0.60

0.70

初版发行

0.92

1.80(MIN)

2.00(MAX)

0.05

d 0.10

8.00±0.10

4.95

0.95

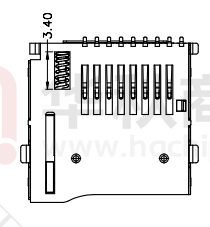

T-Flash

11.00

9.70

2.84

0.30

圳

深

14.75

6.55

8*1.10

c 0.10

子

电

下

韩

市

12.10

0.5°

1°

司

李春风

钟华华

罗孝金

1.60

HX TF PUSH

TF卡座

深圳市韩下电子有限公司

COMPONENT SIDE VIEW(TOLERANCE:+/-0.05)

公

限

有

8.00

1.20

3.00

0.70

RECOMMENDED P.C.B HOLE LAYOUT

2.20

1.20

4.95

1.20

Cd 8 7 6 5 4 3 2 1

1.10

0.60

�深圳市韩下电子有限公司

Shenzhen Hanxia Electronic Co., Ltd

Tel: 0755-33819206

Fax: 0755-27597491

承

书

认

电

产品名称 Project:

有

户 Customer:

子

客

限

公

司

SPECIFICATION FOR APPROVAL

HX TF PUSH

下

规格型号 Part No:

TF卡座

韩

贵公司承认印 Approal slgnatures

签

章/Signatures

深

圳

市

料 号/Part No.

日期 Date:

拟制/Drawn

李春风

审核/Check

钟华华

批准/Approved

罗孝金

�深圳市韩下电子有限公司

1. SCOPE(适用范围)

This product specification defines the product performance and the test methods to ascertain the

performance of the T-FLASH卡座., which is designed and manufactured by Company.

本产品规格书规定了由本公司设计生产的 T-FLASH卡座 连接器产品的特性及测试方法.

2. REFERENCE DOCUMENTS(参考文件)

限

公

司

MIL-STD-1344A Test method for electrical connector (电子连接器测试方法)

MIL-STD-202F Test method for electrical components (电子零件测试方法)

EIA364 Test method for electrical components (电子零件测试方法)

JIS C 0051 Test method for electrical components (电子零件测试方法)

MIL-G-45204C Specification for gold plating (镀金规格)

IEC-512-3 IEC standard for current carrying capacity tests(IEC电流测试标准)

QQ-N-290A Specification for nickel plating (镀镍规格)

MIL-P-81728A Specification for tin/lead plating (镀锡铅规格)

MIL-T-10727B Specification for tin plating (镀锡规格)

UL498 UL standard for safety of attachment plug and receptacle(UL安规要求标准)

EN/ISO5961 Determination of total lead & cadmium content ( 总铅和总镉含量测定)

EN1122 Determination of total lead & cadmium content ( 总铅和总镉含量测定)

EN13346 Determination of heavy metals content ( 重金属含量测定)

EPA3052 Determination of total lead & cadmium content ( 总铅和总镉含量测定)

3.1. PRODUCT DIMENSION (产品尺寸)

有

3. FEATURE & DIMENSIONS (特征及尺寸)

子

These connectors shall have the dimensions as shown in customer drawing。

本产品的相关尺寸参见客户图面。

3.2. PCB/PANEL LAYOUT (印刷电路板布局)

3.3. MATERIAL (材料)

电

The recommended PCB layout is shown in customer drawing。

本产品适用的PCB layout参见客户图面。

下

The harmful material can follow the requirement of RoHS.

本产品使用的材料符合 RoHS 指令要求。

3.4. MECHANICAL & ELECTRICAL CHARACTERISTIC (机械及电气特性)

韩

The connector shall have the mechanical and electrical performance as described in table I:

本产品的机械及电气特性见附表I。

3.5. PACKAGING (包装)

圳

市

Products shall be packaged according to requirements specified in purchase order for safe

delivery. Products required tray or carrier tape should meet the proper specification per

purchase order. Connector container and the packaging specification is shown in customer

drawing。

产品包装可依客户指定要求。本产品采用卷带包装,具体规格见客户图面。

3.6. MARKING(标识)

深

Manufacturer’s name, industry recognized logo, or customer approved marks。

标示制造商的名称,或客户认可的相关标志。

3.7.TRANSPORTATION (运输)

Any vehicle can be adopted for the transportation, but moisture-proof and no mechanical

damage.

可采用任何运输工具运输,勿淋湿及机械性损伤。

3.8.STORAGE (存贮)

Temperature: -40℃~+85℃,Relative humidity: ≤80%,Not to storage in corrosive environments A requalification test shall be conducted immediately while the storage duration exceed 6 months.

温度:-40℃~+85℃;相对湿度:≤80%;勿贮存于腐蚀环境内。贮存期超过6个月后需重新进行 品质确认。

4. ENVIRONMENTAL(环境要求)

4.1. SOLDERABILITY(可焊性)

Connector’s solderability can meet MIL-STD-202F standard. Finish shall be free of contaminants.

产品可焊性符合 MIL-STD-202F 标准规定的相关要求,表面不得有污染物.

�深圳市韩下电子有限公司

4.2. RESISTANCE TO SOLDER HEAT (耐焊接热)

子

有

限

公

司

4.2.1. Wave Soldering (波峰焊)

Consists of three consecutive phases. 包括三个连续的阶段完成;

4.2.1.1. Preheat(预热)

Increase in temperature not to exceed 4℃per second. Final preheat temperature will be within

125℃of solder temperature. 温度增加不超过4℃ /秒,最终预热温度不超过125℃.

4.2.1.2. Soldering(焊接)

Device leads will be exposed to solder wave at 250℃for a maximum of 5 seconds. 设备中

的引导焊接温度最高250℃不超过5秒.

4.2.1.3. Cool Down(冷却)

Cool down in ambient air at approximately 20℃to 25℃. 冷却到周围环境温度20℃~ 25℃. 4.2.2.

INFRARED REFLOW (红外线回流焊)

Three cycles. Each cycle consisting of three consecutive phased. 三个周期,每个周期包括 三个连续

的阶段完成;

4.2.2.1. Preheat(预热)

Increase in temperature not to exceed 4℃ per second. 温度增加不超过4℃ /秒,

4.2.2.2. Soldering(焊接)

Maximum allowable time above reflow temperature of 183 ℃ is 90 seconds. Maximum

temperature in this interval is 260℃, not to exceed 10 seconds. 回流焊温度183℃以上的 时最长不超

过 90秒. 最高温度260℃时间不超过10秒.

4.2.2.3. Cool Down(冷却)

Cool down shall not exceed 6℃ per second. 冷却速度不超过6℃/秒. Note:(注)Device

temperature measurements are referenced from the top-center of the package outer surface. 设备温

度量测时以从顶部中间位置测量为准;

4.3. CLEANING (清洗)

下

电

Connectors resist to cleaning process. Aqueous Cleaning: Three cycles; each cycle consisting

of a maximum of one minute exposure to 54℃ to 66℃ demineralized tap water at a maximum pressure

of 30 psi; followed by air drying for 60℃to 90 seconds at 93℃ to 121℃.

产品本身可以承受清洗制程. 水洗:包含三个循环;每个循环包括以下:以最大压力30帕温度54 ℃ -66℃去除

矿物质的水,用水龙头冲洗一分钟,然后用温度 93℃~121℃的空气吹60到 90秒;

5. PERFORMANCE AND TEST DESCRIPTION (性能及测试)

韩

5.1. REQUIREMENT(要求)

市

Product is designed to meet electrical, mechanical, and environmental performance

requirements specified in Table I.

本产品设计符合附表一所列的机械,电气及环境要求.

5.2. TEST CONDITION (测试条件)

Unless otherwise specified, all tests shall be performed at ambient environmental conditions.

除非特别注明,所有测试在室温条件下完成;

圳

5.3. SAMPLE SELECTION (样品选择)

深

Test samples shall be selected at random from current production. No test samples shall be reused. Samples

are pre-conditioned with 10cycles of durability. Each group shall be containing 5 test samples.

测试样品从现生产的产品中随机抽取,所有测试过的样品不得重复使用. 样品已预先插拔10次, 每组测试有5个

样品;

6. QUALITY ASSURANCE PROVISIONS (品质保证)

Company is responsible for the quality of the part as it is delivered to customer. Failing lots will be return or other

supplier corrective action.

本公司对出给客户的所有产品品质负责,不良批次的产品退回或由供应商做矫正;

�深圳市韩下电子有限公司

1000 mΩ Max. initial

100 mΩ最 大.初态

Connector must withstand test

potential of 500 V AC for 1

minute. Current leakage must

be 1.0 mA max.. 样品必须承受

测试电 500V AC,时间一分钟,

漏电流不大于1.0 mA.

Measure by applying test potential between

the adjacent contacts, and between the

contacts and ground in the mated connector.

MIL-STD-202, Method 301. 测试产品端子间以

及端子与接地间的电压,适用:MIL-STD-202 ,

方法 301 。

深

圳

8. Shock 冲击

9. Thermal shock 热

冲击

Mate and unmate connector for 5000 cycle .

同配合产品进行5000次插拔。

子

电

30°C Max. 不高于30°C

Carry rated current load.0.3A per contact.

(UL498)每根端子负载0.3A 电流。(UL498)

Subject mated connector to 10-55-10 Hz

traversed in 1 minute at 1.5 mm amplitude 2

hours each of 3 mutually perpendicular plane,

10 mA applied MIL-STD-202, Method 201. 对

测试样品,在频率变化每分钟从10-55-10 Hz,

振幅 1.5 mm 条件下,在互相垂直的三个面上,

每个面2 小时下测量,电流 10 mA ;适用:

MIL-STD-202 ,方法 201。

No electrical discontinuity

greater than 1 μsec. shall

occur. No damage to product.

不允许出现超过1 μsec (s) 的

瞬间断开,产品无损坏;

Applying an appropriate holder is allowed in

vibration test and shock test. MIL-STD-202,

Method 213,490m/s2, 3 axes. 使用合适的固定

方式,适用方法. MIL-STD -202,方法213,加

速度490m/s2,三个轴上均做测试。

No electrical discontinuity

greater then 1 μsec (s) shall

occur. Contact resistance:100

mΩmax. 不允许出现超过1 μ

sec (s) 的瞬间断开,接触阻抗:

100 mΩ最大;

市

7.Vibration

Sinusoidal Low

Frequency 低频正弦

振动

Contact Resistance: 100 mΩ

Max. after testing 完成插拨测

试后接触阻抗不大于100 mΩ

公

司

Measure by applying test potential between

the adjacent contacts, and between the

contacts and ground in the mated connector.

MIL-STD-202, Method 302, Condition B (500

V DC±10%). 测试产品端子间以及端子与接地

间的电阻,适用:MIL-STD-202, 方法302,条

件B (500V DC±10%) 。

下

6. Temperature rise

温度急变

Visually, dimensions and functionally

inspected per applicable product drawing.

目视,尺寸及功能依照客户图面检查。

1000 MΩ Min. 1000 MΩ最小

韩

5. Durability (Repeated

Mating/Unmating) 耐

久力

Methods

Subject mated contacts assembled in housing

to closed circuit of 10 mA max. at open circuit

voltage of 20 mV max. 所述固定在外壳里的端

子联结到一个封闭回路中测试:电流10mA,电

压20 mV max.。

3. Insulation

resistance 绝缘阻抗

4. Dielectric Strength

耐电压

Test

限

2. Contact resistance

(Low Level)接触阻抗

Requirements

Product shall be conforming to

the requirements of applicable

product drawing.

产品必须满足相关文件的规定

有

Items

1.Confirmation of

Product 产品确认

No damage, Contact

Resistance (Low Level) (Final)

100 mΩmax. 产品无损坏,接触

阻抗:100 mΩ最大

No damage, Contact Resistance

(Low Level) (Final) 100 mΩmax..

Dielectric Strength should be OK,

Insulation Resistance should

10. Humidity 恒温恒湿

be 100 MΩ min. 产品无损坏,

接触阻抗:100 mΩ最大;耐电

压测试OK, 绝缘阻抗100MΩ最

小;

Temperature range from -55°C to +85°C .Start

from -55°C. After 30 min. change to +85°C,

change time is no more than 30 seconds.

Total 5 cycles. MIL-STD-202, Method

107D,condition A. 温度变化范围: -55°C~

+85°C ;从 -55°C 开始,30 分钟后换到

+85°C ;转换时间不超过30 秒;共5 个循环。

适用:MIL-STD-202 ,方法107D ,条件A。

Temperature :40±2°C 96 hours. Relative

humidity: 90-95%; Duration: 96 Hours.

MIL-STD-202, Method 103, 温度:40±2°C

96 小时;相对湿度:90-95% ;时间:96 小

时;MIL-STD-202 ,方法103。

�深圳市韩下电子有限公司

Items

Requirements

14.High temperature

高温

Contact resistance: 100 mΩ

max. 接触阻抗100 mΩmax.

电

Reference

tsoak

t1

t2

t3

Tpeak

Specification

2.5°C/s

2-3 minutes

60 s

50 s

5s

255°C (+5/-0°C)

Max -5°C/s

深

圳

市

韩

下

Subject product to 85±2°C for 96 hours

continuously. MIL-STD-202, Method 108. 产

品置于85 ±2°C 连续96 小时,适用

MIL-STD-202, 方法108。

子

REFLOW SOLDERING PROFILE

Pb-free reflow profile requirements:

Parameter

Average temperature gradient in

preheating

Soak time

Time above 217°C

Time above 230°C

Time above 255°C

Peak temperature in reflow

Temperature gradient in cooling

司

Contact Resistance (Low

Level) (Final) 100 mΩmax. 接

触阻抗(末态) 100 mΩmax.

Leave subject product in the 255±5°C

chamber for 2 minutes. 产品置于255±5°C 烘

箱内2 分钟。

5±1% salt concentration 24±4 hours 35±

2°C MIL-STD-202, Method 101 Condition B.

盐水浓度(重量比)5±1%,镀金区域时间24

小时,镀锡区域时间8小时。温度35±2°C;

MIL-STD-202,方法101 ,条件B。

有

13. Salt Spray 盐雾

Soldering time: 3 to 5 Seconds Temperature:

255±5°C. 焊接时间:3~5 秒,温度:255±

5°C。

公

12.Resistance to

soldering heat 耐焊

接热

Methods

限

11.Solderability 可焊

性

Test

Appearance of the specimen

shall be inspected after the test

with the assistance of a

magnifier capable of giving a

magnification of 10 X for any

damage such as pinholes, void

or rough surface. 样品在测试完

成后,用放大倍数为10 倍的显

微镜,检查外观损坏如:小孔,

空焊,外观粗糙度;

No damage 产品无损坏

This profile is the minimum requirement for evaluating soldering heat resistance of

components. Heat transfer method used for reflow soldering is hot air convection. The

actual air temperatures used to achieve the specified profile is higher and largely

dependent on the reflow equipment.

�

很抱歉,暂时无法提供与“HX TF PUSH”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 10+0.42406

- 100+0.33541

- 300+0.29109

- 1000+0.24676

- 5000+0.22018

- 10000+0.20685