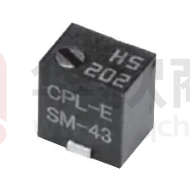

SURFACE MOUNT CERMET TRIMMERS

RoHS compliant

SM-42/43

INTERNAL STRUCTURE

9

1

2

3

8

4

5

7

6

Part name

■ FEATURES

● RoHS compliant

● Fine adjustment is available

● Automatic mounting is available (Taping)

● Reflow soldering is available

● Sealed construction (Washable: Refer to page 698.)

Material

Flammability

Polyphenylenesulphide

UL94V-0

1

Housing

2

Base element

3

Electrode

Ag-Pd cermet

4

Resistive element

RuO2 cermet

5

Adhesive

6

Wiper

7

Terminal pin

8

Rotor gear

9

Shaft

Ceramic

—

Epoxy

Multi metal alloy

Copper alloy, Sn-Cu-plated

Polyamide

UL94V-0

Brass, Nickel-plated

—

■ PART NUMBER DESIGNATION

S M - 4 □ T W 1 0 0Ω ( 1 0 1 )

Series name

Resistance code

Electrical turn

Resistance value

2:11 turns

3:5 turns

Form of packaging

Product shape (Shape of terminal)

T:Taping (Reel)

Blank:Bulk in plastic bag

W, X:Top adjustmet

A, B:Side adjustmet

※ Please refer to the LIST OF PART NUMBERS when placing orders.

�SM-42/43

SURFACE MOUNT TRIMMERS

■ LIST OF PART NUMBERS

Electrical turn

Form of packaging

Adjustment

Shape of terminal

position

Top adjustment

11

Side adjustment

Top adjustment

5

Side adjustment

〈Nominal resistance values〉

Plastic bag

10 k Ω 20 k Ω 50 k Ω 100 k Ω 200 k Ω 500 k Ω 1 M Ω 2 M Ω

W (J-hook)

SM-42TW

SM-42W

The products indicated by A mark are manufactured upon receipt of order basis.

X (Gull wing)

SM-42TX

SM-42X

(J リード)

A (J-hook)

SM-42TA

SM-42A

B (Gull wing)

※The above part numbers are all available with the respective combination of

(Fig. 1).

※ Verify the above part numbers when placing orders.

※ Taping specification is not sold separately and must be purchased in reel units.

SM-42TB

SM-42B

W (J-hook)

SM-43TW

SM-43W

X (Gull wing)

SM-43TX

SM-43X

A (J-hook)

SM-43TA

SM-43A

B (Gull wing)

SM-43TB

SM-43B

TA, TB : 500 pcs./reel

TW, TX : 250 pcs./reel

50 pcs./pack

Pieces in package

■ ELECTRICAL CHARACTERISTICS

Effective electrical turn

11 turns (SM-42), 5 turns (SM-43)

End resistance

1 % or 2 Ω , whichever is greater

C.R.V.

1 % or 3 Ω , whichever is greater

− 65 ~ 150 °C

Operating temp. range

± 100 10 /°C maximum

-6

100 M Ω minimum (DC500 V)

Dielectric strength

AC600 V, 60 s

Net weight

Approx. 0.17 g

〈Reflow profile for soldering heat evaluation〉

Temperature

100

50

200 cycles [ Δ R/R ≦ ± (3 Ω +3 %)]

Thrust to shaft

5 N {0.51 kgf} minimum

Width 90 mm, bend 3 mm, 5 s, 1 time

100 mA or power rating, whichever is smaller

Peak : 250

+5

0

℃

Over 230 ℃

150 ℃

Rotational life

Substrate bending

Maximum wiper current

150

Clutch action

0.25 W (85 °C) 0 W (150 °C)

DC300 V or power rating, whichever is smaller

180 ℃

Mechanical stop

5 N {0.51 kgf} 10 s

Maximum input voltage

200

17.6 mN·m {180 gf·cm} maximum

Shear (Adhesion)

Linear law

(℃)

250

Operating torque

± 10 %

Resistance law

Insulation resistance

■ MECHANICAL CHARACTERISTICS

245 ± 3 °C, 2 ~ 3 s

Resistance tolerance

Temp. coefficient

Fig. 1

Solderability

10 Ω ~ 2 M Ω

Nominal resistance range

Power ratings

A10 Ω A20 Ω 50 Ω 100 Ω 200 Ω 500 Ω 1 k Ω 2 k Ω 5 k Ω

Taping (reel)

Pull-off strength

5 N {0.51 kgf} 10 s

{ }:Reference only

■ ENVIRONMENTAL CHARACTERISTICS

Test item

Test conditions

Thermal shock − 65 ~ 150 °C (0.5 h), 5 cycles

[ Δ R/R ≦ 2 %]

[S.S. ≦ 1 %]

Humidity

[ Δ R/R ≦ 2 %]

Shock

− 10 ~ 65 °C (80 ~ 98 %),

10 cycles, 240 h

981 m/s2, 6 ms

6 directions for 3 times each

Vibration

(Amplitude) 1.52 mm or

(Acceleration) 196 m/s2,

10 ~ 2000 Hz, 3 directions, 12 times each

Load life

85 °C, 0.25 W, 1000 h

Low temp. operation

− 65 °C, 2 h

High temp. exposure

150 °C, 250 h

Immersion seal

85 °C, 60 s

Reflow : Peak temperature 255 °C

(Please refer to the profile below.)

Soldering heat

Manual soldering:350 ±

10 °C, 3 ~ 4 s

Pre Heating Zone

90 ± 30 s

Specifications

[ Δ R/R ≦ 1 %]

[S.S. ≦ 1 %]

[ Δ R/R ≦ 3 % or 3 Ω ]

[S.S. ≦ 2 %]

[ Δ R/R ≦ 1 %]

[S.S. ≦ 1 %]

[ Δ R/R ≦ 2 %]

[S.S. ≦ 1 %]

No leaks

(No continuous bubbles)

[ Δ R/R ≦ 1 %]

30 ± 10 s

Heating time

Soldering Zone

Reflow : two times maximum

Δ R/R:Change in total resistance

S.S. :Setting stability

�SM-42/43

SURFACE MOUNT TRIMMERS

■ MAXIMUM INPUT RATINGS

Nominal resistance Resistance code Maximum input

values ( Ω )

voltage (V)

Maximum wiper

current (mA)

A 10

A 20

50

100

200

500

100

200

500

101

201

501

1.00

2.00

3.53

5.00

7.07

11.2

100

100

70.7

50.0

35.4

22.4

1 k

2 k

5 k

10 k

20 k

50 k

102

202

502

103

203

503

15.8

22.4

35.4

50.0

70.7

112

15.8

11.2

7.07

5.00

3.54

2.24

100 k

200 k

500 k

1 M

2 M

104

204

504

105

205

158

223

300

300

300

1.58

1.12

0.60

0.30

0.15

The products indicated by A mark are manufactured upon receipt of

order basis.

■ RECOMMENDED P.C.B. PAD OUTLINE DIMENSIONS

● SM-42/43B

● SM-42/43X

2

2

2.3

5.1

0

2.3

1.3

2.54

1.3

1.9

1.3

1.3

2.9

0

1.6

5.2

0

2

0

4

1.6

2

1.9

2

2

● SM-42/43W

1.3

● SM-42/43A

(Unit: mm)

2.54

1.3

Note) The zero point is the center of mounting.

�SM-42/43

SURFACE MOUNT TRIMMERS

■ OUTLINE DIMENSIONS�

● SM-42/43W

3.9

1

Resistance code & Production date code

3.5

3

CW rotation

2

※ Note the terminal position.

3 – 0.9

1.2

4.8

2.54

2

1.3

1

2 – 0.8

Unless otherwise specified, tolerance : ± 0.3(Unit : mm)

φ 1.5, Slot

3

0.56W × 0.5D

5.1

2.6

3–1

5.3

● SM-42/43X

5.7

Resistance code & Production date code

3.5

2

2 – 0.8

1.2

4.8

2.54

1.3

1

φ 1.5, Slot

0.56W × 0.5D

3

5.1

3–1

5.3

● SM-42/43A

3.7

3 – 0.8

Resistan ce code & Produ ction d ate code

①

2 – 0.9

4.8

1.2

1.3

2.3

3–1

②

φ 1.5, Slot

0.56W × 0.5D

2.6

③

4.6

5

● SM-42/43B

1

1.2

2.3

1.3

4.8

2

2 – 0.9

φ 1.5, Slot

0.56W × 0.5D

2.8

4.6

6

3

3 – 0.6

3.9

Resistance code & Production date code

�SM-42/43

SURFACE MOUNT TRIMMERS

■ PACKAGING SPECIFICATIONS

Maximum number of consecutive missing pieces = 2

Leader length and reel dimension are shown in the diagrams below.

● Taping version (SM-42/43TA, TB) is packaged in 500

pcs. per reel.

Orders will be accepted for units of 500 pcs., i.e., 500,

1000, 1500 pcs., etc.

SM-42/43TW, TX is packaged in 250 pcs. per reel.

Orders will be accepted for units of 250 pcs., i.e., 500,

750 pcs., etc.

● EMBOSSED TAPE DIMENSIONS

● REEL DIMENSIONS

(Conforms to JIS C 0806-3)

(TA/TB type : In accordance with EIAJ ET-7200A)

Empty

Filled

(Unit: mm)

Empty

+1

Head

40 mm min.

21±0.8

20 pitches min.

2±0.5

Direction of feed

60

Leader

+1

0

End

13 0 (TA/TB)

17±0.3 (TW, TX)

400 mm min.

13±0.2

0

180 –1.5 (TA/TB)

0

180 –3 (TW, TX)

A

1

12 ± 0.1

1.75 ± 0.1

5.5 ± 0.05

1

2 ± 0.1

3

5.75

Cross section A-A

● Unit of bulk in a plastic bag is 50 pcs. per pack.

● Boxing of bulk in a plastic bag is performed with 200

pcs. per box.

2

A

8 ± 0.1

0.4 ± 0.1

Installation example

(SM-42A)

12

A

.1

+0 0

2

4 ± 0.1

5

1.

7.5 ± 0.1

3

0.5 ± 0.1

Installation example

(SM-42W)

+0.3

2 ± 0.1

φ

.1

+0 0

.5

φ1

A

● SM-42/43TA/TB

16 –0.1

4 ± 0.1

1.75 ± 0.1

● SM-42/43TW/TX

15.4±1 (TA/TB)

19.5±1 (TW/TX)

4.5

Cross section A-A

�