AW3644

September 2018 V1.6

High Efficiency, Dual Independent 1.5A Flash LED Driver

GENERAL DESCRIPTION

Support Dual Color Temperature Flash LED

Application

The AW3644 is a dual LED flash driver that

provides a high level of adjustability within a small

solution size. The AW3644 utilizes a 2MHz or 4MHz

fixed-frequency synchronous boost converter to

provide power to the dual 1.5A constant current

LED sources. The dual 128 levels current sources

provide the flexibility to adjust the current of LED1

and LED2 in Flash/Torch/IR modes. The AW3644

provides three IVFM protection modes to prevent

system reset or shutdown under low battery

condition.

l

FEATURES

n

85%

e

High Efficiency:

ti

a

Dual Independent and Programmable 1.5A LED

Current Source

Flash:11.35mA~1.5A,128 levels

11.72mA/level

Torch:2.55mA~372mA,128 levels

2.91mA/level

Flash Timeout:40ms~1.6s,16 levels

Flash/Torch/IR Mode

Optimized Flash LED Current During Low Battery

Conditions (IVFM)

fi

d

The AW3644 are controlled via an I2C - compatible

interface. The main features of the AW3644

include: flash/torch current, flash timeout duration,

IVFM, TX interrupt, and NTC thermistor monitor.

The AW3644 also provides hardware flash and

hardware torch pins (STROBE and TORCH/TEMP)

to control Flash/Torch events.

Hardware Strobe Enable (STROBE)

Hardware Torch Enable (TORCH/TEMP)

Synchronization Input for RF Power Amplifier

Pulse Events (TX)

The 2MHz or 4MHz switching frequency options,

overvoltage protection (OVP), and adjustable

current limit allow for the use of tiny, low-profile

inductors and 10-µF ceramic capacitors. The

device operates over a –40°C to +85°C ambient

temperature range.

o

400kHz I2C:AW3644(I2C Address=0x63)

n

Remote NTC Monitoring

C

0.4mm Pitch,CSP-12 Package

Compatible with AW3643, AW36413, AW36414

APPLICATION

The AW3644 is available in small 0.4mm pitch

1.626mm×1.332mm CSP-12 package.

ic

Smartphone Camera Flash

L 1μH 3A

VIN

CIN

10μF

10V

w

in

TYPICAL APPLICATION CIRCUIT

IN

SW

OUT

COUT

10μF

10V

AW3644CSR

a

TORCH/TEMP

LED1

STROBE

HWEN

TX

SDA

SCL

MCU

Flash

LED

LED2

GND

Fig 1

D1

Flash

LED

D2

Typical Application Circuit of AW3644

All trademarks are the property of their respective owners.

www.awinic.com.cn

1

Copyright © 2016 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

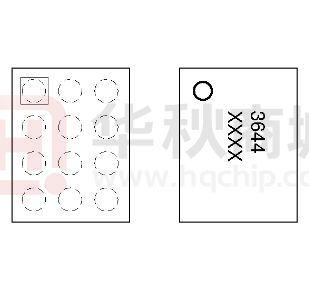

PIN CONFIGURATION AND TOP MARK

AW3644CSR Pin Configuration

(Top View)

SW

STROBE

SCL

C

OUT

HWEN

TORCH

/TEMP

D

LED2

TX

LED1

1

2

3

Pin Configuration and Top Mark

C

PIN DEFINITION

No.

NAME

TYPE

A1

GND

Ground

A2

IN

A3

SDA

I/O

Serial data input/output of the I2C interface.

B1

SW

Power

Switch pin of the step-up DC-DC convertor.

DESCRIPTION

Ground

Input voltage connection. Connect IN to GND with a 10µF or larger ceramic

capacitor.

ic

in

Power

STROBE

I/O

Active high hardware flash enable. Drive STROBE high to turn on Flash pulse.

Internal pull down resistor of 300kΩ between STROBE and GND.

SCL

I/O

Serial clock input of the I2C interface.

C1

OUT

Power

Step-up DC-DC converter output. Connect a 10µF ceramic capacitor between

OUT and GND.

C2

HWEN

I/O

Active high enable pin. High = Standby, Low = Shutdown/Reset. Internal pull

down resistor of 300kΩ between HWEN and GND.

C3

TORCH/TEMP

I/O

Torch terminal input or threshold detector for NTC temperature sensing and

current scale back.

D1

LED2

Power

D2

TX

I/O

D3

LED1

Power

B2

w

B3

a

3644–AW3644CSR

XXXX–Manufacture Tracking Code

o

Fig 2

n

B

e

SDA

fi

d

IN

n

GND

3644

XXXX

A

ti

a

l

AW3644CSR Top Mark

(Top View)

www.awinic.com.cn

High-side current source output for flash LED2.

Power amplifier synchronization input. Internal pull down resistor of 300kΩ

between TX and GND.

High-side current source output for flash LED1.

2

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

ORDERING INFORMATION

Part

Number

Package

Marking

-40°C~85°C

1.626mm×1.332mm

CSP-12

3644

XXXX

Moisture

Sensitivity

Level

MSL1

Environmental

Information

ROHS+HF

Delivery Form

3000 units/

Tape and

Reel

ti

a

l

AW3644

CSR

Temperature

AW3644

Shipping

R: Tape & Reel

n

Package Type

e

CS: CSP

Description

Package

AW3644

2

Boost

High Efficiency, Dual Independent 1.5A Flash LED

Driver

CSP-12

AW36414

2

Boost

High Efficiency, Dual Independent 1.5A Flash LED

Driver

CSP-12

AW3643

2

Boost

High Efficiency, Dual 1.5A Flash LED Driver

CSP-12

AW36413

2

Boost

High Efficiency, Dual 1.5A Flash LED Driver

CSP-12

AW3648

1

Boost

High Efficiency, 1.5A Flash LED Driver

CSP-12

AW3642

1

Boost

High Efficiency, 1.5A Flash LED Driver

CSP-9

1

Charge

Pump

Flash Current & Flash Timer Programmable 1A Flash

LED Driver

ic

in

AW3641E

n

Type

o

Channels

C

Product

fi

d

AWINIC FLASH LED DRIVER SERIES

DFN-10L

1

Current

Sink

200mA 1-wire Configurable Front Flash LED Driver

with Ultra Small Package

DFN-6L

AW36404

1

Current

Sink

400mA 1-wire Configurable Front Flash LED Driver

with Ultra Small Package

DFN-8L

1

Current

Sink

600mA PWM Configurable Front Flash LED Driver

with Ultra Small Package

DFN-8L

w

AW36402

a

AW36406

www.awinic.com.cn

3

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

TYPICAL APPLICATION CIRCUITS

L 1μH 3A

VIN

CIN

10μF

10V

IN

SW

AW3644CSR

TORCH/TEMP

LED1

STROBE

HWEN

TX

SDA

SCL

Flash

LED

D2

fi

d

Fig 3

D1

n

LED2

GND

e

MCU

Flash

LED

ti

a

COUT

10μF

10V

l

OUT

AW3644 Application Circuit

n

Notice for Typical Application Circuits:

Please place CIN,COUT as close to the chip as possible.

2:

Connect the inductor on the top layer close to the SW pin.

o

1:

a

w

in

ic

C

3: For the sake of driving capability, the power lines, output lines, and the connection lines of L and LED

should be short and wide as possible.

www.awinic.com.cn

4

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

ABSOLUTE MAXIMUM RATINGS(NOTE1)

Unit

-0.3 to 6

V

HWEN, SCL, SDA, STROBE, TORCH/TEMP, TX

−0.3 to (VIN+0.3)

V

Continuous power dissipation

Internally limited

IN, SW, OUT, LED1, LED2

Max Junction Temperature TJMAX

155

Storage Temperature TSTG

-65 to 150

260

Junction to Ambient Thermal Resistance θJA

79.2

n

Maximum lead temperature (soldering)

±2000

HBM

e

ESD, All Pins(NOTE2)

±1500

CDM

+IT:+200

fi

d

Latch-Up (Test method: JEDEC STANDARD NO.78D)

-IT:-200

℃

l

Range

ti

a

PARAMETERS

℃

℃

℃/W

V

V

mA

Junction temperature (TJ)

Range

Unit

2.7 to 5.5

V

-40 to 125

℃

-40 to 85

℃

ic

Ambient temperature (TA)

C

VIN

o

PARAMETERS

n

RECOMMENDED OPERATING CONDITIONS

in

NOTE1: Conditions out of those ranges listed in "absolute maximum ratings" may cause permanent

damages to the device. In spite of the limits above, functional operation conditions of the device should

within the ranges listed in "recommended operating conditions". Exposure to absolute-maximum-rated

conditions for prolonged periods may affect device reliability.

a

w

NOTE2: The human body model is a 100pF capacitor discharged through a 1.5kΩ resistor into each pin.

Test method: MIL-STD-883J Method 3015.9

www.awinic.com.cn

5

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

ELECTRICAL CHARACTERISTICS

Typical limits tested at TA=25 ℃ . Minimum and maximum limits apply over the full operating ambient

temperature range(-40℃≤TA≤85℃). Unless otherwise specified, VIN=3.6V, HWEN= VIN.

Symbol

Description

Test Condition

Min

Typ

Max

Unit

5.5

V

IQ

Quiescent supply current

Device not switching, pass mode

ISB

Standby supply current

Device disabled, HWEN=1.8V

2.5V≤VIN≤5.5V

ISD

Shutdown supply current

Device disabled, HWEN=0V

2.5V≤VIN≤5.5V

UVLO

Under voltage lockout

threshold

Falling VIN

VOUT=4V,

flash code=0x7F=1.5A

Boost Converter Specifications

PMOS switch on-resistance

RNMOS

NMOS switch on-resistance

ICL

Switch current limit

in

w

a

VIVFM

ic

RPMOS

FSW

mA

10

0.1

1

2.5

V

2.6

V

1.5

7%

A

VOUT=4V,

torch code=0x3F=186mA

-10%

186

10%

mA

ON threshold

4.85

5

5.15

OFF threshold

4.75

4.9

5.05

n

o

V

85

mΩ

60

mΩ

Reg 0x07, bit[0]=0

-12%

1.9

12%

Reg 0x07, bit[0]=1

-12%

2.8

12%

Reg 0x07, bit[1]=0

-6%

2

6%

Reg 0x07, bit[1]=1

-6%

4

6%

Reg 0x02, bits[3:1]=”000”

-3%

2.9

3%

V

-6%

50

6%

-6%

0.6

6%

V

A

Switching frequency

Input voltage flash monitor

trip threshold

INTC

NTC current

VTRIP

NTC comparator trip

threshold

C

VOUT over-voltage protect

threshold

0.8

-7%

Current source accuracy

VOVP

3

fi

d

Rising VIN

Current Source Specifications

ILED1/2

0.4

ti

a

2.7

n

Input operating range

e

VIN

l

Vin Supply

MHz

Reg 0x09, bit[3:1]=”100”

Thermal shutdown

threshold

155

℃

TSD

Thermal shutdown

hysteresis

www.awinic.com.cn

20

6

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

Symbol

Description

Test Condition

Min

Typ

Max

Unit

I2C-Compatible Interface Specifications(SCL,SDA)

VIL

Input logic low

0

0.4

V

VIH

Input logic high

1.2

VIN

V

VOL

Output logic low

0.4

V

HWEN, STROBE, TORCH/TEMP, TX Voltage Specifications

VIL

Input logic low

0

VIH

Input logic high

1.2

RPD

Internal pull down resistors

0.4

V

VIN

V

kΩ

a

w

in

ic

C

o

n

fi

d

e

n

300

ti

a

l

ILOAD=3mA

www.awinic.com.cn

7

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

I2C INTERFACE TIMING

Typ

Interface Clock frequency

H

Units

400

kHz

SCL

200

ns

SDA

250

ns

Deglitch time

THD:STA

(Repeat-start) Start condition hold time

0.6

TLOW

Low level width of SCL

1.3

THIGH

High level width of SCL

0.6

TSU:STA

(Repeat-start) Start condition setup time

0.6

THD:DAT

Data hold time

TSU:DAT

Data setup time

TR

Rising time of SDA and SCL

TF

Falling time of SDA and SCL

TSU:STO

Stop condition setup time

TBUF

Time between start and stop condition

s

s

s

s

s

e

0

ti

a

TDEGLITC

Max

n

FSCL

Min

Description

s

0.3

s

0.3

s

0.6

s

1.3

s

o

n

fi

d

0.1

tBUF

tLOW

SCL

tHD:STA

ic

Start

tHIGH

tR

tHD:DAT

VIH

VIL

tSP

tF

VIH

VIL

tSU:DAT

tSU:STA

Start

tSU:STO

Stop

I2C INTERFACE TIMING

Fig 4

a

w

in

Stop

C

SDA

l

Symbol

www.awinic.com.cn

8

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

TYPICAL CHARACTERISTICS

1.4

1.4

1.2

1.2

1

1

0.6

0.8

0.6

0.4

0.4

0.2

0.2

0

0

16

32

48

64

80

96

112

128

0

16

32

LED1 Flash Code (dec#)

96

112

128

fi

d

0.4

0.4

0.36

0.32

n

0.32

0.28

0.2

0.16

0.08

0.04

0

0

16

32

48

64

C

0.12

80

96

112

ILED2 (A)

0.28

0.24

o

ILED1 (A)

80

Fig 6. LED2 Flash Current vs Brightness Code

0.36

0.24

0.2

0.16

0.12

0.08

0.04

0

128

0

16

LED1 Torch Code (dec#)

32

48

64

80

96

112

128

ic

LED2 Torch Code (dec#)

in

Fig 7. LED1 Torch Current vs Brightness Code

0.8

Fig 8. LED2 Torch Current vs Brightness Code

1.6

BRC = 63

BRC = 47

0.6

w

ILED1 (A)

BRC = 23

BRC = 15

BRC = 7

0.3

BRC = 111

BRC = 103

1.3

BRC = 31

0.4

BRC = 119

1.4

BRC = 39

0.5

BRC = 127

1.5

BRC = 55

0.7

ILED1 (A)

64

LED2 Flash Code (dec#)

Fig 5. LED1 Flash Current vs Brightness Code

a

48

e

0

n

0.8

l

1.6

ti

a

1.6

ILED2 (A)

ILED1 (A)

Ambient temperature is 25°C, input voltage is 3.6 V, HWEN = IN, CIN = COUT = 2×10 µF and L=1 µH, unless

otherwise noted .

BRC = 0

BRC = 95

BRC = 87

1.2

BRC = 79

1.1

BRC = 71

1.0

0.2

0.9

0.1

0.8

0.0

0.7

2.5

3

3.5

4

4.5

5

5.5

2.5

3

3.5

4

4.5

5

VIN (V)

VIN (V)

Fig 9. LED1 Flash Current vs Input Voltage

Fig 10. LED1 Flash Current vs Input Voltage

www.awinic.com.cn

9

5.5

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

Typical Characteristics (continued)

Ambient temperature is 25°C, input voltage is 3.6 V, HWEN = IN, CIN = COUT = 2×10 µF and L=1 µH, unless

otherwise noted .

1.6

BRC = 63

BRC = 47

BRC = 31

BRC = 23

BRC = 15

0.4

BRC = 7

0.3

BRC = 111

BRC = 0

BRC = 103

1.3

BRC = 95

1.2

BRC = 87

1.1

BRC = 71

l

BRC = 39

0.5

BRC = 119

1.4

ILED2 (A)

BRC = 79

1.0

0.2

0.9

0.1

0.8

0.0

0.7

2.5

3

3.5

4

4.5

5

5.5

2.5

3

3.5

VIN (V)

5.5

e

fi

d

1.10

1.58

1.08

1.06

1.56

1.04

1.54

ILED (A)

1.52

1.50

1.02

1.00

n

ILED (A)

5

Fig 12. LED2 Flash Current vs Input Voltage

1.60

1.48

0.98

0.96

o

1.46

1.44

1.40

2.5

3

3.5

ILED=1.5A

4

C

1.42

4.5

VIN (V)

fSW=2Mhz

5

0.94

0.92

0.90

2.5

5.5

Flash

ic

0.87

0.85

LED2

0.81

ILED (A)

0.79

w

0.77

0.75

0.73

0.71

0.69

0.67

2.5

3

3.5

ILED=0.747A

4

VIN (V)

fSW=2Mhz

4.5

5

5.5

Flash

Fig 15. LED1 & LED2 Current vs Input Voltage

www.awinic.com.cn

10

3.5

4

4.5

5

5.5

Flash

Fig14. LED1/2 Flash Current vs Input Voltage

LED1

in

0.83

3

VIN (V)

ILED=1.006A fSW=2Mhz

Fig 13. LED1/2 Flash Current vs Input Voltage

ILED (A)

4.5

VIN (V)

Fig 11. LED2 Flash Current vs Input Voltage

a

4

n

ILED2 (A)

0.6

BRC = 127

1.5

BRC = 55

0.7

ti

a

0.8

1.12

1.08

1.04

1.00

0.96

0.92

0.88

0.84

0.80

0.76

0.72

0.68

0.64

0.60

LED1

LED2

2.5

3

3.5

ILED=1.006A

4

VIN (V)

fSW=2Mhz

4.5

5

5.5

Flash

Fig 16. LED1 & LED2 Current vs Input Voltage

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

Typical Characteristics (continued)

3

3.5

ILED=0.372A

4

4.5

VIN (V)

fSW=2Mhz

5

5.5

Torch

4

4.5

VIN (V)

fSW=4Mhz

5

5.5

Torch

e

Fig 18. LED1/2 Torch Current vs Input Voltage

0.25

0.24

0.24

0.23

0.23

0.22

0.22

ILED (A)

0.21

0.20

0.21

0.20

n

ILED (A)

3.5

fi

d

0.25

0.19

0.19

0.18

o

0.18

0.17

0.15

2.5

3

3.5

ILED=0.186A

4

C

0.16

4.5

VIN (V)

fSW=2Mhz

5

0.17

0.16

0.15

5.5

2.5

Torch

ic

3.5

4

4.5

VIN (V)

fSW=4Mhz

5

5.5

Torch

Fig 20. LED1/2 Torch Current vs Input Voltage

0.25

LED1

LED1

0.24

LED2

in

0.45

0.44

0.43

0.42

0.41

0.40

0.39

0.38

0.37

0.36

0.35

0.34

0.33

0.32

0.31

0.30

3

ILED=0.186A

Fig 19. LED1/2 Torch Current vs Input Voltage

LED2

0.23

ILED (A)

0.22

w

ILED (A)

3

ILED=0.372A

Fig 17. LED1/2 Torch Current vs Input Voltage

a

l

2.5

ti

a

2.5

0.45

0.44

0.43

0.42

0.41

0.40

0.39

0.38

0.37

0.36

0.35

0.34

0.33

0.32

0.31

0.30

n

0.45

0.44

0.43

0.42

0.41

0.40

0.39

0.38

0.37

0.36

0.35

0.34

0.33

0.32

0.31

0.30

ILED (A)

ILED (A)

Ambient temperature is 25°C, input voltage is 3.6 V, HWEN = IN, CIN = COUT = 2×10 µF and L=1 µH, unless

otherwise noted .

0.21

0.20

0.19

0.18

0.17

0.16

0.15

2.5

3

3.5

ILED=0.372A

4

VIN (V)

fSW=2Mhz

4.5

5

Torch

Fig 21. LED1 & LED2 Current vs Input Voltage

www.awinic.com.cn

11

5.5

2.5

3

3.5

ILED=0.186A

4

VIN (V)

fSW=2Mhz

4.5

5

5.5

Torch

Fig 22. LED1 & LED2 Current vs Input Voltage

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

Typical Characteristics (continued)

95

90

90

85

85

80

80

75

VLED = 3.1V

VLED = 3.3V

VLED = 3.5V

VLED = 3.8V

VLED = 4.1V

VLED = 4.4V

60

55

50

2.5

3.0

3.5

65

60

55

50

4.0

ILED=1.5A

70

4.5

5.0

2.5

5.5

Flash

4.5

5.0

5.5

VLED=3.5V

fSW=2Mhz

Flash

fi

d

100

95

95

90

90

85

85

80

ηLED (%)

n

80

75

70

o

ηLED (%)

4.0

Fig24. LED Efficiency vs Input Voltage

100

65

55

50

2.5

3.0

3.5

4.0

C

60

4.5

VIN (V)

VLED=3.2V

fSW=2Mhz

ic

ILED=1.006A

5.0

75

70

65

60

55

50

5.5

2.5

Flash

3.5

4.0

4.5

VIN (V)

VLED=3.2V

fSW=4Mhz

5.0

5.5

Flash

Fig26. LED Efficiency vs Input Voltage

100

in

100

3.0

ILED=1.006A

Fig25. LED Efficiency vs Input Voltage

95

95

90

90

85

85

w

80

ηLED (%)

ηLED (%)

3.5

ILED=1.5A

Fig23. LED Efficiency vs Input Voltage

a

3.0

VIN (V)

VIN (V)

fSW=2Mhz

e

65

75

n

70

l

100

95

ti

a

100

ηLED (%)

ηLED (%)

Ambient temperature is 25°C, input voltage is 3.6 V, HWEN = IN, C IN = COUT = 2×10 µF and L=1 µH, unless

otherwise noted .

75

70

80

75

70

65

65

60

60

55

55

50

50

2.5

3.0

ILED=0.372A

3.5

4.0

4.5

VIN (V)

VLED=2.9V

fSW=2Mhz

5.0

Torch

Fig 27. LED Efficiency vs Input Voltage

www.awinic.com.cn

12

5.5

2.5

3.0

ILED=0.186A

3.5

4.0

4.5

VIN (V)

VLED=2.75V

fSW=2Mhz

5.0

5.5

Torch

Fig 28. LED Efficiency vs Input Voltage

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

Typical Characteristics (continued)

4.300

2.125

4.250

2.100

4.200

2.075

4.150

2.050

4.100

2.000

4.050

4.000

1.975

3.950

1.950

3.900

1.925

3.850

3.800

2.5 2.75

3

3.25 3.5 3.75

4

4.25 4.5 4.75

5

2.5 2.75

3

n

1.900

ti

a

2.025

l

2.150

fSW (Mhz)

fSW (Mhz)

Ambient temperature is 25°C, input voltage is 3.6 V, HWEN = IN, CIN = COUT = 2×10 µF and L=1 µH, unless

otherwise noted .

3.25 3.5 3.75

5.0

9

4.5

8

4.0

3.5

7

3.0

ISTB (μA)

n

6

5

4

o

ISTB (μA)

5

Fig 30. 4-Mhz Frequency vs Input Voltage

10

3

1

0

2.5

3

3.5

4

VIN (V)

C

2

4.5

5

2.5

2.0

1.5

1.0

0.5

0.0

2.5

5.5

3.5

4

4.5

HWEN=1.8 V

I2C=1.8 V

5

5.5

I2C=0 V

Fig 32. Standby Current vs Input Voltage

Fig 31. Standby Current vs Input Voltage

3.0

in

3.0

3

VIN (V)

ic

HWEN=1.8 V

2.5

2.0

2.0

ISTB (μA)

2.5

w

ISTB (μA)

4.25 4.5 4.75

fi

d

Fig 29. 2-Mhz Frequency vs Input Voltage

a

4

VIN (V)

e

VIN (V)

1.5

1.5

1.0

1.0

0.5

0.5

0.0

0.0

2.5

3

3.5

4

4.5

5

5.5

2.5

3

3.5

VIN (V)

HWEN=VIN

I2C=VIN

Fig 33. Standby Current vs Input Voltage

www.awinic.com.cn

4

4.5

5

5.5

VIN (V)

13

HWEN=VIN

I2C=0 V

Fig 34. Standby Current vs Input Voltage

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

Typical Characteristics (continued)

2.7

2.9

3.1

3.3

3.5

VIN (V)

fSW=2MHz

ICL=1.9A

ILED=1.5A

3.7

3.9

4.1

4.3

l

2.7

VLED=4.5V

2.9

3.1

ILED=1.5A

3.3

3.5

VIN (V)

fSW=4MHz

ICL=1.9A

3.7

3.9

4.1

4.3

VLED=4.5V

Fig 36. Inductor Current Limit vs Input Voltage

fi

d

Fig 35. Inductor Current Limit vs Input Voltage

3.0

3.0

2.8

2.8

2.6

2.6

2.4

2.4

ICL (A)

n

ICL (A)

ti

a

2.5

e

2.5

2.20

2.16

2.12

2.08

2.04

2.00

1.96

1.92

1.88

1.84

1.80

1.76

1.72

1.68

1.64

1.60

n

2.20

2.16

2.12

2.08

2.04

2.00

1.96

1.92

1.88

1.84

1.80

1.76

1.72

1.68

1.64

1.60

ICL (A)

ICL (A)

Ambient temperature is 25°C, input voltage is 3.6 V, HWEN = IN, CIN = COUT = 2×10 µF and L=1 µH, unless

otherwise noted .

2.2

o

2.0

1.8

C

1.6

1.4

2.5 2.7 2.9 3.1 3.3 3.5 3.7 3.9 4.1 4.3 4.5 4.7 4.9

VIN (V)

fSW=2MHz

ICL=2.8A

ic

ILED=1.5A

in

2.0

1.8

1.6

1.4

2.5 2.7 2.9 3.1 3.3 3.5 3.7 3.9 4.1 4.3 4.5 4.7 4.9

ILED=1.5A

VLED=4.5V

Fig 37. Inductor Current Limit vs Input Voltage

VIN (V)

fSW=4MHz

ICL=2.8A

VLED=4.5V

Fig 38. Inductor Current Limit vs Input Voltage

VOUT (2V/DIV)

VOUT (2V/DIV)

ILED (500mA/DIV)

ILED (500mA/DIV)

IIN (1A/DIV)

IIN (1A/DIV)

a

w

2.2

TIME (500 μs/DIV)

ILED1/2=1006mA

fSW=2Mhz

TIME (500 μs/DIV)

VLED=3.4V

Fig 39. Ramp Up

www.awinic.com.cn

ILED1/2=1006mA

fSW=2Mhz

VLED=3.4V

Fig 40. Ramp Down

14

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

Typical Characteristics (continued)

Ambient temperature is 25°C, input voltage is 3.6 V, HWEN = IN, CIN = COUT = 2×10 µF and L=1 µH, unless

otherwise noted .

TX Signal

VOUT (2V/DIV)

l

VIN (50mV/DIV)

ILED (800mA/DIV)

ti

a

ILED (200mA/DIV)

IIN (500mA/DIV)

IIN (800mA/DIV)

fSW=2Mhz

ILED1=ILED2=746.9mA

VLED=3.18V

f SW=2Mhz

VLED=3.18V

VIVFM=3.2V

e

Fig 41. TX Interrupt

n

TIME (500 μs/DIV)

TIME (2 ms/DIV)

ILED1=ILED2=746.9mA

VIN (50mV/DIV)

ILED (200mA/DIV)

IIN (500mA/DIV)

C

o

IIN (500mA/DIV)

VIN (50mV/DIV)

n

ILED (200mA/DIV)

fi

d

Fig 42. IVFM - Stop and Hold

TIME (500 μs/DIV)

ILED1=ILED2=746.9mA

f SW=2Mhz

VLED=3.18V

VIVFM=3.2V

f SW=2Mhz

VLED=3.18V

VIVFM=3.2V

Fig 44. IVFM - Up and Down

a

w

in

ic

Fig 43. IVFM - Down

TIME (500 μs/DIV)

ILED1=ILED2=746.9mA

www.awinic.com.cn

15

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

DETAILED FUNCTIONAL DESCRIPTION

The AW3644 is a high-power white LED flash driver capable of delivering up to 1.5A in either of the two parallel

LEDs. The device incorporates a 2MHz or 4MHz constant frequency-synchronous current-mode PWM boost

converter and dual high-side current sources to regulate the LED current over the 2.7V to 5.5V input voltage

range.

ti

a

l

The AW3644 PWM DC-DC boost converter switches and boosts the output to maintain at least V HR across

each of the current sources (LED1/2). This minimum headroom voltage ensures that both current sources

remain in regulation. If the input voltage is above the LED voltage + current source headroom voltage, the

device would not switch, but turn the PMOS on continuously (Pass mode). In Pass mode the difference

between (VIN − ILED × RPMOS) and the voltage across the LED is dropped across the current source.

n

The AW3644 has three logic inputs including a hardware Flash Enable (STROBE), a hardware Torch Enable

(TORCH/TEMP, TORCH = default), and a Flash Interrupt input (TX) designed to interrupt the flash pulse during

high battery-current conditions. These logic inputs have internal 300kΩ (typical) pull-down resistors to GND.

fi

d

e

Additional features of the AW3644 include an internal comparator for LED thermal sensing via an external

NTC thermistor and an input voltage monitor that can reduce the Flash current during low V IN conditions. It

also has a Hardware Enable (HWEN) pin that can be used to reset the state of the device and the registers by

pulling the HWEN pin to ground.

a

w

in

ic

C

o

n

Control is done via an I2C-compatible interface. This includes adjustment of the Flash and Torch current levels,

changing the Flash Timeout Duration, and changing the switch current limit. Additionally, there are flag and

status bits that indicate flash current timeout, LED over-temperature condition, LED failure (open/short), device

thermal shutdown, TX interrupt, and VIN under-voltage conditions.

www.awinic.com.cn

16

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

FUNCTIONAL BLOCK DIAGRAM

SW

AW3644

IN

OVP

Thermal Shutdown

Protection

VOVP

IVFM

OUT

OSC

2/4Mhz

ti

a

l

UVLO

Boost Controller

INTC=50uA

n

Current

Limit

NTC

monitor

TORCH/TEMP

TX

Control Logic

/Regsiter

HWEN

SDA

I2C

Interface

LED & OUT

Short Detect

LED2

fi

d

SCL

LED1

e

FB

Select

STROBE

n

GND

FEATURE DESCRIPTION

o

HWEN & I2C INTERFACE

C

AW3644 has a logic input HWEN pin to enable/disable the device. When HWEN is set low, the device goes

into shutdown mode, the I2C interface is disabled and all I2C registers are reset to default. In shutdown mode

the device does not respond to any I2C command. When HWEN is set high, the device goes into standby

mode, the I2C interface is enabled, and the device can respond to I2C command.

ic

There are two kinds of power-up sequences, shown in Figure 45 and Figure 46.

If HWEN is tied to IN pin in application, once IN goes above around VPOR (2.0V), HWEN should stay high for

at least twait=2ms time before any I2C command can be accepted.

in

If HWEN is driven by a GPIO, once HWEN goes from low to high, HWEN should stay high for at least twait=2ms

time before any I2C command can be accepted.

w

HWEN=IN

a

twait ≥2ms

I2C command

Fig 45

www.awinic.com.cn

Power-Up Sequence with HWEN Tied to IN

17

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

IN

HWEN

I2C command

Power-Up Sequence with HWEN Driven by GPIO

n

Fig 46

ti

a

l

twait ≥2ms

e

FLASH MODE

fi

d

In Flash Mode, the LED current sources (LED1/2) provide 128 target current levels from 11.35mA to 1.5A. The

Flash currents are adjusted via the LED1 and LED2 Flash Brightness Registers. Flash mode is activated by

the Enable Register(setting M1, M0 to '11'), or by pulling the STROBE pin HIGH when the pin is enabled

(Enable Register). Once the Flash sequence is activated the current source (LED1/2) ramps up to the

programmed Flash current by stepping through all current steps until the programmed current is reached.

n

When the device is enabled in Flash Mode through the Enable Register, all mode bits in the Enable Register

are cleared after a flash timeout event.

o

TORCH MODE

ic

C

In Torch mode, the LED current sources (LED1/2) provide 128 target current levels from 2.55mA to 372mA on

AW3644. The Torch currents are adjusted via the LED1 and LED2 Torch Brightness Registers. Torch mode

is activated by the Enable Register (setting M1, M0 to '10'), or by pulling the TORCH/TEMP pin HIGH when

the pin is enabled (Enable Register) and set to Torch Mode. Once the TORCH sequence is activated the active

current sources (LED1/2) ramps up to the programmed Torch current by stepping through all current steps

until the programmed current is reached. The rate at which the current ramps is determined by the value

chosen in the Timing Register.

Torch Mode is not affected by Flash Timeout or by a TX Interrupt event.

in

IR MODE

a

w

In IR Mode, the target LED current is equal to the value stored in the LED1/2 Flash Brightness Registers.

When IR mode is enabled (setting M1, M0 to '01'), the boost converter turns on and set the output equal to the

input (pass-mode). At this point, toggling the STROBE pin enables and disables the LED1/2 current sources

(if enabled). The strobe pin can only be set to be Level sensitive, meaning all timing of the IR pulse is externally

controlled. In IR Mode, the current sources do not ramp the LED outputs to the target. The current transitions

immediately from off to on and then on to off.

www.awinic.com.cn

18

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

BOOST

VOUT

PASS

OFF

STROBE

ILED2

M1,M0=‘01’

LED1,LED2=‘11’

STROBE EN=‘1’

M1,M0=‘01’

LED1,LED2=‘10’

STROBE EN=‘1’

IR Mode with Boost

fi

d

e

VOUT

n

Fig 47

M1,M0=‘00’

LED1,LED2=‘10’

STROBE EN=‘1’

ti

a

l

ILED1

STROBE

n

ILED1

ILED2

M1,M0=‘01’

LED1,LED2=‘10’

STROBE EN=‘1’

C

o

M1,M0=‘01’

LED1,LED2=‘11’

STROBE EN=‘1’

Fig 48

M1,M0=‘00’

LED1,LED2=‘10’

STROBE EN=‘1’

IR Mode Pass Only

ic

VOUT

a

w

in

STROBE

ILED1

Flash Timeout Value

ILED2

M1,M0=‘01’

LED1,LED2=‘11’

STROBE EN=‘1’

Timeout

Start

Timeout

Reset

Fig 49

Timeout

Start

Timeout

Reset

Timeout

Start

Timeout Reached

VOUT goes low,

LED1 &LED2 turn off

IR Mode Timeout

SOFT START-UP

Turn on of the AW3644 Torch and Flash modes can be done through the Enable Register. On start-up, when

VOUT is less than VIN the internal synchronous PMOS turns on as a current source and delivers 200mA (typical)

to the output capacitor. During this time the current source (LED) is off. When the voltage across the output

www.awinic.com.cn

19

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

capacitor reaches 2.2 V (typical) the current source turns on. At turn-on the current source steps through each

FLASH or TORCH level until the target LED current is reached. This gives the device a controlled turn-on and

limits inrush current from the VIN supply.

PASS MODE

ti

a

l

The AW3644 starts up in Pass Mode and stays there until Boost Mode is needed to maintain regulation. In

Pass Mode the boost converter does not switch, and the synchronous PMOS turns fully on bringing VOUT up to

VIN − ILED × RPMOS. In Pass Mode the inductor current is not limited by the peak current limit. If the voltage

difference between VOUT and VLED falls below VHR, the device switches to Boost Mode.

POWER AMPLIFIER SYNCHRONIZATION (TX)

e

n

The TX pin is a Power Amplifier Synchronization input. This is designed to reduce the flash LED current and

thus limit the battery current during high battery current conditions such as PA transmit events. When the

AW3644 is engaged in a Flash event, and the TX pin is pulled high, the LED current is forced into Torch Mode

at the programmed Torch current setting. If the TX pin is then pulled low before the Flash pulse terminates,

the LED current returns to the previous Flash current level. At the end of the Flash time-out, whether the TX

pin is high or low, the LED current turns off.

fi

d

The TX input can be disable by setting bit[7] (TX Enable) to a ‘0’ in the Enable Register(0x01).

INPUT VOLTAGE FLASH MONITOR (IVFM)

C

o

n

The AW3644 has the ability to adjust the flash current based upon the voltage level present at the IN pin

utilizing the Input Voltage Flash Monitor (IVFM). The adjustable threshold ranges from 2.9 V to 3.6 V in 100mV

steps as well as adjustable hysteresis, with three different usage modes (Stop and Hold, Down, Up and Down).

The IVFM threshold and hysteresis are controlled by bits[5:3] and bit[2] respectively, in the IVFM

Register(0x02). The Flags2 Register has the IVFM flag bit set when the input voltage crosses the IVFM

threshold value. Additionally, the IVFM threshold sets the input voltage boundary that forces the AW3644 to

either stop ramping the flash current during startup in Stop and Hold Mode, or to actively adjust the LED current

lower in Down Mode, or to continuously adjust the LED current up and down in Up & Down Mode.

Stop and Hold Mode: Stops Current Ramp and holds the level for the remaining flash, If VIN falls below the

IVFM threshold value.

ic

Down Mode: Adjust current down if VIN falls below the IVFM threshold value and stops decreasing once VIN

rises above the IVFM threshold (or plus a hysteresis). The AW3644 will decrease the current throughout the

flash pulse anytime VIN falls below the IVFM threshold, not just once. The flash current will not increase again

until the next flash.

a

w

in

Up & Down Mode: Adjust current down if VIN falls below the IVFM threshold value and adjusts current up if

VIN rise above the IVFM threshold (or plus a hysteresis). In Up & Down mode, the LED current will continually

adjust with the rising and falling of VIN throughout the entire flash pulse.

www.awinic.com.cn

20

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

Flash Event

VIN

T-Filter=4μs

IVFM-Threshold

Target Flash Current

Flash Current with

IVFM Disable

l

Stop & Hold

Mode

ti

a

Flash Current

VIN

n

Hysteresis = 0 or 50mV

IVFM-Threshold

e

Down

Mode

o

Up & Down

Mode

C

Flash Current

IVFM Modes

ic

Fig 50

FLASH TIMEOUT

Hysteresis = 0 or 50mV

n

IVFM-Threshold

fi

d

VIN

T-Filter=4μs

T-Filter=4μs

Flash Current

w

in

The Flash Timeout period sets the maximum time of one flash event, whether a flash stop command is received

or not. The AW3644 has 16 timeout levels ranging from 40ms to 1.6s (see TIMING CONFIGURATION

REGISTER (0X08) for more detail). Flash Timeout applies to both Flash and IR modes, and it continues to

count when the Flash mode is forced into Torch mode during a TX high event. The mode bits are cleared and

bit[0] is set in the Flags1 register(0x0A) upon a Flash Timeout. This fault flag can be reset to '0' by reading

back the Flags1 Register (0x0A), or by setting HWEN to '0', or by setting the SW RESET bit to a '1', or by

removing power to the AW3644.

a

CURRENT LIMIT

When the inductor current limit is reached, the AW3644 terminates the charging phase of the switching cycle

until the next switching period. If the over-current condition persists, the device operates continuously in current

limit. The AW3644 features two selectable inductor current limits(1.9A and 2.8A) that are programmable by

bit[0] in Boost configuration Register(0x07).

Since the current limit is sensed in the NMOS switch, there is no mechanism to limit the current when the

device operates in Pass Mode (current does not flow through the NMOS in pass mode). The mode bits are not

cleared upon a Current Limit event, but a flag bit[3] is set in the Flags1 register(0x0A).

www.awinic.com.cn

21

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

This fault flag can be reset to '0' by reading back the Flags1 Register (0x0A), or by setting HWEN to '0', or by

setting the SW RESET bit to a '1', or by removing power to the AW3644.

NTC THERMISTOR INPUT (TORCH/TEMP)

ti

a

l

The TORCH/TEMP pin, when set to TEMP mode, serves as a threshold detector and bias source for negative

temperature coefficient (NTC) thermistors. When the voltage at TEMP goes below the programmed threshold,

bit[0] is set to a ‘1’, and the AW3644 is placed into standby mode. The NTC threshold voltage is adjustable

from 200 mV to 900 mV in 100-mV steps. The NTC bias current is set to 50µA. The NTC detection circuitry

can be enabled or disabled via the Enable Register. If enabled, the NTC block turns on and off during the start

and stop of a Flash/Torch event.

n

Additionally, the NTC input looks for an open NTC connection and a shorted NTC connection. If the NTC input

falls below 100 mV, the NTC short flag is set(bit[4] in the Flags2 Register), and the AW3644 is forced into

standby mode. If the NTC input rises above 2.3 V, the NTC Open flag is set(bit[3] in the Flags2 Register), and

the AW3644 is forced into standby mode. These fault detections can be individually disabled/enabled via the

NTC Open Fault Enable bit and the NTC Short Fault Enable bit in Temp register(0x09)

e

VIN

VOPEN

TORCH/

TEMP

VTRIP

RNTC

Control

Logic

o

n

VSHORT

fi

d

INTC

Temp Detection Diagram

C

Fig 51

The AW3644 is not available for operation until Flags2 register is cleared. The three NTC fault flags can be

reset to '0' by reading back the Flags2 Register (0x0B), or by setting HWEN to '0', or by setting the SW RESET

bit to a '1', or by removing power to the AW3644.

ic

UNDERVOLTAGE LOCKOUT (UVLO)

w

in

The AW3644 has an internal comparator that monitors the voltage at IN and forces the AW3644 into standby

if the input voltage drops to 2.5 V. If the UVLO monitor threshold is tripped, the UVLO flag bit is set in the

Flags1 Register (0x0A). If the input voltage rises above 2.5 V, the AW3644 is not available for operation until

there is an I2C read of the Flags1 Register (0x0A). Upon a read, the Flags1 register is cleared, and normal

operation can resume if the input voltage is greater than 2.5 V.

VOUT SHORT FAULT

a

The Output Short Fault flag reads back a '1' if the device is active in Flash or Torch mode and the boost output

experiences a short condition. VOUT short condition occurs if the voltage at OUT goes below 2.3V (typ.) while

the device is in Torch or Flash mode. There is a deglitch time of 2.048ms before the VOUT Short flag is valid.

The mode bits are cleared upon an the VOUT short fault. The AW3644 is not available for operation until VOUT

Fault flags is cleared. The VOUT Short Faults can be reset to '0' by reading back the Flags1 Register (0x0A),

or by setting HWEN to '0', or by setting the SW RESET bit to a '1', or by removing power to the AW3644.

LED SHORT FAULT

www.awinic.com.cn

22

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

The LED Short Fault flags read back a '1' if the device is active in Flash or Torch mode and either active LED

output experiences a short condition. An LED short condition is determined if the voltage at LED1 or LED2

goes below 500mV (typ.) while the device is in Torch or Flash mode. There is a deglitch time of 256μs before

the LED Short Fault flag is valid. The mode bits are cleared upon an LED short fault. The AW3644 is not

available for operation until the LED Short Fault flags is cleared. The LED Short Faults can be reset to '0' by

reading back the Flags1 Register (0x0A), or by setting HWEN to '0', or by setting the SW RESET bit to a '1',

or by removing power to the AW3644.

l

OVERVOLTAGE PROTECTION (OVP)

e

n

ti

a

The output voltage is limited to typically 5 V. In situations such as an open LED, the AW3644 raises the output

voltage in order to try and keep the LED current at its target value. When VOUT reaches 5 V (typ.) the

overvoltage comparator trips and turns off the internal NMOS. When VOUT falls below the “VOVP Off Threshold”,

the AW3644 begins switching again. The mode bits are cleared, and the OVP Fault flag is set, when an OVP

condition is present for three rising OVP edges. This prevents momentary OVP events from forcing the device

to shut down. The AW3644 is not available for operation until the OVP Fault flag is cleared. The OVP Fault

can be reset to '0' by reading back the Flags2 Register (0x0A), or by setting HWEN to '0', or by setting the SW

RESET bit to a '1', or by removing power to the AW3644.

fi

d

THERMAL SHUTDOWN (TSD)

a

w

in

ic

C

o

n

When the AW3644 die temperature reaches 155°C, the thermal shutdown detection circuit trips, forcing the

AW3644 into standby and writing a '1' to the Thermal Shutdown Fault flag of the Flags1 Register (0x0A) . The

AW3644 is only allowed to restart after the Thermal Shutdown Fault flag is cleared. The Thermal Shutdown

Faults can be reset to '0' by reading back the Flags1 Register (0x0A), or by setting HWEN to '0', or by setting

the SW RESET bit to a '1', or by removing power to the AW3644. Upon restart, if the die temperature is still

above 155°C, the AW3644 resets the Fault flag and re-enters standby.

www.awinic.com.cn

23

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

PROGRAMMING

CONTROL TRUTH TABLE

MODE0

STROBE EN

TORCH EN

STROBE PIN

TORCH PIN

ACTION

0

0

0

0

X

X

Standby

0

0

0

1

X

Pos edge

Ext Torch

0

0

1

0

Pos edge

X

Ext Flash

0

0

1

1

0

Pos edge

Standalone

Torch

0

0

1

1

Pos edge

0

0

0

1

1

Pos edge

Pos edge

1

0

X

X

X

X

1

1

X

X

X

0

1

0

X

X

0

1

1

X

0

0

1

1

X

ti

a

Standalone Flash

Standalone Flash

n

fi

d

e

X

Pos edge

Int Torch

Int Flash

X

IRLED Standby

X

IRLED Standby

X

IRLED enabled

n

I2C INTERFACE

l

MODE1

Data Validation

C

o

When SCL is high level, SDA level must be constant. SDA can be changed only when SCL is low level.

SDA

Data Line

Stable

Data Valid

Fig 52

Change

of Data

Allowed

Data Validation Diagram

in

ic

SCL

I2C Start/Stop

I2C start: SDA changes form high level to low level when SCL is high level.

a

w

I2C stop: SDA changes form low level to high level when SCL is high level.

SDA

SCL

S/Sr

P

S: START condition

Sr: START Repeated condition

www.awinic.com.cn

24

P: STOP condition

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

Fig 53

Start and Stop Conditions

ACK (Acknowledgement)

ACK means the successful transfer of I2C bus data. After master sends 8bits data, SDA must be released;

SDA is pulled to GND by slave device when slave acknowledges.

ti

a

l

When master reads, slave device sends 8bit data, releases the SDA and waits for ACK from master. If ACK is

send and I2C stop is not send by master, slave device sends the next data. If ACK is not send by master, slave

device stops to send data and waits for I2C stop.

Data Output

by Transmiter

Not Acknowledge(NACK)

Data Output

by Receiver

n

Acknowledge(ACK)

2

1

SCL From

Master

8

9

Clock Pulse for

Acknowledgement

e

START

condition

Acknowledgement Diagram

fi

d

Fig 54

Write Cycle

o

n

One data bit is transferred during each clock pulse. Data is sampled during the high state of the serial clock

(SCL). Consequently, throughout the clock’s high period, the data should remain stable. Any changes on the

SDA line during the high state of the SCL and in the middle of a transaction, aborts the current transaction.

New data should be sent during the low SCL state. This protocol allows a single data line to transfer both

command/control information and data using the synchronous serial clock.

C

Each data transaction is composed of a Start Condition, a number of byte transfers (set by the software) and

a Stop Condition to terminate the transaction. Every byte written to the SDA bus must be 8 bits long and is

transferred with the most significant bit first. After each byte, an Acknowledge signal must follow.

In a write process, the following steps should be followed:

Master device generates START condition. The “START” signal is generated by lowering the

ic

a)

SDA signal while the SCL signal is high.

Master device sends slave address (7-bit) and the data direction bit (r/w = 0).

c)

Slave device sends acknowledge signal if the slave address is correct.

d)

Master sends control register address (8-bit)

Slave sends acknowledge signal

a

w

e)

in

b)

f)

Master sends data byte to be written to the addressed register

g)

Slave sends acknowledge signal

h)

If master will send further data bytes the control register address will be incremented by one after

acknowledge signal (repeat step 6, 7)

i)

Master generates STOP condition to indicate write cycle end

SCL

0

1

2

3

4

5

6

7

8

0

1

2

3

4

5

6

7

8

0

1

2

3

4

5

6

7

8

A6 A5 A4 A3 A2 A1 A0 R/WAck A7 A6 A5 A4 A3 A2 A1 A0 Ack D7 D6 D5 D4 D3 D2 D1 D0

SDA

Start

www.awinic.com.cn

Device Address

Register Address

25

Write Data

Stop

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

I2C Write Timing

Fig 55

Read Cycle

In a read cycle, the following steps should be followed:

Master device generates START condition

b)

Master device sends slave address (7-bit) and the data direction bit (r/w = 0).

c)

Slave device sends acknowledge signal if the slave address is correct.

d)

Master sends control register address (8-bit)

e)

Slave sends acknowledge signal

f)

Master generates STOP condition followed with START condition or REPEAT START condition

g)

Master device sends slave address (7-bit) and the data direction bit (r/w = 1).

h)

Slave device sends acknowledge signal if the slave address is correct.

i)

Slave sends data byte from addressed register.

j)

If the master device sends acknowledge signal, the slave device will increase the control register

address by one, then send the next data from the new addressed register.

k)

If the master device generates STOP condition, the read cycle is ended.

SCL

0

1

2

3

4

5

SDA

A6

A5

A4

A3

A2

A1

……

Using

Repeat start……

RS

2

3

4

5

6

7

8

A0 R/W Ack A7

A6

A5

A4

A3

A2

A1

A0

Ack

7

8

n

1

2

3

4

5

A6

A5

A4

A3

A2

A1

6

7

Register Address

8

0

A0 R/W Ack D7

ic

...

6

D6 …… D1

7

8

D0 Ack

stop

0

1

2

3

4

5

A6

A5

A4

A3

A2

A1

6

7

8

0

A0 R/W Ack D7

Device Address

1

...

6

7

D6 …… D1

D0

Write Data

8

Ack

stop

Fig 56 I2C Read Timing

a

w

S

1

Write Data

Device Address

……

in

1

0

Separated

Read/write

transaction ……

P

0

6

o

Device Address

C

start

fi

d

e

n

ti

a

l

a)

www.awinic.com.cn

26

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

REGISTER CONFIGURATION

REGISTER LIST

Read/Write

Default Value

Chip ID Register

0x00

Read

0x36

Enable Register

0x01

Read/Write

0x80

IVFM Register

0x02

Read/Write

0x01

LED1 Flash Brightness Register

0x03

Read/Write

LED2 Flash Brightness Register

0x04

Read/Write

LED1 Torch Brightness Register

0x05

Read/Write

LED2 Torch Brightness Register

0x06

Read/Write

Boost Configuration Register

0x07

Read/Write

Timing Configuration Register

0x08

Read/Write

Temp Register

0x09

Read/Write

0x08

Flags1 Register

0x0A

Read

0x00

Flags2 Register

0x0B

Read

0x00

Device ID Register

0x0C

Read

0x02

Last Flash Register

0x0D

Read

0x00

ti

a

l

Address(HEX)

0xBF

0x3F

0xBF

n

0x3F

0x09

fi

d

e

0x1A

C

o

n

Register name

REGISTER DETAILED DESCRIPTION

Chip ID Register (0x00)

Bit 7

ic

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

LED2 Enable

0=OFF

(Default)

1=ON

LED1 Enable

0=OFF

(Default)

1=ON

in

Chip ID: “00110110”

Enable Register (0x01)

w

Bit 7

a

TX Pin

Enable

0=Disabled

1=Enabled

(Default)

Bit 6

Strobe Type

0=Level

Triggered

(Default)

1=Edge

Triggered

Strobe

Enable

0=Disabled

(Default)

1=Enabled

Torch/Temp

Pin Enable

0=Disabled

(Default)

1=Enabled

Mode Bits: M1, M0

00=Standby (Default)

01=IR Drive

10=Torch

11=Flash

Note:

In Edge or Level Strobe Mode, it is recommended that the trigger pulse width be set greater than 1ms to ensure

proper turn-on of the device.

IVFM Register (0x02)

www.awinic.com.cn

27

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

RFU

UVLO

Circuitry

0=Disabled

(Default)

1=Enabled

Bit 5

Bit 4

Bit 2

IVFM Levels

000=2.9 V (Default)

001=3.0 V

010=3.1 V

011=3.2 V

100=3.3 V

101=3.4 V

110=3.5 V

111=3.6 V

Bit 1

IVFM

Hysteresis

0=0 mV

(Default)

1=50 mV

Bit 5

Bit 3

Bit 2

Bit 7

Bit 6

Bit 0

(Default)

e

0000000=11.35 mA

……………

0111111=746.9 mA

……………

1111111=1.5 A

Bit 1

n

LED1 Flash Brightness Levels

IFLASH(mA)≈(Brightness Code*11.72mA)+11.35mA

LED2 Flash Brightness Register (0x04)

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

LED2 Flash Brightness Levels

IFLASH(mA)≈(Brightness Code*11.72mA)+11.35mA

n

RFU

Bit 4

ti

a

Bit 6

LED2 Flash Current Override

0=LED2 Flash Current is not set to LED1 Flash

Current

1=LED2 Flash Current is set to LED1 Flash

Current

(Default)

Bit 0

IVFM Mode Selection

00=Disabled

01=Stop and Hold Mode

(Default)

10=Down Mode

11=Up and Down Mode

LED1 Flash Brightness Register (0x03)

Bit 7

Bit 3

fi

d

Bit 6

l

Bit 7

(Default)

C

o

0000000=11.35 mA

……………

0111111=746.9 mA

……………

1111111=1.5 A

LED1 Torch Brightness Register (0x05)

Bit 7

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

LED1 Torch Brightness Levels

ITORCH(mA)≈(Brightness Code*2.91mA)+2.55mA

0000000=2.55 mA

……………

0111111=186 mA (Default)

……………

1111111=372 mA

LED2 Torch Brightness Register (0x06)

w

in

ic

LED2 Torch Current Override

0=LED2 Torch Current is not set to LED1 Torch

Current

1=LED2 Torch Current is set to LED1 Torch

Current

(Default)

Bit 6

a

RFU

www.awinic.com.cn

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

LED2 Torch Brightness Levels

ITORCH(mA)≈(Brightness Code*2.91mA)+2.55mA

0000000=2.55 mA

……………

0111111=186 mA (Default)

……………

1111111=372 mA

28

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

Boost Configuration Register (0x07)

Software

Reset Bit

0=Not Reset

(Default)

1=Reset

RFU

Bit 5

RFU

Bit 4

RFU

Bit 3

LED Pin

Short Fault

Detect

0=Disabled

1=Enabled

(Default)

Bit 2

Bit 1

Boost Mode

0=Normal

(Default)

1=Pass Mode

Only

Boost

Frequency

Select

0=2 MHz

(Default)

1=4 MHz

Bit 5

Bit 4

Torch Current Ramp time

000=No Ramp

001=1 ms (Default)

010=32 ms

011=64 ms

100=128 ms

101=256 ms

110=512 ms

111=1024 ms

Bit 3

Bit 2

Flash Time-out Duration

0000=40 ms

0001=80 ms

0010=120 ms

0011=160 ms

0100=200 ms

0101=240 ms

0110=280 ms

0111=320 ms

1000=360 ms

1001=400 ms

1010=600 ms (Default)

1011=800 ms

1100=1000 ms

1101=1200 ms

1110=1400 ms

1111=1600 ms

Bit 1

Bit 0

Temp Register (0x09)

TORCH

Polarity

0=Active High

(Default)

(Pull-down

Resister

Enabled)

1=Active Low

(Pull-down

Resister

Disabled)

NTC Open

Fault Enable

0=Disabled

(Default)

1=Enabled

Bit 7

w

TX Flag

a

Bit 4

NTC Short

Fault Enable

0=Disabled

(Default)

1=Enabled

Bit 3

Bit 2

Bit 1

TEMP Detect Voltage Thresholds

000=200 mV

001=300 mV

010=400 mV

011=500 mV

100=600 mV (Default)

101=700 mV

110=800 mV

111=900 mV

Bit 0

TORCH/TEM

P Function

Select

0=TORCH

(Default)

1=TEMP

Flags1 Register (0x0A)

in

Bit 5

ic

RFU

Bit 6

o

Bit 7

C

n

fi

d

RFU

Bit 6

Boost

Current Limit

0=1.9A

1=2.8A

(Default)

ti

a

Timing Configuration Register (0x08)

Bit 7

Bit 0

n

Bit 6

l

Bit 7

e

Bit 6

VOUT Short

Fault

Bit 5

LED1 Short

Fault

Bit 4

LED2 Short

Fault

Bit 3

Current Limit

Flag

Bit 2

Thermal

Shutdown

(TSD) Fault

Bit 1

UVLO Fault

Bit 0

Flash TimeOut Flag

Flags2 Register (0x0B)

RFU

Bit 7

Bit 6

RFU

www.awinic.com.cn

Bit 5

RFU

Bit 4

Bit 3

Bit 2

IVFM Trip

Flag

Bit 1

OVP Fault

Bit 0

NTC Short

Fault

NTC Open

Fault

TEMP Trip

Fault

29

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

Device ID Register (0x0C)

Bit 7

RFU

Bit 6

RFU

Bit 5

Bit 4

Bit 3

Device ID

“000”

Bit 2

Bit 1

Bit 0

Silicon Revision Bits

“010”

Last Flash Register (0x0D)

Bit 7

RFU

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

a

w

in

ic

C

o

n

fi

d

e

n

ti

a

The value stored is always the last current value the IVFM detection block set ILED=IFLASH-TARGET*((code+1)/128)

l

www.awinic.com.cn

30

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

APPLICATION INFORMATION

The AW3644 can drive two flash LEDs at currents up to 1.5 A per LED. The 2MHz/4MHz DC-DC boost

regulator allows for the use of small value discrete external components. Below are some peripheral selection

guidelines.

l

OUTPUT CAPACITOR SELECTION

n

ti

a

The AW3644 is designed to operate with a 10µF ceramic output capacitor. When the boost converter is running,

the output capacitor supplies the load current during the boost converter on-time. When the NMOS switch

turns off, the inductor energy is discharged through the internal PMOS switch, supplying power to the load and

restoring charge to the output capacitor. This causes a sag in the output voltage during the on-time and a rise

in the output voltage during the off-time. The output capacitor is therefore chosen to limit the output ripple to

an acceptable level depending on load current and input/output voltage differentials and also to ensure the

converter remains stable.

e

Larger capacitors such as a 22µF or capacitors in parallel can be used if lower output voltage ripple is desired.

To estimate the output voltage ripple considering the ripple due to capacitor discharge (ΔV Q) and the ripple

due to the capacitors ESR (ΔVESR) use the following equations:

VQ

fi

d

For continuous conduction mode, the output voltage ripple due to the capacitor discharge is:

(VOUT VIN ) I LED

VOUT f COUT

V I

I

VESR RESR OUT LED L

VIN

2

n

The output voltage ripple due to the output capacitors ESR is found by:

I L

o

Where

VIN (VOUT VIN )

VOUT f L

C

In ceramic capacitors the ESR is very low so the assumption is that 80% of the output voltage ripple is due to

capacitor discharge and 20% from ESR. Table 1 lists different manufacturers for various output capacitors and

their case sizes suitable for use with the AW3644.

ic

INPUT CAPACITOR SELECTION

w

in

Choosing the correct size and type of input capacitor helps minimize the voltage ripple caused by the switching

of the AW3644 boost converter and reduce noise on the boost converter's input pin that can feed through and

disrupt internal analog signals. In the typical application circuit a 10-µF ceramic input capacitor works well. It

is important to place the input capacitor as close as possible to the AW3644 input (IN) pin. This reduces the

series resistance and inductance that can inject noise into the device due to the input switching currents. Table

1 lists various input capacitors recommended for use with the AW3644.

Table 1 Recommended Input/ Output Capacitors (X5R/X7R Dielectric)

PART NUMBER

VALUE

CASE

VOLTAGE RATING

TDK

C1608JB0J106M

10μF

0603

6.3V

TDK

C2012JB1A106M

10μF

0805

10V

Murata

GRM188R60J106M

10μF

0603

6.3V

Murata

GRM21BR61A106KE19

10μF

0805

10V

a

MANUFACTURER

www.awinic.com.cn

31

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

INDUCTOR SELECTION

I LED VOUT

I L

VIN

I L

where

VIN VOUT VIN

2 f SW L VOUT

And f SW =2 or 4MHz.

n

Table 2 lists various inductors and their manufacturers that work well with the AW3644.

ti

a

I PEAK

l

The AW3644 is designed to use a 0.47µH or 1µH inductor. When the device is boosting (VOUT > VIN) the

inductor is typically the largest area of efficiency loss in the circuit. Therefore, choosing an inductor with the

lowest possible series resistance is important. Additionally, the saturation rating of the inductor should be

greater than the maximum operating peak current of the AW3644. This prevents excess efficiency loss that

can occur with inductors that operate in saturation. For proper inductor operation and circuit performance,

ensure that the inductor saturation and the peak current limit setting of the AW3644 are greater than IPEAK in

the following calculation:

e

Table 2 Recommended Inductors

L

PART NO.

SIZE

ISAT

RDC

TOKO

1μH

DFE201610P-1R0M

2.0 mm x 1.6 mm x 1.0 mm

3.7A

58mΩ

TOKO

0.47μH

DFE201610P-R470M

2.0 mm x 1.6 mm x 1.0 mm

4.1A

32mΩ

Sunlord

1μH

WPN252012H1R0MT

2.5mm × 2.0mm ×1.2mm

3.4A

48mΩ

a

w

in

ic

C

o

n

fi

d

MANUFACTURER

www.awinic.com.cn

32

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

PCB LAYOUT

LAYOUT GUIDELINES

The high switching frequency and large switching currents of the AW3644 make the choice of layout important.

The following steps should be used as a reference to ensure the device is stable and maintains proper LED

current regulation across its intended operating voltage and current range.

ti

a

l

1. Place CIN on the top layer (same layer as the AW3644) and as close to the device as possible. The input

capacitor conducts the driver currents during the low-side MOSFET turn-on and turn-off and can detect

current spikes over 1 A in amplitude. Connecting the input capacitor through short, wide traces to both the

IN and GND pins reduces the inductive voltage spikes that occur during switching which can corrupt the

VIN line.

e

n

2. Place COUT on the top layer (same layer as the AW3644) and as close as possible to the OUT and GND

pin. The returns for both CIN and COUT should come together at one point, as close to the GND pin as

possible. Connecting COUT through short, wide traces reduce the series inductance on the OUT and GND

pins that can corrupt the VOUT and GND lines and cause excessive noise in the device and surrounding

circuitry.

fi

d

3. Connect the inductor on the top layer close to the SW pin. There should be a low-impedance connection

from the inductor to SW due to the large DC inductor current, and at the same time the area occupied by

the SW node should be small so as to reduce the capacitive coupling of the high dV/dT present at SW that

can couple into nearby traces.

o

n

4. Avoid routing logic traces near the SW node so as to avoid any capacitive coupling from SW onto any

high-impedance logic lines such as TORCH/TEMP, STROBE, HWEN, SDA, and SCL. A good approach

is to insert an inner layer GND plane underneath the SW node and between any nearby routed traces.

This creates a shield from the electric field generated at SW.

a

w

in

ic

C

5. Terminate the Flash LED cathodes directly to the GND pin of the AW3644. If possible, route the LED

returns with a dedicated path so as to keep the high amplitude LED currents out of the GND plane. For

Flash LEDs that are routed relatively far away from the AW3644, a good approach is to sandwich the

forward and return current paths over the top of each other on two layers. This helps reduce the inductance

of the LED current paths.

www.awinic.com.cn

33

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

PACKAGE DESCRIPTION

Bottom View

Top View

C

B

A

D

D

E

2

3

ti

a

e2

e3

l

1

n

12×∅0.268±0.020

NOM

0.575

0.195

0.340

0.040

1.626

1.332

0.196

0.400

0

Toleranc e

±0.055

±0.020

±0.025

±0.010

fi

d

Symbol

A

A1

A2

A3

D

E

e1

e2

e3

±0.025

±0.025

NA

NA

NA

n

A

A3

A2

A1

Side View

e

e1

o

Note: All dimensions are in millimeter(mm).

C

LAND PATTERN DATA

0.217

in

ic

0.209

0.8

a

w

0.4

12×∅0.240

0.4

1.2

Note: All dimensions are in millimeter(mm).

www.awinic.com.cn

34

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

TAPE AND REEL INFORMATION

TAPE DIMENSIONS

REEL DIMENSIONS

P1

P0

P2

K0

ti

a

B0

D1

Cavity

l

W

A0

e

n

A0:Dimension designed to accommodate the component width

B0:Dimension designed to accommodate the component length

K0:Dimension designed to accommodate the component thickness

W:Overall width of the carrier tape

P0:Pitch between successive cavity centers and sprocket hole

P1:Pitch between successive cavity centers

P2:Pitch between sprocket hole

D0:Reel width

D1:Reel diameter

fi

d

D0

Q2

Q3

Q4

Q1

Q2

Q1

Q2

Q1

Q2

Q3

Q4

Q3

Q4

Q3

Q4

C

Q1

o

n

QUADRANT ASSIGNMENTS FOR PIN 1 ORIENTATION IN TAPE

Sprocket Holes

User Direction of Feed

a

w

in

ic

Pocket Quadrants

www.awinic.com.cn

35

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

REVISION HISTORY

Date

Change Record

V1.0

April 2016

Product Datasheet V1.0 Released

V1.1

Sep 2016

Added ESD CDM Information

Changed LED1 Flash Brightness Level 0111111 to 746.9mA

Changed LED2 Flash Brightness Level 0111111 to 746.9mA

–page27

–page27

V1.2

Jan 2017

Added Awinic Flash Led Driver Series

–page3

V1.3

May 2017

Added HWEN & I2C Interface Description

V1.4

Jan 2018

Add Moisture Sensitivity Level and Environmental Information.

V1.5

July 2018

1. Updated Absolute Maximum Ratings

2. Updated Tape and Reel Information

V1.6

Sep 2018

1. Updated Feature Description

ti

a

l

Vision

–page3

--page5

--page35

--page 17

a

w

in

ic

C

o

n

fi

d

e

n

–page17

www.awinic.com.cn

36

Copyright © 2018 SHANGHAI AWINIC TECHNOLOGY CO., LTD

�AW3644

September 2018 V1.6

DISCLAIMER

Information in this document is believed to be accurate and reliable. However, Shanghai AWINIC

Technology Co., Ltd (AWINIC Technology) does not give any representations or warranties, expressed or

implied, as to the accuracy or completeness of such information and shall have no liability for the

consequences of use of such information.

ti

a

l

AWINIC Technology reserves the right to make changes to information published in this document, including

without limitation specifications and product descriptions, at any time and without notice. Customers shall

obtain the latest relevant information before placing orders and shall verify that such information is current

and complete. This document supersedes and replaces all information supplied prior to the publication

hereof.

e

n

AWINIC Technology products are not designed, authorized or warranted to be suitable for use in medical,

military, aircraft, space or life support equipment, nor in applications where failure or malfunction of an

AWINIC Technology product can reasonably be expected to result in personal injury, death or severe

property or environmental damage. AWINIC Technology accepts no liability for inclusion and/or use of

AWINIC Technology products in such equipment or applications and therefore such inclusion and/or use is at

the customer’s own risk.

fi

d

Applications that are described herein for any of these products are for illustrative purposes only. AWINIC

Technology makes no representation or warranty that such applications will be suitable for the specified use

without further testing or modification.