浙江博众电气有限公司

ZHEJIANG BOZHONG ELECTRIC CO.,LTD

承

认

书

SPECIFICATION FOR APPROVAL

客 户 名 称 Customer:

贵司料号CUSTOMER P/N:

敝司料号INTERIOR P/N:

贵公司承认印 Approal slgnatures

料 号/Part No.

签

章/Signatures

Send us a copy of reference, thank you!

地址: 浙江乐清虹桥镇信岙工业区

Add:Xianyangchen Industry Zone Hongqiao

Yueqing Zhejiang

电话/Tel: 0769-81208309

Http://www.cnbozhong.com

日期 Date:

拟制/Drawn

赵晓峰

审核/Check

陈乐峰

批准/Approved

朱旭静

�新版发行

DIM A±0.2

2.00±0.1

□0.50±0.03

①

技术要求:

1、塑件材料:LCP(UL-94V-0)

2、接触件:黄铜镀锡

3、接触电阻:≤30mΩ

4、绝缘电阻:≥1000MΩ

5、额定电压:250V AC DC

6、额定电流:3.0A AC DC

7、耐压:能承受1000V AC/Min

ute

8、工作温度:-25°~~+85°

9、可焊性试验:浸锡面积≥95%温度250+5°

-0 ,时间

2.5±0.5秒

10、铅和镉等六大有害物质含量要符合环保要求

②

DIM B±0.2

4.25±0.2

2.00±0.1

(7.20)

(8.00)

2PIN外观

③

Circuits

DIM C±0.2

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

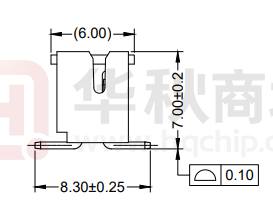

7.00±0.2

6.55±0.2

(6.00)

8.30±0.25

0.10

4.30

9.50

借用登记

Dimensions(mm)

A

B

C

4.90

2.00

6.00

6.90

4.00

8.00

8.90

6.00

10.00

10.90

8.00

12.00

12.90

10.00

14.00

12.00

16.00

14.90

14.00

16.90

18.00

16.00

18.90

20.00

18.00

20.90

22.00

20.00

22.90

24.00

22.00

24.90

26.00

24.00

26.90

28.00

26.00

28.90

30.00

28.00

30.90

32.00

30.00

32.90

34.00

旧底图总号

底图总号

签

字

日

期

2.00±0.05

DIM A±0.1

SUGGESTED PCB LAYOUT

(COMPONENT SIDE)

1.00

序号

GENERAL TOLERANCES

名

称

材

料

数

量

附

注

DRAWN BY 朱江浩/2023.05.08

CHK.BY

丁尔特/2023.05.08

APRV.BY 姚婷/2023.05.08

006-0082-001

PHD-2*NA立贴

60082-**07-5001

�产 品 规 格 书

PRODUCT SPECIFICATION

【1】适用范围 SCOPE

本规格书适用于:2.0 间距压接式连接器

This specification covers the 2.0mm Pitch Pressure Welding Connectors series.

【2】产品名称及型号 PRODUCT NAME AND PART NUMBER

产品名称 Product Name

产品型号 Part Number

D

PHD 压接式连接器

【3】定格及适用电线 RATINGS AND APPLICABLE WIRES

项目

Item

规

最大容许电压

格

250 V

Rated Voltage(MAX)

最大容许电流及适用

电线

Rated Current (MAX.)

and Applicable wires

[AC(有效值 rms)/DC]

AWG#24

AWG#26

2 A

2 A

AWG#28

1.5 A

AWG#30

1A

使用温度范围 Ambient temperature Range

存储温度

存储湿度

Requirement

被覆外径:φ0.6-1.4mm.

Insulation O.D.:

φ0.6-1.4mm.

-25℃ ~ +85℃ *

组装前

-10℃ ~ +40℃

组装后

-10℃ ~ +85℃

组装前

组装后

70%RH

85%RH

镀锡成品的储存期为六个月,镀金成品的储存期为十二个月

*: (包含通电后的温度上升)including terminal temperature rise

默认测试条件 Default test conditions

在具体试验方法中如无其他规定,试验样品应先在下述条件下放置24h后,然后再进行试验,样

品的预处理条件和和默认的试验条件如下(标准GB5095):

环境温度:(18~28)℃

空气相对湿度:25%~85%

大气压力:86kPa~106kPaAll test samples

shall be preconditioned at(18~28)℃ and 45%~75% relative humidity for 24h ,Before the start

�of any test.All test shall be carried out at following basic condition: Ambient temperature:

(18~28)℃, Relative humidity: 25%~85% ,Atmospheric pressure: 86kPa~106kPa

【4】性能 PERFORMANCE

4.1 电气性能 Electrical Performance

项目 Item

4.1.1

4.1.2

4.1.3

接触电阻

Contact

Resistance

绝缘电阻

Insulation

Resistance

耐电压

Dielectric

条

件

Test Condition

适合嵌合状态;开放电压 20mV 以下;短路电

流 10mA 的状态下测定。

Mate applicable and measure by dry circuit,20mV

MAX,10mA. EIA-364-23C

规格 Requirement

30 mΩMAX

适合嵌合状态;相邻端子间或端子与地面间加

DC 500V 下测定。

Mate applicable and apply 500V DC between

adjacent terminal or ground. EIA-364-21C

1000MΩMIN

适合嵌合状态;相邻端子间或端子与地面间加

AC 1000V(有效值)历时 1 分钟下测定。

Mate applicable and apply 1000V AC(rms)for

1minute between adjacent terminal or ground.

EIA-364-20C

无击穿现象

No Breakdown

4.2 机械性能 Mechanical Performance

项目 Item

4.2.1

插入力及拔出力

Locking

and

Withdrawal Force

条

件

Test Condition

规格 Requirement

每分钟 25±3mm 的速度;平行地插入,拔出。 插入力 Insertion

Insert and withdraw connectors at the speed

7 * n (N) MAX

rate of 25±3mm/minute. EIA-364-13D

拔出力 Withdrawal

2.5 * n

4.2.2

4.2.3

4.2.4

端子保持力

Terminal

/Housing

Retention Force

以用每分钟 25±3mm 的速度平行向外拉

Pull the terminal at the speed rate of 25±

3mm per minute. EIA-364-29C

端子的固定力

Terminal/Hous

ing Retention

Force

固定连接器和/或测力计,在连接器轴线方

向施加规定的拉力;速度不大于 25mm/min

Apply axial pull out force at the speed

rate of not more 25mm/min on the pin

assembled in the housing. EIA-364-29C

压着部位抗张

强度

Crimping Pull

Out Force

在试验装置夹头中固定试验样品,在连接的

轴线方向施加张力;速度不大于 25mm/min

Fix the crimped terminal, apply axial

pull out force on the wire at the speed

rate of not more 25mm/min

(N) MIN

10 N MIN

10N MIN

AWG.28#

10N

AWG.26#

20N

AWG.24#

25N

4.3 环境和其他性能 Environmental Performance and Others

�项目 Item

4.3.1

4.3.2

4.3.3

4.3.4

条

件

重复插拔

Repeated

Insertion

and

Withdrawal

无通电状态;以 10 次/分钟的速度插拔

20 次

Insertion and withdrawal actuator up to

20 cycles at the speed rate of less than 10

cycles/minute. EIA-364-13D

温度上升

Temperature

Rise

适合嵌合状态;最大容许电流通电,温

度测定。(UL 498)

Carrying rated current load.(UL 498)

EIA-364-70B

耐振动性

Vibration

耐冲击性

Shock

DC 0.1A 通电状态下;嵌合轴沿 XYZ

三 个 方 向 振 动 ; 振 幅 1.5mm ; 频 率

10-55-10Hz/分;历时 2 小时

Amplitude:1.5mm P-P

Sweep time:10-55-10Hz in 1 minute

Duration:2 hours in each X.Y.Z. axes

EIA-364-28E

4.3.6

4.3.7

耐寒性

Cold

Resistance

耐湿性

Humidity

60 mΩ

MAX

温度上升

Temperature

30 ℃MAX

Rise

外观

Appearance

接触抵抗

Contact

Resistance

无损坏

No Damage

60 mΩ

MAX

1 ms.MAX.

外观

Appearance

无损坏

No Damage

瞬断

Discontinuity

1 ms.MAX.

适合嵌合状态;85±2℃的空气中;放

置 96 小时;再回到室温中放置 1-2 小

时

Engage the connector,and keep the

sample for 96 h under following

conditions.

Ambient temperature +85±2℃,Leave

the sample at the room for 1 to 2 h

before check. EIA-364-17B

外观

Appearance

无损坏

No Damage

适合嵌合状态;-40±2℃的空气中;放

置 96 小时;再回到室温中放置 1-2 小

时

Engage the connector,and keep the

sample for 96 h under following

conditions.

Ambient temperature -40±2℃,Leave

the sample at the room for 1 to 2 h

before check. EIA-364-59A

外观

Appearance

适合嵌合状 态;40±2℃、相对湿 度

90-95%的空气中;放置 96 小时;再回

外观

Appearance

DC 0.1A 通电状态下;嵌合轴沿相互垂

直的 6 个方向;以 490m/s2{50G}冲击;

各3次

EIA-364-27B

耐热性

Heat

Resistance

接触抵抗

Contact

Resistance

瞬断

Discontinuity

490m/s2{50G},3 strokes in each X.Y.Z. axes.

4.3.5

规格 Requirement

Test Condition

接触抵抗

Contact

Resistance

接触抵抗

Contact

Resistance

60 mΩ

MAX

无损坏

No Damage

60 mΩ

MAX

无损坏

No Damage

�到室温中 0.5 小时内测定

Engage the connector,and keep the

sample for 96 h under following

conditions.

Temperature:40±2℃

Relative Humidity:90-95%

Leave the sample at the room for 1

to 2 h before check. EIA-364-31B

接触抵抗

Contact

Resistance

耐电压

必须满足 4.1.3

Dielectric

Must

meet4.1.3

Strength

绝缘抵抗

Insulation

Resistance

4.3.8

4.3.9

4.3.10

4.3.11

4.3.12

温度循环

Temperature

Cycling

耐盐雾性

Salt Spray

耐亚硫酸

SO2 Gas

耐氨性

NH3 Gas

可焊性

Solder

ability

适合嵌合状态;-55±3℃ 30 分钟;常

温常湿 10-15 分钟;85±2℃ 30 分钟;

常温常湿 10-15 分钟,循环 5 次。

Engage the connector,and subject it to 5

cycles of following sequence:

a) -55±3℃

30 minutes

b) 85 ± 2 ℃

30 minutes

EIA-364-32E

适合嵌合状态;35±2℃、5±1%的盐水

喷雾 24 小时;试验后常温水洗;再室温

干燥。Engage the connector,and keep the

sample under following conditions.

24hours exposure to a salt spray from the

5 ± 1% solution at 35 ± 2 ℃ .

EIA-364-26B

适合嵌合状态;40±2℃、50±5ppm 的

亚硫酸中放置 24 小时

Engage the connector,and keep the

sample for 24 hours exposure to 50±

5ppm. SO2 gas at 40±2℃.

适合嵌合状态;浓度为 28%的氨水容器

中;放置 40 分钟。

Engage the connector,and keep the

sample for 40 minutes exposure to NH3

gas evaporating from 28% Ammonia

solution

端子前端基准面 0.2mm 处浸入 245±

5℃的锡槽中;历时 2±0.5 sec。

Soldering Time:2±0.5 sec.

Soldering Temperature:245±5℃

0.2

mm

from

terminal

tip.

EIA-364-52A

60 mΩ

MAX

30 MΩ

MIN

外观

Appearance

无损坏

No Damage

接触抵抗

Contact

Resistance

60 mΩ

MAX

外观

Appearance

功能区无损

坏、腐蚀

No Damage

corrosion in

the functional

area

接触抵抗

Contact

Resistance

60 mΩ

MAX

接触抵抗

Contact

Resistance

60 mΩ

MAX

外观

Appearance

无损坏

No Damage

接触抵抗

Contact

Resistance

60 mΩ

MAX

沾敷性

Solder

Wetting

沾敷面积

95%以上

�耐焊接热

4.3.13

Resistance

to

Soldering

heat

a.回流焊接:温度 260±5℃;历时 10±

0.5 sec;二次回流.

Flow Soldering:Soldering Time:10±0.5

sec,Soldering Temperature:260±5℃,

two times. EIA-364-56D

b.手工焊接:温度 350±10℃;历时 3±

2 sec.

Hand Soldering:Soldering Time:3±2

sec,Soldering Temperature:350±10℃.

EIA-364-56D

外观

无损坏、变形

Appearance

No Damage

外观

无损坏、变形

Appearance

No Damage

( ) :参考规格 Reference Standard{ }:参考单位 Reference Unit

【5】外观形状、寸法及材质

名 称 NAME

基座(A) Wafer

材 质

MATERIALS

LCP(本色)

UL 94V-0

端子 Contact/Terminal

黄铜

Brass

焊片 Fitting Nail

黄铜

Brass

备注 Remark

电镀(锡):整个表面镀底镍 30u"MIN,再镀锡 80u"MIN.

Plating: BRIGHT-TIN 80u"Min OVER Ni 30u"Min.

【6】备注 Remarks

6.1 请参考推荐的 PCB 模式,以保持焊接强度,但基板推荐尺寸,仅是弊司的推荐值.仅

供参考. Refer the recommended PCB pattern to keep the strength of soldering,But board

recommended size is only recommended values spacious Secretary for reference only.

6.2 本产品只是用于一般的基板,不适合于特殊的基板。使用以前请先确认.General

performance confirmation of this product is carried out at a glass epoxy substrate.

If you want to implement to the special substrate such as a flexible board, please

use after conducting a pre-implementation such as confirmation.

6.3 当返修或手工焊接,要避免助焊剂进入连接器内部端子,这可能会引起接触性不

良问题 When reworking or soldering by hand, do not put solder flux to connector

terminal. That may cause contact problem by flux.

6.4 实装过程中塑胶会发生变色现象,但是不会影响产品的性能。Depending on the

reflow conditions, it might discoloration in the resin portion occurs, but there is

no effect on product performance.

6.5 塑胶有时会有熔接线的痕迹,但是如果实验条件不超过弊司指定值时,产品性能

不会有影响 There is a case where the line in the weld portion of the resin portion

is confirmed, but as long as you do not use more than the specification test conditions,

there is no effect on product performance.

6.6 虽然这种产品的镀层在适应于无铅回流焊制程中,在确保镀锡的最大的效果下,可

以延迟锡须生长,但这不可能完全消除锡须的问题,请在选型过程中,注意产品电镀规格。

Although the lead-free plating of this product has performed re-flow tin plating which

�ensures maximum effectiveness for retarding whisker growth ,it is not possible to

completely eliminate the whisker problem,In the selection process, pay attention

to product Plating

6.7 下 图 为 所 推 荐 的 回 流 焊 温 度 曲 线 图 。 The following diagram shows the

recommended reflow soldering temperature profile.

°

°

°

°

�

很抱歉,暂时无法提供与“AB02A0700000127B”相匹配的价格&库存,您可以联系我们找货

免费人工找货