Application Note: SY6703

Low Voltage H-Bridge IC

Preliminary Specification

AN_SY6703 Rev.0.2

Silergy Corp. Confidential-prepared for Customer Use Only

1

�AN_SY6703

Pinout (top view)

nSLEEP

1

16

AIN1

AOUT1

2

15

AIN2

AISEN

3

14

VINT

AOUT2

4

13

GND

BOUT2

5

12

VM

BISEN

6

11

VCP

BOUT1

7

10

BIN2

nFAULT

8

9

BIN1

Package type

SY6703HFC

TSSOP-16E

①

Top Mark

AZRxyz

r

Part Number

Number

nSLEEP

1

AOUT1

2

AISEN

3

AOUT2

BOUT2

4

5

BISEN

6

BOUT1

nFAULT

BIN1

BIN2

VCP

VM

GND

VINT

AIN2

AIN1

GND

7

8

9

10

11

12

13

14

15

16

17

Description

Sleep mode pin. Logic low puts device in low-power sleep mode, this pin has a internal pull-down

resistor

Bridge A output 1 pin. Connect this pin to motor winding.

Bridge A current sense pin. Connect a resistor between this pin and GND for current control, or

connect to GND is current control is not needed.

Bridge A output 2 pin. Connect this pin to motor winding.

Bridge B output 2 pin. Connect this pin to motor winding.

Bridge B current sense pin. Connect a resistor between this pin and GND for current control, or

connect to GND is current control is not needed

Bridge B output 1 pin. Connect this pin to motor winding.

Fault state output pin. Logic low if fault is detected.

Bridge B input 1 pin. Control the state of bridge B, this pin has a internal pull-down resistor.

Bridge B input 2 pin. Control the state of bridge B, this pin has a internal pull-down resistor

Internal charge pump voltage for high side gate driver. Connect a ceramic capacitor to VM.

Motor power supply pin. Decouple this pin to GND pin with 0.1uF ceramic cap.

Device ground pin.

Internal logic and driver supply. Connect this pin with a ceramic capacitor to GND.

Bridge A input 2 pin. Control the state of bridge A, this pin has a internal pull-down resistor.

Bridge A input 1 pin. Control the state of bridge A, this pin has a internal pull-down resistor.

Ground pin for thermal dissipation.

Sil

er

gy

Co

rp

.C

on

fid

en

tia

l-P

re

p

Name

ar

ed

Note① : x=year code, y=week code, z= lot number code.

fo

17

GND

AN_SY6703 Rev.0.2

Silergy Corp. Confidential-prepared for Customer Use Only

2

�AN_SY6703

AN_SY6703 Rev.0.2

Silergy Corp. Confidential-prepared for Customer Use Only

3

�AN_SY6703

Electrical Characteristics

(TA = 25°C, VM=5V, unless otherwise specified)

Parameter

Power Supplies

VM Operating Supply Current

VM Sleep Mode Current

VM Undervoltage Lockout Voltage

Symbol

Test Conditions

IVM

IVMS

VUVLO_RISE

VUVLO_FALL

nSLEEP=0V, VM=5V

VM Rising

VM Falling

Min

VM=5V, xIN=0V, xIN2=0V

Typ

Max

Unit

1

1.8

2.2

2.1

2

2.5

mA

0.5

0.7

V

µA

V

V

Logic Level Input

VIL

nSLEEP

All other pins

nSLEEP

All other pins

VIH

VIHYS

IIL

IIH

Input High Current

RPD

Pulldown Resistance

IO=5mA

VO=3.3V

High Side MOSFETs On Resistance

Rdson

Low Side MOSFETs On Resistance

er

gy

Sil

Startup Time

ns

0.5

1

V

µA

310

400

410

mΩ

310

270

330

±1

2

150

VTRIP

tBLANK

kΩ

260

Internal PWM Frequency

VM=5V,16Ω to GND, 10% to

90% VM

VM=5V

VM=5V

IOCP

tOCPR

tDEG

TSD

THYS

tWAKE

6.6

16.5

600

150

450

V

µA

µA

1

13

33

330

fid

.C

on

fPWM

tR

tF

tPROP

tDEAD

VM=5V, IO=500mA, TJ=25℃

VM=5V, IO=500mA, TJ=85℃

VM=2.7V, IO=500mA, TJ=25℃

VM=2.7V, IO=500mA, TJ=85℃

VM=5V, IO=500mA, TJ=25℃

VM=5V, IO=500mA, TJ=85℃

VM=2.7V, IO=500mA, TJ=25℃

VM=2.7V, IO=500mA, TJ=85℃

VM=5V, VOUT=0V, TJ=25℃

en

IOFF

Co

rp

Off-State Leakage Current

Motor Driver

Current Control PWM Frequency

Rise Time

Fall Time

Propagation Delay INx to OUTx

Dead Time

Protection

Output Over Current Limit

Over Current Retry Time

OCP Deglitch Time

Thermal Shutdown Temperature

Thermal Shutdown hysteresis

Current Control

xISEN Trip Voltage

Current Sense Blanking Time

Sleep Mode

0.4

VIN=0V

VIN=3.3V, nSLEEP

VIN=3.3V, all except nSLEEP

nSLEEP

All other pins

r

Input Deglitch Time

tDEG

nFAULT Output (Open-Drain Output)

Output Low Voltage

VOL

Output High Leakage Current

IOH

H-Bridge MOSFETs

V

fo

Input Hysteresis

Input Low Current

2.5

2

ar

ed

Input High Voltage

tia

l-P

re

p

Input Low Voltage

160

µA

50

50

50

1.1

50

kHz

ns

ns

µs

ns

2.5

1.2

180

160

20

A

ms

ns

℃

℃

200

3.75

180

240

mV

µs

1

ms

nSLEEP Inactive high to Hbridge On

Note 1: Stresses beyond the “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only. Functional operation of the device at these or any other conditions beyond those indicated in the

operational sections of the specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

Note 2: θ JA is measured in the natural convection at TA = 25°C on a low effective single layer thermal conductivity

test board of JEDEC 51-3 thermal measurement standard.

Note 3: Power dissipation and thermal limits must be observed.

AN_SY6703 Rev.0.2

Silergy Corp. Confidential-prepared for Customer Use Only

4

�AN_SY6703

AN_SY6703 Rev.0.2

Silergy Corp. Confidential-prepared for Customer Use Only

5

�AN_SY6703

AN_SY6703 Rev.0.2

Silergy Corp. Confidential-prepared for Customer Use Only

6

�AN_SY6703

Functional Description

PWM Motor Drivers

tia

l-P

re

p

ar

ed

fo

r

SY6703 contains two identical H-bridge motor drivers with current-control PWM circuitry. A block diagram of

the circuitry is shown below:

H-Bridge Driving Control

fid

en

Figure3. Motor Control Circuitry

xIN2

0

1

0

1

er

gy

Co

rp

xIN1

0

0

1

1

.C

on

The Bridge is controlled by a PWM input interface, also called IN/IN interface. The following table shows the

control logic of the device:

Table 1 H-Bridge Logic

xOUT1

Z

L

H

L

xOUT2

Z

H

L

L

Function

Coast/Fast Decay

Reverse

Forward

Brake/Slow Decay

Sil

The inputs can also be used for PWM control of the motor speed. When controlling a winding with PWM, when the

drive current is interrupted, the inductive nature of the motor requires that the current must continue to flow. This is

called recirculation current. To handle this recirculation current, the H-bridge can operate in two different states, fast

decay or slow decay. In fast decay mode, the H-bridge is disabled and recirculation current flows through the body

diodes; in slow decay, the motor winding is shorted.

To PWM using fast decay, the PWM signal is applied to one xIN pin while the other is held low; to use slow decay,

one xIN pin is held high.

AN_SY6703 Rev.0.2

Silergy Corp. Confidential-prepared for Customer Use Only

7

�AN_SY6703

Table 2 PWM Control of Motor Speed

xIN1

PWM

1

0

PWM

xIN2

0

PWM

PWM

1

Function

Forward PWM, Fast Decay

Forward PWM, Slow Decay

Reverse PWM, Fast Decay

Reverse PWM, Slow Decay

Figure 4 shows the current paths in different drive and decay modes.

Forward

Reverse

Figure4. Decay Mode

Current Control

The current through the motor windings may be limited, or controlled, by a fixed-frequency PWM current regulation,

or current chopping. For DC motors, current control is used to limit the start-up and stall current of the motor. For

stepper motors, current control is often used at all times.

When an H-bridge is enabled, current rises through the winding at a rate dependent on the DC voltage and

inductance of the winding. If the current reaches the current chopping threshold, the bridge disables the current until

the beginning of the next PWM cycle. Note that immediately after the current is enabled, the voltage on the xISEN

pin is ignored for a fixed period of time before en

AN_SY6703 Rev.0.2

Silergy Corp. Confidential-prepared for Customer Use Only

8

�AN_SY6703

If a 1-Ω sense resistor is used, the chopping current will be 200 mV/1 Ω = 200 mA.

Once the chopping current threshold is reached, the H-bridge switches to slow decay mode. Winding current is recirculated by enabling both of the low-side FETs in the bridge. This state is held until the beginning of the next

fixed-frequency PWM cycle.

Note that if current control is not needed, the xISEN pins should be connected directly to ground.

Sleep Mode

ar

ed

fo

r

Driving nSLEEP low will put the device into a low power sleep state. In this state, the H-bridges are disabled, the

gate drive charge pump is stopped, all internal logic is reset, and all internal clocks are stopped. All inputs are

ignored until nSLEEP returns inactive high. When returning from sleep mode, some time (up to 1 ms) needs to pass

before the motor driver becomes fully operational. To make the board design simple, the nSLEEP can be pulled up

to the supply (VM). It is recommended to use a pullup resistor when this is done. This resistor limits the current to

the input in case VM is higher than 6.5 V. Internally, the nSLEEP pin has a 500-kΩ resistor to GND. It also has a

clamping zener diode that clamps the voltage at the pin at 6.5 V. Currents greater than 250 µA can cause damage to

the input structure. Hence the recommended pullup resistor would be between 20 kΩ and 75 kΩ.

Protection Circuits

tia

l-P

re

p

The device is fully protected against undervoltage, overcurrent, and overtemperature.

Overcurrent Protection (OCP)

fid

en

An analog current limit circuit on each FET limits the current through the FET by limiting the gate drive. If this

analog current limit persists for longer than the OCP deglitch time, all FETs in the H-bridge will be disabled and the

nFAULT pin will be driven low. The driver will be re-enabled after the OCP retry period (tOCP) has passed.

nFAULT becomes high again at this time. If the fault condition is still present, the cycle repeats. If the fault is no

longer present, normal operation resumes and nFAULT remains deasserted. Please note that only the H-bridge in

which the OCP is detected will be disabled while the other bridge will function normally.

.C

on

Overcurrent conditions are detected independently on both high and low side devices; i.e., a short to ground, supply,

or across the motor winding will all result in an overcurrent shutdown. Note that overcurrent protection does not use

the current sense circuitry used for PWM current control, so functions even without presence of the xISEN resistors.

Co

rp

Thermal Shutdown (TSD)

If the die temperature exceeds safe limits, all MOSFETs in the H-bridge are disabled. Once the die temperature has

fallen to a safe level, operation automatically resumes.

er

gy

Undervoltage Lockout(UVLO)

Sil

If at any time the voltage on the VM pin falls below the undervoltage lockout threshold voltage, all circuitry in the

device will be disabled, and all internal logic will be reset. Operation will resume when VM rises above the UVLO

threshold. nFAULT is driven low in the event of an undervoltage condition.

THERMAL INFORMATION

Thermal Protection

The device has thermal shutdown (TSD) as described in the Protection Circuits section. If the die temperature

exceeds approximately 160°C, the device is disabled until the temperature drops to a safe level.

AN_SY6703 Rev.0.2

Silergy Corp. Confidential-prepared for Customer Use Only

9

�AN_SY6703

Any tendency of the device to enter thermal shutdown is an indication of either excessive power dissipation,

insufficient heatsinking, or too high an ambient temperature.

Maximum Output Current

In actual operation, the maximum output current achievable with a motor driver is a function of die temperature.

This in turn is greatly affected by ambient temperature and PCB design. Basically, the maximum motor current will

be the amount of current that results in a power dissipation level that, along with the thermal resistance of the

package and PCB, keeps the die at a low enough temperature to stay out of thermal shutdown.

The dissipation ratings given in the datasheet can be used as a guide to calculate the approximate maximum power

dissipation that can be expected to be possible without entering thermal shutdown for several different PCB

constructions. However, for accurate data, the actual PCB design must be analyzed via measurement or thermal

simulation.

Power Dissipation

2

(2)

ar

ed

PTOT = R DSON × I OUT ( RMS )

fo

r

Power dissipation in the device is dominated by the power dissipated in the output MOSFET resistance, or RDSON.

A H-bridge Average power dissipation can be roughly estimated by:

tia

l-P

re

p

where PTOT is the total power dissipation, RDSON is the resistance of the HS plus LS MOSFETs, and IOUT(RMS) is

the RMS or DC output current being supplied to the load.

The maximum amount of power that can be dissipated in the device is dependent on ambient temperature and

heatsinking.

Sil

er

gy

Co

rp

.C

on

fid

en

Note that RDSON increases with temperature, so as the device heats, the power dissipation increases.

AN_SY6703 Rev.0.2

Silergy Corp. Confidential-prepared for Customer Use Only

10

�AN_SY6703

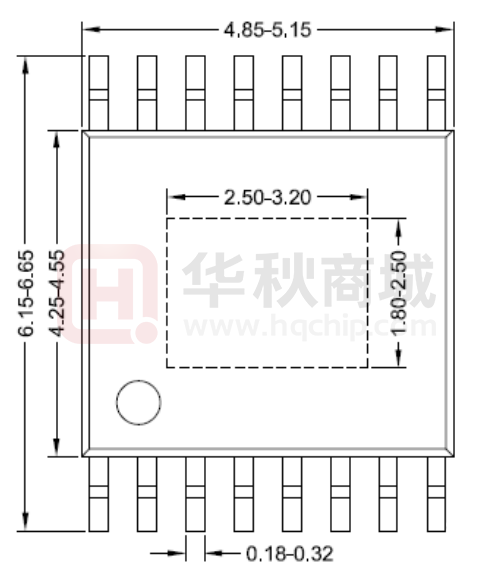

Side view A

Sil

er

gy

Co

rp

.C

on

Top view

fid

en

tia

l-P

re

p

ar

ed

fo

r

TSSOP16E Package Outline Drawing

Side view B

Notes:

All dimension in MM and exclude mold flash & metal burr.

AN_SY6703 Rev.0.2

Silergy Corp. Confidential-prepared for Customer Use Only

11

�