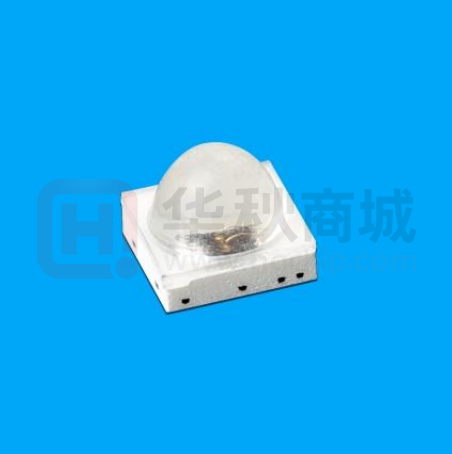

XL-MD3030IR-T4A2

Technical Data Sheet

haracteristic

* 芯片规格: 28mil*28mil

Chip specification : 28mil*28mil

* 发光颜色及胶体: 红外(不可见光)/无色透明胶体

Luminous color and colloid: Infrared (invisible light) / colorless transparent silica gel

* 封装支架:3030 支架

Packaging bracket:3030 support

* 波长:940 nm

Wavelength :940 nm

* 发光角度:45度

Luminous Angle : 45 degrees

* 环保工艺符合ROHS标准

Environmental protection products Complied With RoHS Directive

* EIA规范标准包装

EIA standard packaging

* 适用于SMT贴片自动化生产

Suitable for SMT automatic production

* 适用于回流焊制程

Suitable for reflow soldering process

roduct application

* 红外应用系统

Infrared applications systems

* 红外相机

Infrared lllumination for cameras

* 安防监控

Secunrity monitoring

* 无线通讯

Wireless communication

1

�Catalogue

Electrical Characteristics............................................................................................................................. 3

Typical Characteristic Curves......................................................................................................................4

Reliability Test Items And Conditions........................................................................................................ 5

Outline Dimensions.......................................................................................................................................6

Packaging........................................................................................................................................................7

Guideline for Soldering............................................................................................................................... 9

Precautions....................................................................................................................................................11

2

�Electrical Characteristics

(温度=25℃):Absolute Maximum Ratings (Temperature=25°C):

环境温度

电气特性

符号

最大额定值

Electrical characteristics

Symbol

Absolute Maximum Ratings

单位

Unit

最大持续工作电流

Max continuous working current

IF

≤800

mA

conditionemperatu

re

Ta=25°C

正向脉冲电流

Peak Forward Current

反向电压

Reverse breakdown voltage

工作温度

Operating Temperature

存储温度

Storage Temperature

IFP

2.4

A

Ta=25°C

VR

5

V

Ta=25°C

Topr

-40℃to +100℃

°C

-

Tstg

-40℃to +100℃

°C

-

回流焊温度

Circle solder Temperature

Tsol

245℃for 10sec

°C

-

结温

complete Temperature

Tj

115

°C

-

Electro-Optical Charasteristics (Temperature=25°C):

参数

Parameter

符号

Symbol

测试条件

Test Condition

最小

Min

平均

Typ

最大

Max

单位

Unit

光功率Luminous power

Po

IF=350mA

190

-

-

mW

光强Luminous intensity

Ie

IF=350mA

210

230

270

mW/Sr

视角Emission Angle

2θ1/2

-

-

45

-

Deg

波长Wavelength

λp

IF=350mA

925

940

955

nm

半波宽Half wave width

Δλ

IF=350mA

-

50

-

nm

正向电压Forward Voltage

VF

IF=350mA

1.3

-

2.1

V

反向电流Reverse current

IR

VR=5.0V

-

-

10

μA

备注(Note):

1. 2θ1/2 是半值角,指辐射强度是光学中心线光强的 1/2 到光学中心线的角度

Theta 1/2 is the half-value Angle, which refers to the Angle of radiation intensity from the optical center line to

the optical center line, which is 1/2 of the light intensity of the optical center line

2. 上述辐射通量的测试允许公差是±10%

The permissible tolerance for the above radiation flux test is±10%

3. 以上所示电压测量误差±0.1v

The voltage measurement error shown above is ±0.1v

4. 以上所示波长测量误差±1nm

The above wavelength measurement error is ±1nm

3

�Typical Characteristics Curves

LED光强分布曲线(350mA测试) Intensity distribution curve (350mA test):

4

�Reliability Test Items And Conditions

测试项目

Test Parameter

参考标准

Reference

Criterion

测试条件

时间

数量

接受/拒收

Test Condition

Time

Quantity

Ac/Re

回流焊

Resistance to

Soldering Heat

JESD22-B106

Temp:245℃max

T=10sec

3 times

22Pcs

0/1

温度循环

thermocycling

JESD22-A104

120℃±5℃30min.

-40℃±5℃30min.

100 Cycles

22Pcs

0/1

高温保存

High Temperature

storage

JESD22-A103

Temp:100℃±5℃

1000Hrs

22Pcs

0/1

低温保存

Low Temperature

storage

JESD22-A119

Temp:-40℃±5℃

1000Hrs

22Pcs

0/1

常温通电

Operating Life

Test

JESD22-A108

1000Hrs

22Pcs

0/1

1000Hrs

22Pcs

0/1

高温高湿通电

High Temperature

High Humidity

*1

JESD22-A101

Ta=25℃±5℃

IF=100mA

85℃±5℃/85%

RH

IF=100mA

Criteria For Judging Damage

项目

Parameter

符号

Symbol

测试条件

Test Condition

正向电压

Forward

Voltage

VF

反向电流

Reverse current

辐射强度

Luminous

intensity

判定标准

Judgement standard

最小Min

最大Max

IF=100mA

--

U.S.L*)×1.2

IR

VR=5V

--

U.S.L*)×2.0

mW/sr

IF=100mA

L.S.L*)×0.7

--

* USL:标准值上限值,LSL:标准值下限值

* USL: Upper Standard Level, LSL: Lower Standard Level

* 数据表格中所示的技术信息仅限于典型特征值和电路实例引用的产品,它既不构成工业特性的保证,也不构成任何

许可的授权

* The technical information shown in the data table is limited to products referenced by typical eigenvalues and circuit

instances and does not constitute a guarantee of industrial characteristics nor does it constitute an authorization of any license.

5

�Outline Dimension

Suggest Soldering Pad Dimensions

焊点结构Pad Configuration:

备注:

1

正极Anode

2

负极Cathode

1.单位:毫米(mm)

Remarks: 1 Unit: mm

2.公差: 如无特别标注则为±0.10mm

2. Tolerance: ± 0.10mm unless otherwise specified

6

�1

Packaging (1)

卷轴尺寸Reel Dimensions:

使用方向及尺寸Progressive direction and Dimensions:

Loaded quantity 2000PCS per reel

7

�2

Packaging (2)

8

�1

Guideline for Soldering (1)

1.

Hand Soldering

推荐使用功率低于 6 0 W 的烙铁,焊接时烙铁的温度必须保持在 300℃以下,且每个电极只能进行一次焊

接,每次焊接的持续时间不得超过 3 秒。

人手焊接过程中的不慎操作易引起 LED 产品的损坏,应当小心谨慎。

A soldering iron of less than 60W is recommended to be used in Hand Soldering. Please keep the temperature

of the soldering iron under 300℃ while soldering. Each terminal of the LED is to go for less than 3 second and for

one time only.

Be careful because the damage of the product is often started at the time of the hand soldering.

2.

推荐使用以下无铅回流焊接温度图进行。

Reflow Soldering: Use the conditions shown in the under Figure ofPb-Free Reflow Soldering.

· 回流焊接最多只能进行一次。

Reflow soldering should not be done more than once.

· 在回流焊接升温过程中,请不要对 LED 施加任何压力。

Stress on the LEDs should be avoided during heating in soldering process.

· 在焊接完成后,待产品温度下降到室温之后,再进行其他处理。

After soldering, do not deal with the product before its temperature drop down to room temperature.

9

�2

Guideline for Soldering (2)

3.

Cleaning

在焊接后推荐使用酒精进行清洗,在温度不高于 30℃的条件下持续 3 分钟, 不高于 50℃的条件下持续 30

秒。使用其他类似溶剂清洗前,请先确认使用的溶剂不会对 LED 的封装和环氧树脂部分造成损伤。不可以

采用丙酮之类的清洁剂以免可能造成腐蚀破坏。

超声波清洗也是有效的方法,一般最大功率不应超过 300W ,否则可能对 LED 造成损伤。请根据具体的

情况预先测试清洗条件是否会对 LED 造成损伤。

It is recommended that alcohol be used as a solvent for cleaning after soldering. Cleaning is to go under 30℃ for 3

minutes or 50℃ for 30 seconds. When using other solvents, it should be confirmed beforehand whether the solvents will

dissolve the package and the resin or not. Do not use a cleaner such as acetone to avoid possible corrosion damage.

Ultrasonic cleaning is also an effective way for cleaning. But the influence of Ultrasonic cleaning on LED

depends on factors such as ultrasonic power. Generally, the ultrasonic power should not be higher than 300W. Before

cleaning, a pretest should be done to confirm whether any damage to LEDs will occur.

此一般指导原则并不适用于所有 PCB 设计和焊接设备的配置。具体工艺受到诸多因素的影响,

请根据特定的PCB设计和焊接设备来确定焊接方案。

Note: This general guideline may not apply to all PCB designs and configurations of all soldering equipment.

The technics in practise is influenced by many factors, it should be specialized base on the PCB designs

and configurations of the soldering equipment..

10

�1

Precautions (1)

1.

Storage

· 本产品使用密封防潮抗静电袋包装,并附有干燥剂,未开封的产品有一年的保存时间。

Moisture proof and anti-electrostatic package with moisture absorbent material is used, to keep moisture to a

minimum.

· 开封前,产品须存放在温度不高于 30℃,湿度不高于 60%RH 的环境中。

Before opening the package, the product should be kept at 30℃ or less and humidity less than 60% RH, and be

used within a year.

· 开封后,产品须存放在温度不高于 30℃,湿度不高于 10%RH 的环境中,且应该在 168 小时(7 天) 内使

用完。建议工作环境为温度不高于 30℃,湿度不高于 60%RH。

After opening the package, the product should be stored at 30℃ or less and humidity less than 10%RH, and be

soldered within 168 hours (7 days). It is recommended that the product be operated at the workshop condition of

30℃ or less and humidity less than 60%RH.

· 对于尚未焊接的 LED,如果吸湿剂或包装失效,或者产品没有符合以上有效存储条件,烘焙可以起到一定

的性能恢复效果。烘焙条件: (60±5)℃,持续 24 小时。

If the moisture absorbent material has fade away or the LEDs have exceeded the storage time, baking treatment

should be performed based on the following condition: (60±5)℃ for 24 hours.

2.

Static Electricity

静电和电涌会导致产品特性发生改变,例如正向电压降低等,如果情况严重甚至会损毁产品。所以在使用时必须采

取有效的防静电措施。

所有相关的设备和机器都应该正确接地,同时必须采取其他防止静电和电涌的措施。接地交流电阻小于 1.0

欧姆,工作台上需垫表面电阻 106-109 欧姆的桌垫。 在容易产生静电的环境和设备上,还必须安装离子风

扇。

使用防静电手环,防静电垫子,防静电工作服、工作鞋、手套,防静电容器,都是有效的防止静电和电涌的措施。

Static electricity or surge voltage damages the LEDs. Damaged LEDs will show some unusual characteristic such

as the forward voltage becomes lower, or the LEDs do not light at the low current. even not light.

All devices, equipment and machinery must be properly grounded. The grounding ac resistance is less than 1.0

ohm, the table mat with surface resistance of 106-109 ohm is needed on the work table.Ion fans must also be installed

in electrostatic environments and equipment.At the same time, it is recommended that wrist bands or anti-electrostatic

gloves, anti-electrostatic containers be used when dealing with the LEDs.

11

�2

Precautions (2)

3.

Design Consideration

设计电路时,通过 LED 的电流不能超过规定的最大值,同时,还需使用保护电阻,否则,微小的电压变

化将会引起较大的电流变化,可能导致产品损毁。

建议使用以下(A)电路,该电路能够很好的调节通过每个 LED 的电流; 不推荐使用(B)电路,该电路

在持续的电压驱动下,LED 的正向电压(VF )发生变化,电流会随之而发生变化,可能使某些 LED 承受高于

规定的电流值。

In designing a circuit, the current through each LED must not exceed the absolute maximum rating specified for

each LED. In the meanwhile, resistors for protection should be applied, otherwise slight voltage shift will cause big

current change, burn out may happen.

It is recommended to use Circuit A which regulates the current flowing through each LED rather than Circuit B.

When driving LEDs with a constant voltage in Circuit B, the current through the LEDs may vary due to the variation

in Forward Voltage (VF) of the LEDs. In the worst case, some LED may be subjected to stresses in excess of the

Absolute Maximum Rating.

(A)

(B)

LED 的特性容易因为自身的发热和环境的温度的改变而发生改变。温度的升高会降低 LED 的发光效率、

影响发光颜色等,所以在设计时应充分考虑散热的问题。

Thermal Design is paramount importance because heat generation may result in the Characteristics decline,

such as brightness decreased, Color changed and so on. Please consider the heat generation of the LEDs when

making the system design.

12

�3

Precautions (3)

4.

Others

直接用手拿取产品不但会污染封装树脂表面,也可能由于静电等因素导致产品性能的改变。过度的压力也可能直接

影响封装内部的管芯和金线,因此请勿对产品施加过度压力,特别当产品处于高温状态下,例如在回流焊接过程中。

When handling the product, touching the encapsulant with bare hands will not only contaminate its surface, but

also affect on its optical characteristics. Excessive force to the encapsulant might result in catastrophic failure of the

LEDs due to die breakage or wire deformation. For this reason, please do not put excessive stress on LEDs, especially

when the LEDs are heated such as during Reflow Soldering.

LED 的环氧树脂封装部分相当脆弱,请勿用坚硬、尖锐的物体刮、擦封装树脂部分。在用镊子夹取的时

候也应当小心注意。

The epoxy resin of encapsulant is fragile, so please avoid scratch or friction over the epoxy resin surface. While

handling the product with tweezers, do not hold by the epoxy resin, be careful.

5.

Safety Advice For Human Eyes

LED 发光时,请勿直视发光光源,特别是对于一些光强较高的 LED ,强光可能伤害你的眼睛。

Viewing direct to the light emitting center of the LEDs, especially those of great Luminous Intensity, will cause

great hazard to human eyes. Please be careful.

13

�

很抱歉,暂时无法提供与“XL-MD3030IR-T4A2”相匹配的价格&库存,您可以联系我们找货

免费人工找货