东莞市科雅电子科技有限公司

规

格

承

认

书

SPECIFICATIONS FOR APPROVAL

TEL0769-83919069 FAX:0769-83500269

客户名称

CUSTOMER

规格类别

DESCRIPTION

科雅料号

CHIEFCON P/N

客户料号

CUSTOMER P/N

承认编号

APPROVAL NO

发行日期

ISSUED DATE

立创商城

MPP:金屬化聚丙烯薄膜電容器(CBB22 粉包型)

KP224J2J1502

2019041201

2019/04/12

东莞市科雅电子科技有限公司

广东省东莞市常平镇朗贝村常泰新村 4 街 128 号四楼

刘斌 13537302676 TEL:0769-83919069

FAX:0769-83500269

工厂地址:广东省中山市港口镇建达工业村 C 厂房三楼 B 区

Website : HTTP://www.dgkeya.com

客户承认栏 CUSTOMER APPROVAL

製作 PREPARED BY

審核 CHECKED BY

核準 APPROVAL BY

This specification will be invalidated assuming that it is not accepted when it is not returned within sixth months from the date of issue.

此承认书若未在发行日期起二个月内签回,将视为无效。

东莞市科雅电子科技有限公司

1/11

�SPECIFICATION

CHIEFCON ELECTRONICS CO LTD

客户名称

CUSTOMER

科 雅 料号

立创商城

KP224J2J1502

CHIEFCON TYPE

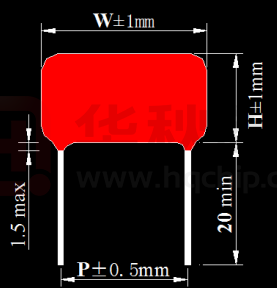

产品尺寸图 PRODUCT DIMENSIONS

实际产品印字:

印字标识

Marking

客户产品型号

CUSTOMER P/N

容值

标志 公差 电压

R.V.

CAP.

(uF)

Symbol

0.22

224

Tol. ±%

5

东莞市科雅电子科技有限公司

(VDC)

宽W

高H

630

17

14

±1

±1

尺寸毫米为单位

厚 脚距 线径φd 脚长 L

Dimensions in mm

T

P

±1

±0.5

7.0

15

±0.05

0.8

15

科雅产品型号

CHIEFCON P/N

KP224J2J1502

2/11

�产品编码对照表 PRODUCT CODE COMPARATIVE TABLE

产品编码 Product coding

○产品类别 Type of capacitor

1

类别 model

代码 Code

型号 model

代码 Code

MPP

MPR

KP

KP

CBB21

CBB22

KP

KP

MER

CL21

PPS

CBB81

PE

PE

PS

PS

○产品容量代码 Capacitance code (EIA Code)

2

代码 Code

容量换算

代码 Code

Capacitance

容量换算

CBB28

PPN

CBB13

X2

MPB

PN

PN

PX

PC

PS

代码 Code

Capacitance

容量换算

Capacitance

101

100pF

0.1nF

0.0001uF

103

10,000pF

10nF

0.01uF

105

1,000,000pF

1,000nF

1uF

102

1,000pF

1nF

0.001uF

104

100,000pF 100nF

0.1uF

106

10,000,000pF

10,000nF

10uF

○产品容量误差 Tolerance (EIA Code)

3

误差 Tol.

代码 Code

±1%

F

±2%

G

±3%

I

±5%

J

○产品额定电压 Rated Voltage

±10%

K

±20%

M

–10%~ 0%

L

0%~+10%

P

–5%~+10%

U

–10%~+5%

V

0%~+20%

W

4

电压 Voltage

代码 Code

63

100

125

250

275

310

350

380

400

450

630

800

1000

1200

1250

1600

2000

3000

1J

2A

2B

2E

2C

2H

2K

2L

2G

2W

2J

2D

3A

3I

3B

3C

3F

3G

○产品本体脚距 Lead Space

5

本体脚距 Lead Space

代码 Code

5

05

7.5

07

10

10

○辅助码(内部识别码) Accessories Yards

6

NO.

1

2

说明

15

15

20

20

22.5

22

24

24

25

25

26

26

27.5

27

31

31

Descriptions

每个规格第一料号时用“01" Each specification first edit with" 01"

同种规格原料、外观及尺寸有差异时用“01,02,03...”进行区分

The same specifications appearance and size differ with non-simultaneous 01, 02, 03 to distinguish

Guideline of notabilia for the usage of plastic film capacitors

塑胶薄膜电容器的使用上注意事项及指导

Plastic film capacitors use organic films for their dielectrics, thus the capacitors may fume of flame, depending on the circuit conditions they are in, when they are

damaged by applying over-voltage or over-current.

塑胶薄膜电容器使用有机薄膜为介质,当使用超过额定电压及额定电流,可能产生火焰,导致电容损坏,故请使用于正确的电路。

1. Circuit Design 电路设计

① Please use capacitors within the range of their characteristic ratings, only after confirming their operating and mounting

environments.

请确认电容器的使用范围仅止于明定之额定特性规范,请先确认电容器使用之环境是否符合规范。

请依照适合的作业条件选择相对应的电容器使用。

② In case of selecting a capacitor, please select the most suitable one which fits to your operating conditions.

③ An applying voltage to a capacitor, including the peak of surge and ripple voltage (D.C. voltage + A.C. Peak), cannot be exceeded the

rating voltage.

电容器之应用电压,包括突波和纹波电压的峰值 直流电压 交流峰值 不可超过额定电压。

(

+

)

④ Do not apply a current over its permissible level. Also, make sure the check the surrounding temperature and inherent temperature

rise of a capacitor since a permissible current can be restricted by those factors.

切勿使用超出电容器可承载之电流并检查电容器周围之温度,因有许多因素会影响电流之变化,进而造成电容器之温度上升。

⑤ Do not conduct a rapid charge and discharge to a capacitor which may lead to characteristics degradations or break down of the

capacitor.

请不要对电容器进行快速的充电和放电,此可能会导致电容器之特性退化或损坏。

安装

请不要使用任何超过电容导线可承受之张力进行插件。

② Please mount a capacitor where it dose not contact any other heating parts, high voltage parts and other parts.

请确认电容器使用环境,避免接触任何其他升温热物件 高压和其他部分料件。

③ Please conduct soldering process by strictly following the specified conditions.

进行焊接过程实,请严格遵循指定之焊接条件。

3.Storing and handling 储存和处理

① A storage needs to be kept indoors at -10~+30℃ and relative humidity of under 75% without any sudden temperature changes,

direct sunlight and corrosive gas around.

需保存于

,相对湿度低于 并确保没有任何突然的温度变化,避免直接阳光之曝晒及接触腐蚀性气体之环境。

② Do not apply and exceeding vibration, shock (dropping) and pressure.

不应过度震动、碰撞和及外力的冲击。

③ According to normal conditions, the storage time exceeds 3 months, and all capacitor characteristics must be checked before production and use.

按正常条件储存时间超出3个月时间,生产使用前需全部检查电容器特。

2. Mounting

① Do not apply any exceeding tension or torsion to lead wires of a capacitor, during the mounting process.

,

-10 ~ 30℃

75%

东莞市科雅电子科技有限公司

3/11

�产品规格说明

NO. 项目 ITEM

PRODUCT SPECIFICATIONS

1

2

2.1

承认范围

SCOPE

说明 DESCRIPTIONS

本规格适用于科雅之要求

This specifications cover the requirements of KYET

金属化聚丙烯薄膜电容器

Metallized Polypropylene Film capacitor

MPP/MPR/CBB21/CBB22

各测量皆于标准大气下进行 STANDARD ATMOSPHERIC CONDITIONS FOR MAKING MEASUREMENTS

环境温度 AMBIENT TEMPERATURE

15℃

至 35℃ (如对结果有任何疑问,该测量环境温度应为+20 ± 5℃之间)

15℃ to 35℃ (If there is any doubt on the results, the measurements shall be made

at +20 ± 5℃)

至

如对结果有任何疑问,该测量相对湿度应为

之间

2.2

相对湿度 RELATIVE HUMIDITY(R.H.)

45% 75% (

60% to 70%

)

45%to 75% (If there is any doubt on the results, the measurements shall be made at

60% to 70%)

2.3

大气压力 AIR PRESSURE

86

106

86 kpa to 106 kpa

2.4

工作温度范围

3

3.1

3.2

3.3

3.4

3.5

4

千帕之

于-40℃至+100℃间,电容可在额定电压下持续运作

OPERATING TEMPERATURE RANGE

结构 CONSTRUCTION

电介质

喷金层

导线

环氧树脂

塑料外壳

千帕至

DIELECTRIC

METAL SPRAY

LEAD WIRE

EPOXY RESIN

PLASTIC CASE

打印 MARKING

-40℃ to +100℃ for which the capacitor can be operated continuously at rated

voltage.

金属化聚丙烯薄膜 Metallized Polypropylene Film

特殊焊料

Special Solder

镀锡铜包钢线 Copper-clad Steel Wire

UL V-0 耐燃等级

UL V-0 耐燃等级

4.1

制造商标志

MANUFACTURER'S SYMBOL

4.2

型号或材质

TYPE OR MATERIAL

“MPP” stands for “Metallized Polypropylene Film”

4.3

电容类别

CAPACITOR CLASS

“CBB22”

“CBB”

“CBB22stands for “CBB” class

4.4

静电容量

NOMINAL CAPACITANCE

EIA

Capacitance Expressed in 3-digit (EIA) code.

4.5

容量容许差值 TOLERANCE

J (±5%) , K(±10%) , M(±20%)

4.6

额定电压

100, 250,400,450,630 VDC

4.7

RATED VOLTAGE

工作温度范围

Operating Temperature

Range

4.8

散逸因素(损耗角正切)

4.9

绝缘电阻

Insulation Resistance

东莞市科雅电子科技有限公司

表示为”科雅电子科技有限公司 KYET ELECTRONICS CO., LTD”

“MPP”代表“金属化聚丙烯”材质

代表

类别

容量用 三码表示

-40

范例

example

℃~100℃

Max 0.1%(at 1KHZ, 25℃)

CR≤0.33µF IR≥10000MΩ

UR≤100V

CR

0.33 F IR 5000M / F UR 100V

> μ

≥

Ωμ

≤

4/11

�产品规格说明

PRODUCT SPECIFICATIONS

5

ELECTRICAL CHARACTERISTICS

NO.

5.1

电气特性

项目 ITEM

耐压 (TV)

说明 DESCRIPTIONS

引线之间

应无异常

引线与外包封之间

应无异常

Between Terminals

5.3

5.4

Apply 1.5*Ur (DC) for 60 sec (Should be no

more than 150V/s rate increased from zero to

the test voltage, testing time, meets the test

voltage should be calculated at the end of the

trial, the voltage should be reduced to zero

and the capacitor through a resistor of

appropriate discharge.

Shall be no abnormality

Withstand

Voltage

Between Terminals

&Enclosure

5.2

施加 1.6 倍额定直流电压测试 60 秒(电压应

以不超过 150V/s 的速率从零升高到试验电

压,时间应从达到电压时计算,在结束时,

电压应减少到接近零,并且电容器应通过一

个适当的电阻放电)

介质损耗 (DF)

2 倍额定电压+500V,测试 2 到 5 秒

最小值 1,000VDC

Shall be no abnormality

Apply 2*Ur+500V for 2 to 5 sec.

Min. 1,000VDC

于 1KHz 时 ≤ 0.001(0.1%)

Dissipation Factor

≤ 0.001(0.1%) at 1 KHz

容量 (CAP)

( +20 ± 5℃)

Within the tolerance specified

环境温度 于

Capacitance

。

(at +20 ± 5℃).

≥10,000 Mohm (C≤0.33uf)

≤0.33uf

≥10,000M

≥5,000 Mohm*uF/C (C>0.33uf)

>0.33uf

容值

绝缘电阻 (I.R.)

Insulation Resistance

容值

Ω

Ω

时,绝缘电阻

时,绝缘电阻

测量频率

测量电压

测量频率

测量电压

: ±2% ;

: ≤1 rms

Measuring Frequency: ±2%

Measuring Voltage: ≤1 Vrms..

: ±2% ;

: ≤1 rms

Measuring Frequency: ±2%

Measuring Voltage: ≤1 Vrms..

测试电压 100 伏

充电时间 60±5 秒。

Vt=100 VDC

Charge Time : 60±5 sec.

≥5,000M *uF / C

5.5

6

6.1

焊料覆盖面积应超过导线表面

圆周 90%。

焊料附着性

Soldering Property

焊接温度为: +260 ± 5℃

浸焊时间为: 2 ± 0.5 秒

More than 90% of circumferential

surface of lead wire shall be

covered with new solder.

Soldering temperature: +260 ± 5℃

Immersion duration: 2 ± 0.5 sec.

应无异常。

沿着引出方向,施加 1 公斤力量,保持 10±1

秒。

机械特性 MECHANICAL CHARACTERISTICS

引线强度

引线强度

Tensile Strength

Terminal

Strength

东莞市科雅电子科技有限公司

Shall be no abnormality

Apply 1.0Kg for 10 ± 1 sec. to the terminal in

the axial direction and acting in a direction

away from the body.

5/11

�产品规格说明

PRODUCT SPECIFICATIONS

7

NO.

耐久性特性 ENDURANCE CHARACTERISTICS

项目 ITEM

外观

Appearance

耐压

Withstand Voltage

7.1

说明 DESCRIPTIONS

应当无显著变化

Shall be no remarkable change

应满足

NO.5.1

shall satisfy NO.5.1

容值变化率 (△C/C)

变化率小于 ±5%

温度变化循环 Capacitance

Change Rate

Within ±5% of the value before test

Temperature

Cycle

介质损耗

Dissipation Factor

于 1KHz 时: 最大值为 0.002 (0.2%)

@ 1KHz: 0.002 (0.2%) max.

共 5 次温度循环测试,循环条件:

1. +20 ± 2℃ 持续 3 分钟

2. -40 ± 3℃ 持续 10 分钟

3. +20 ± 2℃ 持续 3 分钟

4. +100 ± 2℃ 持续 10 分钟

5. +20 ± 2℃ 持续 3 分钟

试验后放置于室内 1.5 ± 0.5 小时后再进行量

测。

Test Temperature Cycle: Total 5 cycles.

Each cycle includes

1. 20 ± 2℃ for 3 min.

2. -40 ± 3℃ for 10 min.

3. +20 ± 2℃ for 3 min.

绝缘电阻 (I.R.)

≥50%

NO.5.4

≥50% of the limit value of NO.5.4

外观

应当无显著变化

Appearance

耐压

Withstand Voltage

7.2

耐干热试验

Dry Heat

Resistance

容值变化率 △

于 1KHz 时: 最大值为 0.002 (0.2%)

外观

应当无显著变化

Shall be no remarkable change

应满足

Withstand Voltage

NO.5.1

Shall satisfy NO.5.1

容值变化率 (△C/C)

变化率小于 ±5%

Capacitance Change Rate

Within ±5% of the value before test

介质损耗

于 1KHz 时: 最大值为 0.002 (0.2%)

绝缘电阻 (I.R.)

Insulation Resistance

东莞市科雅电子科技有限公司

Test Temperature: +100 ± 2℃

Test Duration: 16 + 1/-0 hrs.

的限制值在

≥50%

NO.5.4

≥50% of the limit value of NO.5.4

Dissipation Factor

试验温度: +100 ± 2℃

测试时间: 16 ± 1 小时

@ 1KHz: 0.002 (0.2%) max.

Insulation Resistance

耐压

Cold

Resistance

变化率小于

介质损耗

Appearance

7.3

应满足

NO.5.1

Shall satisfy NO.5.1

±5%

Within ±5% of the value before test

绝缘电阻 (I.R.)

5. +20 ± 2℃ for 3 min.

After test, allow it stay alone for 1.5 ± 0.5 Hrs.

at ordinary condition before making

measurements.

Shall be no remarkable change

( C/C)

Capacitance Change Rate

Dissipation Factor

耐干寒试验

的限制值在

Insulation Resistance

4.+100 ± 2℃ for 10min.

试验温度: -40 ± 3℃

测试时间: 2 ± 1 小时

Test Temperature: -40 ± 3℃

Test Duration: 2 ± 1 hrs.

@ 1KHz: 0.002 (0.2%) max.

的限制值在

≥50%

NO.5.4

≥50% of the limit value of NO.5.4

6/11

�产品规格说明

PRODUCT SPECIFICATIONS

NO.

项目 ITEM

外观

说明 DESCRIPTIONS

应当无显著变化

耐压

应满足 NO.5.1

Appearance

Withstand Voltage

7.4

耐湿绝缘

Damp Heat

容值变化率 △

变化率小于

±5%

Within ±5% of the value before test

介质损耗

于 1KHz 时: 最大值为 0.002 (0.2%)

绝缘电阻 (I.R.)

@ 1KHz: 0.002 (0.2%) max.

的限制值在

Insulation Resistance

≥50%

NO.5.4

≥50% of the limit value of NO.5.4

外观

应无机械性损伤

连接强度

不得为短路或开路连接。

连接点应稳定。

外观

应当无显著变化

印字标志应清晰

Appearance

Shall be no mechanical damage.

振动试验

Vibration

Resistance

Connection strength

Appearance

端子间的耐电压值

Withstand Voltage

Between Terminals

焊接耐热

7.6

Shall satisfy NO.5.1

( C/C)

Capacitance Change Rate

Dissipation Factor

7.5

Shall be no remarkable change

Soldering

Heat

Resistance

容值变化率 △

( C/C)

Capacitance Change Rate

介质损耗

Dissipation Factor

绝缘电阻 (I.R.)

Insulation Resistance

连接元件

Connection of Element

东莞市科雅电子科技有限公司

Shall be no short-circuiting or open.

The connection shall be stable.

Shall be no remarkable change.

The marking shall be legible.

应满足

NO.5.1

Shall satisfy NO.5.1

变化率小于

±5%

Within ±3% of the value before test

于 1KHz 时: 最大值为 0.002 (0.2%)

@ 1KHz: 0.002 (0.2%) max.

的限制值在

≥50%

NO.5.4

≥50% of the limit value of NO.5.4

试验温度:+40 ± 2℃

试验湿度:90%至 95%相对湿度

试验时间:2 ± 1 小时

试验后放置于室内 1.5 ± 0.5 小时后再进行量

测。

Test Temperature: +40 ± 2℃.

Test Humidity: 90% to 95% R.H.

Test Duration: 2 ± 1 hrs..

After test, allow it stay alone for 1.5 ± 0.5 Hrs.

at ordinary condition before making

measurements.

频率变化: 10-55-10Hz

振动距离: 1.5 毫米.

试验方向: X,Y,Z

试验时间:每个方向 2± 1 小时

Frequency Change : 10-55-10 Hz

Vibration Distance:1.5 mm.

Test Direction : X,Y,Z

Test Duration : 2± 1hrs each direction

预热温度: 85 ~100℃

预热时间:最大为 60 秒

温度升高:最大为 3℃/秒

锡炉温度: +260 ± 5℃

浸焊时间: 2 ± 1 秒

浸焊深度:导线根部 4 ± 0.8 毫米

试验后放置于室内 1.5 ± 0.5 小时后再进行量

测。

Preheat Temp. : 85~100℃

Preheat Duration : 60 sec. max.

Temperature Increase by 3℃/sec. max.

Soldering Temperature : +260 ± 5℃

Immersion Duration : 2 ± 1sec.

Immersion Depth : 4 ± 0.8mm from roots. After

test, allow it stay alone for 1.5 ± 0.5 Hrs. at

ordinary condition before making

measurements.

应稳定

Shall be stable

7/11

�产品规格说明

PRODUCT SPECIFICATIONS

NO.

7.7

项目 ITEM

耐久寿命

Endurance

外观

Appearance

耐压

Withstand Voltage

Shall satisfy NO.5.1

容值变化率 (△C/C)

变化率小于 ±10%

Capacitance Change Rate

介质损耗

Dissipation Factor

绝缘电阻 (I.R.)

7.8

耐湿负荷

Moisture

Resistant

Loading

性能 PERFORMANCE

应当无显著变化

Shall be no remarkable change

应满足 NO.5.1

Within±10% of the value before test

于 1KHz 时: 最大值为@ 1KHz

Cr ≤1uF : 0.008 (0.8%) max.

Cr >1uF : 0.005 (0.5%) max.

的限制值在

Insulation Resistance

≥50%

NO.5.4

≥50% of the limit value of NO.5.4

外观

Appearance

耐压

应当无显著变化

Shall be no remarkable change

应满足 NO.5.1

Withstand Voltage

Shall satisfy NO.5.1

容值变化率 (△C/C)

变化率小于 ±5%

Capacitance Change Rate

Within ±5% of the value before test

介质损耗

于 1KHz 时: 最大值为 0.002 (0.2%)

Dissipation Factor

绝缘电阻 (I.R.)

Insulation Resistance

东莞市科雅电子科技有限公司

@ 1KHz: 0.002 (0.2%) max.

的限制值在

≥50%

NO.5.4

≥50% of the limit value of NO.5.4

测试条件 TEST CONDITIONS

试验温度: +85 ± 2℃

测试电压: 额定电压

试验时间 小时

每小时将电压升至额定电压,持续 0.1 秒

每个电容分别通过一个 47Ω±5 %.电阻。

: 16

Test Temperature: +85± 2℃

Test Voltage: 100% * rated voltage.

Test Duration: 16 Hrs.

Once every hour the voltage For 0.1 sec. The

test voltage is applied to each capacitor

individually through a resistor of 47Ω±5 %.

试验温度: +40 ± 2℃.

试验湿度: 87%至 93%相对湿度

测试电压: 额定电压

试验时间 小时

试验后放置于室内 1.5 ± 0.5 小时后再进行量

测。

: 16

Test Temperature: +40 ± 2℃.

Test Humidity: 87% to 93% R.H.

Test Voltage: rated voltage.

Test Duration: 16 Hrs.

After test, allow it stay alone for 1.5 ± 0.5 Hrs.

at ordinary condition before making

measurements.

8/11

�