AS3930

Single Channel Low Frequency

Wakeup Receiver

General Description

The AS3930 is a single-channel low power ASK receiver that is

able to generate a wake-up upon detection of a data signal

which uses a LF carrier frequency between 110 - 150 kHz. The

integrated correlator can be used for detection of a

programmable 16-bit wake-up pattern.

The AS3930 provides a digital RSSI value, it supports a

programmable data rate. The AS3930 offers a real-time clock

(RTC), which is either derived from a crystal oscillator or the

internal RC oscillator.

The programmable features of AS3930 enable to optimize its

settings for achieving a longer distance while retaining a

reliable wake-up generation. The sensitivity level of AS3930 can

be adjusted in presence of a strong field or in noisy

environments. The device is available in a 16-pin TSSOP and a

16-LD QFN (4x4) package.

Ordering Information and Content Guide appear at end of

datasheet.

Key Benefits & Features

The benefits and features of AS3930, Single Channel Low

Frequency Wakeup Receiver are listed below:

Figure 1:

Added Value of Using AS3930

Benefits

Features

Enables low power active tags

Single channel ASK wake-up receiver

Selectable carrier frequency

Carrier frequency range 110 – 150 kHz

Highly resistant to false wake-ups

16-bit programmable wake-up pattern

Improved immunity to false wake-ups

Supporting doubling of wake-up pattern

Allows frequency only detection

Wake-up without pattern detection selectable

Improved range with best-in-class sensitivity

Wake-up sensitivity 100μVRMS (typ.)

Adjustable range

Sensitivity level adjustable

Provides tracking of false wake-ups

False wake-up counter

Ensures wake-up in a noise environment

Periodical forced wake-up supported (1s – 2h)

Extended battery life

Current consumption in listening mode 1.37 μA (typ.)

Flexible clock configuration

RTC based 32 kHz XTAL, RC-OSC, or external clock

ams Datasheet

[v1-62] 2014-Nov-27

Page 1

Document Feedback

�AS3930 − General Description

Benefits

Features

Operates from a 3V battery

Operating supply range 2.4V – 3.6V (TA = 25°C)

Industrial temperature range

Operation temperature range -40°C to +85°C

Applications

The AS3930, Single Channel Low Frequency Wakeup Receiver

is ideal for Active RFID tags, real-time location systems, operator

identification, access control, and wireless sensors.

Figure 2:

AS3930 Typical Application Diagram with Crystal Oscillator

VCC

CL

CBAT

VCC

CS

XIN

TRANSMITTER

TX

Page 2

Document Feedback

Transmitting Antenna

XTAL

XOUT

DAT

LF1P

NC

WAKE

AS3930

SCL

NC

SDO

LFN

SDI

VSS

GND

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − General Description

Figure 3:

AS3930 Typical Application Diagram without Crystal Oscillator

VCC

VCC

CS

CBAT

TRANSMITTER

TX

Transmitting Antenna

XIN

XOUT

DAT

LF1P

WAKE

AS3930

NC

SCL

NC

SDO

LFN

SDI

VSS

GND

Figure 4:

AS3930 Typical Application Diagram with Clock from External Source

VCC

CBAT

External Clock

VCC

CS

R

XIN

C

TX

ams Datasheet

[v1-62] 2014-Nov-27

Transmitting Antenna

XOUT

TRANSMITTER

DAT

LF1P

NC

AS3930

WAKE

SCL

NC

SDO

LFN

SDI

VSS

GND

Page 3

Document Feedback

�AS3930 − Pin Assignments

Pin Assignments

16-pin TSSOP

Figure 5:

Pin Diagram (Top View)

CS

1

16

NC

SCL

2

15

DAT

SDI

3

14

WAKE

SDO

4

13

VSS

VCC

5

12

XOUT

GND

6

11

XIN

NC

7

10

LFN

NC

8

9

AS3930

LF1P

Figure 6:

Pin Description

Pin Number

Pin Name

1

CS

2

SCL

3

SDI

4

SDO

5

VCC

Pin Type

Description

Chip select

Digital input

SDI interface clock

SDI data input

Digital output / tristate

SDI data output (tristate when CS is low)

Positive supply voltage

Supply pad

6

GND

7

NC

8

NC

9

LF1P

10

LFN

Negative supply voltage

-

Not Connected

Input antenna

Antenna ground

Analog I/O

11

XIN

Crystal oscillator input

12

XOUT

Crystal oscillator output

13

VSS

14

WAKE

Supply pad

Substrate

Wake-up output IRQ

Digital output

15

DAT

16

NC

Page 4

Document Feedback

Data output

-

Not connected

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Pin Assignments

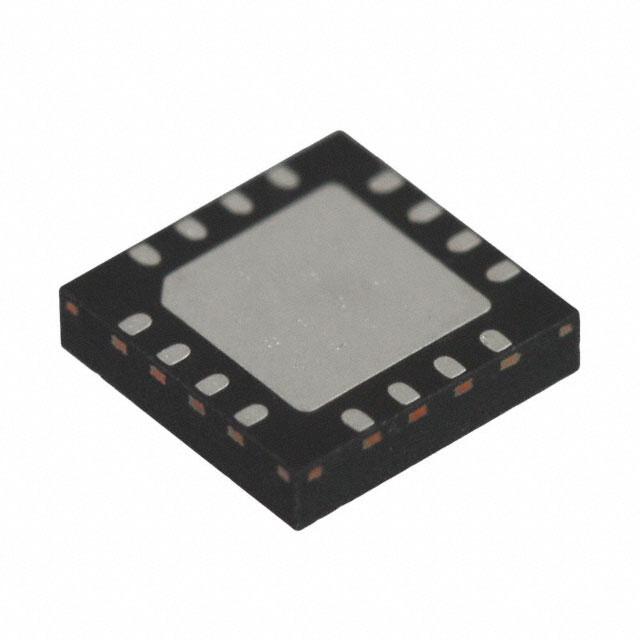

QFN 4x4 16 LD

��

��

�

���

���

���

���

Figure 7:

Pin Diagram (Top View)

�

�

�

�

�

���

��

������

��

���

�

�

��

�

�

�

VSS

�

��

�

��

��

�

����

�

Figure 8:

Pin Description

Pin Number

Pin Name

Pin Type

Description

1

NC

-

2

NC

-

3

LF1P

Input antenna

4

LFN

Antenna ground

5

XIN

6

XOUT

7

VSS

8

WAKE

Not connected

Analog I/O

Crystal oscillator input

Crystal oscillator output

Supply pad

Substrate

Wake-up output IRQ

Digital output

9

DAT

10

NC

11

CS

12

SCL

13

SDI

14

SDO

15

VCC

Data output

-

Not connected

Chip select

Digital input

SDI interface clock

SDI data input

Digital output / tristate

SDI data output (tristate when CS is low)

Positive supply voltage

Supply pad

16

ams Datasheet

[v1-62] 2014-Nov-27

GND

Negative supply voltage

Page 5

Document Feedback

�AS3930 − Absolute Maximum Ratings

Stresses beyond those listed in Absolute Maximum Ratings may

cause permanent damage to the device. These are stress ratings

only. Functional operation of the device at these or any other

conditions beyond those indicated in Electrical Characteristics

is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

Absolute Maximum Ratings

Figure 9:

Absolute Maximum Ratings

Parameter

Min

Max

Unit

Note

Electrical Parameters

DC supply voltage (VDD)

-0.5

5

V

Input pin voltage (VIN)

-0.5

5

V

Input current (latch up immunity)

(ISOURCE)

-100

100

mA

Norm: Jedec 78

Electrostatic Discharge

Electrostatic discharge (ESD)

±2

kV

Norm: MIL 883 E method 3015 (HBM)

Continuous Power Dissipation

Total power dissipation

(all supplies and outputs)

(Pt)

0.07

mW

Temperature Ranges and Storage Conditions

Storage temperature (Tstrg)

-65

150

Package body temperature

(Tbody)

Humidity non-condensing

Moisture Sensitivity Level (MSL)

Page 6

Document Feedback

5

3

°C

260

°C

85

%

Norm: IPC/JEDEC J-STD-020

The reflow peak soldering temperature

(body temperature) is specified according

IPC/JEDEC J-STD-020 “Moisture/Reflow

Sensitivity Classification for Non-hermetic

Solid State Surface Mount Devices”.

Represents a maximum floor life time of

168h

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Electrical Characteristics

Electrical Characteristics

Figure 10:

Electrical Characteristics

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

Operating Conditions

VDD

Positive supply voltage

2.4

3.6

V

VSS

Negative supply voltage

0

0

V

TAMB

Ambient temperature

-40

85

°C

DC/AC Characteristics for Digital Inputs and Outputs

CMOS Input

VIH

High level input voltage

0.58*

VDD

0.7*

VDD

0.83*

VDD

V

VIL

Low level input voltage

0.125*

VDD

0.2*

VDD

0.3*

VDD

V

ILEAK

Input leakage current

100

nA

CMOS Output

VOH

VDD 0.4

High level output voltage

V

With a load current of 1mA

VOL

Low level output voltage

CL

Capacitive load

For a clock frequency of 1 MHz

VSS +

0.4

V

400

pF

Tristate CMOS Output

VOH

VDD 0.4

High level output voltage

V

With a load current of 1mA

VOL

Low level output voltage

IOZ

Tristate leakage current

ams Datasheet

[v1-62] 2014-Nov-27

To VDD and VSS

VSS +

0.4

V

100

nA

Page 7

Document Feedback

�AS3930 − Electrical Characteristics

Figure 11:

Electrical System Specifications

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

Input Characteristics

RIN

Input Impedance

Fmin

Fmax

In case no antenna damper is

set (R1=0)

2

MΩ

Minimum Input

Frequency

110

kHz

Maximum Input

Frequency

150

kHz

Current Consumption

IPWD

Power Down Mode

400

nA

ICHRC

Current Consumption

in standard listening

mode with channel

active all the time and

RC-oscillator as RTC

2.7

μA

ICHOORC

Current Consumption

in ON/OFF mode and

RC-oscillator as RTC

ICHXT

Current Consumption

in standard listening

mode and crystal

oscillator as RTC

IDATA

Current Consumption

in Preamble detection

/ Pattern correlation /

Data receiving mode

(RC-oscillator)

11% Duty Cycle

1.37

50% Duty Cycle

2

μA

With 125 kHz carrier frequency

and 1kbps data-rate.

No load on the output pins.

3.5

5.9

μA

5.3

9

μA

Input Sensitivity

SENS

Input Sensitivity

With 125 kHz carrier frequency,

chip in default mode, 4 half bits

burst + 4 symbols preamble

and single preamble detection

100

μVrms

250

μs

32.768

kHz

Channel Settling Time

TSAMP

Amplifier settling time

Crystal Oscillator

FXTAL

Frequency

Crystal dependent

TXTAL

Start-up Time

IXTAL

Current consumption

Page 8

Document Feedback

1

1

s

μA

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Electrical Characteristics

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

External Clock Source

IEXTCL

Current consumption

μA

1

RC Oscillator (1)

FRCNCAL

If no calibration is performed

27

32.768

42

kHz

FRCCAL32

If calibration with 32.768 kHz

reference signal is performed

31

32.768

34.5

kHz

Frequency

FRCCALMAX

Maximum achievable

frequency after calibration

35

kHz

FRCCALMIN

Minimum achievable

frequency after calibration

30

kHz

TRC

Start-up time

TCALRC

Calibration time

IRC

Current consumption

From RC enable (R1 = 0)

200

1

s

65

Periods

of

reference

clock

nA

Note(s) and/or Footnote(s):

1. RC calibration is only successful after start-up is completed.

ams Datasheet

[v1-62] 2014-Nov-27

Page 9

Document Feedback

�AS3930 − Typical Operating Characteristics

Typical Operating

Characteristics

Figure 12:

Sensitivity over Voltage and Temperature

120

95 oC

100

27 oC

-40 oC

Sensitivity [μVrms]

80

60

40

20

0

2.4

3

3.6

Supply Voltage [V]

Figure 13:

Sensitivity over RSSI

1000000

VIN = 2.4V

100000

Input Voltage [μVrms]

VIN = 1.5V

10000

VIN = 1.0V

1000

100

10

1

2

4

6

8

10 12 14 16 18 20 22 24 26 28 30

RSSI [dB]

Page 10

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Typical Operating Characteristics

Figure 14:

RC-Oscillator Frequency over Voltage (calibr.)

34.5

RC-OSC Frequency [KHz]

34

33.5

33

32.5

32

31.5

31

2.4

2.6

2.8

3

3.2

3.4

3.6

Supply Voltage [V]

Figure 15:

RC-Oscillator Frequency over Temperature (calibr.)

34.5

RC-OSC Frequency [KHz]

34

33.5

33

32.5

32

31.5

31

-36 -30 -20 -10

0

10

20

30

40

50

60

70

80

90

Operating Temperature [oC]

ams Datasheet

[v1-62] 2014-Nov-27

Page 11

Document Feedback

�AS3930 − Detailed Description

The AS3930 is a one-dimensional low power low-frequency

wake-up receiver. The AS3930 is capable of detecting the

presence of an inductive coupled carrier and extract the

envelope of the ON-OFF-Keying (OOK) modulated carrier. In

case the carrier is Manchester coded, then the clock is recovered

from the transmitted signal and the data can be correlated with

a programmed pattern. If the detected pattern corresponds to

the stored one, then a wake-up signal (IRQ) is risen up. The

pattern correlation can be bypassed in which case the wake-up

detection is based only on the frequency detection.

Detailed Description

The AS3930 is made up of a single receiving channel, one

envelop detector, one data correlator, 8 programmable

registers with the main logic and a real time clock.

The digital logic can be accessed by an SDI. The real time clock

can be based on a crystal or on an internal RC. If the internal RC

oscillator is used, a calibration procedure can be performed to

improve its accuracy.

Figure 16:

Block Diagram of LF Wake-up Receiver AS3930

AS3930, 1-D LF Wakeup Receiver

IRQ

Wakeup

SCL

Main

Logic

SDI

SDI

SDO

RSSI

LF1P

CS

Channel

Amplifier1

Envelope Detector / Data Slicer

Correlator

DAT

I/V

Bias

Xtal RTC

RC RTC

LFN

VCC

Page 12

Document Feedback

GND

XIN

XOUT

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Detailed Description

AS3930 needs the following external components:

• Power supply capacitor - CBAT - 100 nF.

• 32.768 kHz crystal with its two pulling capacitors - XTAL

and CL - (it is possible to omit these components if the

internal RC oscillator is used instead of the crystal

oscillator).

• Input LC resonator.

In case the internal RC-oscillator is used (no crystal oscillator is

mounted), the pin XIN has to be connected to the supply, while

pin XOUT should stay floating. Application diagrams with and

without crystal are shown in Figure 2 and Figure 3.

Operating Modes

Power Down Mode

In Power Down Mode AS3930 is completely switched OFF. The

typical current consumption is 400 nA.

Listening Mode

In listening mode only the channel amplifier and the RTC are

running. In this mode the system detects the presence of a

carrier. In case the carrier is detected, the RSSI can be displayed.

In this mode it is possible to distinguish the following three sub

modes:

Standard Listening Mode

The channel amplifier that is capable of detecting the presence

of the carrier frequency, is active all the time.

ON/OFF Mode (Low Power mode )

The channel amplifier is active for one millisecond after which

it is switched OFF. The OFF-time is programmable (see R4).

Figure 17:

ON/OFF Mode

Channel

t0

t0 + 1ms

t0 + T

t0 + T + 1ms

t0 + 2T

Time

Presence

of Carrier

Time

ams Datasheet

[v1-62] 2014-Nov-27

Page 13

Document Feedback

�AS3930 − Detailed Description

Further, for both sub modes, it is possible to enable a feature

called Artificial Wake-up. If the Artificial Wake-up is enabled,

then the AS3930 produces an interrupt after a certain time

regardless of whether any activity is detected on the input. The

period of the Artificial Wake-up is defined in the register

R8. The user can distinguish between Artificial Wake-up

and Wake-up based on the field detection (frequency or pattern

detection) since the Artificial Wake-up interrupt lasts only

128μs. With this interrupt the microcontroller (μC) can get

feedback on the surrounding environment (e.g. read the false

wake-up register R13) and/or take actions in order to

change the setup.

Preamble Detection / Pattern Correlation

The preamble detection and pattern correlation are only

considered for the wake-up when the data correlator function

is enabled (see R1). The correlator searches first for

preamble frequency (constant frequency of Manchester clock

defined according to bit-rate transmission, see Figure 36) and

then for data pattern.

If the pattern is matched, then the wake-up interrupt is

displayed on the WAKE output and the chip goes in data

receiving mode. If the pattern fails, then the internal wake-up

is terminated and no IRQ is produced.

Data Receiving

After a successful wake-up the chip enters the data receiving

mode. In this mode the chip can be retained a normal OOK

receiver. The received data are streamed out on the pin DAT. It

is possible to put the chip back to listening mode either with a

direct command (CLEAR_WAKE see Figure 24) or by using the

timeout feature. This feature automatically sets the chip back

to listening mode after a certain time R7.

Page 14

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Detailed Description

System and Block Specification

Main Logic and SDI

Figure 18:

Register Table

7

6

R0

N.A..

R1

ABS_HY

R2

S_ABSH

R3

HY_20m

R4

5

4

3

ON_OFF

AGC_TLIM

AGC_UD

ATT_ON

N.A.

HY_POS

R_VAL

T_OUT

EN_WPAT

EN_RTC

S_WU1

T_HBIT

N.A.

T_AUTO

N.A.

Reserved

N.A..

RSSI1

R11

N.A..

R12

N.A..

R13

F_WAKE

ams Datasheet

[v1-62] 2014-Nov-27

PWD

GR

TS1

R10

EN_A

FS_ENV

R6

R9

EN_PAT2

FS_SLC

TS2

R8

0

Reserved

R5

R7

1

Reserved

W_PAT_T

T_OFF

2

Page 15

Document Feedback

�Register Table Description and Default Values

Figure 19:

Description and Default Values of Registers

Register

Name

Type

Default Value

Description

R0

ON_OFF

R/W

0

ON/OFF operation mode. (Duty-cycle defined in the

register R4

R0

MUX_123

R/W

0

Reserved (it is not allowed to set this bit to 1)

R0

Reserved

1

Reserved

R0

Reserved

1

Reserved

R0

EN_A

R/W

1

Channel enable

R0

PWD

R/W

0

Power down

R1

ABS_HY

R/W

0

Data slicer absolute reference

R1

AGC_TLIM

R/W

0

AGC acting only on the first carrier burst

R1

AGC_UD

R/W

1

AGC operating in both direction (up-down)

R1

ATT_ON

R/W

0

Antenna damper enable

R1

Reserved

0

Reserved

R1

EN_PAT2

R/W

0

Double wake-up pattern correlation

R1

EN_WPAT

R/W

1

Data correlation enable

R1

EN_RTC

R/W

1

Crystal oscillator enable

R2

S_ABSH

R/W

0

Data slicer threshold reduction

R2

W_PAT

R/W

00

Pattern correlation tolerance (see Figure 37)

R2

Reserved

000

Reserved

R2

S_WU1

R/W

00

Tolerance setting for the stage wake-up (see

Figure 31)

R3

HY_20m

R/W

0

Data slicer hysteresis

if HY_20m = 0 then comparator hysteresis = 40mV

if HY_20m = 1 then comparator hysteresis = 20mV

R3

HY_POS

R/W

0

Data slicer hysteresis on both edges (HY_POS = 0 →

hysteresis on both edges; HY_POS = 1 → hysteresis

only on positive edges)

R3

FS_SCL

R/W

100

Data slicer time constant (see Figure 35)

R3

FS_ENV

R/W

000

Envelop detector time constant (see Figure 34)

Page 16

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Detailed Description

Register

Name

Type

Default Value

Description

OFF time in ON/OFF operation mode

R4

T_OFF

R/W

00

T_OFF=00

1ms

T_OFF=01

2ms

T_OFF=10

4ms

T_OFF=11

8ms

R4

D_RES

R/W

01

Antenna damping resistor (see Figure 33)

R4

GR

R/W

0000

R5

TS2

R/W

01101001

2nd Byte of wake-up pattern

R6

TS1

R/W

10010110

1st Byte of wake-up pattern

R7

T_OUT

R/W

000

R7

T_HBIT

R/W

01011

Gain reduction (see Figure 32)

Automatic time-out (see Figure 38)

Bit rate definition (see Figure 36)

Artificial wake-up

R8

T_AUTO

R9

Reserved

R10

RSSI1

R/W

000

000000

T_AUTO=000

No artificial wake-up

T_AUTO=001

1 sec

T_AUTO=010

5 sec

T_AUTO=011

20 sec

T_AUTO=100

2 min

T_AUTO=101

15min

T_AUTO=110

1 hour

T_AUTO=111

2 hour

Reserved

R

RSSI channel

R11

R

N.A.

R12

R

N.A.

R

False wake-up register

R13

F_WAK

ams Datasheet

[v1-62] 2014-Nov-27

Page 17

Document Feedback

�AS3930 − Detailed Description

Serial Data Interface (SDI)

This 4-wires interface is used by the Microcontroller (μC) to

program the AS3930. The maximum clock frequency of the SDI

is 2MHz.

Figure 20:

Serial Data Interface (SDI) pins

Name

Signal

Signal Level

Description

CS

Digital Input with pull down

CMOS

Chip Select

SDI

Digital Input with pull down

CMOS

Serial Data input for writing registers, data to

transmit and/or writing addresses to select

readable register

SDO

Digital Output

CMOS

Serial Data output for received data or read

value of selected registers

SCLK

Digital Input with pull down

CMOS

Clock for serial data read and write

Note(s): SDO is set to tristate if CS is low. In this way more than

one device can communicate on the same SDO bus.

SDI Command Structure. To program the SDI the CS signal has

to go high. A SDI command is made up by a two bytes serial

command and the data is sampled on the falling edge of SCLK.

Figure 21 shows how the command looks like, from the MSB

(B15) to LSB (B0). The command stream has to be sent to the

SDI from the MSB (B15) to the LSB (B0).

Figure 21:

SDI Command Structure

Mode

B15

B14

Register address / Direct Command

B13

B12

B11

B10

B9

B8

Register Data

B7

B6

B5

B3

B2

B1

B0

The first two bits (B15 and B14) define the operating mode.

There are three modes available (write, read, direct command)

plus one spare (not used), as shown in Figure 22.

Figure 22:

Bits B15, B14

Page 18

Document Feedback

B15

B14

Mode

0

0

WRITE

0

1

READ

1

0

NOT ALLOWED

1

1

DIRECT COMMAND

ams Datasheet

[v1-62] 2014-Nov-27

�In case a write or read command happens the next 6 bits (B13

to B8) define the register address which has to be written

respectively read, as shown in Figure 23.

Figure 23:

Bits B13-B8

B13

B12

B11

B10

B9

B8

Read/Write register

0

0

0

0

0

0

R0

0

0

0

0

0

1

R1

0

0

0

0

1

0

R2

0

0

0

0

1

1

R3

0

0

0

1

0

0

R4

0

0

0

1

0

1

R5

0

0

0

1

1

0

R6

0

0

0

1

1

1

R7

0

0

1

0

0

0

R8

0

0

1

0

0

1

R9

0

0

1

0

1

0

R10

0

0

1

0

1

1

R11

0

0

1

1

0

0

R12

0

0

1

1

0

1

R13

The last 8 bits are the data that has to be written respectively

read. A CS toggle high-low-high terminates the command

mode.

If a direct command is sent (B15-B14=11) the bits from B13 to

B8 defines the direct command while the last 8 bits are omitted.

Figure 24 shows all possible direct commands:

Figure 24:

List of Direct Commands

COMMAND_MODE

B13

B12

B11

B10

B9

B8

clear_wake

0

0

0

0

0

0

reset_RSSI

0

0

0

0

0

1

trim_osc

0

0

0

0

1

0

clear_false

0

0

0

0

1

1

preset_default

0

0

0

1

0

0

ams Datasheet

[v1-62] 2014-Nov-27

Page 19

Document Feedback

�AS3930 − Detailed Description

All direct commands are explained below:

• clear_wake: Clears the wake state of the chip. In case the

chip has woken up (WAKE pin is high) the chip is set back

to listening mode.

• reset_RSSI: Resets the RSSI measurement.

• trim_osc: Starts the trimming procedure of the internal

RC oscillator (see Figure 45).

• clear_false: Resets the false wake-up register

(R13=00).

• preset_default: Sets all register in the default mode, as

shown in Figure 19.

Note(s): In order to get the AS3930 work properly after sending

the preset_default direct command, it is mandatory to write

R0=0 and R0=0.

Writing of Data to Addressable Registers (WRITE Mode).

The SDI is sampled at the falling edge of SCLK (as shown in the

following diagrams).

A CS toggling high-low-high indicates the end of the WRITE

command after register has been written. The following

example shows a write command.

Figure 25:

Writing of a Single Byte (falling edge sampling)

CS

SCLK

SDI

X

0

0

Two leading

Zeros indicate

WRITE Mode

A5

A4

A3

SCLK rising

edge Data is

transfered from

μC

A2

A1

A0

D7

D6

D5

D4

D3

SCLK

falling edge

Data is

sampled

D2

D1

X

D0

Data is moved

to Address

A5-A0

CS falling

edge signals

end of

WRITE Mode

Figure 26:

Writing of Register Data with Auto-incrementing Address

CS

SCLK

SDI

A A A A A D D D D D D D D D D D D D D D D D D

X 0 0 A

5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6

Two leading

Zeros indicate

WRITE Mode

Page 20

Document Feedback

Data is moved

to Address

Data is moved

to Address

+ 1

D D D D D D D D D D

1 0 7 6 5 4 3 2 1 0

Data is moved

to Address

+ (n-1)

Data is moved

to Address

+ n

X

CS falling

edge signals

end of

WRITE Mode

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Detailed Description

Reading of Data from Addressable Registers (READ Mode).

Once the address has been sent through SDI, the data can be

fed through the SDO pin out to the microcontroller.

A CS LOW toggling high-low-high has to be performed after

finishing the read mode session, in order to indicate the end of

the READ command and prepare the Interface to the next

command control Byte.

To transfer bytes from consecutive addresses, SDI master has to

keep the CS signal high and the SCLK clock has to be active as

long as data need to be read.

Figure 27:

Reading of Single Register Byte

CS

SCLK

SDI

X

0

1

A5

SDO

A4

A3

A2

A1

X

D7

SCLK rising

edge Data is

transfered from

μC

01 pattern

indicates

READ Mode

X

A0

SCLK

falling edge

Data is

sampled

D6

D5

SCLK rising

edge Data is

moved from

Address

D4

D3

D2

D1

D0

X

CS falling

edge signals

end of READ

Mode

SCLK falling

edge Data is

transfered to

μC

Figure 28:

Send Direct COMMAND Byte

CS

SCLK

SDI

X

1

1

Two leading

ONE indicate

COMMAND

Mode

ams Datasheet

[v1-62] 2014-Nov-27

C5

C4

C3

SCLK rising

edge Data is

transfered from

μC

C2

C1

SCLK

falling edge

Data is

sampled

C0

X

CS falling edge

signals the end of

COMMAND Mode

Page 21

Document Feedback

�AS3930 − Detailed Description

SDI Timing

Figure 29:

SDI Timing Parameters

Symbol

Parameter

Min

Typ

Max

Units

TCSCLK

Time CS to Sampling Data

500

ns

TDCLK

Time Data to Sampling Data

300

ns

THCL

SCLK High Time

200

ns

TCLK

SCLK period

500

ns

TCLKCS

Time Sampling Data to CS down

500

ns

TCST

CS Toggling time

500

ns

Figure 30:

SDI Timing Diagram

TCST

CS

SPI

SCLK

SCL

t

TCSCLK

TDCLK

t

THCL

TCLKCS

t

TCLK

Channel Amplifier and Frequency Detector

The channel amplifier consists of a variable gain amplifier

(VGA), an automatic gain control, and a frequency detector. The

latter detects the presence of a carrier. As soon as the carrier is

detected the AGC is enabled, the gain of the VGA is reduced

and set to the right value and the RSSI can be displayed.

Page 22

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Detailed Description

Frequency Detector / AGC

The frequency detection uses the RTC as time base. In case the

internal RC oscillator is used as RTC, it must be calibrated, but

the calibration is guaranteed for a 32.768 kHz crystal oscillator

only. The frequency detection criteria can be tighter or more

relaxed according to the setup described in R2 (see

Figure 31).

Figure 31:

Tolerance Settings for Wake-up

R2

R2

Tolerance

0

0

Relaxed

0

1

Tighter (Medium)

1

0

Stringent

1

1

Reserved

The AGC can operate in two modes:

• AGC down only (R1=0)

• AGC up and down (R1=1)

As soon as the AGC starts to operate, the gain in the VGA is set

to maximum. If the AGC down only mode is selected, the AGC

can only decrease the gain. Since the RSSI is directly derived

from the VGA gain, the system holds the RSSI peak.

When the AGC up and down mode is selected, the RSSI can

follow the input signal strength variation in both directions.

Regardless which AGC operation mode is used, the AGC needs

maximum 35 carrier periods to settle.

The RSSI is stored in the register R10.

Both AGC modes (only down or down and up) can also operate

with time limitation. This option allows AGC operation only in

time slot of 256μs following the internal wake-up. Then the AGC

(RSSI) is frozen till the wake-up or RSSI reset occurs.

The RSSI is reset either with the direct command 'clear_wakeup'

or 'reset_RSSI'. The 'reset_RSSI' command resets only the AGC

setting but does not terminate wake-up condition. This means

that if the signal is still present the new AGC setting (RSSI) will

appear not later than 300μs (35 LF carrier periods) after the

command was received. The AGC setting is reset if for duration

of 3 Manchester half symbols no carrier is detected. If the

wake-up IRQ is cleared the chip will go back to listening mode.

In case the maximum amplification at the beginning is a

drawback (e.g. in noisy environment) it is possible to set a

smaller starting gain on the amplifier Figure 32. In this way it is

possible to reduce the false frequency detection.

ams Datasheet

[v1-62] 2014-Nov-27

Page 23

Document Feedback

�AS3930 − Detailed Description

Figure 32:

Bit Setting of Gain Reduction

R4

R4

R4

R4

Gain Reduction

0

0

0

0

No gain reduction

0

0

0

1

N.A..

0

0

1

0 or 1

N.A..

0

1

0

0 or 1

-4dB

0

1

1

0 or 1

-8dB

1

0

0

0 or 1

-12dB

1

0

1

0 or 1

-16dB

1

1

0

0 or 1

-20dB

1

1

1

0 or 1

-24dB

Antenna Damper

The antenna damper allows the chip to deal with higher field

strength, it is enabled by register R1. It consists of shunt

resistors which degrade the quality factor of the resonator by

reducing the signal at the input of the amplifier. In this way the

resonator sees a smaller parallel resistance (in the band of

interest) which degrades its quality factor in order to increase

the linear range of the channel amplifier (the amplifier doesn't

saturate in presence of bigger signals). Figure 33 shows the bit

setup.

Figure 33:

Antenna Damper Bit Setup

Page 24

Document Feedback

R4

R4

Shunt resistor (parallel to the

resonator at 125 kHz)

0

0

1 kΩ

0

1

3 kΩ

1

0

9 kΩ

1

1

27 kΩ

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Detailed Description

Demodulator / Data Slicer

The performance of the demodulator can be optimized

according to bit rate and preamble length as described in

Figure 34 and Figure 35.

Figure 34:

Bit Setup for Envelop Detector for Different Symbol Rates

R3

R3

R3

Symbol Rate

[Manchester symbol/s]

0

0

0

4096

0

0

1

2184

0

1

0

1490

0

1

1

1130

1

0

0

910

1

0

1

762

1

1

0

655

1

1

1

512

If the bit rate gets higher, the time constant in the envelop

detector must be set to a smaller value. This means that higher

noise is injected because of the wider band. The next table is a

rough indication of how the envelop detector looks like for

different bit rates. By using proper data slicer settings it is

possible to improve the noise immunity paying the penalty of

a longer preamble. In fact if the data slicer has a bigger time

constant it is possible to reject more noise, but every time a

transmission occurs, the data slicer need time to settle. This

settling time will influence the length of the preamble.

Figure 35 gives a correlation between data slicer setup and

minimum required preamble length.

ams Datasheet

[v1-62] 2014-Nov-27

Page 25

Document Feedback

�AS3930 − Detailed Description

Figure 35:

Bit Setup for Data Slicer for Different Preamble Length

R3

R3

R3

Minimum Preamble

Length [ms]

0

0

0

0.8

0

0

1

1.15

0

1

0

1.55

0

1

1

1.9

1

0

0

2.3

1

0

1

2.65

1

1

0

3

1

1

1

3.5

Note(s): These times are minimum required, but it is

recommended to prolong the preamble.

The comparator of the data slicer can work only with positive

or with symmetrical threshold R3. In addition the threshold

can be 20 or 40 mV R3. In case the length of the preamble

is an issue the data slicer can also work with an absolute

threshold R1. In this case the bits R3 would not

influence the performance. It is even possible to reduce the

absolute threshold in case the environment is not particularly

noisy R2.

Correlator

After frequency detection the data correlation is only

performed if the correlator is enabled (R1=1).

The data correlation consists of checking the presence of a

preamble (ON/OFF modulated carrier) followed by a certain

pattern.

After the frequency detection the correlator waits 16 bits (see

bit rate definition in Figure 36) and if no preamble is detected

the chip is set back to listening mode and the false wake-up

register (R13) is incremented by one.

To get started with the pattern correlation the correlator needs

to detect at least 4 bits of the preamble (ON/OFF modulated

carrier).

The bit duration is defined in the register R7(Figure 36) as

function of the Real Time Clock (RTC) periods.

Page 26

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Detailed Description

Figure 36:

Bit Rate Setup

R7

R7

R7

R7

R7

Bit Duration in

RTC Clock Periods

Bit Rate

(bits/s)

Symbol Rate

(Manchester symbols/s)

0

0

0

1

1

4

8192

4096

0

0

1

0

0

5

6552

3276

0

0

1

0

1

6

5460

2730

0

0

1

1

0

7

4680

2340

0

0

1

1

1

8

4096

2048

0

1

0

0

0

9

3640

1820

0

1

0

0

1

10

3276

1638

0

1

0

1

0

11

2978

1489

0

1

0

1

1

12

2730

1365

0

1

1

0

0

13

2520

1260

0

1

1

0

1

14

2340

1170

0

1

1

1

0

15

2184

1092

0

1

1

1

1

16

2048

1024

1

0

0

0

0

17

1926

963

1

0

0

0

1

18

1820

910

1

0

0

1

0

19

1724

862

1

0

0

1

1

20

1638

819

1

0

1

0

0

21

1560

780

1

0

1

0

1

22

1488

744

1

0

1

1

0

23

1424

712

1

0

1

1

1

24

1364

682

1

1

0

0

0

25

1310

655

1

1

0

0

1

26

1260

630

1

1

0

1

0

27

1212

606

1

1

0

1

1

28

1170

585

1

1

1

0

0

29

1128

564

1

1

1

0

1

30

1092

546

1

1

1

1

0

31

1056

528

1

1

1

1

1

32

1024

512

ams Datasheet

[v1-62] 2014-Nov-27

Page 27

Document Feedback

�AS3930 − Detailed Description

If the preamble is detected correctly the correlator keeps

searching for a data pattern. The duration of the preamble plus

the pattern should not be longer than 40 bits (see bit rate

definition in Figure 36). The data pattern can be defined by the

user and consists of two bytes which are stored in the registers

R5 and R6. The two bytes define the pattern

consisting of 16 half bit periods. This means the pattern and the

bit period can be selected by the user. The only limitation is that

the pattern (in combination with preamble) must obey

Manchester coding and timing. It must be noted that according

to Manchester coding a down-to-up bit transition represents a

symbol "0", while a transition up-to-down represents a symbol

"1". If the default code is used (96 [hex]) the binary code is

(10 01 01 10 01 10 10 01). MSB has to be transmitted first.

The user can also select (R1) if single or double data pattern

is used for wake-up. In case double pattern detection is set, the

same pattern has to be repeated 2 times.

Additionally it is possible to set the number of allowed missing

zero bits (not symbols) in the received bitstream (R2), as

shown in the Figure 37.

Figure 37:

Allowed Pattern Detection Errors

R2

R2

Maximum allowed error in the

pattern detection

0

0

No error allowed

0

1

1 missed zero

1

0

2 missed zeros

1

1

3 missed zeros

If the pattern matches the wake-up, interrupt is displayed on

the WAKE output.

If the pattern detection fails, the internal wake-up (on all active

channels) is terminated with no signal sent to MCU and the false

wake-up register will be incremented (R13).

The wake-up state is terminated with the direct command

‘clear_wake’ (see Figure 24). This command terminates the MCU

activity. The termination can also be automatic in case there is

no response from MCU. The time out for automatic termination

is set in a register R7, as shown in theFigure 38.

Page 28

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Detailed Description

Figure 38:

Timeout Setup

R7

R7

R7

Time out

0

0

0

0 sec

0

0

1

50 msec

0

1

0

100 msec

0

1

1

150 msec

1

0

0

200 msec

1

0

1

250 msec

1

1

0

300 msec

1

1

1

350 msec

Wake-up Protocol - Carrier Frequency 125 kHz

Without Pattern Detection

Figure 39:

Wake-up Protocol Overview without Pattern Detection (only carrier frequency detection)

Carrier Burst

Data

Carrier Burst > 550 us

DAT

WAKE

Clear_wake

ams Datasheet

[v1-62] 2014-Nov-27

Page 29

Document Feedback

�AS3930 − Detailed Description

In case the data correlation is disabled (R1=0) the AS3930

wakes up upon detection of the carrier frequency only as shown

in Figure 39. In order to ensure that AS3930 wakes up the carrier

burst has to last longer than 550 μs. To set AS3930 back to

listening mode there are two possibilities: either the

microcontroller sends the direct command clear_wake via SDI

or the time out option is used ( R7). In case the latter is

chosen, AS3930 is automatically set to listening mode after the

time defined in T_OUT ( R7), counting starts at the

low-to-high WAKE edge on the WAKE pin.

Single Pattern Detection

The Figure 40 shows the wake-up protocol in case the pattern

correlation is enabled (R1=1) for a 125 kHz carrier

frequency. The initial carrier burst has to be longer than 550 μs

and can last maximum 16 bits (see bit rate definition in

Figure 36). If the ON/OFF mode is used ( R1=1), the

minimum value of the maximum carrier burst duration is

limited to 10 ms. This is summarized in Figure 41. In case the

carrier burst is too long the internal wake-up will be set back to

low and the false wake-up counter (R13) will be

incremented by one.

The carrier burst must be followed by a preamble (0101...

modulated carrier with a bit duration defined in Figure 36) and

the wake-up pattern stored in the registers R5 and

R6. The preamble must have at least 4 bits and the

preamble duration together with the pattern should not be

longer than 40 bits. If the wake-up pattern is correct, the signal

on the WAKE pin goes high one bit after the end of the pattern

and the data transmission can get started. To set the chip back

to listening mode the direct command clear_wake, as well as

the time out option ( R7) can be used.

Figure 40:

Wake-up Protocol Overview with Single Pattern Detection

Carrier Burst

Preamble

Pattern

Data

1-bit Preamble

Carrier Burst>360 us

Carrier Burst 4-bit duration

Preamble + Pattern < 40-bit duration

DAT

WAKE

Clear_wake

Page 30

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Detailed Description

Figure 41:

Preamble Requirements in Standard Mode, Scanning Mode and ON/OFF Mode

Bit Rate

(bits/s)

Maximum Duration of the Carrier Burst in

Standard Mode and Scanning Mode (ms)

Maximum Duration of the Carrier

Burst in ON/OFF Mode (ms)

8192

1.95

10

6552

2.44

10

5460

2.93

10

4680

3.41

10

4096

3.90

10

3640

4.39

10

3276

4.88

10

2978

5.37

10

2730

5.86

10

2520

6.34

10

2340

6.83

10

2184

7.32

10

2048

7.81

10

1926

8.30

10

1820

8.79

10

1724

9.28

10

1638

9.76

10

1560

10.25

10.25

1488

10.75

10.75

1424

11.23

11.23

1364

11.73

11.73

1310

12.21

12.21

1260

12.69

12.69

1212

13.20

13.20

1170

13.67

13.67

1128

14.18

14.18

1092

14.65

14.65

1056

15.15

15.15

1024

15.62

15.62

ams Datasheet

[v1-62] 2014-Nov-27

Page 31

Document Feedback

�AS3930 − Detailed Description

False Wake-up Register

The wake-up strategy in the AS3930 is based on 2 steps:

1. Frequency Detection: In this phase the frequency of

the received signal is checked.

2. Pattern Correlation: Here the pattern is demodulated

and checked whether it corresponds to the valid one.

If there is a disturber or noise capable to overcome the first step

(frequency detection) without producing a valid pattern, then

a false wake-up call happens.Each time this event is recognized

a counter is incremented by one and the respective counter

value is stored in a memory cell (false wake-up register). Thus,

the microcontroller can periodically look at the false wake-up

register, to get a feeling how noisy the surrounding

environment is and can then react accordingly (e.g. reducing

the gain of the LNA during frequency detection, set the AS3930

temporarily to power down etc.), as shown in the Figure 42. The

false wake-up counter is a useful tool to quickly adapt the

system to any changes in the noise environment and thus avoid

false wake-up events.

Most wake-up receivers have to deal with environments that

can rapidly change. By periodically monitoring the number of

false wake-up events it is possible to adapt the system setup to

the actual characteristics of the environment and enables a

better use of the full flexibility of AS3930.

Figure 42:

Concept of the False Wake-up Register Together with System

Wakeup

Level 1

Frequency Detector

Wakeup

Level 2

Pattern Correlator

WAKE

Unsuccessful

pattern

correlation

CHANGE SETUP TO

MINIMIZE THE FALSE

WAKEUP EVENTS

Register Setup

False wakeup

register

READ FALSE WAKEUP REGISTER

Microcontroller

Page 32

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Detailed Description

Real Time Clock (RTC)

The RTC can be based on a crystal oscillator (R1=1), the

internal RC-oscillator (R1=0), or an external clock source

(R1=1). The crystal has higher precision of the frequency

but a higher current consumption and needs three external

components (crystal plus two capacitors). The RC-oscillator is

completely integrated and can be calibrated if a reference

signal is available for a very short time to improve the frequency

accuracy. The calibration gets started with the trim_osc direct

command. Since no non-volatile memory is available the

calibration must be done every time after the RCO was turned

OFF. The RCO is turned OFF when the chip is in power down

mode, a POR happened, or the crystal oscillator is enabled.

Since the RTC defines the time base of the frequency detection,

the selected frequency (frequency of the crystal oscillator or

the reference frequency used for calibration of the RC oscillator)

should be about one forth of the carrier frequency:

(EQ1)

F RTC ∼ F CAR∗ 0.25

Where:

F CAR is the carrier frequency

F RTC is the RTC frequency

Note(s): The third option for the RTC is the use of an external

clock source, which must be applied directly to the XIN pin

(XOUT floating).

Crystal Oscillator

Figure 43:

Characteristics of XTAL

Parameter

Conditions

Crystal accuracy (initial)

Overall accuracy

Min

Typ

Crystal motional resistance

Max

Units

±120

p.p.m.

60

KΩ

Frequency

32.768

kHz

Contribution of the oscillator to

the frequency error

±5

p.p.m

1

s

Start-up Time

Duty cycle

Current consumption

ams Datasheet

[v1-62] 2014-Nov-27

Crystal dependent

45

50

1

55

%

μA

Page 33

Document Feedback

�AS3930 − Detailed Description

RC-Oscillator

Figure 44:

Characteristics of RCO

Parameter

Conditions

Min

Typ

Max

Units

If no calibration is performed

27

32.768

42

kHz

If calibration is performed

31

32.768

34.5

kHz

65

cycles

Frequency

Calibration time

Periods of reference clock

Current consumption

200

nA

To trim the RC-Oscillator, set the chip select (CS) to high before

sending the direct command trim_osc over SDI. Then 65 digital

clock cycles of the reference clock (e.g. 32.768 kHz) have to be

sent on the clock bus (SCLK), as shown in Figure 45. After that

the signal on the chip select (CS) has to be pulled down.

The calibration is effective after the 65th reference clock edge

and it will be stored in a volatile memory. In case the

RC-oscillator is switched OFF or a power-ON-reset happens (e.g.

battery change) the calibration has to be repeated.

Figure 45:

RC-Oscillator Calibration via SDI

65 clock cycles

CS

SCLK

SDI

X

1

1

0

0

0

DIRECT COMMAND

Trim_osc

0

1

X

0

REFERENCE CLOCK

External Clock Source

To clock the AS3930 with an external signal the crystal oscillator

has to be enabled (R1=1). As shown in the Figure 4 the clock

must be applied on the pin XIN while the pin XOUT must stay

floating. The RC time constant has to be 100μs with a tolerance

of ±10% (e.g. R=680 kΩ and C=22pF). In the Figure 46 the clock

characteristics are summarized.

Page 34

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Detailed Description

Figure 46:

Characteristics of External Clock

Symbol

Parameter

Min

VI

Low level

Vh

High level

Tr

Max

Units

0

0.1 * VDD

V

0.9 * VDD

VDD

V

Rise-time

3

μs

Tf

Fall-time

3

μs

T =1/2πRC

RC Time constant

110

μs

90

Typ

100

Note(s): In power down mode the external clock has to be set

to V DD.

ams Datasheet

[v1-62] 2014-Nov-27

Page 35

Document Feedback

�AS3930 − Package Drawings & Mark ings

Package Drawings & Markings

The product is available in a 16-pin TSSOP and QFN 4×4 16 LD

package.

Figure 47:

16-pin TSSOP Package

AS3930 @

YYWWMZZ

Symbol

Min

Nom

Max

A

-

-

1.20

A1

0.05

-

0.15

A2

0.80

1.00

1.05

b

0.19

-

0.30

c

0.09

-

0.20

D

4.90

5.00

5.10

E

-

6.40 BSC

-

E1

4.30

4.40

4.50

e

-

0.65 BSC

-

L

0.45

0.60

0.75

L1

-

1.00 REF

-

R

0.09

-

-

R1

0.09

-

-

-

S

0.20

Θ1

0º

-

Θ2

-

12 REF

-

Θ3

-

12 REF

-

8º

aaa

-

0.10

-

bbb

-

0.10

-

ccc

-

0.05

-

ddd

-

0.20

-

N

16

Green

RoHS

Note(s) and/or Footnote(s):

1. Dimensions and tolerancing conform to ASME Y14.5M-1994.

2. All dimensions are in millimeters. Angles are in degrees.

Figure 48:

Marking: @YYWWMZZ

@

YY

WW

M

ZZ

Sublot identifier

Year

Manufacturing Week

Assembly plant identifier

Assembly traceability code

Page 36

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Package Drawings & Markings

Figure 49:

QFN 4× 4 16 LD Package

AS3930

YYWWXZZ

@

Symbol

Min

Nom

Max

A

0.80

0.85

0.90

A1

0

A3

0.05

0.203 REF

b

0.18

0.23

0.28

D

4.00 BSC

E

4.00 BSC

D2

2.60

2.70

2.80

E2

2.60

2.70

2.80

e

0.65 BSC

L

0.35

L1

0.00

0.40

0.10

aaa

0.10

bbb

0.10

ccc

0.10

ddd

0.05

eee

0.08

RoHS

0.45

Green

Note(s) and/or Footnote(s):

1. Dimensions and tolerancing conform to ASME Y14.5M-1994.

2. All dimensions are in millimeters. Angles are in degrees.

3. Dimension b applies to metallized terminal and is measured between 0.25mm and 0.30mm from terminal tip. Dimension L1

represents terminal full back from package edge up to 0.15mm is acceptable.

4. Coplanarity applies to the exposed heat slug as well as the terminal.

5. Radius on terminal is optional.

Figure 50:

Marking: YYWWXZZ@

YY

WW

X

ZZ

@

Year

Manufacturing Week

Assembly plant identifier

Assembly traceability code

Sublot identifier

ams Datasheet

[v1-62] 2014-Nov-27

Page 37

Document Feedback

�AS3930 − Ordering & Contact Information

Ordering & Contact Information

Figure 51:

Ordering Information

Ordering

Code

Type

Marking

Delivery Form(1)

Delivery Quantity

AS3930-BTST

16-pin TSSOP

AS3930

7 inches Tape & Reel

1000 pcs

AS3930-BQFT

QFN (4×4) 16LD

AS3930

7 inches Tape & Reel

1000 pcs

Note(s) and/or Footnote(s):

1. Dry Pack: Moisture Sensitivity Level (MSL) = 3, according to IPC/JEDEC J-STD-033A.

Buy our products or get free samples online at:

www.ams.com/ICdirect

Technical Support is available at:

www.ams.com/Technical-Support

Provide feedback about this document at:

www.ams.com/Document-Feedback

For further information and requests, e-mail us at:

ams_sales@ams.com

For sales offices, distributors and representatives, please visit:

www.ams.com/contact

Headquarters

ams AG

Tobelbaderstrasse 30

8141 Unterpremstaetten

Austria, Europe

Tel: +43 (0) 3136 500 0

Website: www.ams.com

Page 38

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − RoHS Compliant & ams Green Statement

RoHS Compliant & ams Green

Statement

RoHS: The term RoHS compliant means that ams AG products

fully comply with current RoHS directives. Our semiconductor

products do not contain any chemicals for all 6 substance

categories, including the requirement that lead not exceed

0.1% by weight in homogeneous materials. Where designed to

be soldered at high temperatures, RoHS compliant products are

suitable for use in specified lead-free processes.

ams Green (RoHS compliant and no Sb/Br): ams Green

defines that in addition to RoHS compliance, our products are

free of Bromine (Br) and Antimony (Sb) based flame retardants

(Br or Sb do not exceed 0.1% by weight in homogeneous

material).

Important Information: The information provided in this

statement represents ams AG knowledge and belief as of the

date that it is provided. ams AG bases its knowledge and belief

on information provided by third parties, and makes no

representation or warranty as to the accuracy of such

information. Efforts are underway to better integrate

information from third parties. ams AG has taken and continues

to take reasonable steps to provide representative and accurate

information but may not have conducted destructive testing or

chemical analysis on incoming materials and chemicals. ams AG

and ams AG suppliers consider certain information to be

proprietary, and thus CAS numbers and other limited

information may not be available for release.

ams Datasheet

[v1-62] 2014-Nov-27

Page 39

Document Feedback

�AS3930 − Copyrights & Disclaimer

Copyrights & Disclaimer

Copyright ams AG, Tobelbader Strasse 30, 8141

Unterpremstaetten, Austria-Europe. Trademarks Registered. All

rights reserved. The material herein may not be reproduced,

adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner.

Devices sold by ams AG are covered by the warranty and patent

indemnification provisions appearing in its General Terms of

Trade. ams AG makes no warranty, express, statutory, implied,

or by description regarding the information set forth herein.

ams AG reserves the right to change specifications and prices

at any time and without notice. Therefore, prior to designing

this product into a system, it is necessary to check with ams AG

for current information. This product is intended for use in

commercial applications. Applications requiring extended

temperature range, unusual environmental requirements, or

high reliability applications, such as military, medical

life-support or life-sustaining equipment are specifically not

recommended without additional processing by ams AG for

each application. This product is provided by ams AG “AS IS”

and any express or implied warranties, including, but not

limited to the implied warranties of merchantability and fitness

for a particular purpose are disclaimed.

ams AG shall not be liable to recipient or any third party for any

damages, including but not limited to personal injury, property

damage, loss of profits, loss of use, interruption of business or

indirect, special, incidental or consequential damages, of any

kind, in connection with or arising out of the furnishing,

performance or use of the technical data herein. No obligation

or liability to recipient or any third party shall arise or flow out

of ams AG rendering of technical or other services.

Page 40

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Document Status

Document Status

Document Status

Product Preview

Preliminary Datasheet

Datasheet

Datasheet (discontinued)

ams Datasheet

[v1-62] 2014-Nov-27

Product Status

Definition

Pre-Development

Information in this datasheet is based on product ideas in

the planning phase of development. All specifications are

design goals without any warranty and are subject to

change without notice

Pre-Production

Information in this datasheet is based on products in the

design, validation or qualification phase of development.

The performance and parameters shown in this document

are preliminary without any warranty and are subject to

change without notice

Production

Information in this datasheet is based on products in

ramp-up to full production or full production which

conform to specifications in accordance with the terms of

ams AG standard warranty as given in the General Terms of

Trade

Discontinued

Information in this datasheet is based on products which

conform to specifications in accordance with the terms of

ams AG standard warranty as given in the General Terms of

Trade, but these products have been superseded and

should not be used for new designs

Page 41

Document Feedback

�AS3930 − Revision Information

Revision Information

Changes from 1.5 (2013-Feb-04) to current revision 1-62 (2014-Nov-27)

Page

Content was updated to the latest ams design

Updated General Description & Figure 1

1

Updated Pin Assignments section

4

Added TRC (start-up time) parameter in Figure 11 and a note under it

8

Updated Figure 29

22

Updated Package Drawings & Markings section

36

Note(s) and/or Footnote(s):

1. Page and figure numbers for the previous version may differ from page and figure numbers in the current revision.

2. Correction of typographical errors is not explicitly mentioned.

Page 42

Document Feedback

ams Datasheet

[v1-62] 2014-Nov-27

�AS3930 − Content Guide

Content Guide

ams Datasheet

[v1-62] 2014-Nov-27

1

1

2

General Description

Key Benefits & Features

Applications

4

4

5

Pin Assignments

16-pin TSSOP

QFN 4x4 16 LD

6

7

10

Absolute Maximum Ratings

Electrical Characteristics

Typical Operating Characteristics

12

13

13

13

13

13

14

14

15

15

16

18

22

22

23

24

25

26

29

29

30

32

33

33

34

34

Detailed Description

Operating Modes

Power Down Mode

Listening Mode

Standard Listening Mode

ON/OFF Mode (Low Power mode )

Preamble Detection / Pattern Correlation

Data Receiving

System and Block Specification

Main Logic and SDI

Register Table Description and Default Values

Serial Data Interface (SDI)

SDI Timing

Channel Amplifier and Frequency Detector

Frequency Detector / AGC

Antenna Damper

Demodulator / Data Slicer

Correlator

Wake-up Protocol - Carrier Frequency 125 kHz

Without Pattern Detection

Single Pattern Detection

False Wake-up Register

Real Time Clock (RTC)

Crystal Oscillator

RC-Oscillator

External Clock Source

36

38

39

40

41

42

Package Drawings & Markings

Ordering & Contact Information

RoHS Compliant & ams Green Statement

Copyrights & Disclaimer

Document Status

Revision Information

Page 43

Document Feedback

�