TJ-L3FYTXHMCYLC2R7K-A5 数据手册

TAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

GUANGDONG TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

承 認 書

Specification For Approval

Customer: (客戶)

Description: (產品描述) 3MM圓頭紅普綠雙色共陽霧狀

Part number:(產品型號) TJ-L3FYTXHMCYLC2R7K-A5

Date:

(日期)

Approved By: (客戶承認)

Prepared By:(我司承認)

Approval

核准

Check

Design

審核

製作

Sales

業務

Customer Service Hotline:400-676-8616

TEL:0769-8662 5999

0769-8200 2226

E-MIAL∶dg@togialed.com

FAX:0769-8200 2227

WEB:www.togi aled. c om

�TAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

GUANGDONG TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

Features :

* Low power consumption

* Small efficiency.

* Versatile mounting on p.c board or panel.

* I.C compatible/ low current requirement.

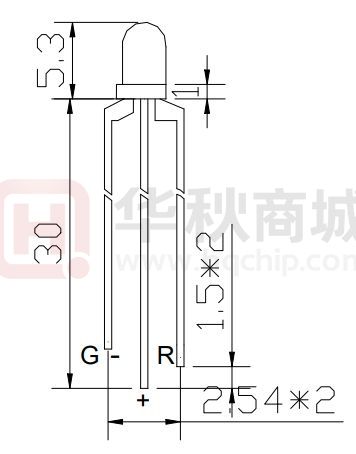

* Package Dimensions:

Unit : mm

+

G -

R

+

0.5 pin*3

Note:

1:All dimensions are in millimeters (inches).

2:Tolerance is ±0.25mm (.010”) unless otherwise noted.

3: Specifications are subject to change without notices.

2/9

-

�TAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

GUANGDONG TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

Absolute Maximum Ratings at Ta=25℃

℃

Parameter

Rating

Unit

144

mW

Peak Forward Current(1/10 Duty Cycle 0.1ms

pulse Width

100

mA

Forward Current(IF)

20

mA

Reverse Voltage(VR)

5

V

Power Dissipation(Pd)

Operating Temperature Range

-20℃ ~ +80℃

Storage Temperature Range

-30℃ ~ +100℃

Lead Soldering Temperature(4.0mm Form

Body

260℃ for 5 Seconds

Electronical / Optical Charateristics at Ta=25℃

℃ `

参

Max

Unit

Test

Condition

-----

100

mcd

If=20mA

20

-----

50

mcd

If=20mA

Red

620

-----

630

nm

If=20mA

Green

565

-----

575

nm

If=20mA

Red

1.8

-----

2.6

V

If=20mA

Green

1. 8

-----

2.6

V

If=20mA

5

µA

Vr=5V

数

Luminous Intensity(IV)

The wavelength

Forward Voltage(VF)

Reverse Current(IR)

Min

Tvo

Red

50

Green

-----

-----

Selection Guide :

Lens color

White Diffused

Chip

Material

Emittedcolor

λp(nm )

AlGaInP

Red

630

AlGaInP

Green

575

3/9

�TAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

GUANGDONG TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

Selection Guide

10°

0°

20°

30°

光 谱 分布 特 性 曲线

Relative Spectral Distribution

1. 2

1. 0

40°

0. 8

1.0

50°

0. 6

60°

0. 4

0.8

70°

0. 2

80°

0

350

400

450

500

550

600

650

700

90°

750

0

0.5

波 长( Wavelength ) (nm )

SPATIAL DISTRIBUTION

2.5

Luminous Intensity

Relative Volue at IF=20mA

Forward Current(mA)

50

40

30

20

10

0

2.0

1.5

1.0

0.5

0

1.5

1.7

1.9

2.1

2.3

2.5

0

10

20

30

40

50

Forward Voltage(V)

IF-Forward Current(mA)

FORWARD CURRENT Vs.

FORWARD VOLTAGE

LUMINOUS INTENSITY Vs.

FORWARD CURRENT

Relative Luminous Intensity

50

Forward Current(mA)

相 对 光 强 ( Relativ e Lu mino us In ten s ity ) ( % )

Typical Electrical/Optical Characteristics Curves(25℃ Ambient Temperature Unle

40

30

20

10

2.5

2.0

1.5

1.0

0.5

0

0

0

20

40

60

80

-40

100

Ambient Temperature(° C)

-20

0

20

40

60

Ambient Temperature(° C)

FORWARD CURRENT

DERATING CURVE

LUMINOUS INTENSITY Vs.

AMBIENT TEMPARATURE

4/9

80 90

�TAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

GUANGDONG TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

Selection Guide

10°

0°

20°

30°

光 谱 分布 特 性 曲线

Relative Spectral Distribution

1. 2

1. 0

40°

0. 8

1.0

50°

0. 6

60°

0. 4

0.8

70°

0. 2

80°

0

350

400

450

500

550

600

650

700

90°

750

0

0.5

波 长( Wavelength ) (nm )

SPATIAL DISTRIBUTION

2.5

Luminous Intensity

Relative Volue at IF=20mA

Forward Current(mA)

50

40

30

20

10

0

2.0

1.5

1.0

0.5

0

1.5

1.7

1.9

2.1

2.3

2.5

0

10

20

30

40

50

Forward Voltage(V)

IF-Forward Current(mA)

FORWARD CURRENT Vs.

FORWARD VOLTAGE

LUMINOUS INTENSITY Vs.

FORWARD CURRENT

Relative Luminous Intensity

50

Forward Current(mA)

相 对 光 强 ( Relativ e Lu mino us In ten s ity ) ( % )

Typical Electrical/Optical Characteristics Curves(25℃ Ambient Temperature Unle

40

30

20

10

2.5

2.0

1.5

1.0

0.5

0

0

0

20

40

60

80

-40

100

Ambient Temperature(° C)

-20

0

20

40

60

Ambient Temperature(° C)

FORWARD CURRENT

DERATING CURVE

LUMINOUS INTENSITY Vs.

AMBIENT TEMPARATURE

5/9

80 90

�TAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

GUANGDONG TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

Labe

P/N: The product model

IV: Luminous intensity rank

VF: Forward voltage rank

TC: Color temperature

Q`T: number

QC: Production order

The packing

Desiccant

Aluminum moisture-proof bag

The cardboard

Package specification:

Package Method: packaged in anti-static bag White:Packaged in sorted light and color

1000pcs/bag

note:

General light 1000pcs/bag

Package specification mentioned above is under normal circumstance. Specific

demand can be negotiated

6/9

�TAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

GUANGDONG TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

Supporter shaping:

Shaping of the supporter must be conducted before welding. While shaping, the bending

position of the supporter must at least be located at 3mm from the bottom of the

encapsulating resin. Also, avoid multiple bending on the same position。Please choose the

appropriate apparatus to fixate the supporter in order to avoid exerting extra pressure on

resin. Using the jointing section of the pin and resin as fulcrum is strictly prohibited since

the pressure mounted would directly damage the internal 。illuminating structure and thus

cause irreversible defection of the product..Due to the same reason, the interval between

the welding hole on the PCB board should be strictly matched with the pin interval of the

product when assembling the product.

7/9

�TAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

GUANGDONG TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

Reliability experiment items and conditions

Serial

number

1

Sample

quantity

Acceptance/rejection

20

0/1

20

0/1

-40℃- +100℃

20min 10s 20min

Testing time;100 cycle

20

0/1

High temperature;100℃

20

0/1

20

0/1

-40℃-- +100℃

60min 20min 60min

Testing time;20 A cycle

20

0/1

260℃(Max), The biggest not

more than 5 seconds

20

0/1

Testing project Test conditions

Life test

Test current;20MA

temperature;25℃

Testing time;1000 hours

2

3

High

temperature

high humidity

(static test)

Cold and hot

impact

temperature;=+65℃

humidity;90% RH

Testing time;240 hours

High temperature

4

storage

Testing time;1000 hours

5

6

7

Low temperature

Low temperature;-40℃

storage

Testing time;1000 hours

temperature

cycle

Reflow

soldering

note

Reliability experiment unqualified decision criteria

IV; Attenuation of more than 30% VF; Change more than 20% ;

1. The same project experimental results of the test must be completed within two hours

2. Testing must be in every experiment is completed. Material return to normal conditions to carry out

8/9

�TAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

GUANGDONG TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

ESD protective

1 Electrostatic generation

1;Friction: in the daily life. Any two different material object contact after the

separation, can produce a staticelectric,Static electricity and the most

common method,Is triboelectrification。The insulation material, the better,More

letEasy triboelectrification。In addition,Any two different material object contact

after separation,Can also produce electrostatic。

2. Induction: in view of the conductive material is concerned, because the

surface of the electronic can free flow, such as placed it in electric

fieldbecauseGay repellent,Opposites attract,Are negative ions will transfer,

In its surface can produce charge。

3. Transmission: in view of the conductive material is concerned, because the

surface of the electronic can free flow,If charged object contact, will be

charge transfer.

4. The harm of static electricity LED:

.1 For the moment's electric field or the heat generated by the current,Make LED

localinjury,For the performance of the leakage current increase quickly,Can

stillwork,But the brightness is reduced (white light will change color), life is

damaged。

5 Because the electric field or current failure LED insulating layer,Make device can't work

(destroyed),Performance for die lamp。

6;Electrostatic protection and elimination measures:

a.

For the whole process (production, testing, packaging, etc.) All LED directly contact member

must do it well Prevent and Eliminate electrostatic measures, basically have: workshop laid

anti-static floor and well grounded。

b. Table for esd workstation, the production of the good earth

c. Operator wear anti-static clothing, with wrist strap, gloves or foot ring。

d. Application of ion fan, welding solder iron well grounding measures。

e. The package antistatic material

9/9

�

TJ-L3FYTXHMCYLC2R7K-A5 价格&库存

很抱歉,暂时无法提供与“TJ-L3FYTXHMCYLC2R7K-A5”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 10+0.27200

- 50+0.25160

- 200+0.23460

- 600+0.21760

- 1500+0.20400

- 3000+0.19550

- 国内价格

- 10+0.43144

- 100+0.35263

- 300+0.31324

- 1000+0.24430

- 5000+0.22069

- 10000+0.20879