规 格 承 认 书

APPROVED

SHEET

客户 CUSTOMER

品名 PRODUCT :

规格 TYPE

碳膜电阻

:

客户承认印

CUSTOMERAPPROVED

地址:广东省东莞市企石镇新南管理区第二工业区

电话: 0769--86732558 传真: 0769--86666308

一式二份

发行

粤翔一份

出图

DRAWING

业务

ISSUE

SALES

DATE:

2018年 12月 13 日

客户一份

审核

核准

AUDITING

APPROVED

粤翔电子科技品保部

承认书编号 CR20181213001

�C R

CARBON FILM FIXED RESISTORS

碳膜固定电阻器

CR( 1/8W,1/4WS,1/4W,1/2WS,1/2W,1WS,1W,2WS,2W,3WS,3W,5WS,5W,7WS)

FEATURES 特点

1

2

3

4

5

HIGH QUALITY

高品质.

WITHSTAND VOITAGE,SHOCK RESISTANCE

耐电压,耐冲击

STANDARD TOLERANCE :±5%,(±2%).

±5%,(±2%)的标准误差

VARIETY OF PACKAGING-BULK 26mm AND 52mm TAPE,CUT AND FORMED

可供散装,带装26mm/52mm,成型剪脚。

HIGH RESISTANCE RANGE (0Ω1-10MΩ).

阻抗范围高 (0Ω1-10MΩ).

CONSTRUCTION 结构图

1

CERAMIC CORE (HIGH CONDUCTIVITY)

陶瓷棒心(高热传导)

2

HIGH STABILITY FILM

高稳定性皮膜

3

END CAP (HIGH RELIABILITY FITTING BY ORIGINAL CAP-PRESSING METHOD)

端帽(卯和度信赖性高)

4

HIGH INSU LATION AND SOLVENT RESISTANCE OF EPOXY RESIN COATING

(BULK POWER TO KHAKI,MINIATURE PINK)

高绝缘及耐溶剂之环氧树脂涂料(本体功率为土黄色,小型化为粉红色)

5

COLOR CODE (PER MIL& EIA STANDARDS).

6

LEAD WIRE(EXCELLENT SOLDER ABILITY)

7

WELDING (LONG

符合MIL & EIA规定之标准色码带。

焊锡性良好的导线

RELIABILITY GUARANTEE)

信赖性良好的焊接

SPECIFICATION: 规格描述

EXAMPLE 例:

CR1WS-9Ω1±5%-XT52

CR

品名

PRODUCT

CR

MF

MO

MGR

KNP

NKNP

FR

FRKNP

SCF

碳膜电阻

金膜电阻

氧化膜电阻

高压玻璃釉电阻

绕线电阻

无感绕线电阻

保险电阻

绕线保险电阻

高压脉冲电阻

1WS

9Ω1

±5%

X

T52

额定功率

RATED POWER

阻值范围

RESISTANCE RANGE

误差值

TOLERANCE

线径

WIRE DIAMETER

形状

SHAPE

1/8W

1/4W

1/2W

1W

2W

3W

5W

1/4WS

1/2WS

1WS

2WS

3wS

5WS

7WS

NOTE1注解: RATED VOLTAGE 额定电压 =

0Ω1-22MΩ

阻值表示方法

RESISTANCE VALUE

REPRESENTATION

阻值单位按Ω,K,M

1000Ω=1K 1000K=1M

例:9Ω1/5K6/4M7

±10%

±5%

±2%

±1%

O:0.43CU

2:0.53CU

6:0.63CU

9:0.73CU

C:0.83CU

A;0.75CU

S:0.43CP

X:0.53CP

T:0.63CP

Q:0.73CP

D:0.83CP

T26

T52

T63

T73

T93

P

M、F

FK/MB/TF

POWER RATING 额定功率 *

RESISTANCE

VALUE 公称阻值

编带26MM

编带52MM

编带63MM

编带73MM

编带93MM

散装

成型

成型

�C R

CARBON FILM FIXED RESISTORS

碳膜固定电阻器

CHARACTERISTICS

特性项目

SPECIFICATIONS

规格值

DC RESISTANCE

直流阻抗值

J(±5%)

T.C.R温度系数

LOAD LIFE IN HUMIDITY

湿度寿命

LOAD LIFE

温度寿命

SHORT TIME OVER LOAD

短时间过负荷

1/8W 1/4WS

1/4W 1/2WS

1/2W 1WS

1W

2WS

2W

3WS

3W

5WS

5W

7WS

TEST METHODS JIS C 5202

测试方法 JIS C 5202标准

RESISTANCE VALUE TEST AT ROOM TEMPERATURE 25℃

阻值测试在室温25℃

<10Ω±400PPM

10Ω-1M±350PPM

>1M±1000PPM

RESISTANCE CHANGE RATE ±(5%+0.05Ω)

WITH NO EVIDENCE OF RESISTOR DAMAGE.

阻坑值变化率(5%±0.05Ω),电阻器不可有损伤

R2-R1

X 106PPM/℃)

R1(T2-T1)

R1: RESISTANCE VALUE AT ROOM TEMPERATURE(T1)

常温(T1)阻抗值

R2:RESISTANCE VALUE AT ROOM TEMPERATURE +100℃(T2)

常温+100℃阻抗值

RESISTANCE CHANGE AFTER 1000H(1.5H ON,0.5H OFF)AT RATED

VOLTAGE IN A HUMIDITY CHAMBER CONTROLLED AT40+/-2℃ AND

90-95% RELATIVE HUMIDITY.(when thetest voltage exceeds the working

voltage,considerusing the working voltage)

温度40+/-2℃,相对湿度90-95%于恒温恒湿箱中,加额定直流电压测试1.5小时停止

0.5小时,连续1000小时。(当实验电压超过最高使用电压,采用最高使用电压)

RESISTANCE CHANGE AFTER 1000H OPERATING AT RATED VOLTAGE

RESISTANCE CHANGE RATE ±(5%+0.05Ω)MAX WITH NO WITH DUTY CYCLE OF 1.5H ON 0.5H OFF AT 70℃±2℃(when thetest voltage

EVIDENCE OF RESISTOR DAMAGE.

exceeds the working voltage,considerusing the working voltage)

阻坑值变化率(5%±0.05Ω),电阻器不可有损伤

温度70+/2℃,加额定直流电压测试1.5小时停止0.5小时,连续1000小时(当实验电压

超过最高使用电压时,采用最高使用电压)

±(1%+0.05Ω)

1/8W,1/4W,1/2W,

1W,2W,3W,5W

±(1%+0.05Ω)

PULSE OVER LOAD

断续过负荷

1/4WS,1/2WS,1WS,2WS,

3WS,5WS,7WS

±(2%+0.05Ω)

RESISTANCE TO SOLVENT

耐溶剂性

NO VISIBLE DAMAGES TO PROTECTIVE COAATING AND

MARKING(外观无异常,标识能够清楚易辨

INSULATION RESISTANCE

绝缘阻抗

>1000MΩ

ELECTRIC WITHSTANDING

VOLTAGE

绝缘耐电压

RESISTANCE CHANGE RATE ±(1%+0.05Ω) WITH NO

EVIDENCE OR RESISTOR DAMAGE.

阻坑值变化率±(1%+0.05Ω),电阻器不可有损伤

TEMPERATURE CYCLING

温度偱环

RESISTANCE CHANGE RATE IS ±(1%+0.05Ω)

MAX, WITH NO EVIDENCE OF RESISTOR DAMAGE.

阻坑值变化率±(1%+0.05Ω) 以内,电阻器不可有损

伤

RESISTANCE CHANGE AFTER THE APPLICATION OF APOTENTIAL OF 2.5T RATED

VOLTAGE FOR 5 SE(when the test voltage exceeds the maximum

overload,consider using the maximum overload voltage)

额定电压X2.5倍,测试5秒(当实验电压超过最高过负载时,采用最高过负载电压)

RESISTANCE CHANGE AFTER 10000C(1SEC ON,25SEC OFF)AT 4T

RATED VOLTAGE (AC)when the test voltage exceeds the maximam

overload,consider using the maxmum overload voltage)

额定电压*4倍(交流电压),测试1秒停止25秒,测试10000次。(当实验电压超过最

高过负荷电压,采用最高过负荷电压)

RESISTANCE CHANGE AFTER 10000C(1SEC ON,25SEC OFF)AT 4T

RATED VOLTAGE (AC)when the test voltage exceeds the maximam

overload,consider using the maxmum overload voltage)

额定电压*4倍(交流电压),测试1秒停止25秒,测试10000次。(当实验电压超过最

高过负荷电压,采用最高过负荷电压)

SOAK 3MIN IN THE MELTING AGENT TO AGAIN AND AGAIN WIPE 10 TIMES

(三氯乙稀浸泡3分钟,再用湿布反复擦拭10次)

ELECTRIC RESISTANCE BOTH ENDS THE CONJUNCTION LINE PUT ON

THE METALS V TYPE THE SLOT,ACCORDING TO THE ELECTRIC VOLTAGE PROVISION OF

THE CHARACTERISTIC WATCH 60 SECONDS INFLICTION

电阻两端导线置于金属V型槽上,依特性表之电压规定施加60秒

STEP 步骤、

1

2

3

4

TEMPERATURE 温度

-55℃±2℃

ROOM TEMP室温

85℃±2℃

ROOM TEMP室温

TIME(MIN)放置时间

30

10-15

30

10-15

PUT THE LEAD LINE OF RESISTANCE INTO THE SOLDERING ABOUT 3.2 TO 4.8MM

PIEASE TAKE IMPLEMENTATION ON THE BASISO OF THE TABLE BELOW

RESISTANCE CHANGE RATE IS ±(2%+0.05Ω)

将电阻两端导线浸入锡炉约3.2至4.8MM依下表规定实施

RESISTANCE TO SOLDERING HEAT

MAX, WITH NO EVIDENCE OF RESISTOR DAMAGE.

耐热性

阻坑值变化率(2%±0.05Ω) 以内,电阻器不可有损伤

TEMPERATURE温度

DIP TIME放置时间

350℃±10℃

3±0.5 SEC

260℃±5℃

10±1.0 SEC

SOLDERABILITY

焊锡性

SOLDER JOINT PULL

焊点拉力

Life & failure rate

寿命失效率

95% COVERAGE MINIMUM

95%覆盖于导线上

TEST TEMPERATURE OF SOLDER:230℃±5℃

DWELL TIME IN SOLDER:3±0.5 SEC

锡炉温度:230℃±5℃ 浸锡时间:3±0.5 秒

PULLING TEST FOR 1/8W≥1.8KG,1/4W≥3.8KG,1/2W

BIGGER THAN ≥5KG

SECURE BOTH LDAD WIRE ON EACH SIDE OF PULLING MACHING AND THEN PULL IT

拉力强度 1/8W≥1.8KG,1/4W≥3.8KG,1/2W 含以上 ≥ 将成品电阻铜线一端夹在拉力器的一端,铜线另一端也夹在拉力器上,再摇动拉力器

5KG

Under the rated condition Use Lire≥

10000H

额定条件下使用寿命≥10000小时

failure rate≤10PPM

失效率≤10PPM

�C R

CARBON FILM FIXED RESISTORS

碳膜固定电阻器

POWER CHARACTERISTIC 电力特性

POWER PATED

额定功率

ITEM

项目

0.125W 0.25WS 0.25W

0.5WS

0.5W

(1/8W) (1/4W)S (1/4W) (1/2W)S (1/2W)

1WS

1W

2WS

2W

3WS

3W

5WS

5W

7WS

500V

500V

500V

500V

500V

500V

750V

750V

MAX WORKING VOLTAGE

最高使用电压

200V

250V

250V

350V

350V

500V

MAX OVERLOAD VOLTAGE

最高过负荷电压

400V

500V

500V

700V

700V

1000V 1000V 1000V

1000V 1000V 1000V 1000V 1000V

1000V

MAX INTERMITTENCE OVER

LOAD VOLTAGE

最高断续过负荷

400V

500V

500V

700V

700V

1000V 1000V 1000V

1000V 1000V 1000V 1000V 1000V

1000V

ELECTRIC WITHSTANDING

VOLTAGE

绝缘耐电压

300V

300V

400V

400V

500V

500V

700V

700V

700V

RESISTANCE TOLERANCE

阻抗误差值

RANGE(OHM)

阻抗值范围

700V

700V

700V

700V

700V

J(±5%)G(±2%)

MIN

0.1Ω

0.1Ω

0.1Ω

0.1Ω

0.1Ω

0.1Ω 0.1Ω 0.1Ω

0.1Ω 0.1Ω 0.1Ω 0.1Ω 0.1Ω

0.1Ω

MAX

22MΩ

22MΩ

22MΩ

22MΩ

22MΩ

22MΩ 22MΩ 22MΩ

22MΩ 22MΩ 22MΩ 22MΩ 22MΩ

22MΩ

NOTE注解: 1M ohm is high risk resistance for thin film resistors.

薄膜电阻1M以上阻值为高风险阻值

POWER DERATING CURVE 负载衰减曲线

100

-55℃

70℃

80

60

RATED LOAD (%)

定功率百分比(%)40

20

0

155℃

-60℃

-30

0

30

60

90

120

150

180

210 240℃

AMBIENT TEMPERTURE(℃)

周围 温度(℃)

NOTE注解:

1

RATED AMBIENT TEMPERATURE :70℃

2

OPERATING TEMPERATURE RANGE:-55℃~+155℃

额定周围温度:70℃

使用温度范围:-55℃~+155℃

3

FOR RESISTORS IPERATED IN AMBIENT TEMPERATURE OVER 70℃,POWER RATING SHALL BE DERATED IN

ACCORDANCE WITH THE FIGURE

周围温度70℃以上使用时,根据降功率曲线将减轻额定功率

�C R

CARBON FILM FIXED RESISTORS

BULK TYPE

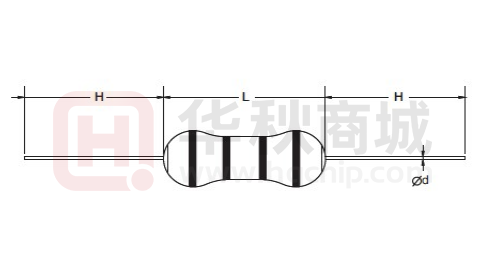

DIMENSION (TO

碳膜固定电阻器

TYPE)

TYPE

TO

LEAD TYPING DIMENSION(mm)

L±1.0

D±1.0

Φd±0.05

H±3.0

1/8W

1/4WS

3.7

2.3

0.43

26

1/4W

1/2WS

6.2

2.7

0.43

26

1/2W

1WS

9

3.5

0.53

26

1W

2WS

11

4.5

0.63

31

2W

3WS

15.5

5

0.73

31

3W

5WS

17.5

6

0.73

31

5W

7WS

25

8

0.83

39

TYPE

LEAD TYPING DIMENSION(mm)

TYPE

1

LEAD DIMENSIONS INCLUDED IN TAPE

纸带内缘导线长度

2

LEAD PAINT DIMENSION

涂漆于导线上的长度

3

DIFFERENCE OF A & B

A带与B带的位差

4

[L1-L2]

NKNP2WS-2Ω7±2%-6T63 价格&库存

很抱歉,暂时无法提供与“NKNP2WS-2Ω7±2%-6T63”相匹配的价格&库存,您可以联系我们找货

免费人工找货