SQ76003D

High Efficiency, 3 A , 2.5V- 6V Input

Synchronous Step Down DC/DC converter

General Description

Features

The SQ76003D is a step-down module converter with

built-in power MOSFETs and inductor. The

SQ76003D achieves 3A of continuous output current

from a 2.5V to 6V input voltage with excellent load

and line regulation. It provides accurate regulation for a

variety of loads over Tj= -40°C to 125°C. The output

voltage can be regulated as low as 0.6V. Only input

capacitors, output capacitor and FB resistor divider are

needed to complete the design.

The SQ76003D adopts the instant PWM architecture to

achieve fast transient responses for high step down

applications. The device is also equipped with cycleby-cycle current limit, hiccup over current protection

and thermal shutdown protection.

RO

N

IR

IT

rep

are

Ordering Information

SQ76003 □(□□ □)

Applications

de

nti

a

Note

--

on

fi

Package type

MDFN2.5×2-10

Smart Phone

Telecom Applications

Light Module

lP

Package Code

Optional Spec Code

Ordering Number

SQ76003DAFM

or

K

dF

Wide Input Voltage Range: 2.5V to 6V

Capable of 3A constant output current

High Output Voltage Accuracy Over Temperature

Range (Ta -40°C to 105°C)

Instant PWM architecture to achieve fast transient

response

FCCM under all Io Range

Pseudo 2.4MHz switching frequency

Internal Soft-start Limits the Inrush Current

Reliable Protection Mode:

Auto-retry Mode for UVP, UVLO and OTP.

Hiccup Mode for OCP

Power good indicator

100% dropout operation

RoHS Compliant and Halogen Free

Compact Package: 2.5×2×1.3 mm

.C

Typical Applications

orp

VIN

VOUT

VIN

VOUT

yC

RPG

CIN

erg

Sil

RH

PG

EN

REN

CFF

COUT

FB

GND

RL

Figure 1. Schematic Diagram

SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Silergy Corp. Confidential-prepared for Customer Use Only

1

All Rights Reserved.

�AN_SQ76003D

Pinout (top view)

1

10

GND

VIN

2

9

GND

EN

3

8

FB

PG

4

7

VOUT

VOUT

5

6

VOUT

or

K

IR

IT

RO

N

VIN

(MDFN2.5×2-10)

Pin Number

Pin Description

VIN

1,2

EN

3

Enable pin. Pull high to enable the device. Pull low to disable the device.

PG

4

Power good open drain output pin.

VOUT

5,6,7

FB

8

GND

9,10

dF

Pin Name

Input pin. Decouple this pin to GND pin with at least 20μF ceramic

rep

are

capacitor.

lP

Output voltage pin. Decouple this pin to GND pin with at least a 30μF

ceramic capacitor.

de

nti

a

Output Feedback Pin. Connect this pin to the center point of the output

resistor divider to program the output voltage: VOUT=0.6×(1+RH/RL).

Ground pin.

on

fi

Absolute Maximum Ratings (Note 1)

erg

yC

orp

.C

Supply Input Voltage -------------------------------------------------------------------------------------------------- 0.3V to 7V

All Other Pins ------------------------------------------------------------------------------------------------ -0.3V to VIN + 0.3V

Power Dissipation, PD @ TA = 25°C, MDFN------------------------------------------------------------------------------ 3.7W

Package Thermal Resistance (Note 2)

θ JA ------------------------------------------------------------------------------------------------ ---------------------- 27℃/W

ΨJB ----------------------------------------------------------------------------------------------- ----------------------- 18℃/W

Lead Temperature (Soldering, 10 sec.) ------------------------------------------------------------------------------------ 260℃

Storage Temperature Range -------------------------------------------------------------------------------------- -55℃ to 125℃

Junction Temperature, Operating-------------------------------------------------------------------------------- -40℃ to 125℃

Sil

Recommended Operating Conditions (Note 3)

Supply Input Voltage ------------------------------------------------------------------------------------------------- -0.3V to 6V

Output voltage --------------------------------------------------------------------------------------------------------- 0.6V to Vin

Output Current Range ---------------------------------------------------------------------------------------------------- 0A to 3A

Junction Temperature Range ------------------------------------------------------------------------------------ -40℃ to 125℃

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Silergy Corp. Confidential-prepared for Customer Use Only

2

All Rights Reserved.

�AN_SQ76003D

Electrical Characteristics

ΔVLNR

∆T

Rise Time

tRISE

dF

ILIM,BOT

rep

are

From EN high to 95% of VOUT

nominal

VEN,HYS

REN

de

nti

a

VEN

lP

fSW

TSD

THYS

DMAX

tON,MIN

EN Low

VOUT rising

VOUT falling

VPG,ASSERTS

±0.5

±2

5

%

%

A

0

0.3

1

ms

1.92

2.4

150

20

2.88

MHz

°C

°C

%

ns

100

50

1.0

300

93.5

86

V

0.6

400

95

88

500

97.5

91

V

kΩ

%

%

.C

Power Good Asserts Threshold

VIN=2.5-6V ,Io=3A

TA=-40°C to 105°C, IO=3A

on

fi

General Specifications

Switching Frequency

Thermal Shutdown Temperature

Thermal Shutdown Hysteresis

Maximum Duty Cycle (Note 4)

Min On Time

Signal Specifications

EN Pin Logic High Threshold

(rising)

EN Hysteresis

EN Pull-down Resistance

or

K

Line Regulation

Temperature Regulation

Bottom FET Valley Current

Limit

IR

IT

RO

N

(VIN = 3.3V, VO =1.8V, IO = 3A, CO = 3*10µF, TA = 25°C, FB divider resistor accuracy = 0.5%, unless otherwise

specified)

Symbol

Parameter

Test Conditions

Min

Typ

Max Unit

Input Specifications

Input Voltage Range

VIN

2.5

6

V

Input UVLO Threshold (falling) VUVLO,FALLING EN=VIN

2.1

2.2

2.3

V

VHYS

Input UVLO Hysteresis

200

mV

IIN

Input Current with No Load

IO=0A

10

16

30

mA

I

Shutdown Current

0.1

0.5

µA

SHDN

Output Specifications

VREF

Feedback Reference Voltage

TJ=-40°C-125°C

0.594

0.6

0.606

V

ΔVLDR

Load Regulation

TA=25°C, IO=0 to 3A

±1

%

yC

orp

Note 1: Stresses beyond the “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only. Functional operation of the device at these or any other conditions beyond those indicated in the

operational sections of the specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

erg

Note 2:θJA and ΨJB are based on a four-layer Silergy Evaluation Board in the natural convection at TA = 25°C. Board

temperature refers to the PCB point to the hottest IC pin with a 1mm distance on the same PCB surface layer.

Note 3: The device is not guaranteed to function outside its operating conditions.

Sil

Note 4: The values are guaranteed by design.

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Silergy Corp. Confidential-prepared for Customer Use Only

3

All Rights Reserved.

�AN_SQ76003D

Typical Performance Characteristics

(COUT = 3×10μF, TA = 25°C, resistor tolerance is ±1%, unless otherwise specified.)

VOUT=0.75V

Load Transient

Efficiency vs. Output Current

90

70

ΔVOUT

50

40

IOUT

VIN=2.5V, VOUT=0.75V

VIN=3.3V, VOUT=0.75V

VIN=5V, VOUT=0.75V

30

20

VIN=6V, VOUT=0.75V

10

0

0.5

1

1.5

2

2.5

3

dF

0

Output Current (A)

rep

are

Output Ripple

lP

(VIN=3.3V, VOUT=0.75V, IOUT=3A)

2mV/div

2A/div

Time (400μs/div)

Output Ripple

(VIN=3.3V, VOUT=0.75V, IOUT=0A)

∆VOUT

2mV/div

on

fi

de

nti

a

∆VOUT

50mV/div

IR

IT

60

or

K

Efficiency (%)

80

RO

N

(VIN=3.3V, VOUT=0.75V, ILOAD=0.3A~3A)

100

.C

Time (1μs/div)

orp

Startup from EN

(VIN=3.3V, VOUT=0.75V, IOUT=3A)

2V/div

yC

EN

erg

VOUT 1V/div

2V/div

Shutdown from EN

(VIN=3.3V, VOUT=0.75V, IOUT=3A)

EN

2V/div

VOUT

1V/div

PG

2V/div

IOUT

2A/div

Sil

PG

Time (1μs/div)

IOUT

2A/div

Time (200μs/div)

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Time (200μs/div)

Silergy Corp. Confidential-prepared for Customer Use Only

4

All Rights Reserved.

�AN_SQ76003D

Startup from VIN

Shutdown from VIN

(VIN=3.3V, VOUT=0.75V, IOUT=3A)

(VIN=3.3V, VOUT=0.75V, IOUT=3A)

2V/div

VIN

2V/div

VOUT

1V/div

VOUT

1V/div

2V/div

IOUT

2A/div

IOUT

2A/div

Time (20ms/div)

Short Circuit Protection

Short Circuit Protection

(VIN=3.3V, VOUT=0.75V, IOUT=3A-Short)

rep

are

dF

(VIN=3.3V, VOUT=0.75V, IOUT=0A-Short)

lP

1V/div

5A/div

de

nti

a

IOUT

2V/div

or

K

Time (2ms/div)

VOUT

PG

IR

IT

PG

RO

N

VIN

IOUT

1V/div

5A/div

Time (10ms/div)

Sil

erg

yC

orp

.C

on

fi

Time (10ms/div)

VOUT

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Silergy Corp. Confidential-prepared for Customer Use Only

5

All Rights Reserved.

�AN_SQ76003D

VOUT=1V

Load Transient

Efficiency vs. Output Current

(VIN=3.3V, VOUT=1V, IOUT=0.3A~3A)

100

90

ΔVOUT

50mV/div

IOUT

2A/div

60

50

40

VIN=2.5V, VOUT=1V

VIN=3.3V, VOUT=1V

VIN=5V, VOUT=1V

30

20

VIN=6V, VOUT=1V

10

0

0.5

1

1.5

2

2.5

3

or

K

0

Time (400μs/div)

dF

Output Current (A)

Output Ripple

Output Ripple

(VIN=3.3V, VOUT=1V, IOUT=0A)

rep

are

(VIN=3.3V, VOUT=1V, IOUT=3A)

2mV/div

∆VOUT

2mV/div

on

fi

de

nti

a

lP

∆VOUT

RO

N

70

IR

IT

Efficiency (%)

80

Startup from EN

.C

Time (1μs/div)

2V/div

VOUT

1V/div

PG

2V/div

IOUT

erg

yC

EN

Sil

orp

(VIN=3.3V, VOUT=1V, IOUT=3A)

2A/div

Time (200μs/div)

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Time (1μs/div)

Shutdown from EN

(VIN=3.3V, VOUT=1V, IOUT=3A)

EN

2V/div

VOUT

1V/div

PG

2V/div

IOUT

2A/div

Time (200μs/div)

Silergy Corp. Confidential-prepared for Customer Use Only

6

All Rights Reserved.

�AN_SQ76003D

VIN

2V/div

VOUT

1V/div

2V/div

1V/div

PG

2V/div

IOUT

2A/div

RO

N

VOUT

Shutdown from VIN

(VIN=3.3V, VOUT=1V, IOUT=3A)

IOUT

2A/div

Time (20ms/div)

Short Circuit Protection

Short Circuit Protection

(VIN=3.3V, VOUT=1V, IOUT=3A-Short)

rep

are

dF

(VIN=3.3V, VOUT=1V, IOUT=0A-Short)

lP

1V/div

5A/div

de

nti

a

IOUT

2V/div

or

K

Time (2ms/div)

VOUT

PG

IR

IT

VIN

Startup from VIN

(VIN=3.3V, VOUT=1V, IOUT=3A)

1V/div

IOUT

5A/div

Time (10ms/div)

Sil

erg

yC

orp

.C

on

fi

Time (10ms/div)

VOUT

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Silergy Corp. Confidential-prepared for Customer Use Only

7

All Rights Reserved.

�AN_SQ76003D

VOUT=1.2V

Load Transient

Efficiency vs. Output Current

(VIN=3.3V, VOUT=1.2V, ILOAD=0.3A~3A)

100

90

70

50

40

VIN=2.5V, VOUT=1.2V

VIN=3.3V, VOUT=1.2V

30

VIN=5V, VOUT=1.2V

20

VIN=6V, VOUT=1.2V

IOUT

10

0

0.5

1

1.5

2

2.5

3

Time (400μs/div)

dF

Output Current (A)

Output Ripple

rep

are

(VIN=3.3V, VOUT=1.2V, IOUT=3A)

∆VOUT

Output Ripple

(VIN=3.3V, VOUT=1.2V, IOUT=0A)

∆VOUT

2mV/div

on

fi

de

nti

a

lP

2mV/div

2A/div

or

K

0

50mV/div

RO

N

ΔVOUT

60

IR

IT

Efficiency (%)

80

Startup from EN

.C

Time (1μs/div)

2V/div

1V/div

PG

2V/div

Sil

IOUT

erg

VOUT

yC

EN

orp

(VIN=3.3V, VOUT=1.2V, IOUT=3A)

2A/div

Time (200μs/div)

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Time (1μs/div)

Shutdown from EN

(VIN=3.3V, VOUT=1.2V, IOUT=3A)

EN

2V/div

VOUT

1V/div

PG

2V/div

IOUT

2A/div

Time (200μs/div)

Silergy Corp. Confidential-prepared for Customer Use Only

8

All Rights Reserved.

�AN_SQ76003D

Shutdown from VIN

(VIN=3.3V, VOUT=1.2V, IOUT=3A)

VOUT

1V/div

PG

2V/div

IOUT

2A/div

VIN

2V/div

VOUT

1V/div

RO

N

2V/div

IR

IT

VIN

Startup from VIN

(VIN=3.3V, VOUT=1.2V, IOUT=3A)

Short Circuit Protection

2A/div

Short Circuit Protection

rep

are

dF

(VIN=3.3V, VOUT=1.2V, IOUT=3A-Short)

lP

1V/div

5A/div

de

nti

a

IOUT

IOUT

Time (20ms/div)

(VIN=3.3V, VOUT=1.2V, IOUT=0A-Short)

VOUT

2V/div

or

K

Time (2ms/div)

PG

IOUT

1V/div

5A/div

Time (10ms/div)

Sil

erg

yC

orp

.C

on

fi

Time (10ms/div)

VOUT

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Silergy Corp. Confidential-prepared for Customer Use Only

9

All Rights Reserved.

�AN_SQ76003D

VOUT=1.8V

Load Transient

Efficiency vs. Output Current

(VIN=3.3V, VOUT=1.8V, ILOAD=0.3A~3A)

100

90

70

50

40

VIN=2.5V, VOUT=1.8V

VIN=3.3V, VOUT=1.8V

30

IOUT

VIN=5V, VOUT=1.8V

20

VIN=6V, VOUT=1.8V

10

0

0.5

1

1.5

2

2.5

3

Time (400μs/div)

dF

Output Current (A)

Output Ripple

rep

are

(VIN=3.3V, VOUT=1.8V, IOUT=3A)

∆VOUT

Output Ripple

(VIN=3.3V, VOUT=1.8V, IOUT=0A)

∆VOUT

2mV/div

on

fi

de

nti

a

lP

2mV/div

2A/div

or

K

0

50mV/div

RO

N

ΔVOUT

60

IR

IT

Efficiency (%)

80

Startup from EN

.C

Time (1μs/div)

2V/div

2V/div

IOUT

2A/div

Sil

PG

yC

VOUT

2V/div

erg

EN

orp

(VIN=3.3V, VOUT=1.8V, IOUT=3A)

Time (200μs/div)

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Time (1μs/div)

Shutdown from EN

(VIN=3.3V, VOUT=1.8V, IOUT=3A)

EN

2V/div

VOUT

2V/div

PG

2V/div

IOUT

2A/div

Time (200μs/div)

Silergy Corp. Confidential-prepared for Customer Use Only

10

All Rights Reserved.

�AN_SQ76003D

Shutdown from VIN

(VIN=3.3V, VOUT=1.8V, IOUT=3A)

VOUT

2V/div

PG

2V/div

IOUT

2A/div

VIN

2V/div

VOUT

2V/div

RO

N

2V/div

IR

IT

VIN

Startup from VIN

(VIN=3.3V, VOUT=1.8V, IOUT=3A)

2V/div

IOUT

2A/div

Time (20ms/div)

or

K

Time (2ms/div)

PG

Short Circuit Protection

Short Circuit Protection

(VIN=3.3V, VOUT=1.8V, IOUT=3A-Short)

VOUT

rep

are

dF

(VIN=3.3V, VOUT=1.8V, IOUT=0A-Short)

2V/div

lP

5A/div

de

nti

a

IOUT

IOUT

2V/div

5A/div

Time (10ms/div)

on

fi

Time (10ms/div)

VOUT

Thermal Derating Curve @VIN=3.3V

.C

3.5

orp

yC

2.5

2

erg

IOUT (A)

3

1

25

Sil

1.5

45

65

No Airflow

85

105

125

TA (°C)

1)

2)

3)

4)

TA: Air temperature, 0.5 inch above IC.

Based on a four-layer Silergy Evaluation Board in the natural convection.

The inductor temperature is not beyond 115℃ under this TD curve.

For customer’s specific application, the recommended inductor temperature limitation is 115℃.

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Silergy Corp. Confidential-prepared for Customer Use Only

11

All Rights Reserved.

�AN_SQ76003D

Operation General Description

The SQ76003D is a high efficiency 2.4MHz synchronous step down DC/DC regulator which is capable of delivering up to

3A output currents. It can operate over a wide input voltage range from 2.5V to 6V and integrate main switch and

synchronous switch with very low RDS (ON) to minimize the conduction loss.

RO

N

Low output voltage ripple, small external inductor and capacitor sizes are achieved with 2.4MHz switching

frequency.

Applications Information

IR

IT

Because of the high integration in the SQ76003D, the application circuit based on this regulator is rather simple.

Only the input capacitor CIN, the output capacitor COUT, and the feedback resistors (RH and RL) need to be selected

for the targeted application specifications.

rep

are

dF

or

K

Feedback Resistor Dividers RH and RL

Choose RH and RL to program the proper output voltage. To minimize the power consumption under light loads, it is

desirable to choose large resistance values for both RH and RL. A value of between 10kΩ and 1MΩ is highly

recommended for both resistors. If RH =100kΩ is chosen, then RL can be calculated to be:

0.6V × R H

RL =

(VOUT − 0.6V)

de

nti

a

lP

Input Capacitor CIN

To minimize the potential noise problem, place a typical X7R or better grade ceramic capacitor with higher than 10V

rating and greater than 20μF capacitance, Place this ceramic capacitor really close to the IN and GND pins. Care

should be taken to minimize the loop area formed by CIN, and IN/GND pins.

External Capacitor Recommendation

Description

Vendor

PN

CIN

10μF/10V/X7R, 0603 Murata GRM188D71A106KA73#

yC

orp

.C

on

fi

Output Capacitor COUT

The output capacitor is selected to handle the output ripple noise requirements. Both steady state ripple and transient

requirements must be taken into consideration when selecting this capacitor. For the best performance, it is

recommended to use X7R or better grade ceramic capacitor with higher than 6.3V rating and greater than 30μF

capacitance. Place this ceramic capacitor really close to the OUT and GND pins to minimize the loop area formed by

COUT, and the OUT/GND pins.

External Capacitor Recommendation

Description

Vendor

PN

COUT 10μF/6.3V/X7T, 0603

Murata GRM188D70J106MA73D

erg

If the output capacitance is larger than 100μF or other type of capacitor (polymer, tantalum…) is used, please contact

Silergy supporting team to get more assessment.

Sil

Over Current Protection

With load current increasing, as soon as the high side power FET current gets higher than peak current limit

threshold, the high side power FET will turn off and the low side power FET will keep turning on until low side

power FET current decrease below the valley current limit threshold. If the load current continues to increase, the

output voltage will drop.

Thermal Shutdown Protection

If the junction temperature of SQ76003D is higher than the thermal shutdown temperature (typical 150℃), the IC

will turn off both high side power FET and low side power FET, and then enters thermal shutdown protection mode.

It will remain in this state until the junction temperature decreases below 130℃. After exiting this state, the IC auto

retries to normal operation.

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Silergy Corp. Confidential-prepared for Customer Use Only

12

All Rights Reserved.

�AN_SQ76003D

Layout Design

To achieve a higher efficiency and better noise immunity, following components should be placed close to the IC:

CIN and COUT.

1) CIN must be close to the pins IN and GND. The loop area formed by CIN and GND must be minimized.

2) COUT must be close to the pins OUT and GND. The loop area formed by COUT and GND must be minimized.

RO

N

3) Place the FB components (RH, RL) as close to the FB pin as possible. Avoid routing the FB trace near LX as it is

noise sensitive.

on

fi

de

nti

a

lP

rep

are

dF

or

K

IR

IT

4) It is desirable to maximize the PCB copper area connecting to the GND pin to achieve the best thermal and noise

performance. If the board space allowed, a ground plane is highly desirable.

Sil

erg

yC

orp

.C

Figure 2. PCB Layout Suggestion

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Silergy Corp. Confidential-prepared for Customer Use Only

13

All Rights Reserved.

�AN_SQ76003D

rep

are

dF

or

K

IR

IT

RO

N

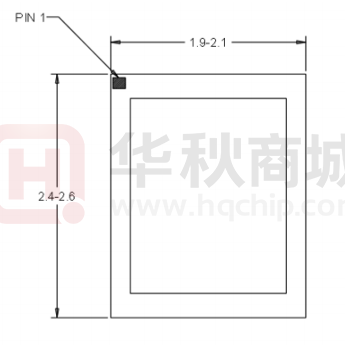

MDFN2.5×2-10 Package Outline Drawing

Bottom View

erg

yC

orp

.C

on

fi

de

nti

a

lP

Top View

Sil

Side View

Recommended PCB layout

(Reference Only)

Notes: 1, All dimension in millimeter and exclude mold flash & metal burr.

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Silergy Corp. Confidential-prepared for Customer Use Only

14

All Rights Reserved.

�AN_SQ76003D

Taping & Reel Specification

rep

are

dF

or

K

IR

IT

RO

N

1. MDFN2.5×2 taping orientation

lP

Feeding direction

Package type

Sil

orp

erg

yC

Reel

Size

.C

on

fi

de

nti

a

2. Carrier Tape & Reel specification for packages

Tape width

(mm)

Pocket

pitch(mm)

Reel size

(Inch)

Trailer

length(mm)

Leader length

(mm)

Qty per

reel

8

4

7"

400

160

2500

MDFN2.5×2

3. Others: NA

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Silergy Corp. Confidential-prepared for Customer Use Only

15

All Rights Reserved.

�AN_SQ76003D

Packaging Information\

Device Marking: a9

RO

N

Label Information

IR

IT

W/O: XXXXXXXXXX

P/N: SQ76003DAFM

rep

are

dF

QTY: 2500

D/C Lot: XXXXXXXXXX

Pb-Free

RoHS Compliant

Halogen Free

or

K

MSL1

Sil

erg

yC

orp

.C

on

fi

de

nti

a

lP

(The barcode is for demonstration only.)

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Silergy Corp. Confidential-prepared for Customer Use Only

16

All Rights Reserved.

�AN_SQ76003D

IMPORTANT NOTICE

RO

N

1. Right to make changes. Silergy and its subsidiaries (hereafter Silergy) reserve the right to change any information

published in this document, including but not limited to circuitry, specification and/or product design, manufacturing or

descriptions, at any time and without notice. This document supersedes and replaces all information supplied prior to the

publication hereof. Buyers should obtain the latest relevant information before placing orders and should verify that such

information is current and complete. All semiconductor products are sold subject to Silergy’s standard terms and conditions of

sale.

rep

are

dF

or

K

IR

IT

2. Applications. Application examples that are described herein for any of these products are for illustrative purposes only.

Silergy makes no representation or warranty that such applications will be suitable for the specified use without further testing or

modification. Buyers are responsible for the design and operation of their applications and products using Silergy products.

Silergy or its subsidiaries assume no liability for any application assistance or designs of customer products. It is customer’s sole

responsibility to determine whether the Silergy product is suitable and fit for the customer’s applications and products planned.

To minimize the risks associated with customer’s products and applications, customer should provide adequate design and

operating safeguards. Customer represents and agrees that it has all the necessary expertise to create and implement safeguards

which anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures

that might cause harm and take appropriate remedial actions. Silergy assumes no liability related to any default, damage, costs or

problem in the customer’s applications or products, or the application or use by customer’s third-party buyers. Customer will

fully indemnify Silergy, its subsidiaries, and their representatives against any damages arising out of the use of any Silergy

components in safety-critical applications. It is also buyers’ sole responsibility to warrant and guarantee that any intellectual

property rights of a third party are not infringed upon when integrating Silergy products into any application. Silergy assumes no

responsibility for any said applications or for any use of any circuitry other than circuitry entirely embodied in a Silergy product.

de

nti

a

lP

3. Limited warranty and liability. Information furnished by Silergy in this document is believed to be accurate and reliable.

However, Silergy makes no representation or warranty, expressed or implied, as to the accuracy or completeness of such

information and shall have no liability for the consequences of use of such information. In no event shall Silergy be liable for

any indirect, incidental, punitive, special or consequential damages, including but not limited to lost profits, lost savings, business

interruption, costs related to the removal or replacement of any products or rework charges, whether or not such damages are

based on tort or negligence, warranty, breach of contract or any other legal theory. Notwithstanding any damages that customer

might incur for any reason whatsoever, Silergy’ aggregate and cumulative liability towards customer for the products described

herein shall be limited in accordance with the Standard Terms and Conditions of Sale of Silergy.

orp

.C

on

fi

4. Suitability for use. Customer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory

and safety-related requirements concerning its products, and any use of Silergy components in its applications, notwithstanding

any applications-related information or support that may be provided by Silergy. Silergy products are not designed, authorized or

warranted to be suitable for use in life support, life-critical or safety-critical systems or equipment, nor in applications where

failure or malfunction of an Silergy product can reasonably be expected to result in personal injury, death or severe property or

environmental damage. Silergy assumes no liability for inclusion and/or use of Silergy products in such equipment or

applications and therefore such inclusion and/or use is at the customer’s own risk.

erg

yC

5. Terms and conditions of commercial sale. Silergy products are sold subject to the standard terms and conditions of

commercial sale, as published at http://www.silergy.com/stdterms, unless otherwise agreed in a valid written individual

agreement specifically agreed to in writing by an authorized officer of Silergy. In case an individual agreement is concluded only

the terms and conditions of the respective agreement shall apply. Silergy hereby expressly objects to and denies the application

of any customer’s general terms and conditions with regard to the purchase of Silergy products by the customer.

Sil

6. No offer to sell or license. Nothing in this document may be interpreted or construed as an offer to sell products that is

open for acceptance or the grant, conveyance or implication of any license under any copyrights, patents or other industrial or

intellectual property rights. Silergy makes no representation or warranty that any license, either express or implied, is granted

under any patent right, copyright, mask work right, or other intellectual property right. Information published by Silergy

regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from Silergy under the patents or other intellectual property of Silergy.

For more information, please visit: www.silergy.com

© 2021 Silergy Corp.

AN_SQ76003D Rev.0.9A

© 2021 Silergy Corp.

Powered by TCPDF (www.tcpdf.org)

All Rights Reserved.

Silergy Corp. Confidential-prepared for Customer Use Only

17

All Rights Reserved.

�