discharge

当常规电容器被用作快速充电用途,其使用寿命可能会因为容量下降,温度急剧上升等而缩减。

When aluminum electrolytic capacitors for general purpose-use are employed in rapid charge and

discharge application, its life expectancy may be shortened resulted from capacitance decrease,

heat rise, etc.

(4)电容器贮存 Storage of the capacitor

当铝电解电容器作了长期贮存后,其漏电流通常升高,贮存温度愈高,漏电流上升愈快。因此应注意贮存

环境,在电容器上施加电压后,漏电流值将不断下降,如铝电解电容器的漏电流值上升对电路有不良影响,

请在使用前充电处理。

Leakage current tends to increase when aluminum electrolytic capacitors have been stored

for long period of time. The higher the storage temperature, the higher the leakage current

increase.Please take caution when selecting the storage location. The leakage current will

decrease gradually as voltage is applied to the capacitor. The capacitor is subjected to aging

before using where increased leakage current may cause problems in the circuit.

(5)施加纹波电流应小于额定值 Use capacitor within rated ripple current

施加纹波电流超过额定值后,会导致电容器体过热,容量下降,寿命缩短。所施加纹波电压的峰值应小于

额定工作电压。

If excessive ripple current is applied on the capacitor,which will result in generating excessive

heat inside , reducing capacitance and shortening life of capacitor . Therefore the peak value

of the ripple voltage should be less than the rated value.

(6)使用环境温度 Ambient temperature

铝电解电容器的使用寿命会受到环境温度的影响。据科学统计,使用环境温度下降 10℃其使用寿命增加 1

倍。

Life of aluminum electrolytic capacitor is affected by the ambient temperature. It is generally

known that the life doubles for each 10℃ decrease in temperature.

�铝电解电容器使用注意事项

IMPORTANT INFORMATION ON THE APPLICATION OF ALUMINUM ELECTROLYTIC CAPACITORS

(7)引出线强度 Tensile strength of lead wire

当拉力施加到电容器引出线,该拉力将作用于电容器内部,这可能导致电容器内部短路,开路或漏电流上

升。在电容器焊装到电路板,请勿强烈摇动电容器。

When a strong force is applied to the lead wires or terminals, stress is put on the internal

connections,which may result in short circuit, open circuit or increased leakage current. So it

is not advisable to bend or handle a capacitor after it has been soldered to the PC board.

(8)焊接过程耐热性 Heat resistance at the soldering process

铝电解电容器装至电路板进行浸焊或波峰焊时,其塑料套管可能因焊接时间过长、温度过高而发生破裂或

二次收缩。

During soldering process, secondary shrinkage or sleeve crack

may occur

when

soldering

temperature is too high or soldering time is too long.

(9)电路板的安装孔孔距及安装位置 Hole pitch and position of PC board

电路板安装孔的设计应与产品说明书的引线脚距相一致,如果将电容器强行插入孔距不配套的电路板,

那么会有应力作用于引出线,这可能导致短路或漏电流上升。

When designig a PC board , its hole pitch should be designed to coincide with the lead pitch(lead

spacing) of the capacitor specified in the catalog or specifications.When a capacitor is forcibly

inserted into an unmatched hole pitch,a force will put on the leads and which could result in a

short circuit or increased leakage current.

(10) 关于焊接以后的清洗 Cleaning after soldering

① 电容器不能用卤化有机物系列的清洗剂进行清洗。如果必须进行清洗,请使用能够保证电容器质量的清

洗剂。

The aluminum electrolyte capacitors should be fee halogenated solvents during board cleaning after

soldering. Use solvent proof capacitors when halogenated solvents are used.

② 对于能够保证电容器质量的清洗剂,清洗后请不要在清洗溶液或者密封容器中保管。清洗后的电容器请

和电路板一起在热风下干燥 10 分钟以上,热风的温度不可高于电容器规定上限温度。

After cleaned with the solvent which should proof the quality of capacitors, the capacitors should

not be kept in solvent environments of non-ventilated places. Let the capacitors after cleaning

dry with hot blast fully above 10mins and the temperature of hot blast should not be over than

specified upper limit of capacitors.

(11) 关于固定剂以及镀层(涂层剂)Adhesives、fixative and coating materials(coating agent)

① 请不要使用含有卤化有机物系列的固定剂及镀层(涂层剂)。

Do not use halogenated adhesives and coating materials to fix aluminum electrolytic capacitors.

② 请不要让固定剂及镀层(涂层剂)将电容器封口部位(端子一侧)全部封住。

Do not cover up all the sealing area of capacitors with adhesives 、 fixative or coating

materials(coating agent), make coverage only partial

2 符合 RoHS

RoHS compliance

符合欧盟 RoHS 的最新标准,若客户有特殊要求,按照双方签订的相关协议为准.

Accord with the latest standard of RoHS, if customers have any special requirments,

according to the relevant agreements which signed by both parts.

�